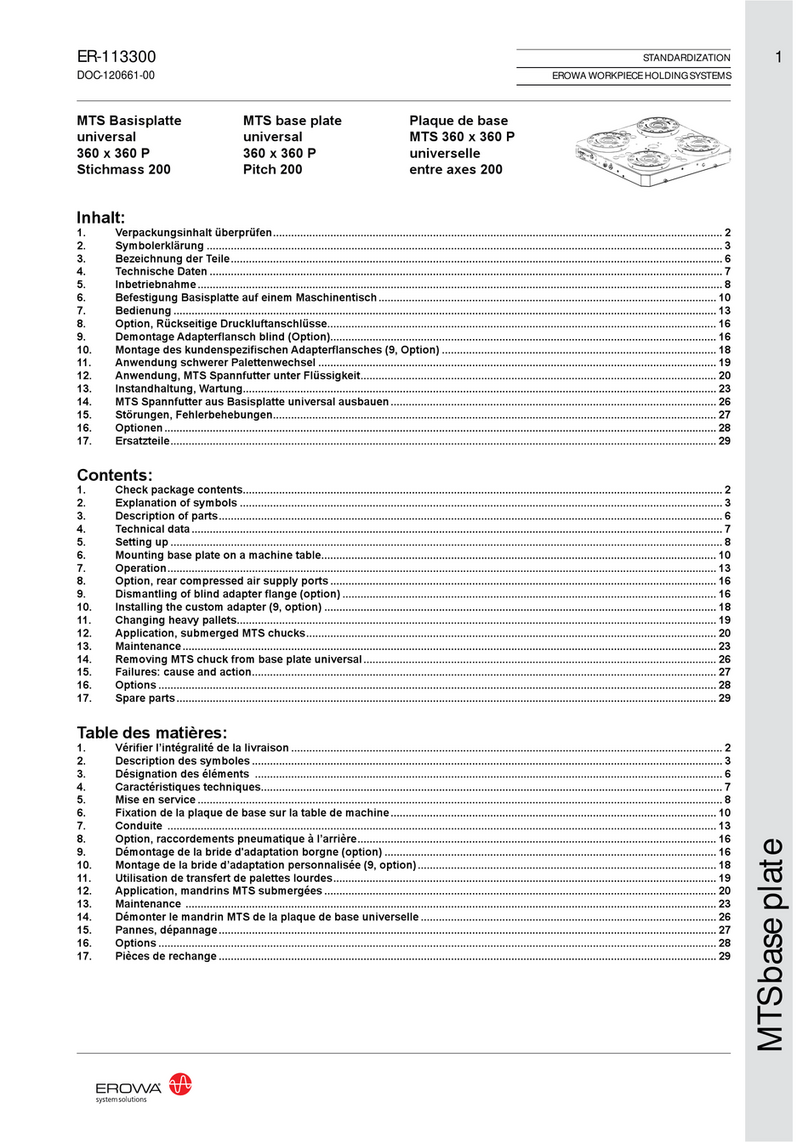

ermengineering LRWG-10 User manual

This manual suits for next models

1

Table of contents

Other ermengineering Industrial Equipment manuals

ermengineering

