EPV Polar Star Series User manual

JA12132021 www.epvscreens.com U-00222 1

Polar Star Special Edition Series

Ceiling/Ambient Light Rejecting (CLR®/ALR) Fixed Frame Screen

USER’S GUIDE

V 2.1

Product Description

The Polar Star® Special Edition Series is a fixed frame projection screen from EPV Screens. It has a

hand wrapped velvet covered frame and a tension system for attaching the material for improved flatness.

The screen material included is our award winning ISF Certified Polar Star® which is a front projection

material, precisely formulated forenvironments with minimal control over room lighting. It was designed

to enhance picture brightness, offer accurate color fidelity, and improve contrast levels. The Polar

Star® is best for family rooms, educational facilities, conference rooms, house of worship or any

applications in which incident light is a factor.

In order for the Polar Star® to maintain its projection qualities and optimum performance please refer to the list

below for proper maintenance and cleaning.

•Use a dry microfiber cloth to remove dust from the screen’s surface.

•When cleaning, use a damp microfiber cloth with warm water to remove any marks.

•Never rub or apply pressure when cleaning the surface.

•Never attempt to use any solutions, chemicals or abrasive cleaners on the screen surface.

•In order to avoid damaging the screen, avoid touching it directly with your fingers, pens/pencils or any

other sharp or abrasive objects.

