Eskon EPA300 User manual

EPA300

USER

MANUAL

PROCESS CONTROL DEVICE

2

1. INDEX

1. INDEX ------------------------------------------------------------------------------------ 2

2. CONNECTIONS ------------------------------------------------------------------------- 3

3. FRONT PANEL DEFINITIONS------------------------------------------------------- 5

4. SETUP------------------------------------------------------------------------------------ 6

4.1 CONNECTION TO SENSOR DEVICE------------------------------------------------------------------ 6

4.2 DEVICE CALIBRATION---------------------------------------------------------------------------------- 7

4.3 ENTER RELAY SET VALUE ----------------------------------------------------------------------------- 8

5. OPERATING MODE: FUNCTIONS -------------------------------------------------10

5.1 Tare Function------------------------------------------------------------------------------------------ 10

5.2 Viewing the Maximum and Minimum Reading Values-------------------------------------- 10

5.3 Changing Quick Set Values------------------------------------------------------------------------- 10

5.4 Transition to Programming Mode---------------------------------------------------------------- 10

6. PROGRAMMING MODE: PROGRAMMING DIVICE ----------------------------12

6.1 Output Menu [OUT] --------------------------------------------------------------------------------- 12

6.1.1 1. Relay Output Setting (OUT-1)--------------------------------------------------------------- 12

6.1.2 2., 3., 4. Relay Output Settings (OUT-2-3-4)------------------------------------------------ 14

6.1.3 Current and Voltage Analog Output Settings (ANLOG)---------------------------------- 14

Wave Form (VAVE.F.)--------------------------------------------------------------------------------------- 14

Analog Output Scale Setting (Scale)-------------------------------------------------------------------- 14

