Index:

Page

-CE Declaration of conformity:................................................................................................................................................3

-Transport and unloading the machine:..............................................................................................................................4

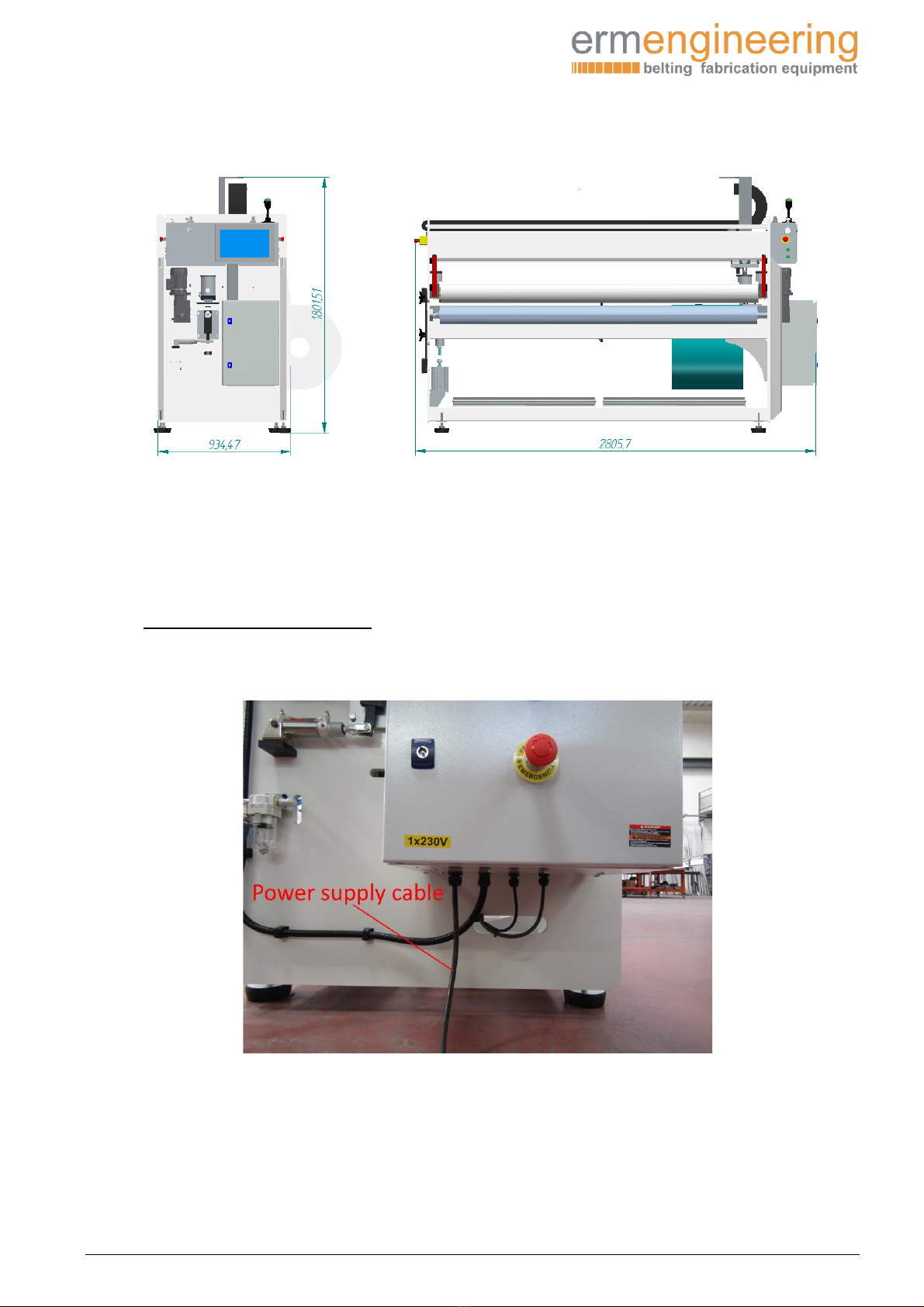

-Dimensions and weights:.........................................................................................................................................................5

-Set-up and connection: .............................................................................................................................................................6

