eqss OverWatch 6253 User manual

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|1 of 22|

EQSS Model6253 –OverWatch™

User Manual

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

The OverWatch™ is an aid to the operator and this system should not in any way replace operator training.

The system relies on optical detection principles and may not work in all situations and environments.

The system must be properly maintained, and preoperational checks must be completed.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|2 of 22|

AUTHORS:

Kieren Grogan, Greg Santucci, Jay

Nandakumar

AUTHORISED BY:

Kieren Grogan

CHECKED BY:

Andrew Donegan

DOCUMENT ABSTRACT:

This User Manual details the use and operation of the Model6253 OverWatch™

PRODUCT NAME:

Model6253 OverWatch™ Operator Detection System

CURRENT DOCUMENT REVISION:

1.7

REVISION INFORMATION:

•1.1 Initial Document Creation

•1.2 Inclusion of drill guides and update of electrical connection schematics

•1.3 Inclusion of Wi-Fi front end use cases and web pages

•1.4 Inclusion of detail images to add in explanation of functionality and addition of part ID

•1.5 Conformity changes and grammar check

•1.6 Addition of emergency lowering notices and WiFi access procedures

•1.7 Added additional detail to the operation of the motionless detection / horn event and added warning

for correct operator standing position

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|3 of 22|

Important Information

Information contained in this publication regarding this device’s applications, and the like, is provided only for your

convenience and may be superseded by updates. It is your responsibility to ensure that the application of our

equipment meets with your specifications.

EQUIPMENT SAFETY SYSTEMS MAKE NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR OTHERWISE, RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO, IT’S CONDITION, QUALITY, PERFORMANCE, MERCHANTABILITY OR FITNESS FOR PURPOSE.

Equipment Safety Systems disclaims all liability arising from this information and its use. Use of Equipment Safety

Systems’ products as critical components in life support systems is not authorised, except with express written

approval by Equipment Safety Systems. No licenses are conveyed, implicitly or otherwise, under any Equipment Safety

Systems’intellectual property rights.

This is a class A product certified to AS/NZS CISPR 22:2006. In a domestic environment, this product may

cause radio interference, in which case, the user may be required to take adequate measures.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|4 of 22|

Table of Contents

Principle of Operation.........................................................................................................................................................5

Preoperational Checks........................................................................................................................................................6

Operational Instructions.....................................................................................................................................................7

Standing Position ...........................................................................................................................................................7

Session Calibration......................................................................................................................................................... 8

Crush Event Cutout ........................................................................................................................................................9

Shear Event Cutout ......................................................................................................................................................10

System Override...........................................................................................................................................................11

Visual & Audio Notifications ........................................................................................................................................11

Obstructed Operator Sensor........................................................................................................................................12

Cutout Behaviour Processing............................................................................................................................................13

Elevate Mode ...............................................................................................................................................................13

Drive Mode ..................................................................................................................................................................14

Wi-Fi Access......................................................................................................................................................................15

General Use..................................................................................................................................................................15

Minimum system requirements ..................................................................................................................................15

Enable Wi-Fi Connection.............................................................................................................................................. 15

Accessing the Home Page ............................................................................................................................................16

Diagnostics........................................................................................................................................................................17

Retrieving Event logs ........................................................................................................................................................18

Inspection & Maintenance ............................................................................................................................................... 19

Periodic Maintenance ..................................................................................................................................................19

Periodic Testing............................................................................................................................................................20

Component Identification.................................................................................................................................................21

System Components ....................................................................................................................................................21

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|5 of 22|

Principle of Operation

The OverWatch™ is an innovative system designed as an aid to the operator. The system does not replace operator

training.

The system works on the premise of detecting the operator’s position and movements, with respect to the scissor

lift’s direction of movement in real time. This information is used to determine if a crushing or shearing event is about

to occur. This is determined by the physical movements and position of the operator’s body, with respect to the

platform control box.

When the operator pushes the dead-man trigger, the system calibrates the position of the operator relative to the

control box. The system senses the machine’s mode of operation (Drive or Elevate) and determines the position of the

joystick. This initial calibration is done each time the dead-man trigger is pushed; therefore, the system calibrates for

each use session with the specific operator and environmental conditions at that point in time.