6.1.4 UART and CANopen Digital Output Settings (DGTAL)------------------------------------ 15

6.1.5 Keypad Setting (SOUND) ------------------------------------------------------------------------ 15

6.2 Calibration Menu [CALIB] -------------------------------------------------------------------------- 15

6.2.1 Specifying Scale Values (SCALE) --------------------------------------------------------------- 15

6.2.2 Manual Calibration Method Determination (CALOP) ------------------------------------ 16

6.2.3 Number of Calibration (CL.CNT)--------------------------------------------------------------- 16

6.2.4 Automatic Calibration (START) ---------------------------------------------------------------- 16

6.3 Display Menu [DISP] --------------------------------------------------------------------------------- 16

6.3.1 Choice of decimal point location (POINT) --------------------------------------------------- 16

6.3.2 Tare Functain Settings (TARE) ----------------------------------------------------------------- 16

6.3.3 Screen Refresh Rate (REFRS) ------------------------------------------------------------------- 17

6.3.4 Blocking the on Screen Volatility (FILTR) ---------------------------------------------------- 18

6.4 Secure Menu [SECUR]------------------------------------------------------------------------------- 18

6.4.1 Hide Menu (HIDE)--------------------------------------------------------------------------------- 18

6.4.2 Menu Lock (LOCK)-------------------------------------------------------------------------------- 19

6.4.3 Set Password (PASS)------------------------------------------------------------------------------ 19

6.4.4 Return to Factory Setting (FTRY) -------------------------------------------------------------- 19

6.4.5 Restart the Device (RESET)---------------------------------------------------------------------- 19

7. WARRANTY DOCUMENT-----------------------------------------------------------21

3

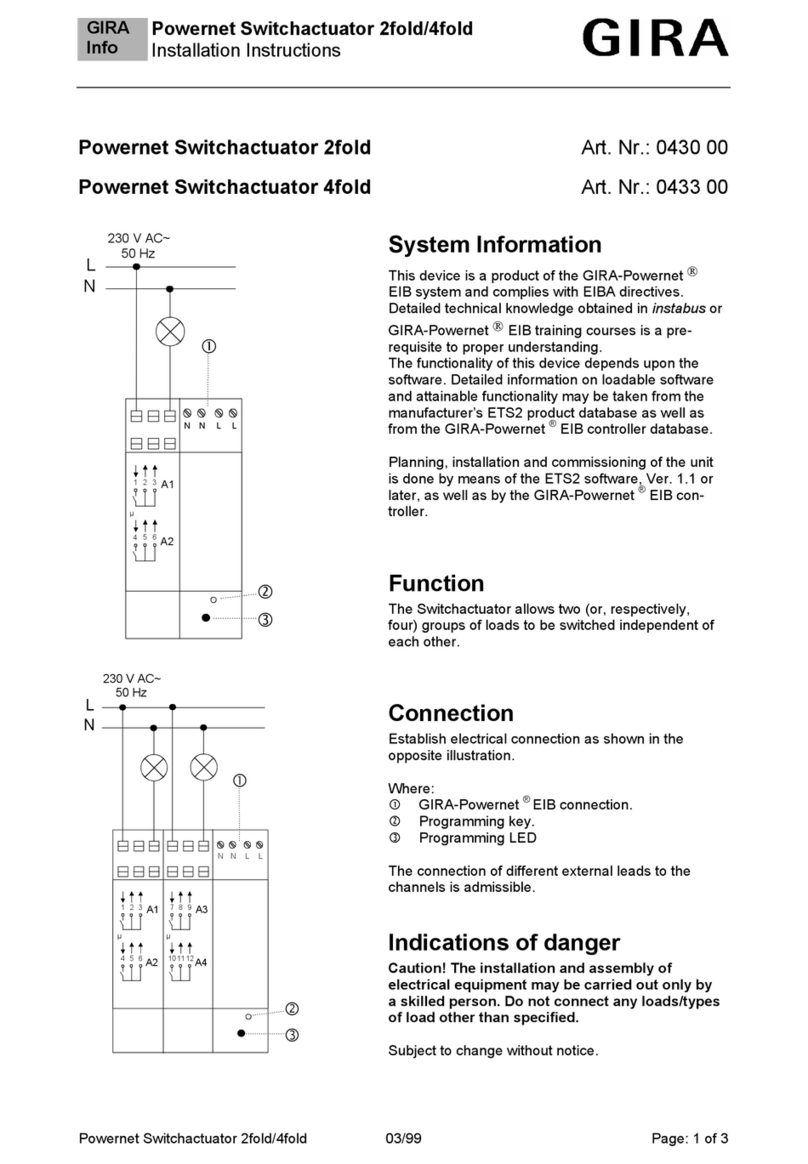

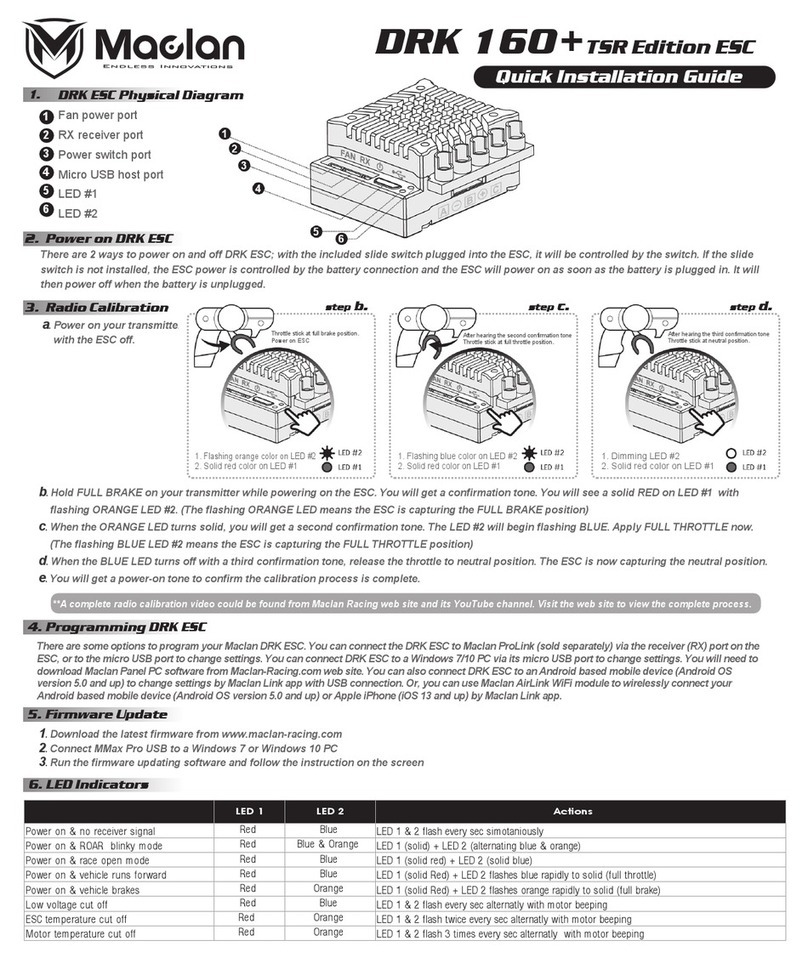

Supply Voltage

24 VAC / DC or 85 /

265 VAC

1. Relay Output

OUT-1

2. Relay Output

OUT-2

Shown in tables

below with pin

numbers assigned.

3. Relay Output

OUT-3

4. Relay Output

OUT-4

2. CONNECTIONS

Digital Comn.

28

29

30

RS485

A

B

GND

RS232

Rx

Tx

GND

USB HID

USB CONNECTOR

USB VIRTUAL

USB CONNECTOR

CANopen

CAN HIGH

CAN LOW

GND

Analog

Outputs

20

21

22

23

24

25

26

27

4-20 mA

Output

4-20 mA

Output

GND

4-20 mA

Output

GND

4-20 mA

Output

GND

0-10 V

Output

0-10 V

Output

GND

0-10 V

Output

GND

0-10 V

Output

GND

Tare

Output

Tare

Input

GND

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

L

N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

-

+

-

4

SENSOR

15

16

17

18

19

Potentiometer

1. tip

2. tip

3. tip

X

X

4-20 mA Input

Supply

Sensor Signal

GND

X

X

0-10 V Input

Supply

Sensor Signal

GND

X

X

3,33 mV/V Input

Supply

X

GND

Signal(+)

Signal(-)

SAFETY WARNINGS

1. Follow the instructions and warnings in the user guide.

2. Please check the power supply type before connects energy to the device.

3. Please the device mounted on panel against dangers of fall, snap, shake

during working.

4. Make Sensor connections without energy on the device; do not connect in

any way during operation.

5. Make sure that is shielded cables between device and sensor.

6. Do not leave the device exposed to a heat source (solar, heater etc.)

7. EPA300 industrial control device is not suitable for use in the external

environment, Use only room conditions.

8. Wipe with a damp cloth to clean the device, do not use water, thinner etc.

9. Comply with the limit values specified in the technical specifications for

relay outputs.

10. The device cannot be changed by the user in the event of a fault, Please

contact our technical service in case of failure.