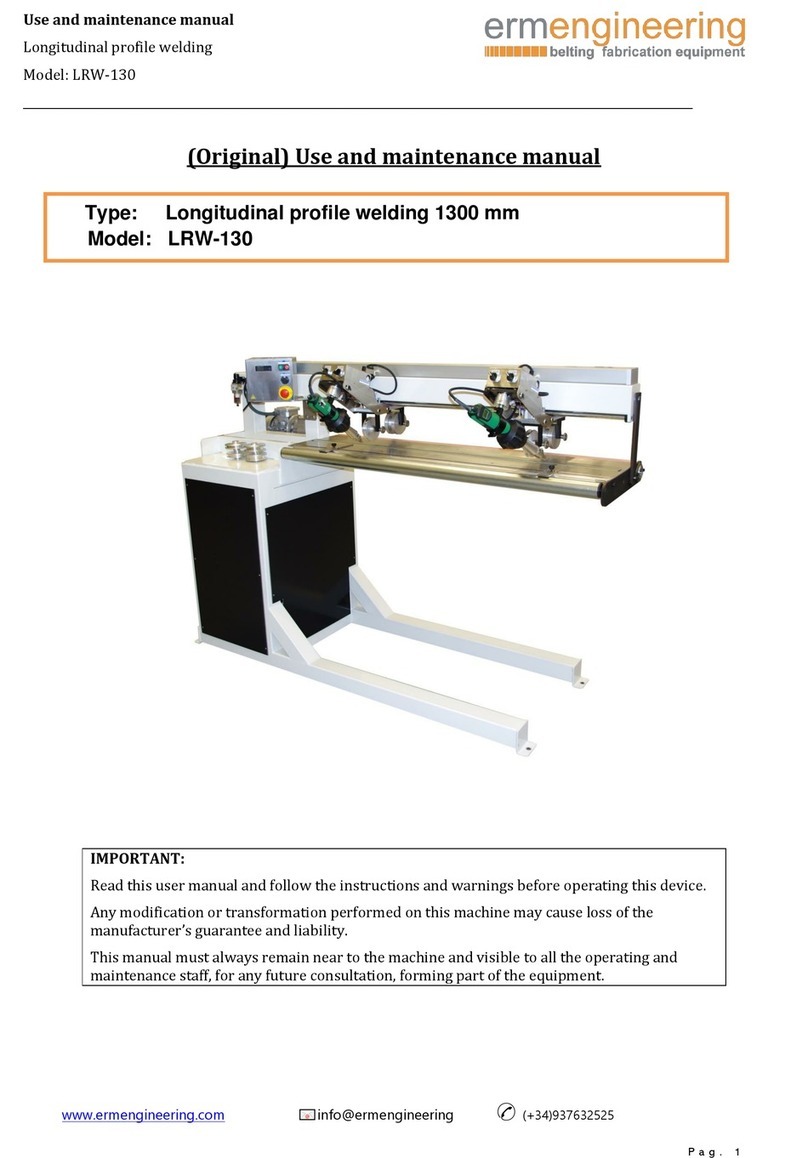

ermengineering LRW-130 User manual

ermengineering

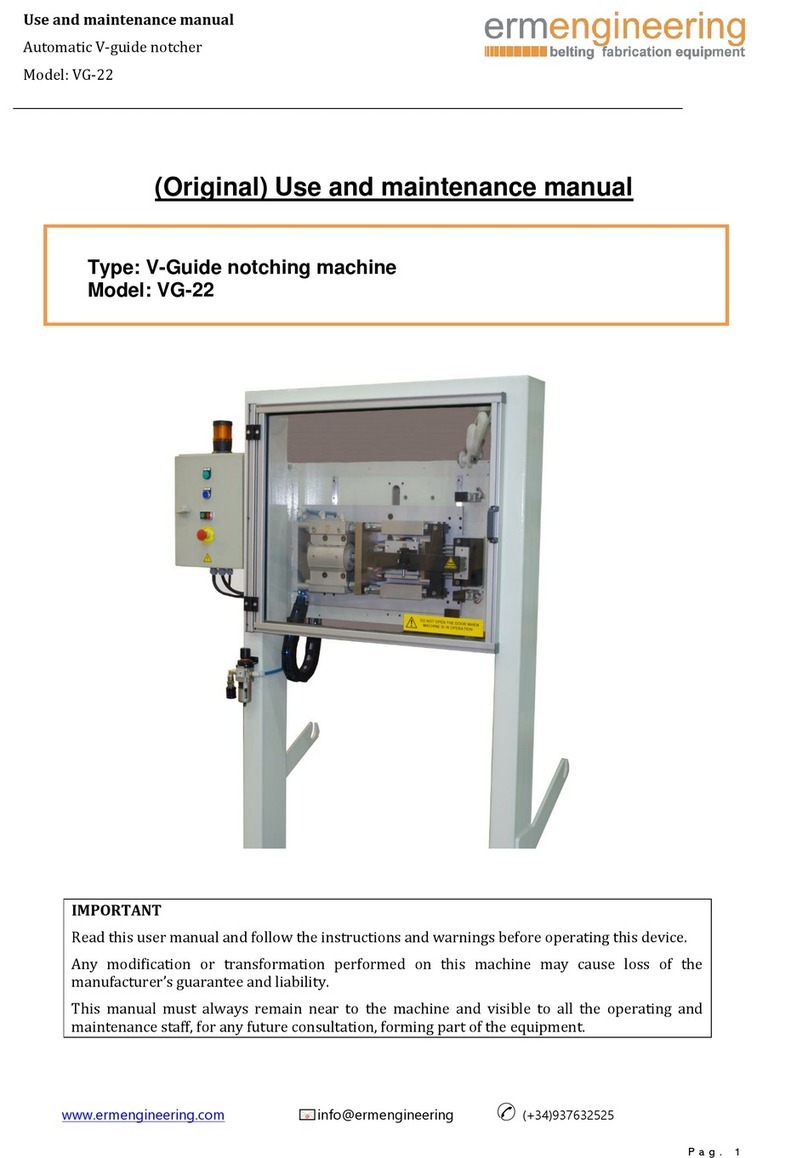

ermengineering VG-22 User manual

ermengineering