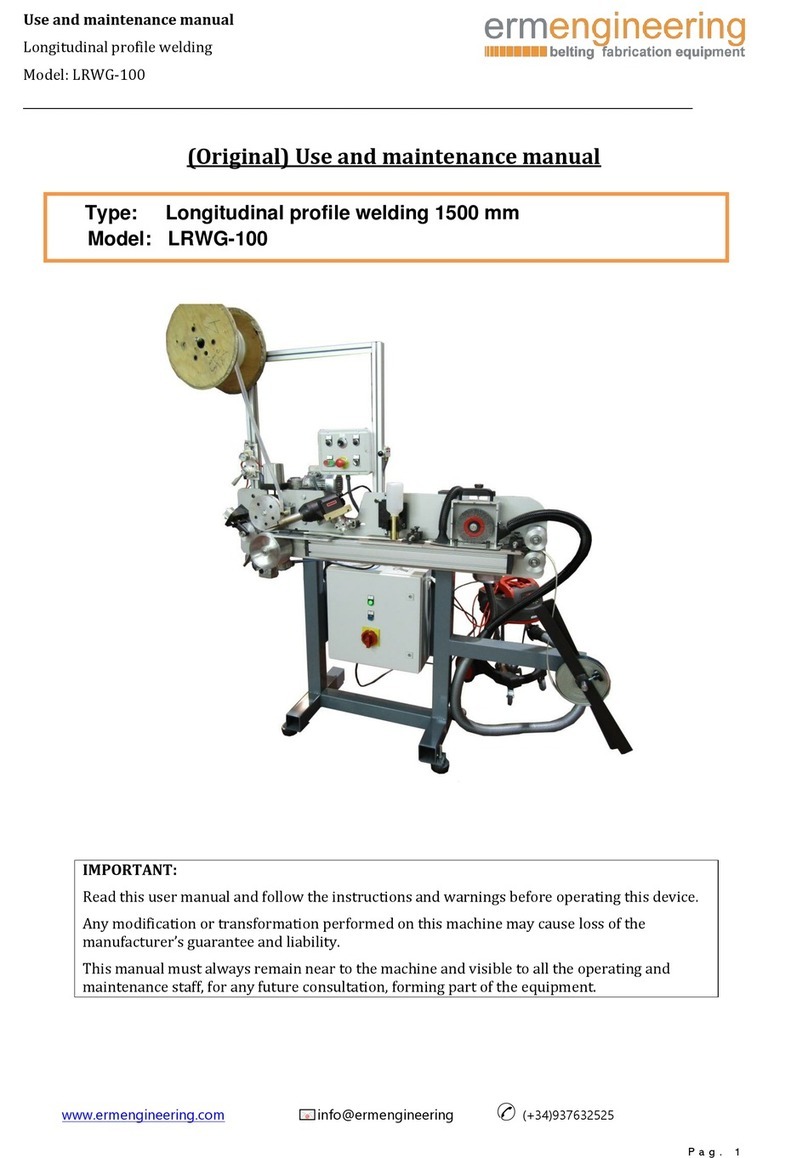

-Description: ..................................................................................................................................................................................8

-Technical features:.....................................................................................................................................................................8