JA12132021 www.epvscreens.com U-00222 2

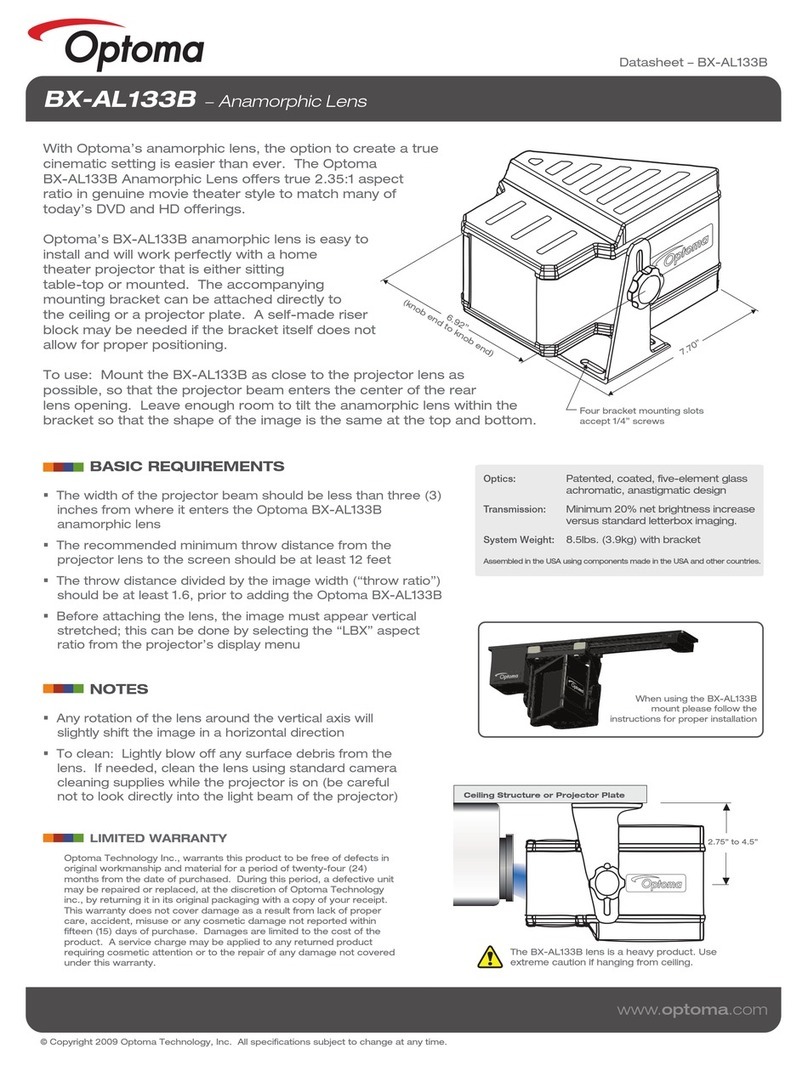

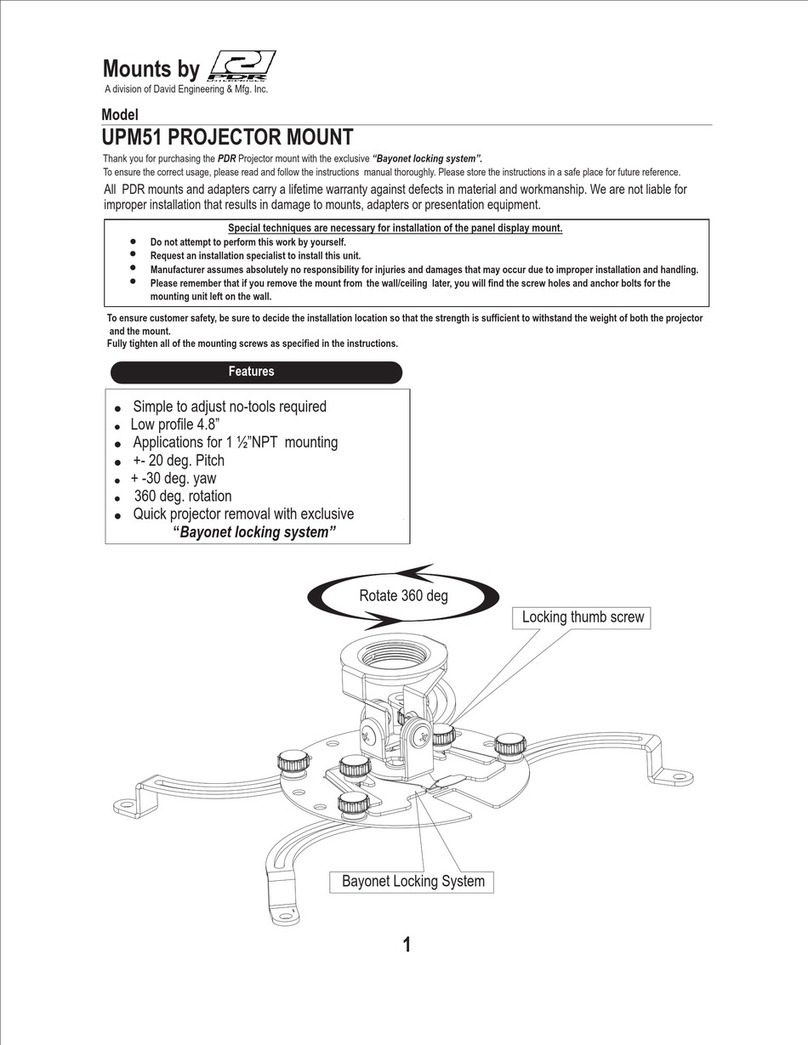

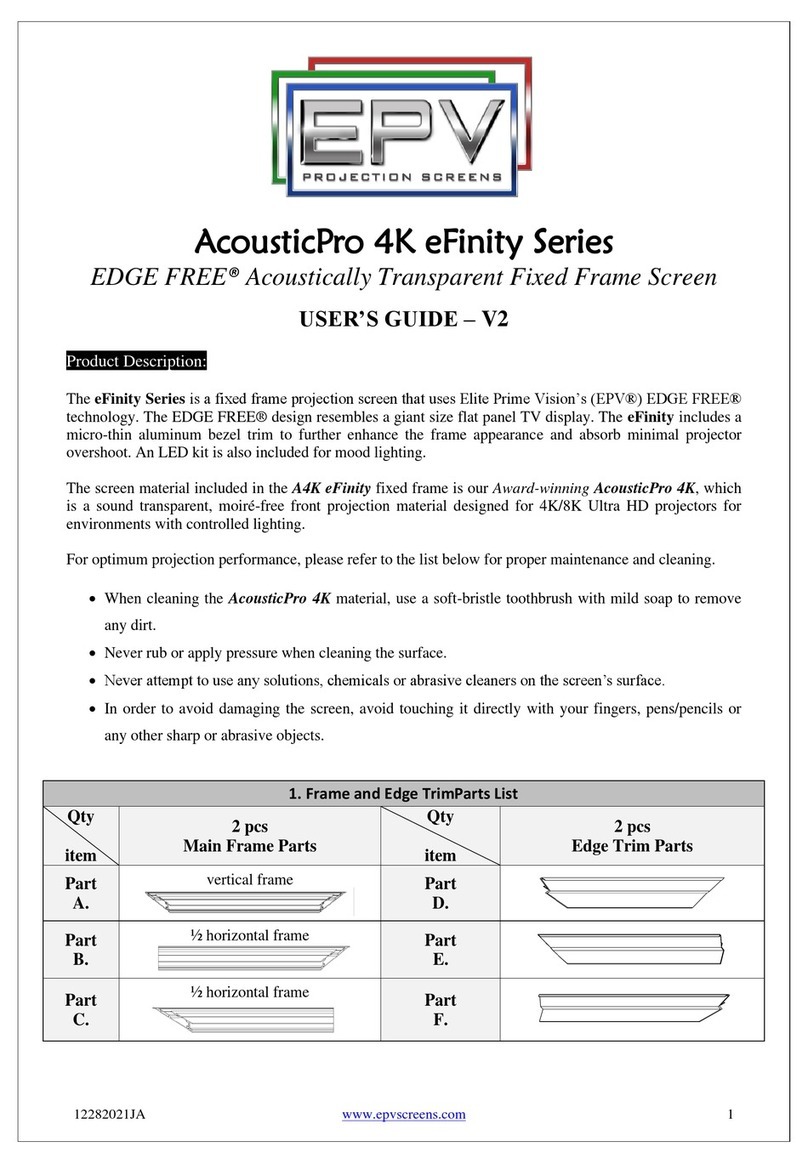

Frame Parts List

A. Vertical Frame x 2pcs

B. ½ Horizontal Frame x2 pcs

C. ½ Horizontal Frame x 2 pcs

Hardware Parts List

a. M4*4

b. D5*4

c. M4*4

d. D5*4

g.

h.

i.

j.

k.

l.

o.

p.

r.

Item

Parts List

92”

100”

110”

120”

135”

150”

a.

Center Joints- M4 (bottom position)

2

2

2

2

2

2

b.

Center Joints-D5 (top position)

2

2

2

2

2

2

c.

Elbow Joints M4 (bottom position)

4

4

4

4

4

4

d.

Elbow Joints D5 (top position)

4

4

4

4

4

4

g.

M4x7 Screws

24

24

24

24

24

24

h.

Spring

56

60

66

72

80

88

i.

Pull Hook

2

2

2

2

2

2

j.

Wall brackets

4

4

4

4

4

4

k.

Wall Screws M5x50

8

8

8

8

8

8

l.

Hollow Wall anchors

8

8

8

8

8

8

o.

Center Support Bar

1

1

1

1

1

1

p.

White gloves

2

2

2

2

2

2

r.

Φ3 mm Long Iron (sides) rod /

Short rod (top/bottom)

2/4

2/4

2/4

2/4

2/4

2/4

8.

