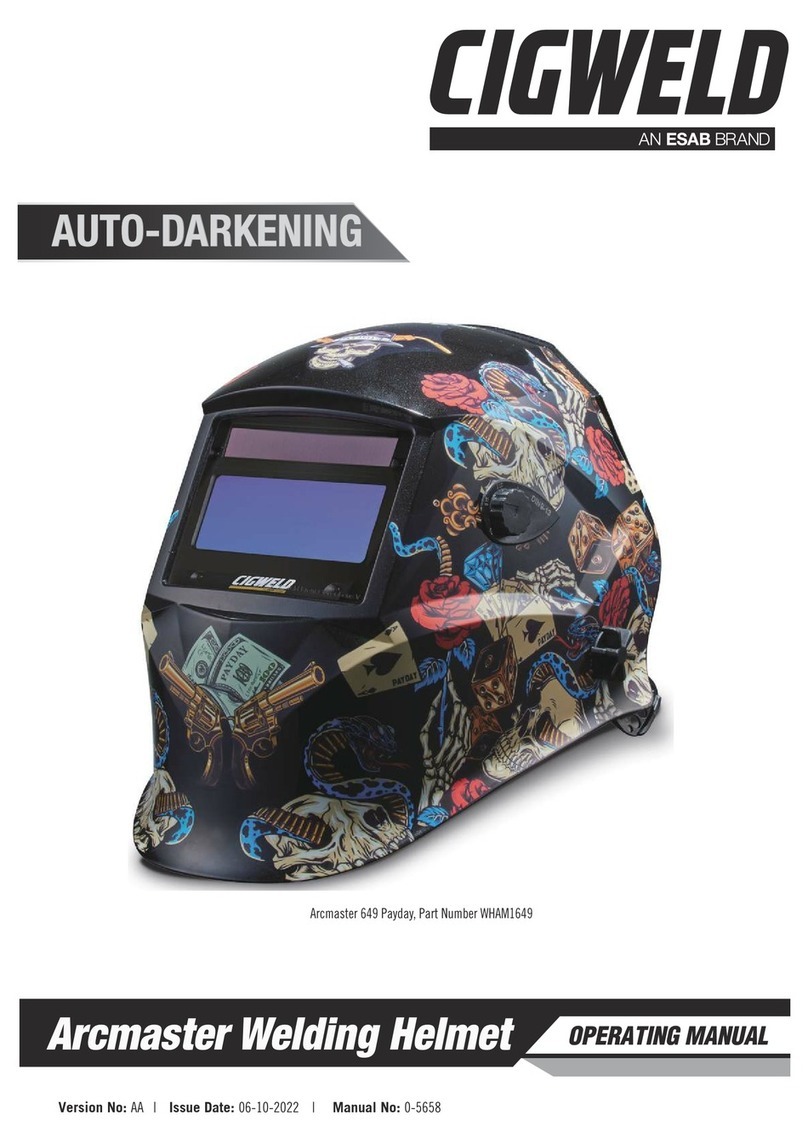

INSTRUCTIONS for

Eye-Tech 10-12 Select

Welding Helmet

P/N 15F20

ARC RAYS can burn eyes and skin. Wear safety

glasses and set proper filter shade. See ANSI/AWS

Z 9.1 for guide. Available from American Welding

Society, Miami, FL 33135.

The Eye-Tech 10-12 Select welding helmet is deliv-

ered fully assembled and ready for use. You only need

to adjust the headband and set the shade level. The

shade cartridge automatically darkens with arc igni-

tion.

Safety Precautions

lPitted or scratched plates reduce vision and protec-

tion. Replace worn or damaged parts immediately.

lAlways keep the external and internal protective plates

in place. Failure to do so will allow welding spatter to

pit the front surface of the shade cartridge. This can

reduce the built-in V and IR protection. (Also, the

weld spatter will void the warranty on the shade car-

tridge.)

lDo not attempt to open the shade cartridge.

lDo not use in cold weather (below 14° F).

lKeep solar cells clean. Clean with a damp not wet,

cloth dipped in soapy water. Dry with a soft, clean

cloth.

lDo not drop, strike, or bend helmet.

lDo not use abrasive cleaning agents.

lFumes and gases can be hazardous to your health.

Keep your head out of the fumes. Ventilate area or

use breathing devices, if necessary.

Keep helmet dry (especially the shade cartridge) and

do not place on hot surfaces.

Operation

lSet the slideswitch until it clicks to the shade level recom-

mended for your arc welding process. If you have doubts,

start with slideswitch in the 11-12 position. If you find that

the arc zone is too dark, then set slideswitch to the 1 -11

position.

lCheck to see if the front cover lens is inserted and front

lens frame is in place.

Troubleshooting

lUneven darkening

- Protective helmet is not on straight, causing the dis-

tance between your eyes and the shade cartridge to

vary. If necessary, decrease distance to shade cartridge.

lThe shade cartridge does not darken or it flickers

- Sensors are dirty; clean

- Front cover lens is dirty or damaged; clean or replace

- Welding current is too low

- Slideswitch not set properly (is in non-active center

position).

lSlow switching times

- Temperature is too low (should not be below 14° F)

- Lighting is insufficient

lPoor visibility

- Shade levels are set incorrectly

- Front or rear cover lens is dirty

- Room lighting is insufficient

lWelding helmet slips

- Headband is not properly adjusted (set too low)

If these faults cannot be corrected, do not use

helmet. Contact your distributor for assistance.

F-15-432

December, 1997

Be sure this information reaches the operator.

You can get extra copies through your supplier.

Specifications

Viewing Area: 3.86 x 1.50 (98 x 38mm)

Light transmittance: Ranges of sha e levels 10-11 & 11-12

Automatic sha e level function with selec-

tion of switch

Ultra-violet protection 15

Infra-re protection 14

Sha e level 4 in non-active state

Switch Time: From light to ark 0.1 millisecon s at room

temperature; from ark to light 0.2-0.3 sec-

on s

Operating Temp.: 14° F to 158° F (-10°C to +70°C)

Power Supply: Solar cells

Helmet Construction: High impact, synthetic material

Weight: 16.6 oz (470 grams)

Technical details are subject to change.