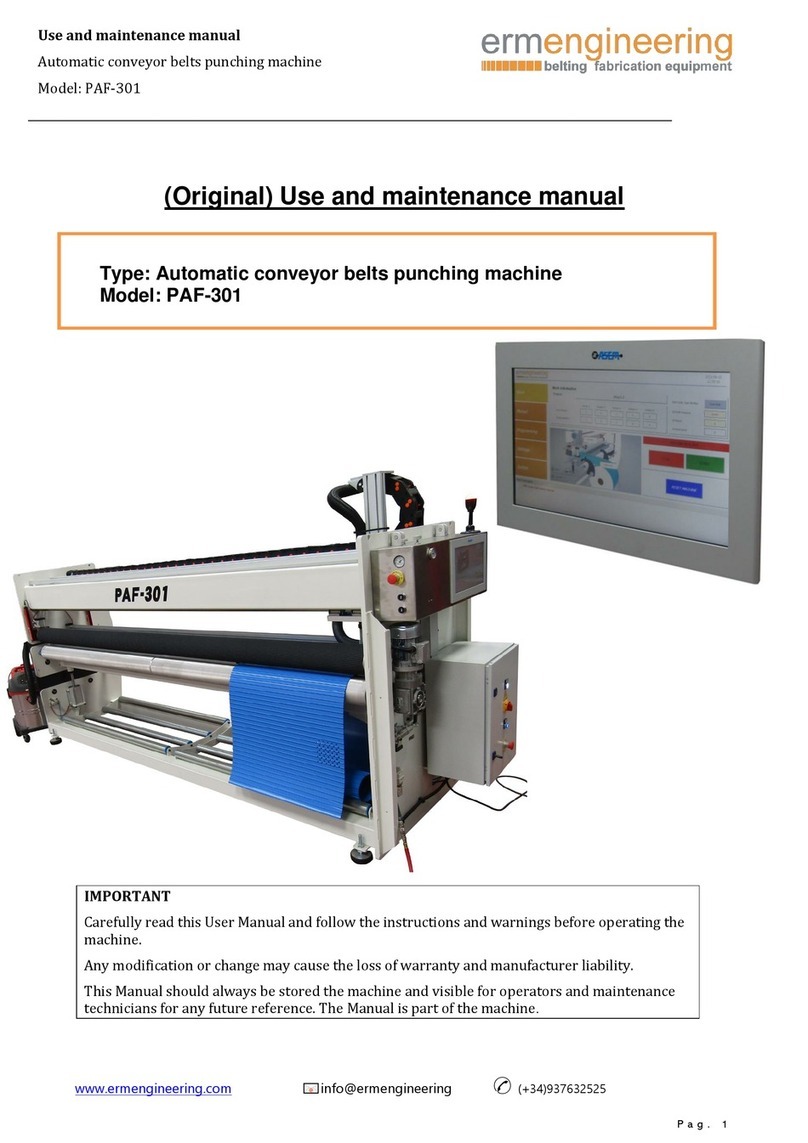

ermengineering PAF-301 User guide

ermengineering

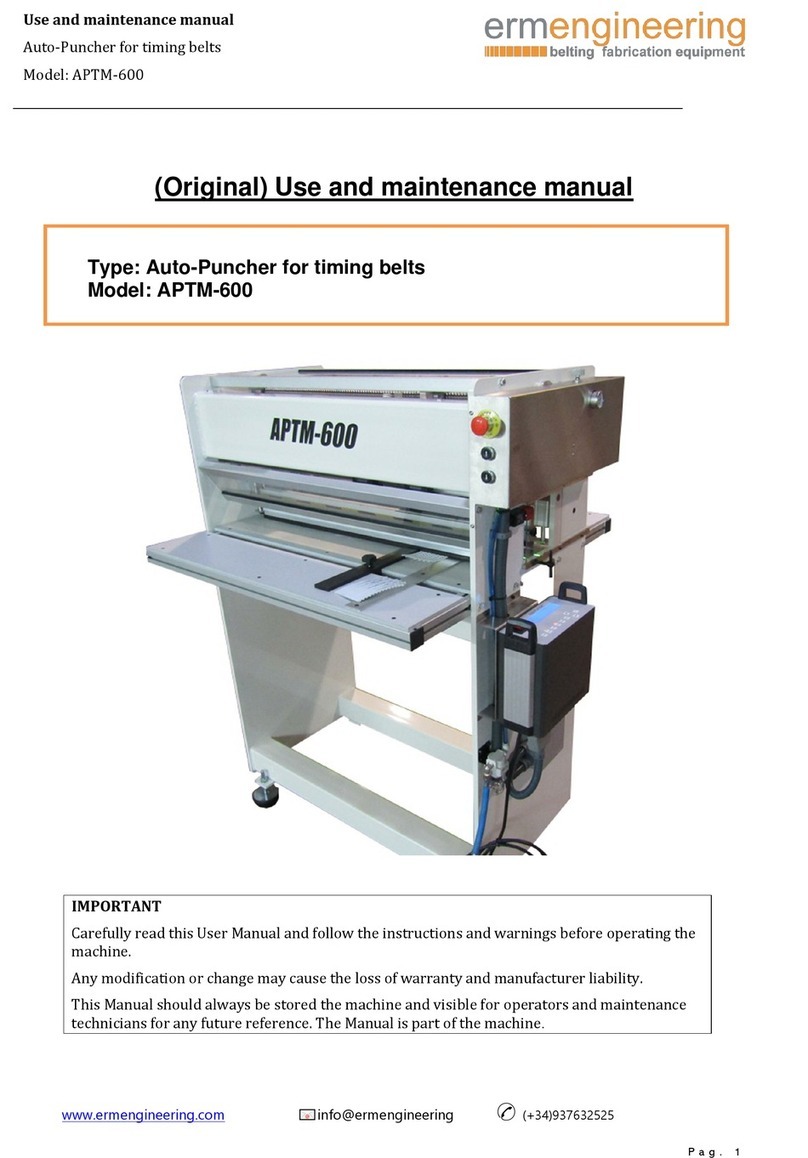

ermengineering APTM-600 User manual

ermengineering