C+B

B+C

A

A

Red

Black

JA12132021 www.epvscreens.com U-00222 3

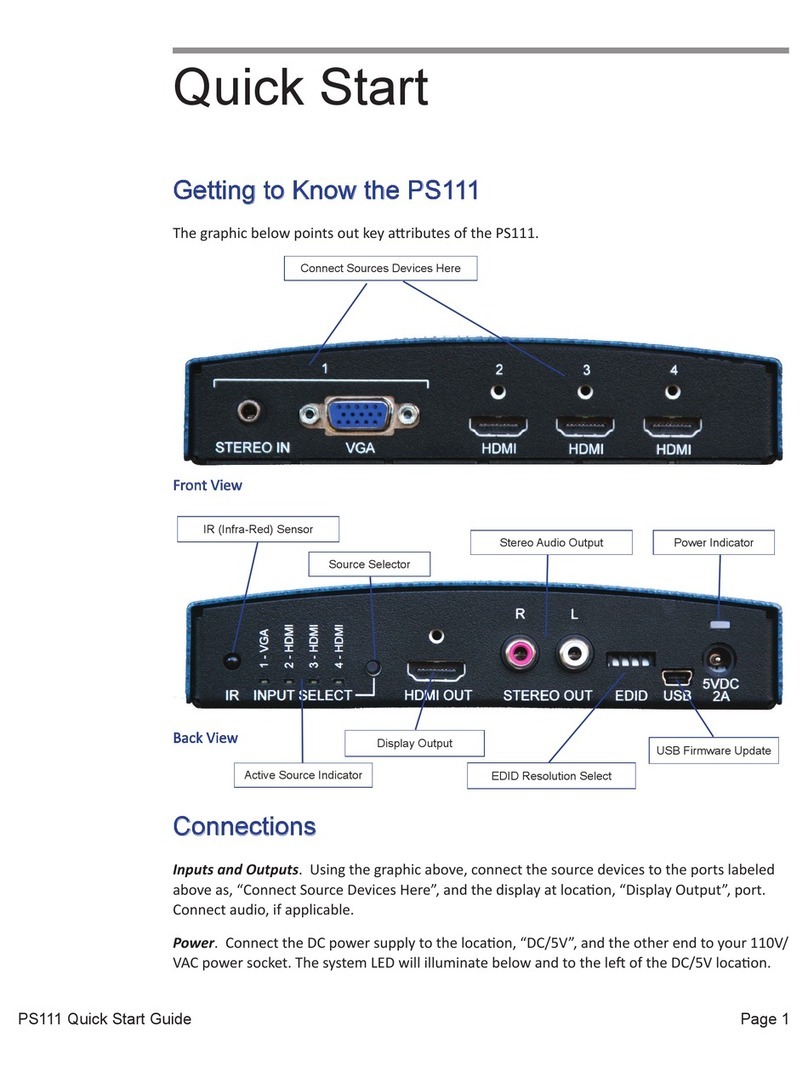

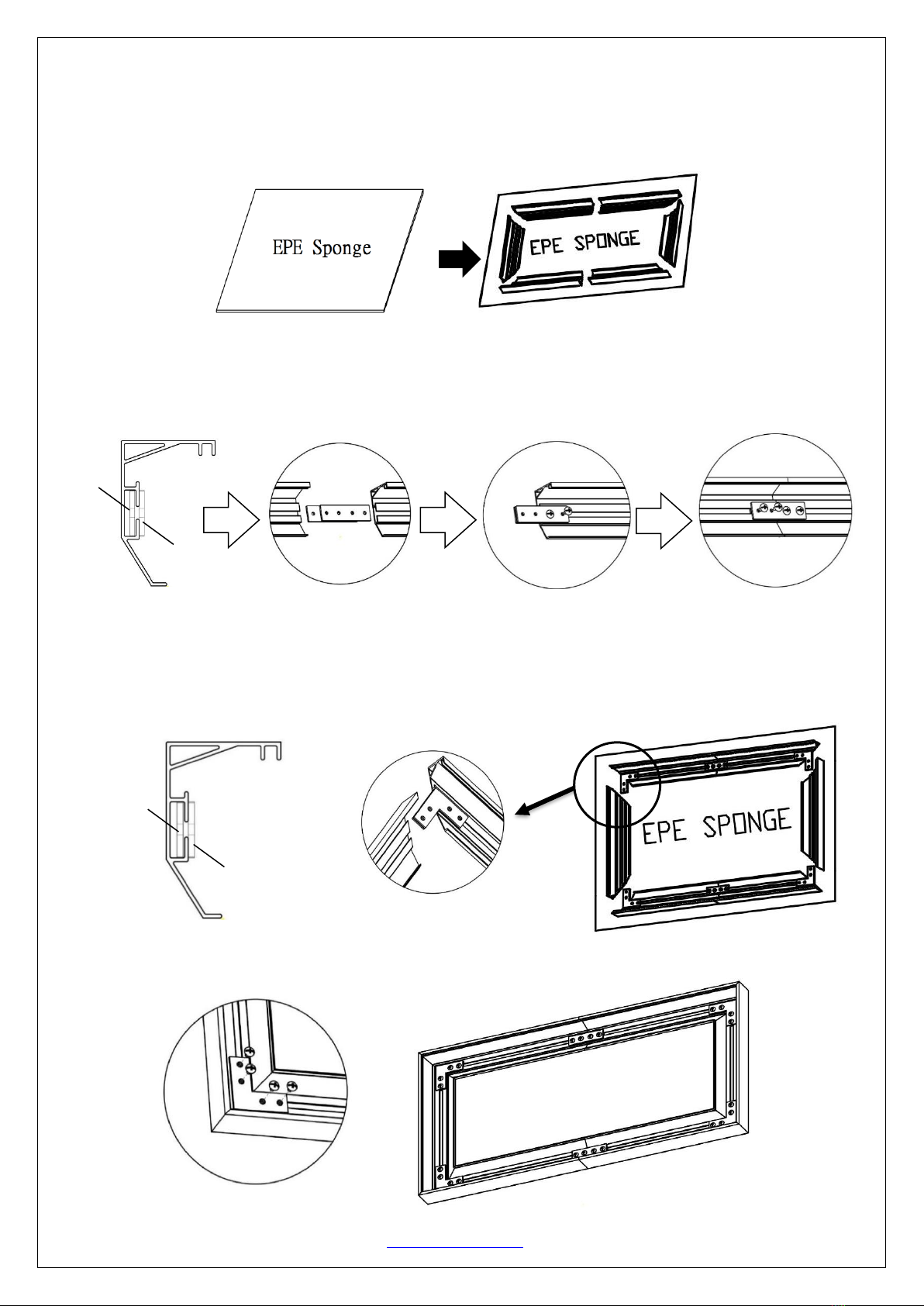

Frame Assembly

Step 1: Place the EPE sponge (foam) sheet on the ground of the area where the screen will be assembled.

Step 2: Position the pieces of the frame on the EPE sponge in the arrangement shown below.

Step 3: Insert center joint (a/b) connectors into one-half of the horizontal frame (B/C) and secure with the

M4x7 screws (g) as shown in the illustration below.

Tip: The center joint (b) with the larger diameter holes should be on top.

Step 4: Connect the elbow joints (c/d) to the top and bottom sections of the vertical frame. Once inserted,

connect the vertical sections to the horizontal frame sections. Make sure all holes are in alignment and the frame

pieces are flush (no gaps). They should form perfect right angles.

Tip: The elbow joint (d)with the larger diameter holes should be on top.