5

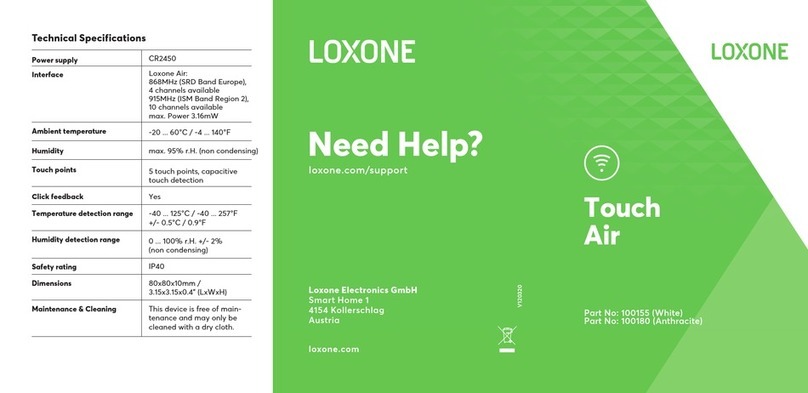

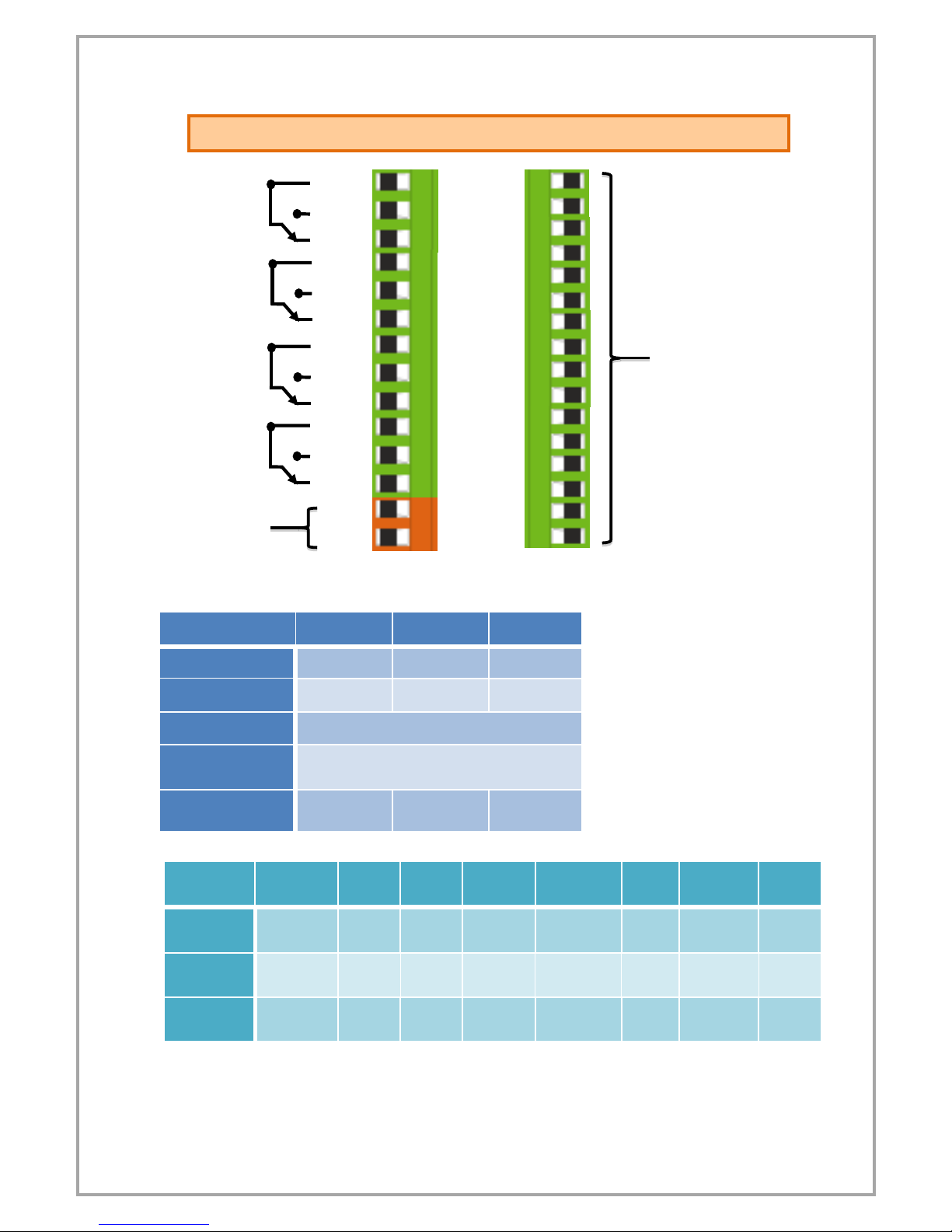

3. FRONT PANEL DEFINITIONS

8

7

1

2

3

4

6

5

1) PRG ( ): Programming and Enter key. It is used to enter the menus or

confirm the entered values.

2) ESC ( ): Escape, exit and backspace key. It is used to return to the upper

menu or to exit the menus.

3) UP ( ): Up key. Navigating between menus; Is used to increment the

value or move to a higher digit when entering a value.

4) DOWN ( ): Down key. Navigating between menus; Used to decrease the

value when entering a value or to switch to a lower step.

5)Set1 Status LED: 1. Display when the relay output is active.

6)Set2 Status LED: 2. Display when the relay output is active.

7)Set3 Status LED: 3. Display when the relay output is active.

8)Set4 Status LED: 4. Display when the relay output is active.

9)Min Status LED: Lights up when the lowest (minimum) value read from the

moment the device starts to operate.

10)Max Status LED: Lights up when the maximum read value is displayed

when the device starts operating.

11)Tare Status Led: Indicator that is lit when the key function is active.

12) Display Screen: Display screen consisting of 5 lines from a single line.

13) LED bar: The entered scale values increase and decrease in range.