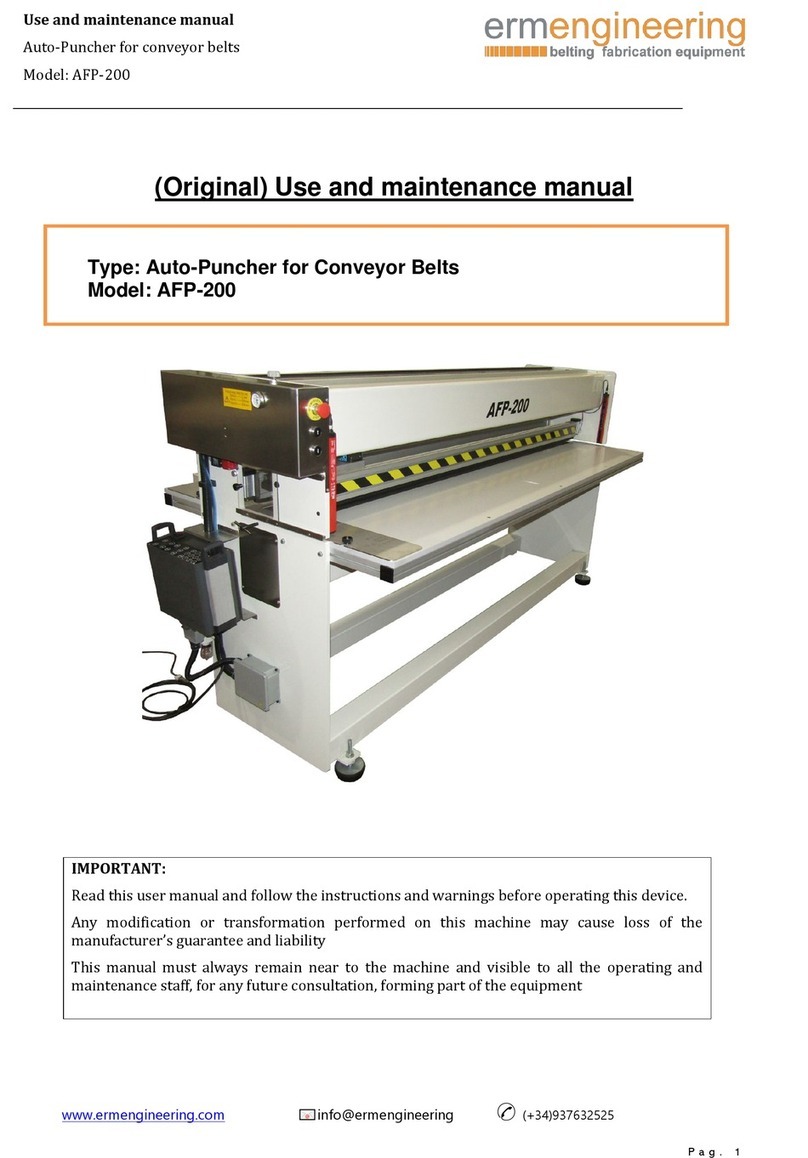

ermengineering AFP-200 User manual

ermengineering

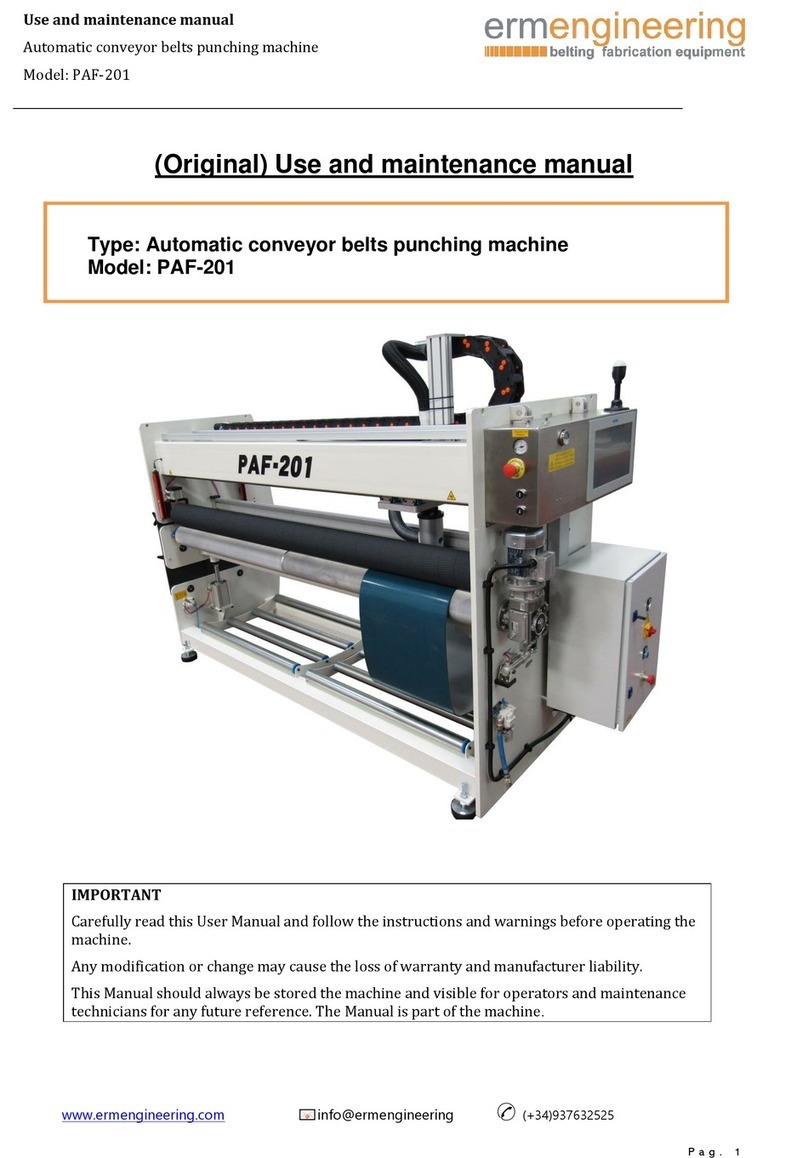

ermengineering PAF-201 User manual

ermengineering