Step 5. Secure the elbow joints by fastening them with M4x7 screws

(g), 4 at each corner.

a.

b.

d.

c.

JA12132021 www.epvscreens.com U-00222 4

c

c

c

c

c

c

c

c

c

c

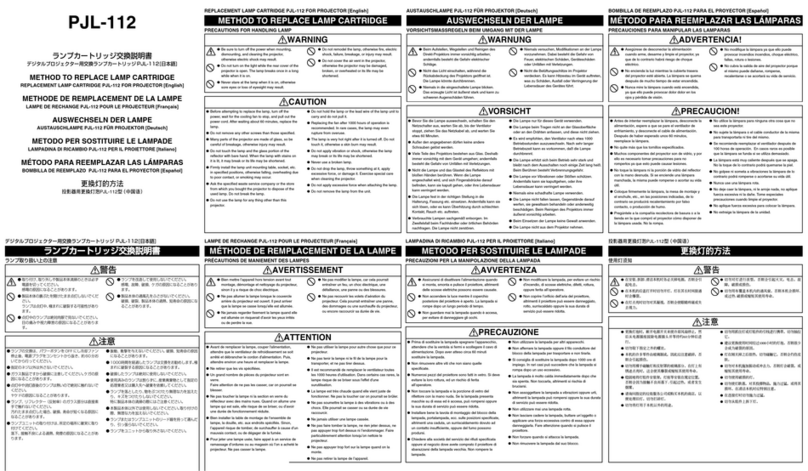

Screen Material

Step 6: Put on the white gloves (p) and carefully unroll the screen material on a clean surface from the roller to the

other side as shown below. The back

side of the screen material should be

placed upwards. Then place a bottom

grommet (r) on the screen material’s

eyelet and snap in the top grommet (s)

as shown below.

Repeat the process for all eyelets.

Step7: Carefully place the screen on top of the assembled frame as shown below.Make sure that the angular

edges of the frame are not allowed to come into direct contact with the screen material to avoid puncturing.

Step 8: Insert the rods (r) through the sleeves according to their corresponding lengths on each edge of the

screen as shown below. The short rods (top/bottom) will overlap to secure a firm grasp in the middle areas.