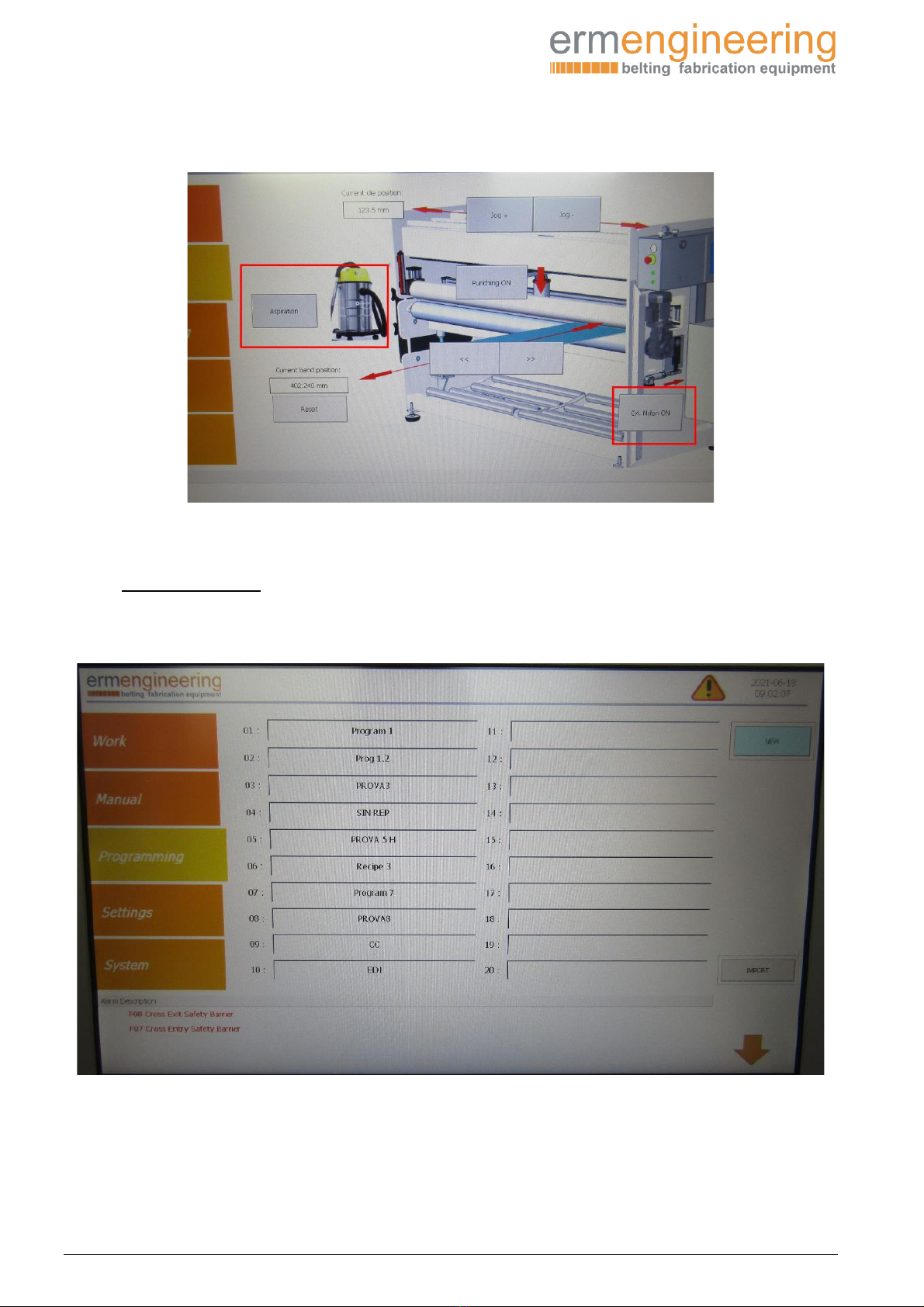

-Instructions for Use: ..................................................................................................................................................................8