9

10

00

00

00

00

00

11

12

13

6

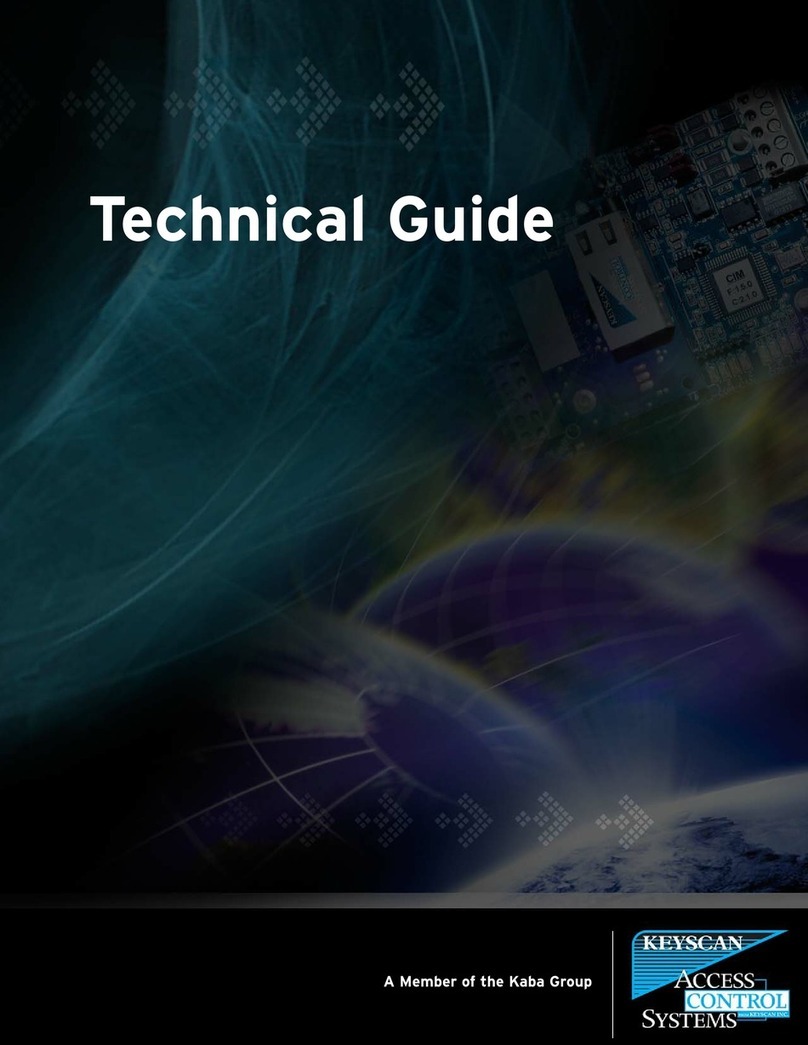

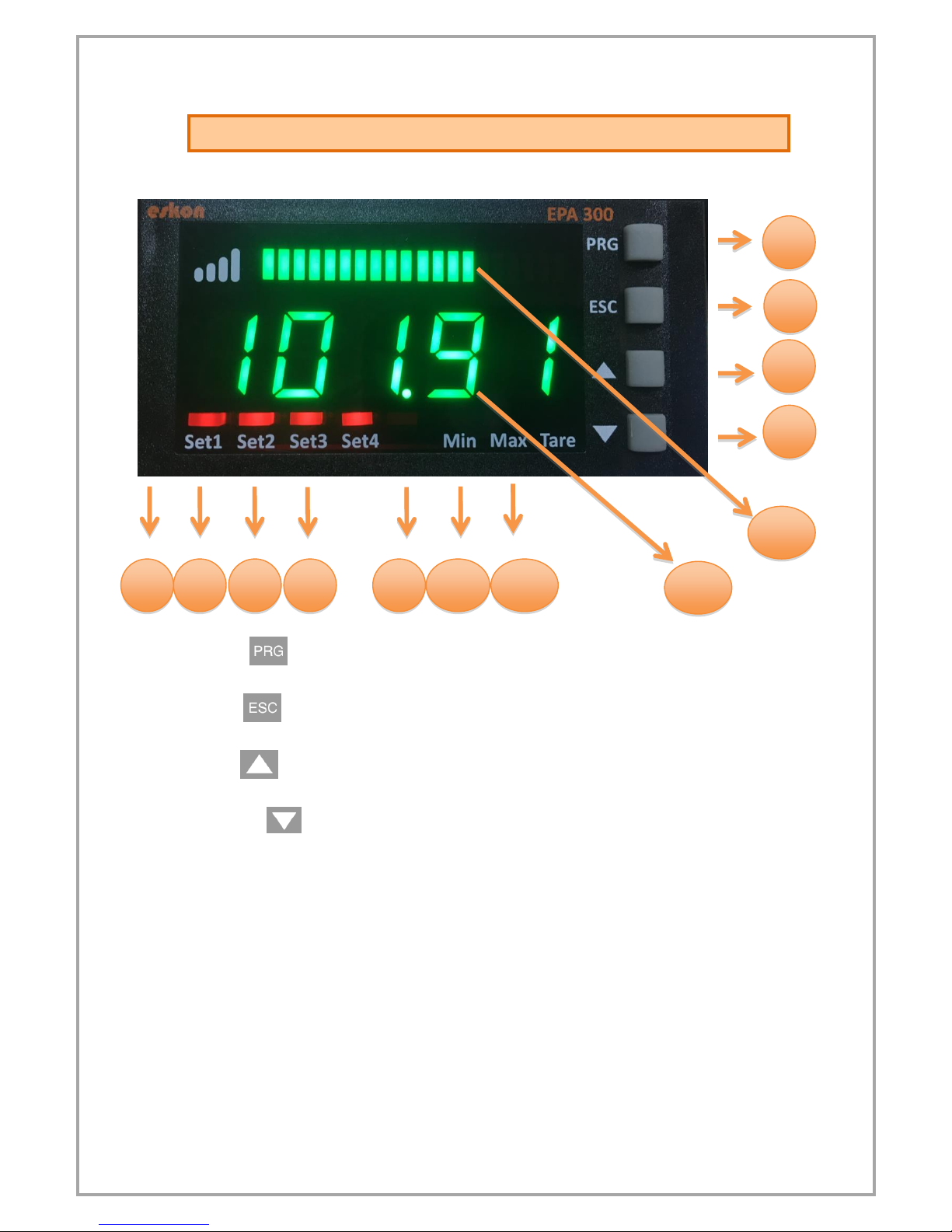

4. SETUP

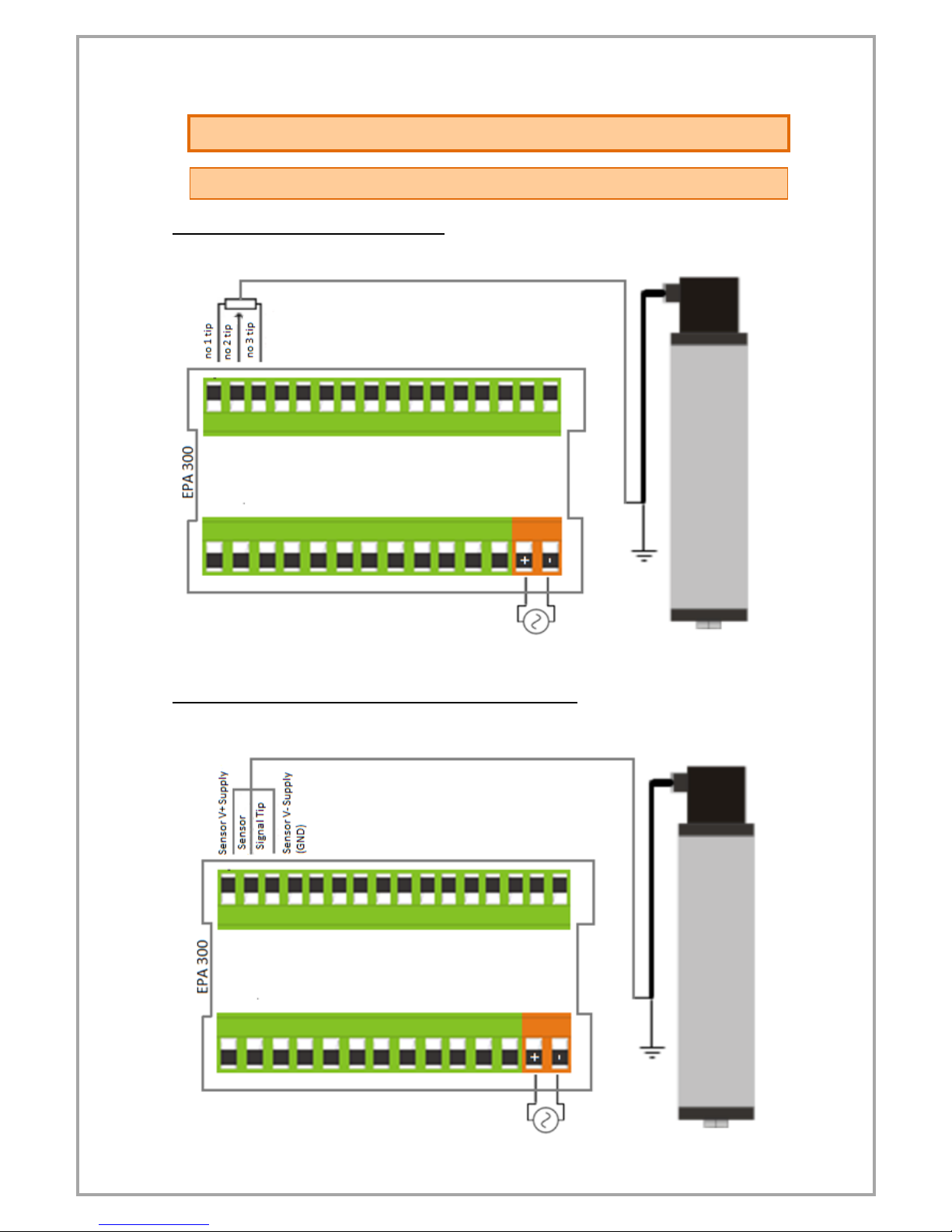

4.1 CONNECTION TO SENSOR DEVICE

Potentiometer connections:

Connections of 4-20mA or 0-10 V sensors:

Linear potentiometer

Pressure sensor with 4-20 mA

or 0-10 V output

+

7

3.33 mV / V Ratiometric Sensor connections:

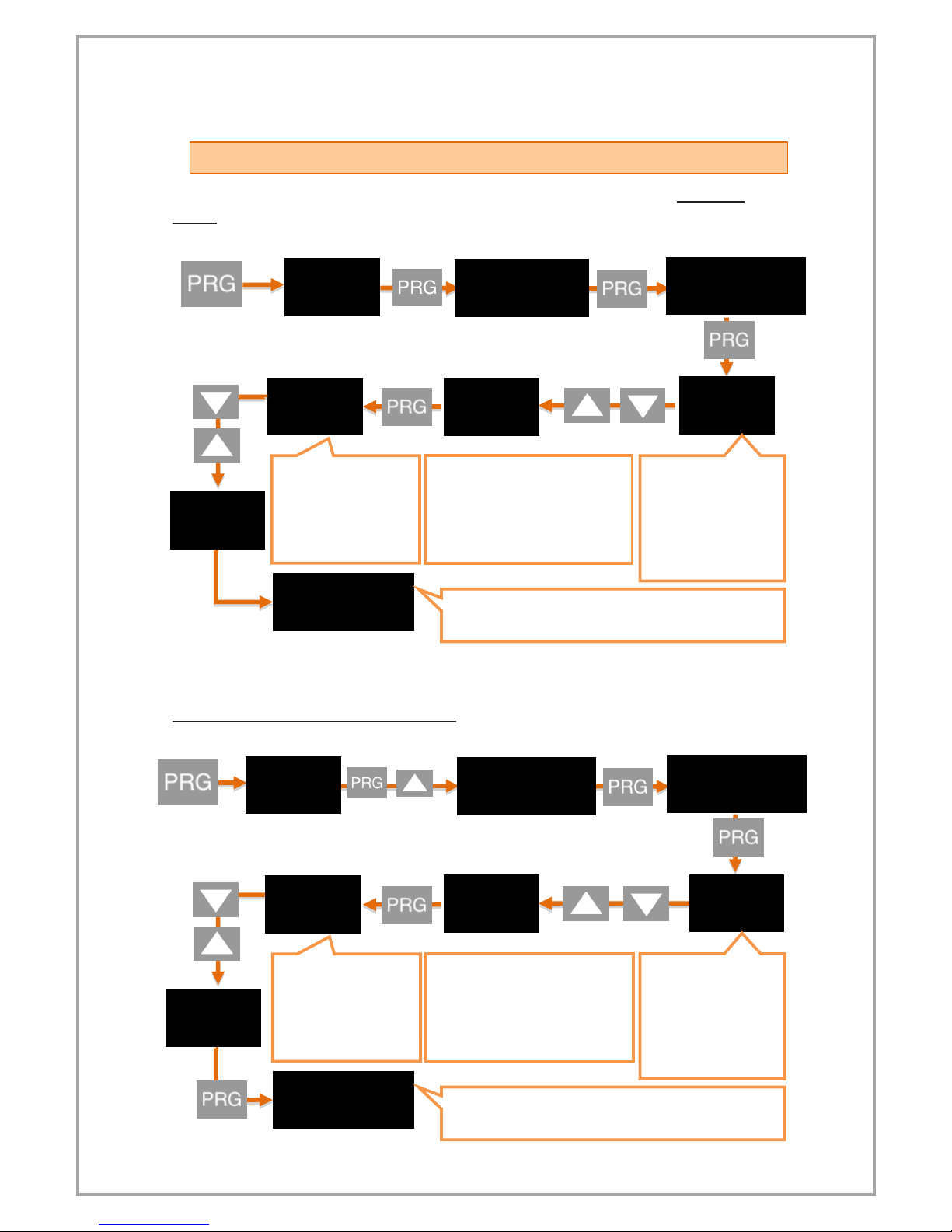

4.2 DEVICE CALIBRATION

Your device is calibrated automatically according to factory settings and operates in

the 0-100 value range. That is, the smallest reading on the sensor shows 0 on the

screen and 100 on the screen. You can change this scale from the calibration menu.

Use S-LO for the minimum value that will be shown on the screen, S-HI for the

maximum value.

+

(Keep it pressed)

.

.

The decimal point

starts flashing. Use

the UP and DOWN

keys to select the

decimal point.

Press and hold the UP and DOWN

keys to move to the next step. To

enter a negative (-) value, press

the DOWN key to come to one of

the non-digitized steps.

When PRG key is

pressed and entered,

the value input screen

opens. Enter the

desired value using

the UP and DOWN

keys.