Front

Back Side

r. (Red tips)

Back Side

r. (Black tips)

Back Side

Back

Side

Go through the hole

from bottom to top

JA12132021 www.epvscreens.com U-00222 5

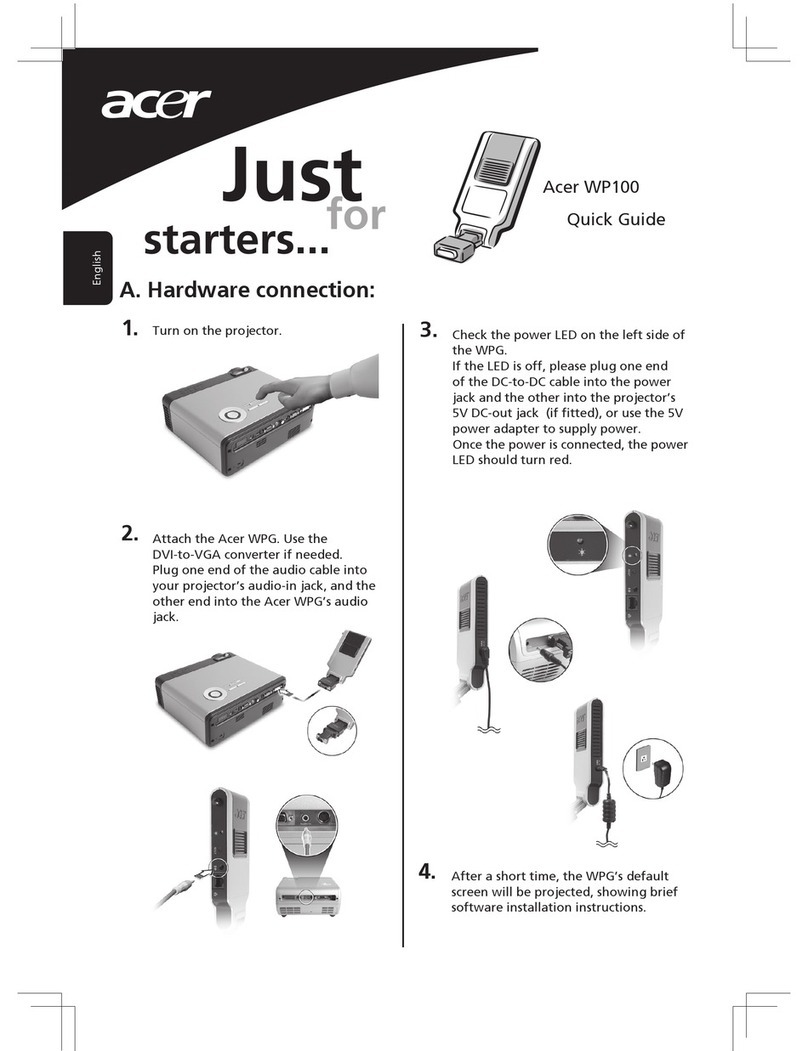

How to attach the springs

Step 9: Hook one end of the spring and secure inside the groove of the frame, use the spring hook (i)to attach

the spring to the hole located on the screen material’s outer edge in the following order.

First connect on four corners, steps 1-4. make sure all four corners are fixed before proceeding with next spring.

Continue to attach the remaining springs to the material in steps 5-12 in the follow order.

h.

i.

Spring must hook both

overlapping

short rods.

c

c

1

2

4

3

5

6

7

8

9

10

11

12

JA12132021 www.epvscreens.com U-00222 6

Step 10: Insert the Center Support Bar (o) into the upper top groove on the back of the frame with the bottom end

near the approximate center point of the frame and rotate it in at an angle so that both ends of the bar are in

alignment with the groove.

Notice to Installer:

Please use the following installation instructions to obtain superior optical performance from the Polar

Star Angular Reflective ALR (Ambient Light Rejecting) Screen

Make sure to follow these instructions in order for the CineGrey3D/ 5D to perform correctly.

1. Ambient Light must not come from the same direction as the projector’s light

2. Not compatible with Ultra/Short-Throw Projectors

Projector Ceiling Installation: Make sure the projector (light in) is angled (ϴ1) to reflect (ϴ2) at the mirror-

opposite angle (light out) to align with the viewer’s eye level.

Diagonal Models 150” and

below use 1 x Center Support

Bar

Diagonal Models above 150”

require 2 x Center Support Bars

Place a center support

bar 30 cm (11.8”) apart

from the center (red

line).

JA12132021 www.epvscreens.com U-00222 7

Projector Tabletop: Make sure the projector (light in) is angled (ϴ1) to reflect (ϴ2) at the mirror-opposite

angle (light out) to align with the viewer’s eye level.

Images are not up to scale and are for illustrations purposes only.

Note: Improper installation will result in light loss and produce a dark image. This is due to the projector’s light

reflecting in the wrong direction.