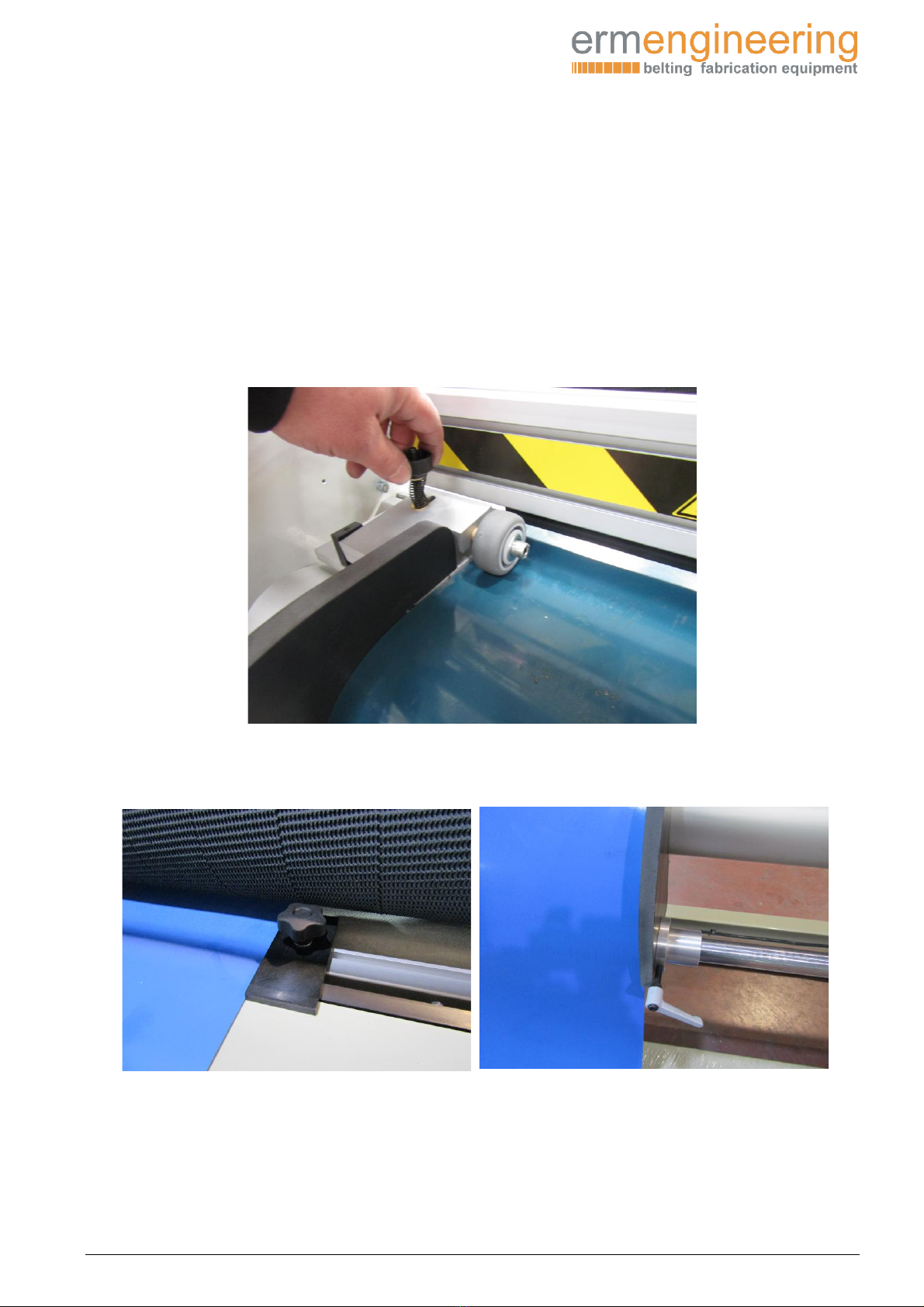

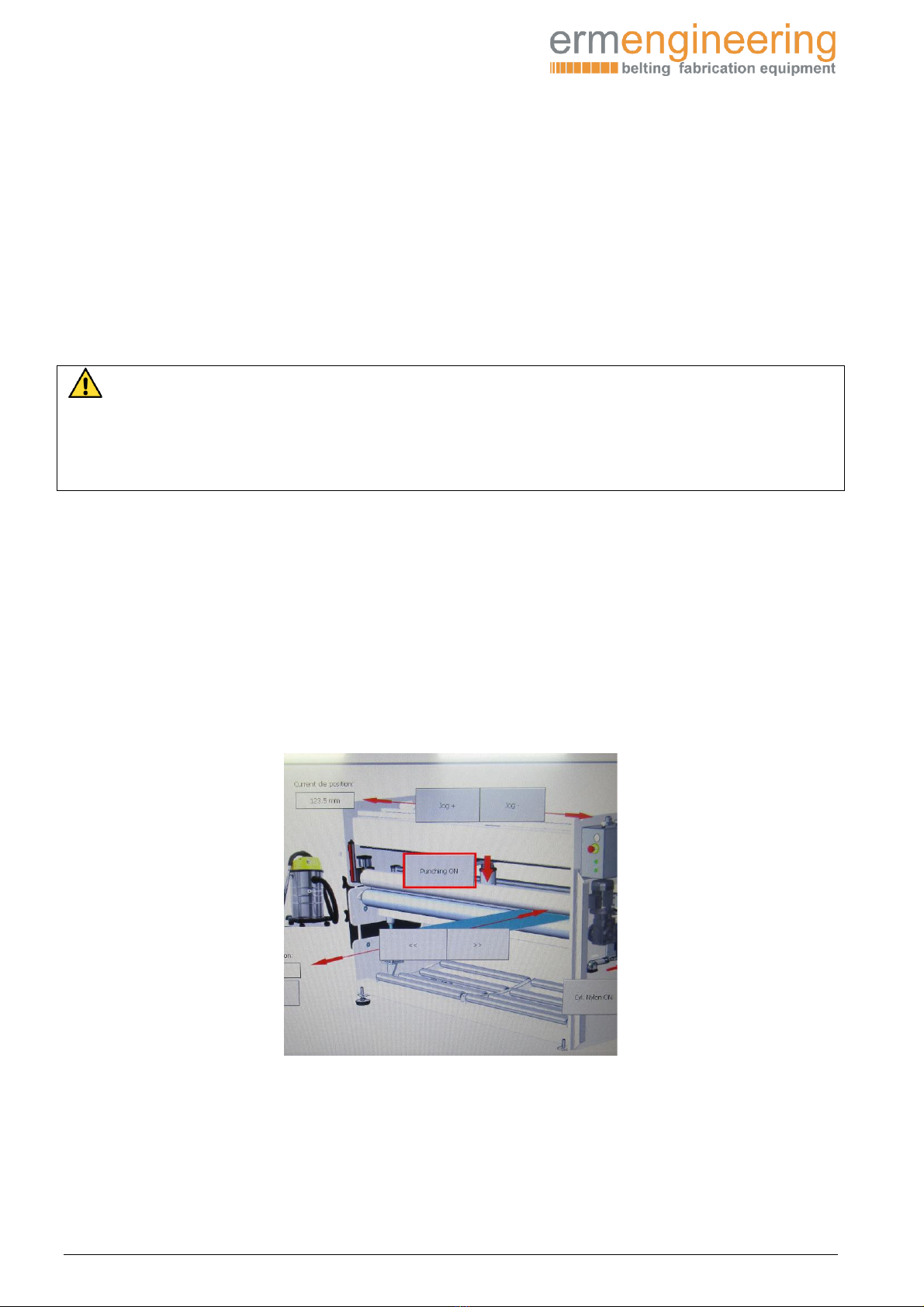

Preparation................................................................................................................................................................................................................ 9

Safety systems and messages: ...........................................................................................................................................................................12

Functions of the main MENU.............................................................................................................................................................................13

Work: ..........................................................................................................................................................................................................................13

Manual. ......................................................................................................................................................................................................................15