The system constantly measures the operator’s position, acceleration and velocity. The system will trigger and cut the

machine operation if the system detects movements above the threshold limits. For example, if the machine is driving

forward and the operator moves forward to look over the front of the platform, the system will not trigger. If the

machine is driving backwards and the operator moves towards the platform controls quickly with a high acceleration,

this may indicate a dangerous shearing event, and therefore, the system will trigger.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|6 of 22|

Preoperational Checks

The OverWatch™ is an electronic detection system and is an aid the operator. Before use make sure that the system is

in good working condition. Conduct the following pre-operation checks.

1. Make sure the sensor optics are clean, free of dust, water, paint, etc. Power up the system. Make sure you hear

the ‘welcome tone’and the green light is active

2. Select the drive mode. Stand in position. Make sure the light goes blue and you hear “Drive”

3. Drive the machine forward slowly. Duck down into the basket, then the system light will change to red and it

will say “Cutout” and the machine will stop.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|7 of 22|

Operational Instructions

Standing Position

The OverWatch™ Sensor is mounted on the platform control box. This sensor is an infrared (invisible) LIDAR, which

is used to measure the operator’s position, acceleration and velocity. The OverWatch™ must always maintain a

visible line of sight to the operator. The operator must always remain in position and maintain normal movements

in order to control the machine functions.

The operator must stand in the following position for the OverWatch™ to function correctly and allow control of

the machine functions.

The OverWatch™ will not allow control of the machine functions if the operator is not in position. In most cases

the OverWatch™ stops operation of the machine in the conditions shown below.

Warning: Risk of Severe Injury or Death

* The OverWatch™ is an aid to the operator and this system should not in any way replace operator

training. The system relies on optical detection principals and may not work in all situations

and environments. The operator must use the machine while standing in front of the control box

at all times in the natural standing position.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|8 of 22|

Session Calibration

The OverWatch™ starts sensing the operator from the time the platform’s dead-man trigger is pressed. When the

machine is powered, and the system is functional, the operator will see a green light on the OverWatch™ sensor.

This indicates that the OverWatch™ is ready for use.

When the operator pushes the joystick dead-man trigger, the system will calibrate to the operator’s current

position. If the calibration is successful, the light will change to blue and an audio announcement of either “Drive”

or “Elevate” will be made, depending on the platform’s mode of operation.

When the operator pushes the joystick dead-man trigger, and if the operator is not detected or is standing too

close or too far away from the sensor, the light will change to purple with an audio announcement of “Operator

Zone”. If the system is not able to calibrate, the operator must release the joystick dead-man trigger and move

into the correct working position.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|9 of 22|

Crush Event Cutout

A normal crush event can occur when the platform is in elevate mode and the operator becomes pressed against

the platform handrail and an object above. With the OverWatch™ this event is detected based on the operator’s

acceleration, velocity and current position. An illustration of a crush event is shown below.

If a crush event is detected by the OverWatch™, the machine cutout will be applied, and the operator will be

disabled from elevating the machine and the system will announce “Cutout”. The operator can always descend the

platform or apply the system override to regain control and move out of the dangerous situation. Since the

OverWatch™only applies the cutout to the upper control panel, the lower panel can be used at any time to take

control of the machine and lower the platform.

In the situation where a crush event has been detected, and the OverWatch™ has sensed that the operator has not

moved position in 5 seconds since cutout, the OverWatch™ calculates that the operator may be pinned, stuck or

incapacitated. The OverWatch™ will sound the machine’s horn 3 times every 10 seconds. This is to alert

surrounding workers about the situation, so that they may assist where required. If the operator releases and then

presses the joystick trigger, the OverWatch™ determines that the operator is not incapacitated and is able to

control the machine and cancels the horn alert.

Warning: Risk of Severe Injury or Death

* The OverWatch™ is an aid to the operator and this system should not in any way replace operator

training. The system relies on optical detection principals and may not work in all situations

and environments.

* The OverWatch™only applies the cutout to the upper control panel, the lower panel can be used at

any time to take control of the machine and lower the platform.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|10 of 22|

Shear Event Cutout

A shear event can occur when the platform is in drive mode and the operator is struck by a stationary object. This

event is detected based off the operator’s acceleration, velocity and current position. The direction of the

operator’s movement is opposite to the movement of the platform. For example, if driving forward the operator

can move forward to look over the front of the platform when driving, and when driving forward, if a shear event

occurs, the object would push the operator backwards. If the operator is driving backwards, a shear event would

push the operator forward towards the control box.