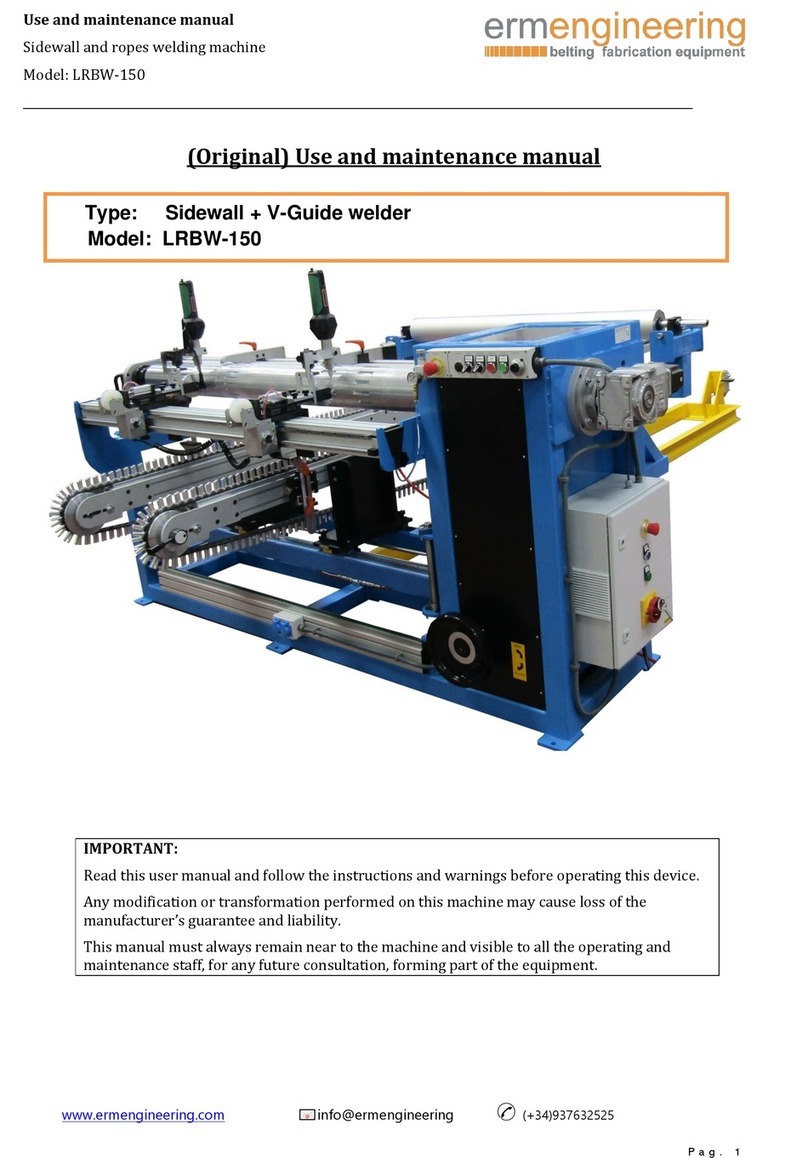

ermengineering LRBW-150 User manual

ermengineering

ermengineering SKR-350 User manual

ermengineering

ermengineering SK-270 User manual

Popular Industrial Equipment manuals by other brands