.

.

The new S-LO value you confirmed with the PRG key has been

set. Press UP to move to S-HI.

8

After specifying the S-LO value, you can do the same for the S-HI value.

4.3 ENTER RELAY SET VALUE

Set the SET values for the relay outputs of your device to be activated. For SET-1

value:

2. Set the SET-2 value for Relay output:

(Keep it pressed)

.

The decimal point

starts flashing. Use the

UP and DOWN keys to

select the decimal

point.

Press and hold the UP and DOWN

keys to move to the next step. To

enter a negative (-) value, press

the DOWN key to come to one of

the non-digitized steps.

When PRG key is

pressed and entered,

the value input screen

opens. Enter the

desired value using

the UP and DOWN

keys.

.

The new S-LO value you confirmed with the PRG key has

been set. Press UP to move to S-HI.

.

(Keep it pressed)

.

When PRG key is

pressed and entered,

the value input screen

opens. Enter the

desired value using

the UP and DOWN

keys.

.

The new S-LO value you confirmed with the PRG key has

been set. Press UP to move to S-HI.

.

The decimal point

starts flashing. Use the

UP and DOWN keys to

select the decimal

point.

Press and hold the UP and DOWN

keys to move to the next step. To

enter a negative (-) value, press

the DOWN key to come to one of

the non-digitized steps.

9

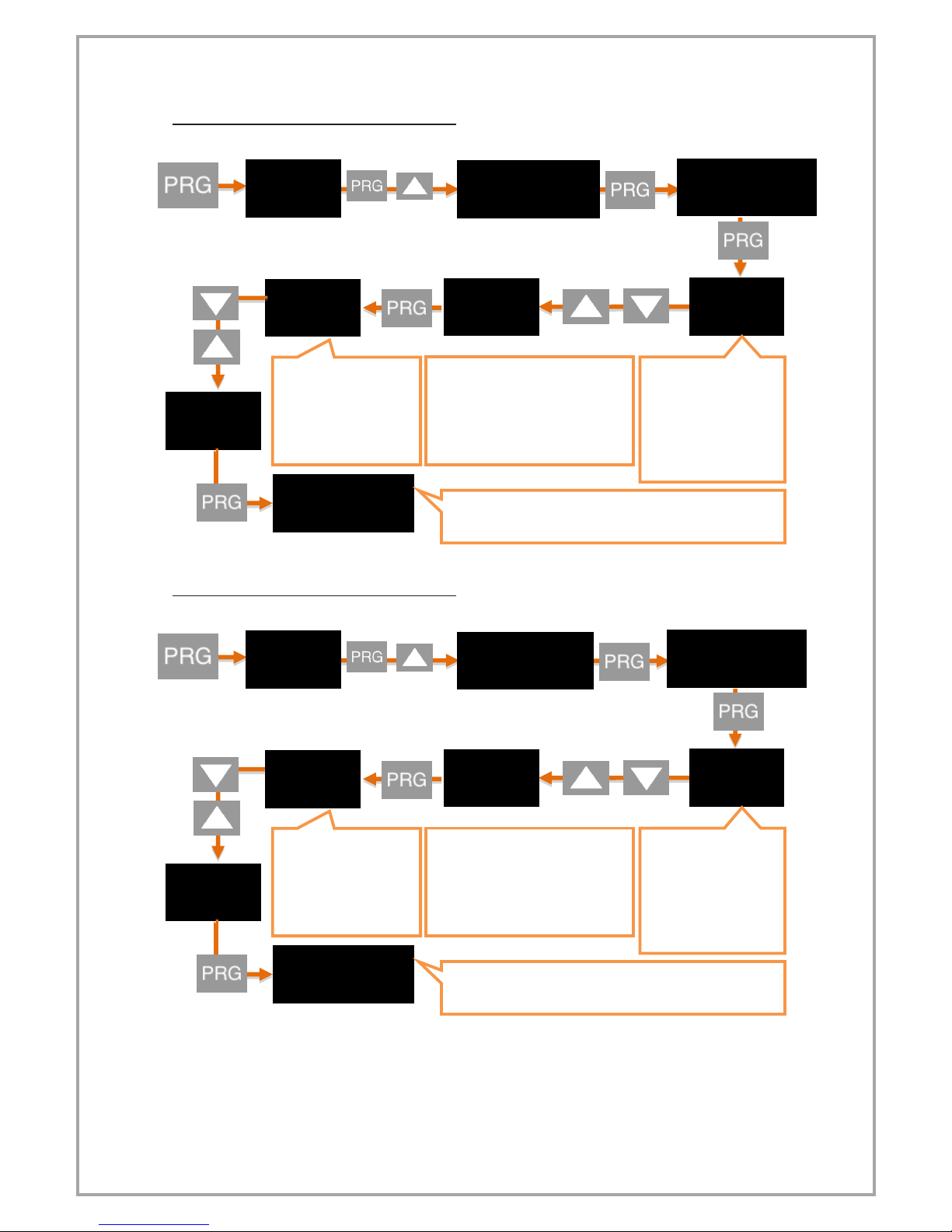

3. Set the SET-3 value for Relay output:

4. Set the SET-4 value for Relay output:

(Keep it pressed)

.

The decimal point

starts flashing. Use the

UP and DOWN keys to

select the decimal

point.

Press and hold the UP and DOWN

keys to move to the next step. To

enter a negative (-) value, press

the DOWN key to come to one of

the non-digitized steps.

When PRG key is

pressed and entered,

the value input screen

opens. Enter the

desired value using

the UP and DOWN

keys.

.

The new S-LO value you confirmed with the PRG key has

been set. Press UP to move to S-HI.

.

(Keep it pressed)

.

The decimal point

starts flashing. Use the

UP and DOWN keys to

select the decimal

point.

Press and hold the UP and DOWN

keys to move to the next step. To

enter a negative (-) value, press

the DOWN key to come to one of

the non-digitized steps.

When PRG key is

pressed and entered,

the value input screen

opens. Enter the

desired value using

the UP and DOWN

keys.

.

The new S-LO value you confirmed with the PRG key has

been set. Press UP to move to S-HI.