If a shear event is detected, the machine cutout will be applied, and the operator will be prevented from driving

the machine. The system will then announce “Cutout”. The operator can always regain control of the machine by

moving back into the correct working position or by applying the system override to move out of the dangerous

situation. Since the OverWatch™only applies the cutout to the upper control panel, the lower panel can be used

at any time to take control of the machine and lower the platform.

In the situation where a shear event has been detected, and the OverWatch™ has sensed that the operator has

not moved position within 5 seconds, the OverWatch™ calculates that the operator may be pinned, stuck or

incapacitated. As with a crush event and subsequent pinning of the operator, the OverWatch™ will sound the

machine’s horn 3 times every 10 seconds. This is to alert surrounding workers about the situation, so that they

may assist where required. If the operator releases and then presses the joystick trigger, the OverWatch™

determines that the operator is not incapacitated and is able to control the machine and cancels the horn alert.

Warning: Risk of Severe Injury or Death

* The OverWatch™ is an aid to the operator and this system should not in any way replace operator

training. The system relies on optical detection principals and may not work in all situations

and environments.

* The OverWatch™only applies the cutout to the upper control panel, the lower panel can be used at

any time to take control of the machine and lower the platform.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|11 of 22|

System Override

The OverWatch™ has an override function. This function will allow free control of the machine for 15 seconds. This

function is only available for 15 seconds and can only be used every 60 seconds.

To activate the override, the operator must press and release the joystick dead-man trigger 3 times within 2

seconds. When this triple tap occurs, the system will announce “Override Active” and the light will change to

orange. When the override times-out, the system will announce “Override Expired”. If the operator tries to enable

the override again within 60 seconds, the system will announce “Override Unavailable”. This 60 second time-out is

referred to as the ‘override cool down period’.

Visual & Audio Notifications

Light –Colour

Audio Announcement

Description

Welcome chime at start up

System has started, is powered up

and is working with no errors

Drive / Elevate

Trigger pressed, movement

selection determined, system

calibrated to operator’s position.

System sensing

Sensor Obstruction

There is an object covering the

sensor (e.g. dust, water, paint, etc)

or the operator is too close to the

sensor

Operator Zone

The operator has moved out of

sight of the sensor

None

The sensor is pointing on a

reflective surface, such as the

reflective stripes on a safety vest

To Override:

3 quick presses of

the joystick trigger

“Triple Tap”

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|12 of 22|

Cutout

The EWP movements have been

cutout to prevent injury to the

operator

Override Active

The OverWatch™ is in override

mode to allow full control when

the operator is in a compromised

position

Override Expired

The override mode has timed out

and the OverWatch™ has returned

to normal operation

Override Unavailable

The override mode has been

disabled

Obstructed Operator Sensor

The OverWatch™ can detect if the operator sensor is obstructed. An obstruction may occur if the sensor is

physically covered with an object or a material such as dust, water or paint, etc. The OverWatch™ will announce

“Sensor Obstruction”. The operator must then clean the sensor in order to operate the machine. Alternatively, if

the sensor is damaged, the system override may be used to regain control and move the machine.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|13 of 22|

Cutout Behaviour Processing

For the system to start functioning and release the machine’s cutout so that the operator can gain control of the

machine, the following conditions must be established:

1. The OverWatch™ system must be powered

2. The OverWatch™ system must be operational and pass all self-checks

3. The operator must be present and within the defined zone when the enable trigger is pressed. At this point,

the system measures the operator’s position relative to the platform control box. This calibration position is

reset when the enable trigger is released.