Emerson

Emerson Aventics EtherCAT 580 Technical manual

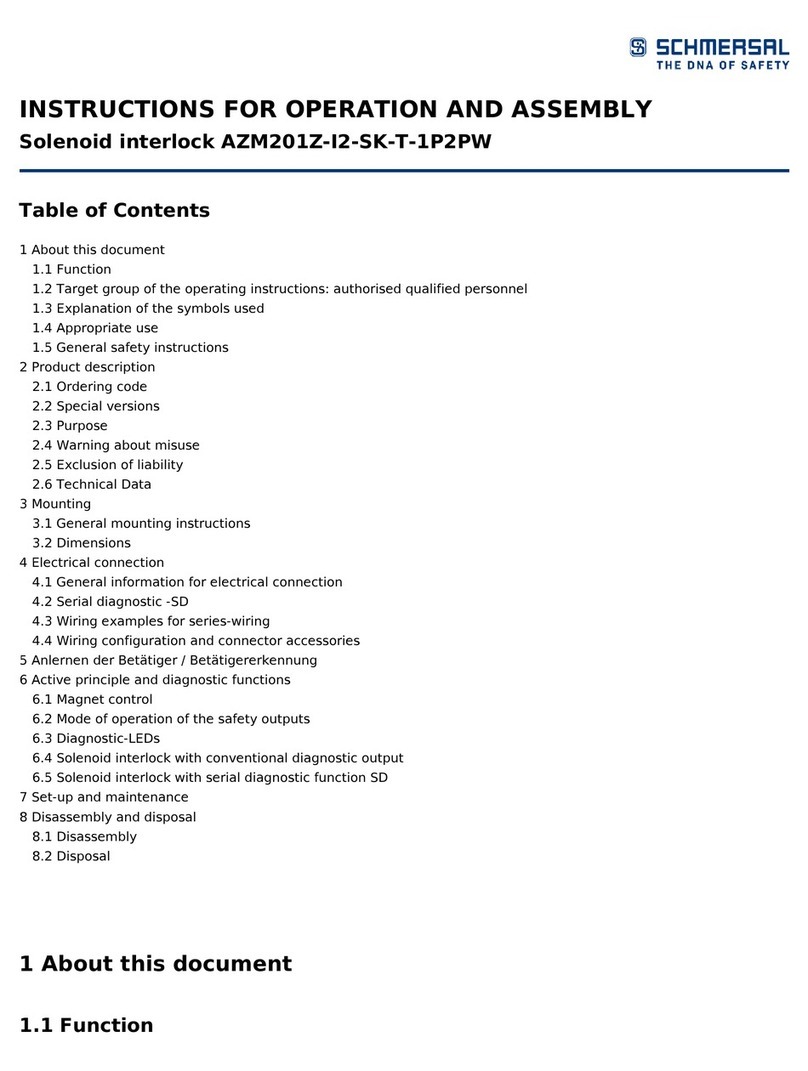

schmersal

schmersal AZM201Z-I2-SK-T-1P2PW Instructions for operation