10

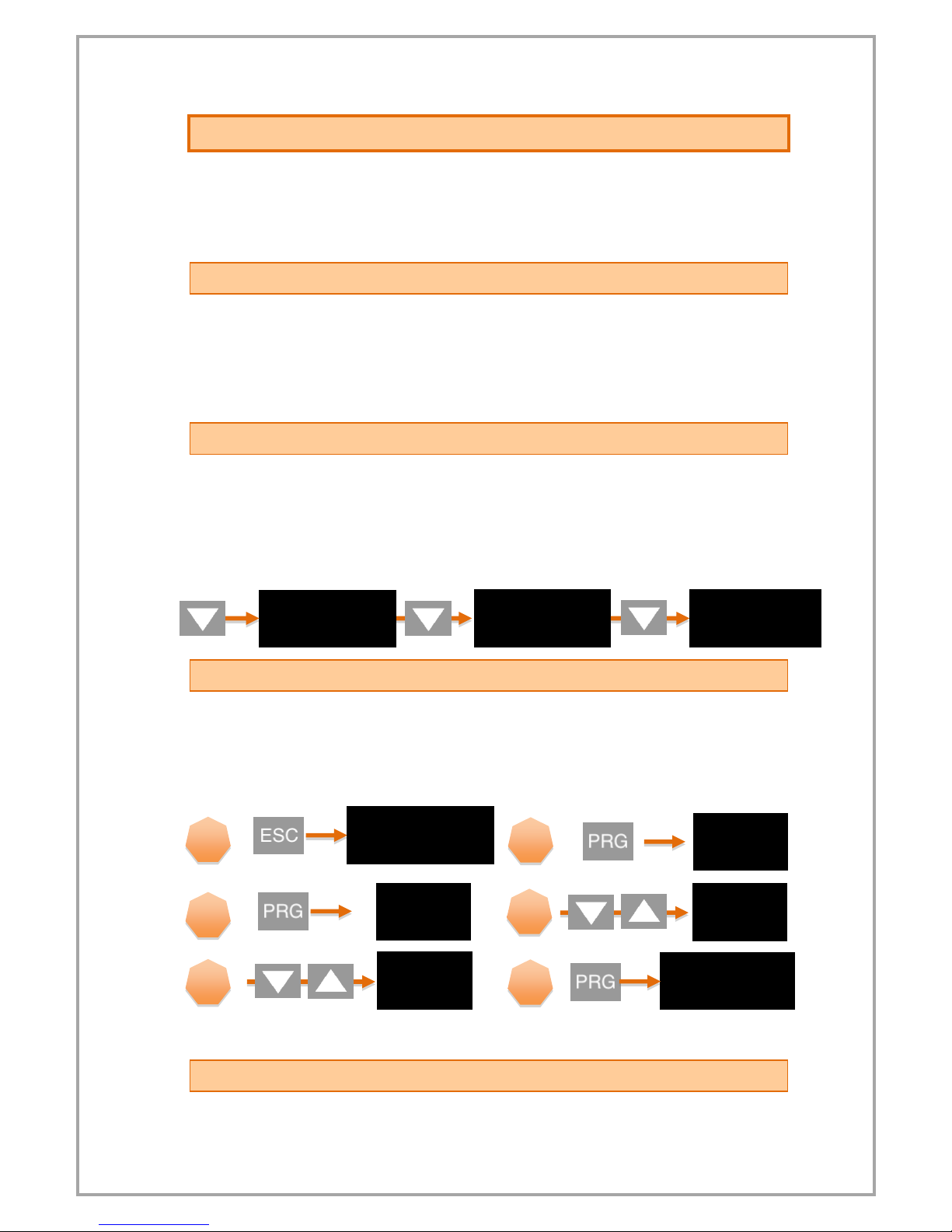

5. OPERATING MODE: FUNCTIONS

Your EPA300 process controller operates in two different modes. Your device is in

'operating mode' while the initial value of the sensor readout is displayed; In the

'programming mode' on the screen where the settings are changed and the parameters are

changed. In this section, the functions in operating mode are explained.

5.1 Tare Function

***Only works when the Tare function is active. For activating or explaining the types of functions,

6.3.2 Setting the Tare Function

Each time the UP key is pressed while the unit is in the operating mode, the Tare function is

activated according to the type of the selected function and the Tare status lights up.

5.2 Viewing the Maximum and Minimum Reading Values

If you press the DOWN key while the unit is in operating mode, you can see the lowest

(minimum) value read from the moment the unit starts to operate. At the same time, Min

status will flash on the screen.

When you press the DOWN key again, you can see the highest (maximum) value read from

the moment the device starts to operate. At the same time Max will be on the screen.

5.3 Changing Quick Set Values

Press and hold the ESC key to quickly change all adjustable setpoints while the unit is

in run mode. You can then change the desired SET value by pressing the PRG key. When

entering a value, press and hold the UP and DOWN keys to move to the next step. To enter a

negative (-) value, press the DOWN key to come to one of the non-digitized steps.