4. The operator sensor must not be obstructed

Elevate Mode

The OverWatch™ will apply the cutout when the machine mode is Elevate according to the following table:

Operator action

Elevate

Descend

Operator leaning over sensor

Cutout

No cutout

Operator far from sensor

Cutout

No cutout

Operator ducks down

Cutout

No cutout

Operator moving rapidly toward sensor

Cutout

No cutout

Operator moving rapidly away from sensor

Cutout

No cutout

Calibration position

Cutout

Operator is too far

Sensor

Cutout

Operator is too close or is

leaning over

No cutout

Operator is within safe working envelope

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|14 of 22|

Drive Mode

The OverWatch™ will apply the cutout when the machine mode is Drive according to the following table:

Operator action

Drive forward

Drive backward

Operator leaning over sensor

No cutout

Cutout

Operator far from sensor

Cutout

Cutout

Operator ducks down

Cutout

Cutout

Operator moving rapidly toward sensor

No cutout

Cutout

Operator moving rapidly away from sensor

Cutout

Cutout

Calibration position

Cutout

Operator is too far

Sensor

No cutout

Operator is leaning over

No cutout

Operator is within safe working envelope

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|15 of 22|

Wi-Fi Access

General Use

The OverWatch™ includes an embedded web server, accessible via Wi-Fi. The use of this interface is limited to

viewing the system’s diagnostic information, performing routine tests on all inputs / outputs and accessing the

time stamped log files.

Minimum system requirements

Any smart phone, tablet or laptop that meets the following requirements:

•The device can connect to a Wi-Fi access point

•The device has an up to date web browser installed (2019 onwards). Firefox or Chrome are

recommended.

Enable Wi-Fi Connection

The system’s Wi-Fi module is disabled by default. In order to enable Wi-Fi, the user must turn the machine on and

allow the OverWatch™ to bootup until the green light is visible. Within 10 seconds of power up, the user must

press the dead-man trigger 10 consecutive times. The OverWatch™ will announce “Wi-Fi On” and the user can

access the web page by connecting to the module’s web server, using its SSID and generic password. Follow the

instructions below to switch on the OverWatch™ Wi-Fi with the dead-man trigger switch.

1. Power down the platform control box with the ESTOP

2. Wait 10 seconds

3. Power up the platform control box with the ESTOP

4. Toggle the dead-man joystick trigger 10 times or more within 10 seconds after power up

5. When the OverWatch™ detects more than 10 trigger presses an announcement “Wi-Fi On” will occur

In the event that there is a system fault, and the OverWatch™ cannot sense the dead-man trigger input signal, the

system’s Wi-Fi can be enabled by following the instructions below to switch on the OverWatch™ Wi-Fi using the

operator sensor:

1. Power down the platform control box with the ESTOP

2. Wait 10 seconds

3. Power up the platform control box with the ESTOP

4. While standing in the operator position, switch on the OverWatch™

5. As the welcome chime starts to play, cover the sensor. The LED will flash white then black to

acknowledge.

6. Remove your hand from the sensor. The LED will flash white then black to acknowledge.

7. After covering then uncovering the sensor this way 2 more times, "Wi-Fi On" will be announced.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|16 of 22|

After the Wi-Fi is enabled, the user may connect to the Wi-Fi network. The SSID OverWatch_6253E_XXXX_XXXX

will appear, the XXXX_XXXX being the device’s unique serial number. Connect to the Wi-Fi network and enter the

generic access point password which is 12345678.

SSID

OverWatch_6253E_XXXX_XXXX

Password

12345678

Accessing the Home Page

Once the user’s Wi-Fi enabled device is connected to the OverWatch™, open a web browser and enter the IP

address of the device’s internal web server 192.168.4.1. Press enter and the following main page will be displayed:

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|17 of 22|

Diagnostics

The diagnostics page allows real time monitoring of the sensor data. The graph shows the raw position, raw velocity,

computed displacement and velocity.

Below the graph the diagnostics page also shows the state of the various subsystems in the OverWatch™.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|18 of 22|

Retrieving Event logs

The Log Viewer page allows viewing and downloading of the log file information. The log information is time stamped

and details the event and associated parameters / measurements at the time of the event. The log data can be

downloaded in a csv format if required. This page also allows adjustment of the system’s real time clock and calendar

if required. Please note, any time or date change is logged and recorded.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|19 of 22|

Inspection & Maintenance

Periodic Maintenance

Regular maintenance must be performed on the OverWatch™components to ensure the system operates

correctly. This maintenance must be performed every 12 months in a rental situation, or before the machine is

released to the hire customer.

Inspect the sensor module for any cracks or damage that may compromise

the seal. Replace the sensor module, if required.

Clean the surface of the sensor using soap and water. DO NOT HIGH-

PRESSURE WASH. Replace the screen protectors on the Lidar, if required.