CaptiveAire

CaptiveAire DW Installation, operation and maintenance manual

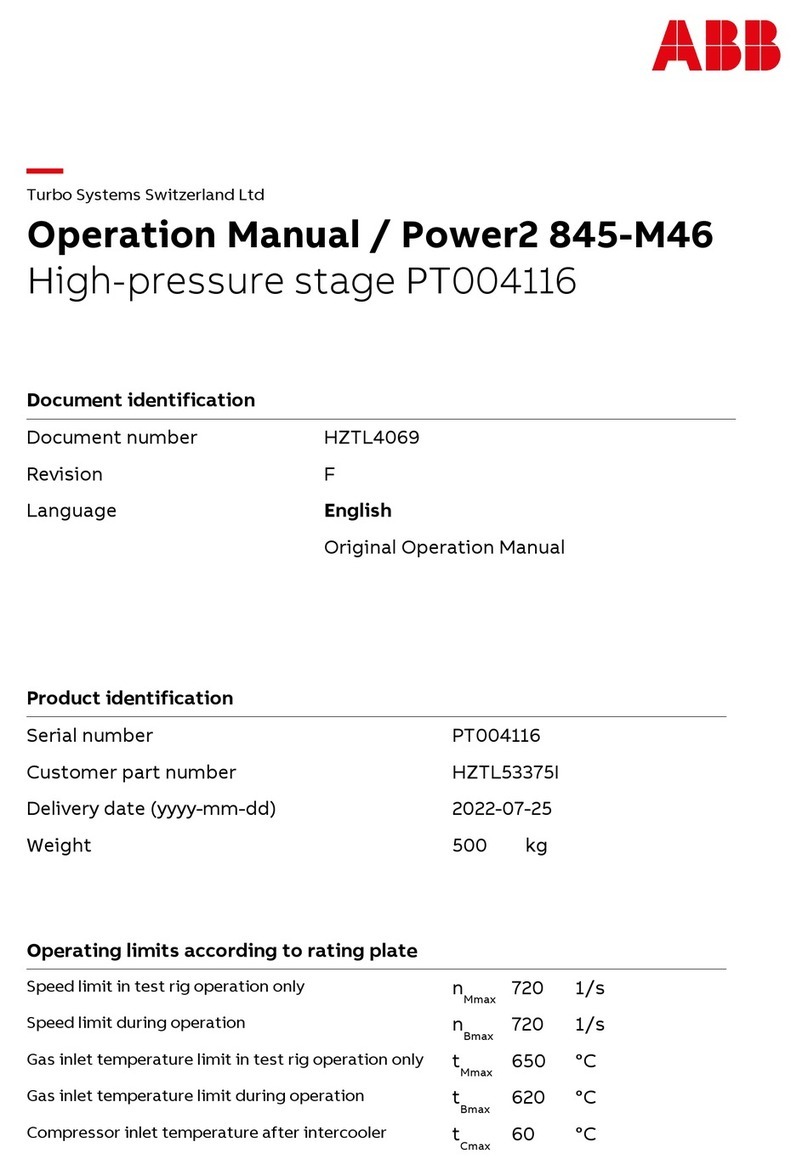

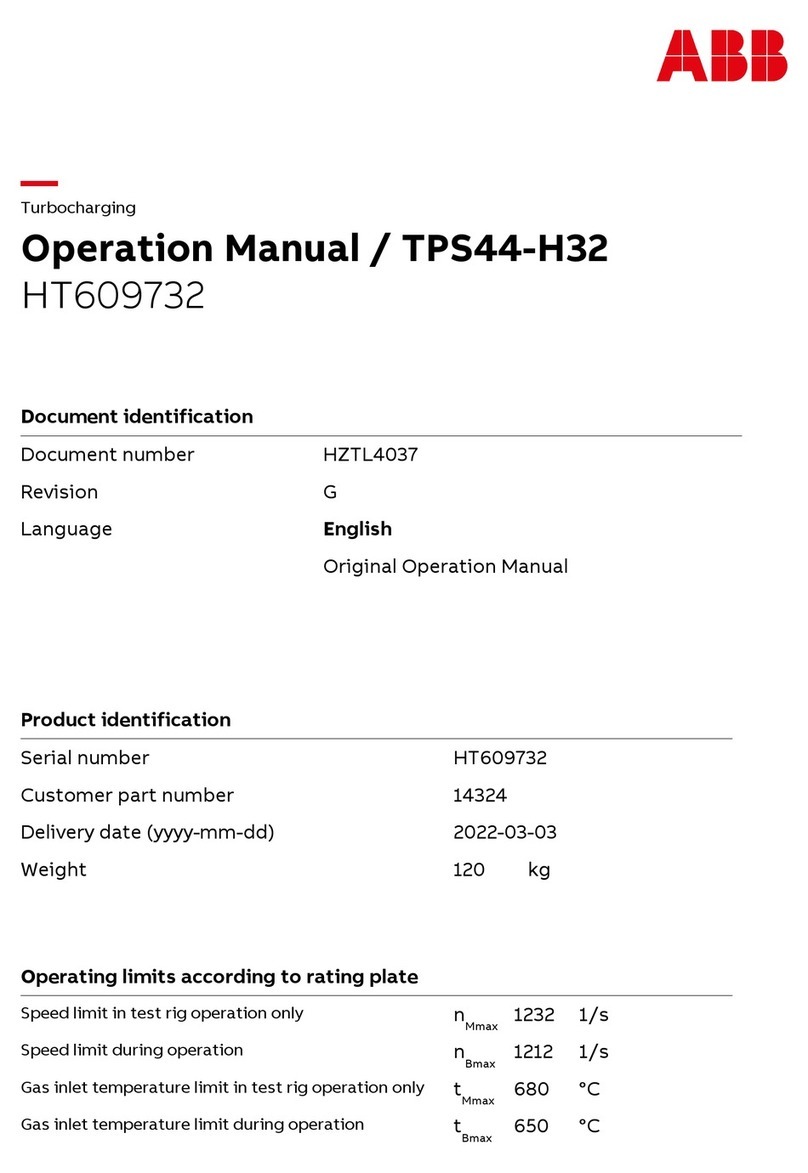

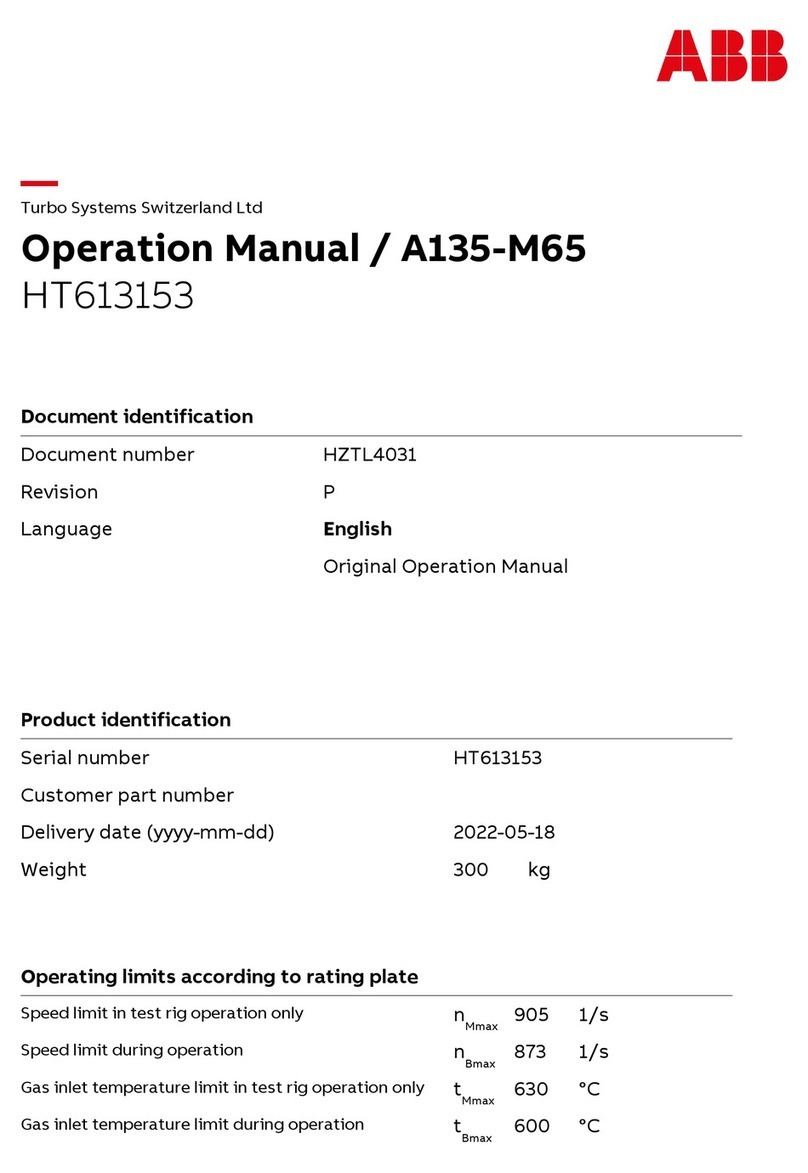