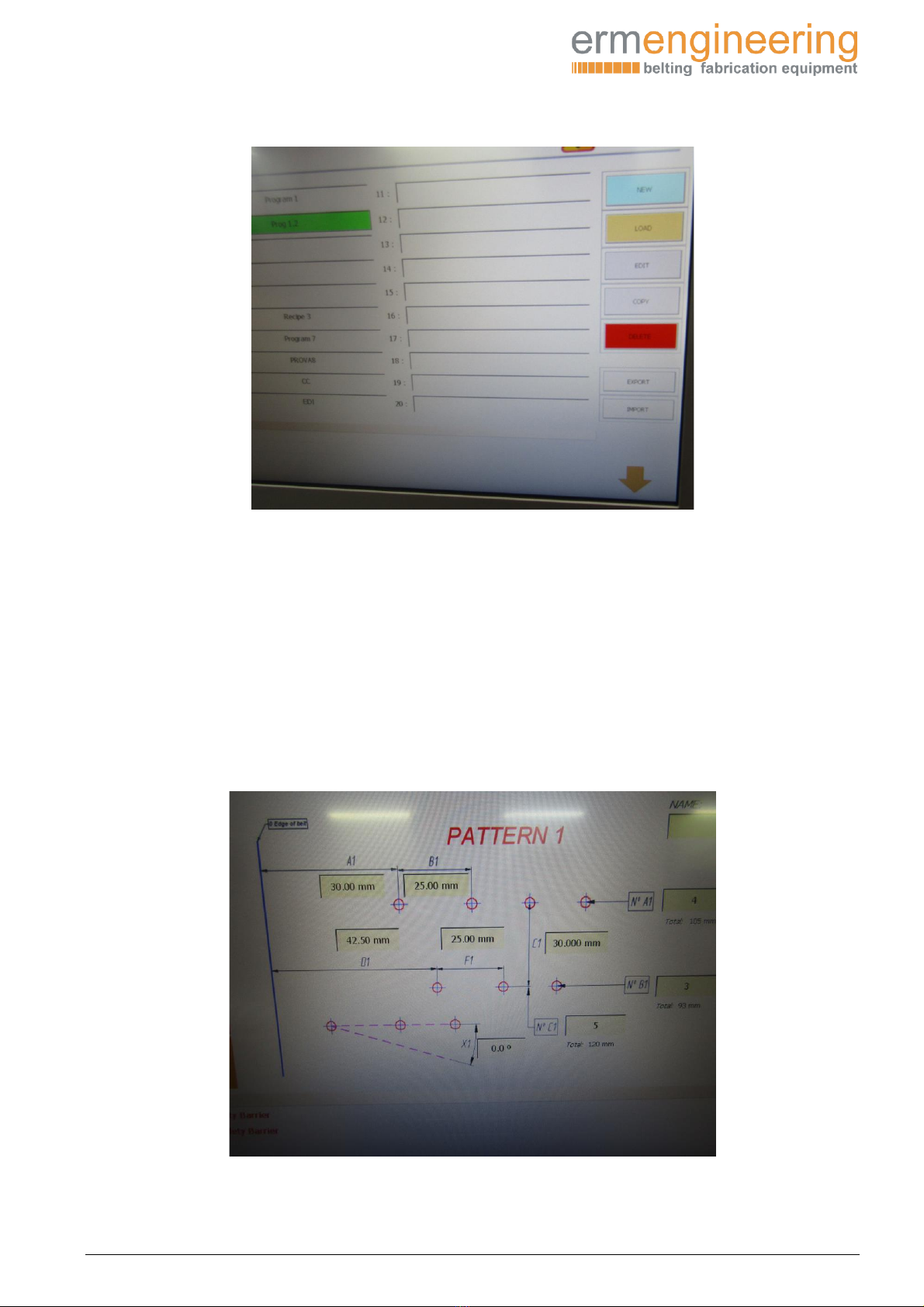

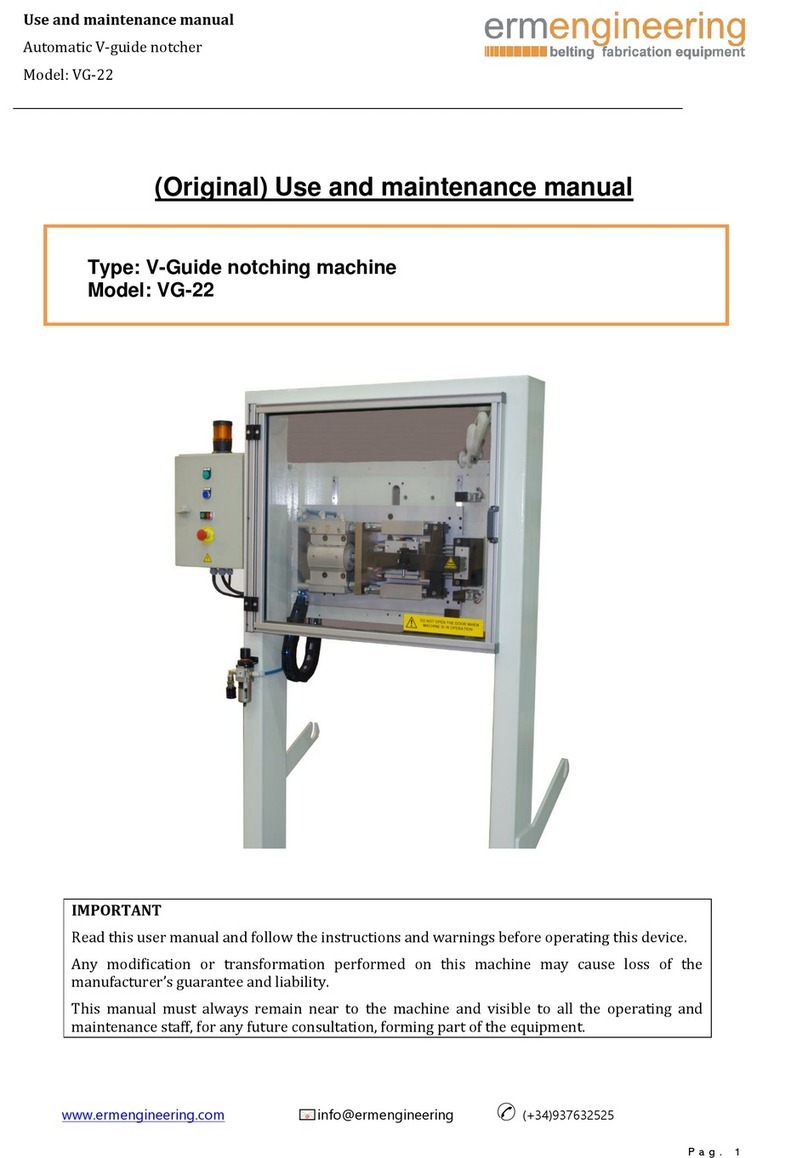

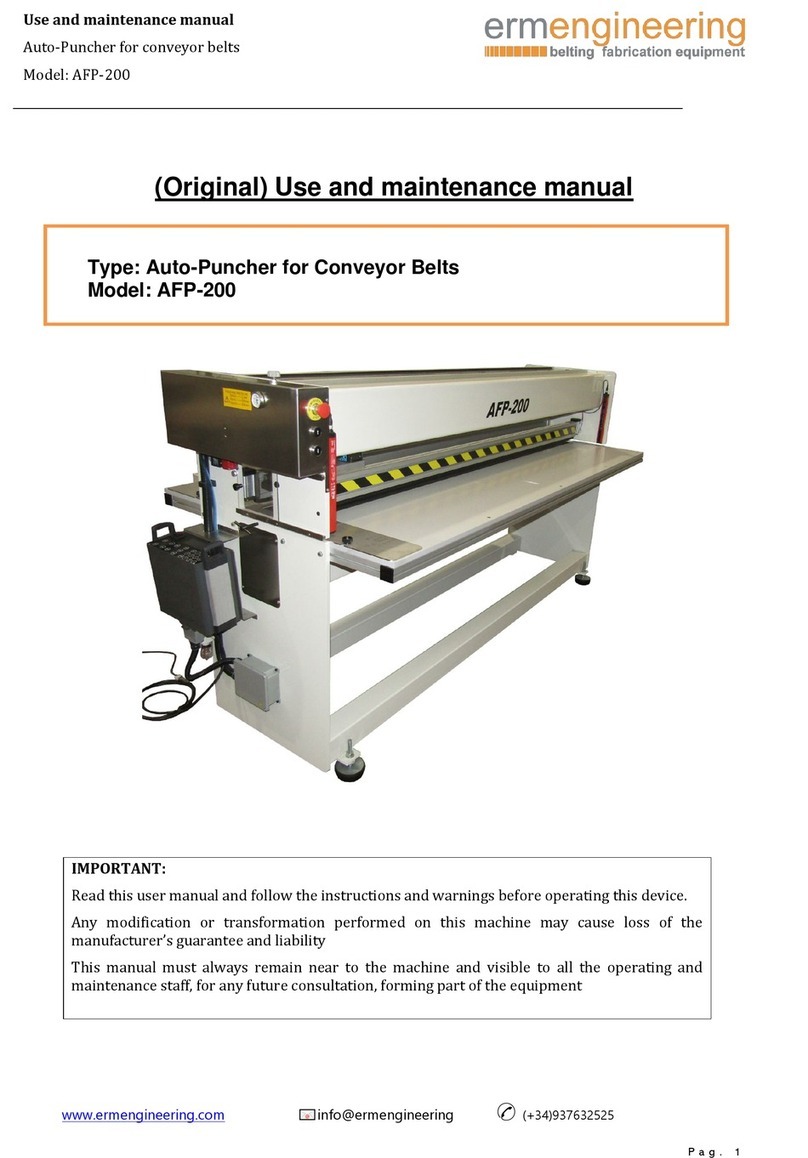

-Programming ............................................................................................................................................................................ 17

New..............................................................................................................................................................................................................................18

Memories:..................................................................................................................................................................................................................23

-Settings:....................................................................................................................................................................................... 25

-Endless belt option.................................................................................................................................................................. 26

-Die change .................................................................................................................................................................................. 30

-Electrical drawings: ................................................................................................................................................................ 32

-Spare parts:................................................................................................................................................................................ 56