Blow out any dust that may block or muffle the speaker behind the sensor

module. This can be done with low pressure < 10 psi compressed air.

Inspect the cable running from the sensor to the cable gland and into the

EWP control box. Check for any cuts or wear on the cable especially around

the entry points for any exposed wires. Patch or replace the cable, if

required.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

User Manual

REV 1.7

20/05/2020

Model6253 OverWatch™User Manual

Document # DO001195

|20 of 22|

Periodic Testing

Testing must be performed on the OverWatch™components to ensure the system operates correctly. This testing

must be performed every 12 months or after any type of maintenance or repair work has been carried out on the

machine’s control box. Connect to the OverWatch™Wi-Fi, then access the main page and select the test menu.

Follow the instructions on the screen to complete the system test.

Other manuals for OverWatch 6253

11

Table of contents

Popular Security Sensor manuals by other brands

Clifford

Clifford Proximity Sensor 4 owner's manual

Gira

Gira 2050 Series operating instructions

Altronix

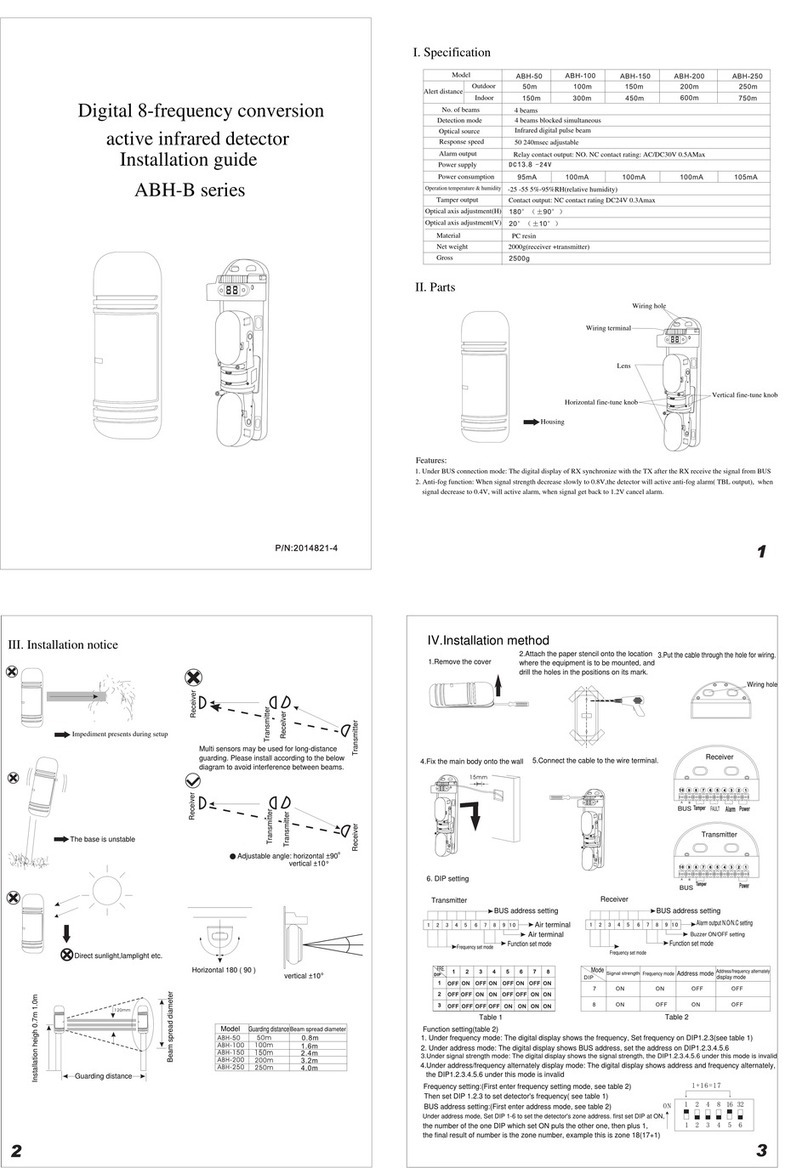

Altronix ABH-B Series installation guide

Electronics Line

Electronics Line EL-4755 manual

urmet domus

urmet domus 1051 Installation, programming and functions manual

Elko

Elko iNels RFMD-100 quick start guide