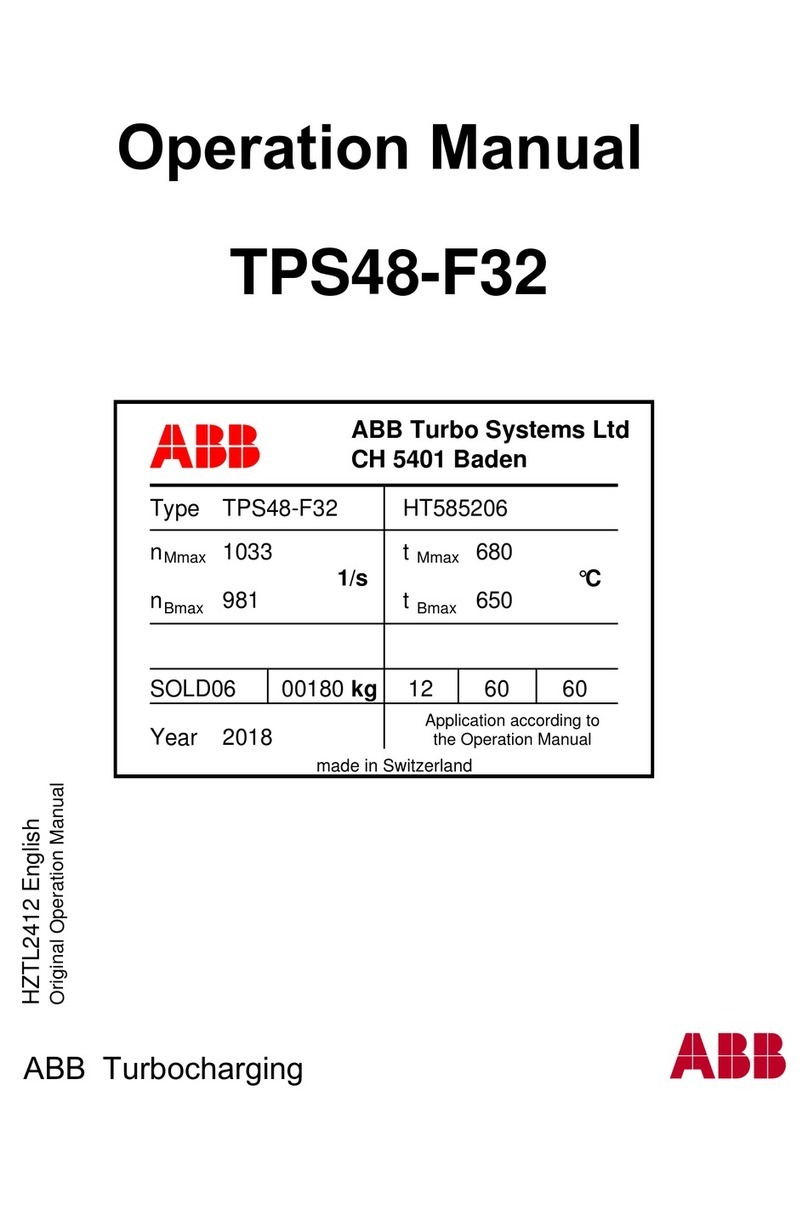

ABB

ABB HT845298 Operation manual

schmalenberger

schmalenberger fluvo NT2 rondo manual

TAKEDA SEIKI

TAKEDA SEIKI TM-200 instruction manual