Installation

Step 11: Measure the overall length and height of the frame and drill holes for the top brackets. Line up the wall

brackets with the drilled holes on the installation location and screw them in using a Phillips screwdriver. If not

installing into a structural wood stud, use a hollow wall anchor then screw in the M5x50 wood screws with a

screwdriver. Make sure the brackets are leveled.

Model/Size

X = Wall bracket distance

X1 = Bracket hole distance

Y = Top/Bottom Wall Bracket Height

92”

1100mm (43.30”)

30mm (1.18”)

1180mm (46.46”)

100”

1170mm (46.06”)

30mm (1.18”)

1280mm (50.39”)

110”

1280mm (50.39”)

30mm (1.18”)

1410mm (55.51”)

120”

1390mm (54.72”)

30mm (1.18”)

1530mm (60.24”)

135”

1550mm (61.02”)

30mm (1.18”)

1720mm (67.72”)

150”

1720mm (67.72”)

30mm (1.18”)

1900mm (74.80”)

Don’t lock the screw for

bottom brackets to allow the

screen to move up/down.

j.

k.

Diagonal Sizes of 150” and below use 4 x wall brackets

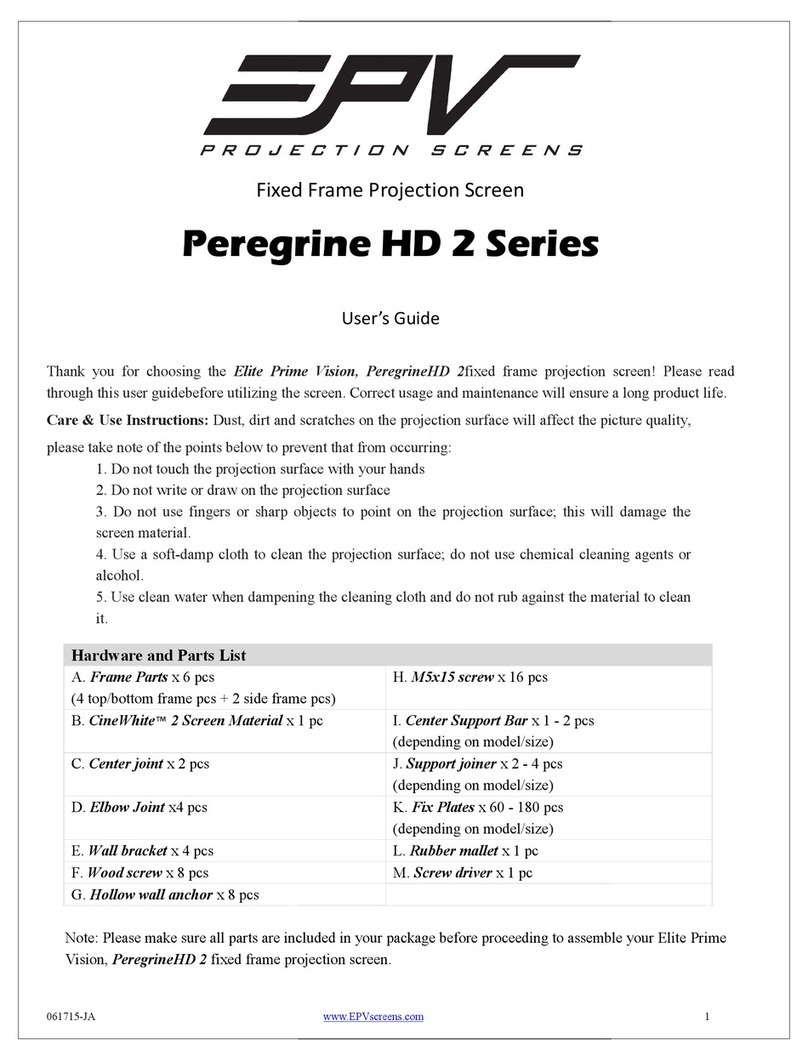

Table of contents

Other EPV Projector Accessories manuals

EPV

EPV Peregrine HD 2 series User manual

EPV

EPV Twilight Manual User manual

EPV

EPV Polar Max Recessed Series User manual

EPV

EPV EDGE FREE Sonic AT8 ISF eFinity Series User manual

EPV

EPV Twilight Portable Series User manual

EPV

EPV DarkStar Max UST Series User manual

EPV

EPV EDGE FREE AcousticPro 4K eFinity Series User manual