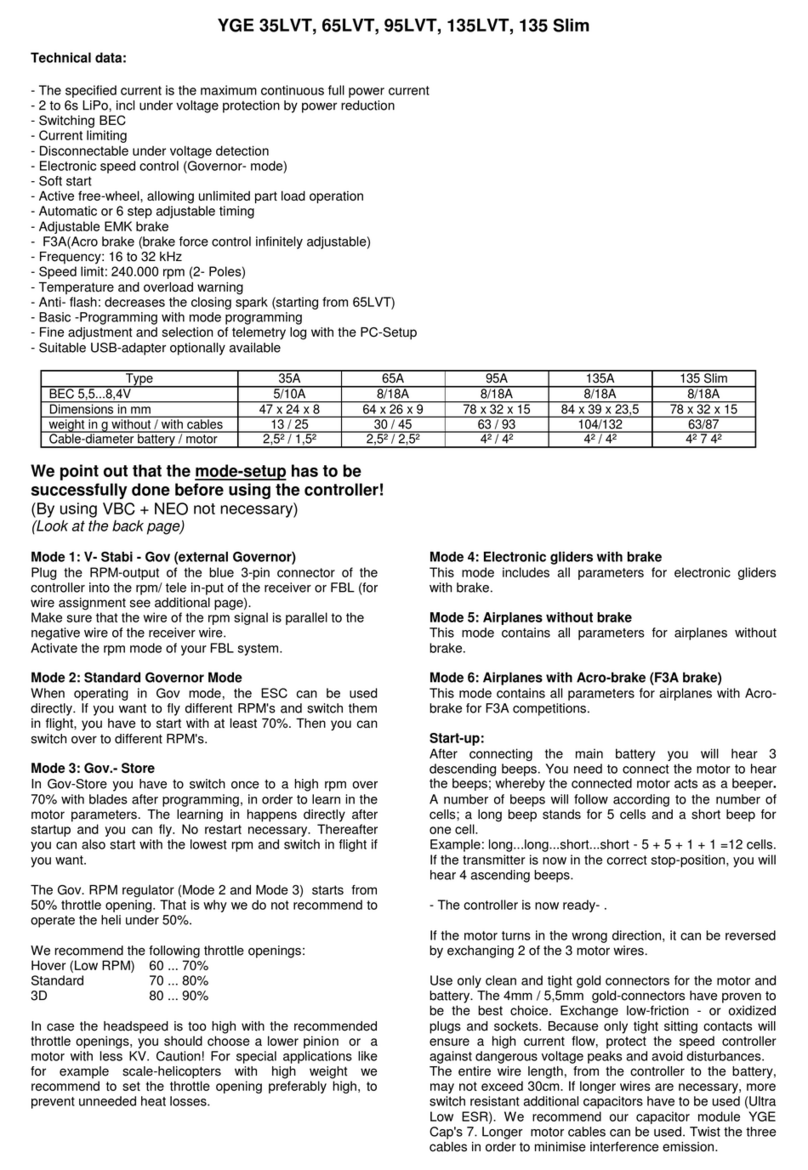

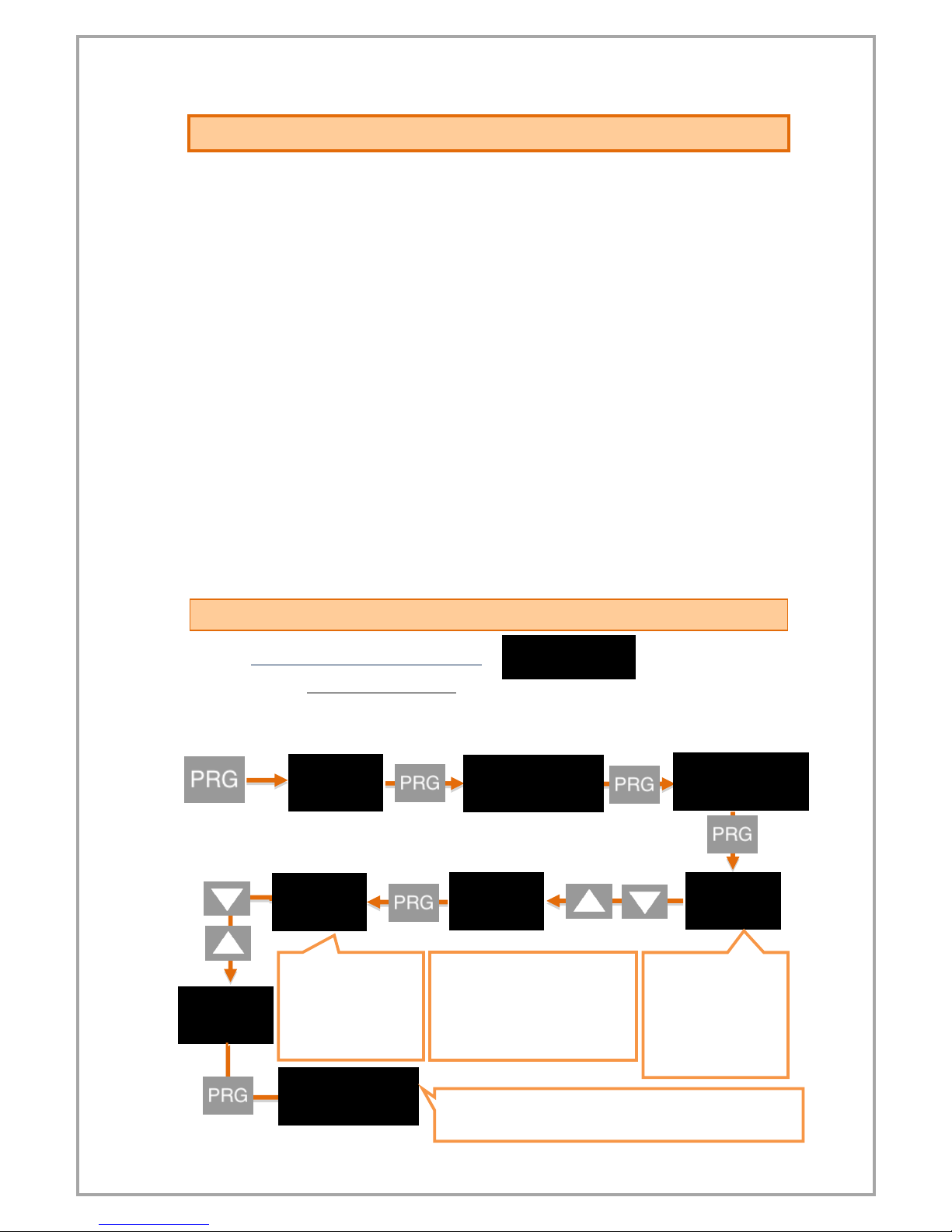

5.4 Transition to Programming Mode

To switch your device from working mode to programming mode

.

.

.

(Keep it pressed)

1

2

3

.

.

4

5

6

11

Press and hold PRG until OUT appears in the display. To return to the operating mode, press

the ESC key repeatedly until you return to the operating mode.

12

6. PROGRAMMING MODE: PROGRAMMING DIVICE

Your EPA300 process controller operates in two different modes. Your device is in

'operating mode' while the initial value of the sensor readout is displayed; In the

'programming mode' on the screen where the settings are changed and the parameters are

changed. In this section, the functions in Programming Mode are explained.

To switch your device from working mode to programming mode Press and hold

PRG until OUT appears in the display. To return to the operating mode, press the ESC key

repeatedly until you return to the operating mode. While your device is in Programming

Mode;

-To scroll between menus, press the DOWN and UP keys

-Press enter (PRG) to enter any menu.

-Use the ESC key to exit from any menu and return to the upper menu.

-When entering any parameter value, press the DOWN key to dicrease, press the UP

to increase the value. Press and hold the keys to move to the next or previous digit.

The EPA300 consists of 4 main menu items: Output, Secure, Display and Calibration.

6.1 Output Menu [OUT]

6.1.1 1. Relay Output Setting (OUT-1)

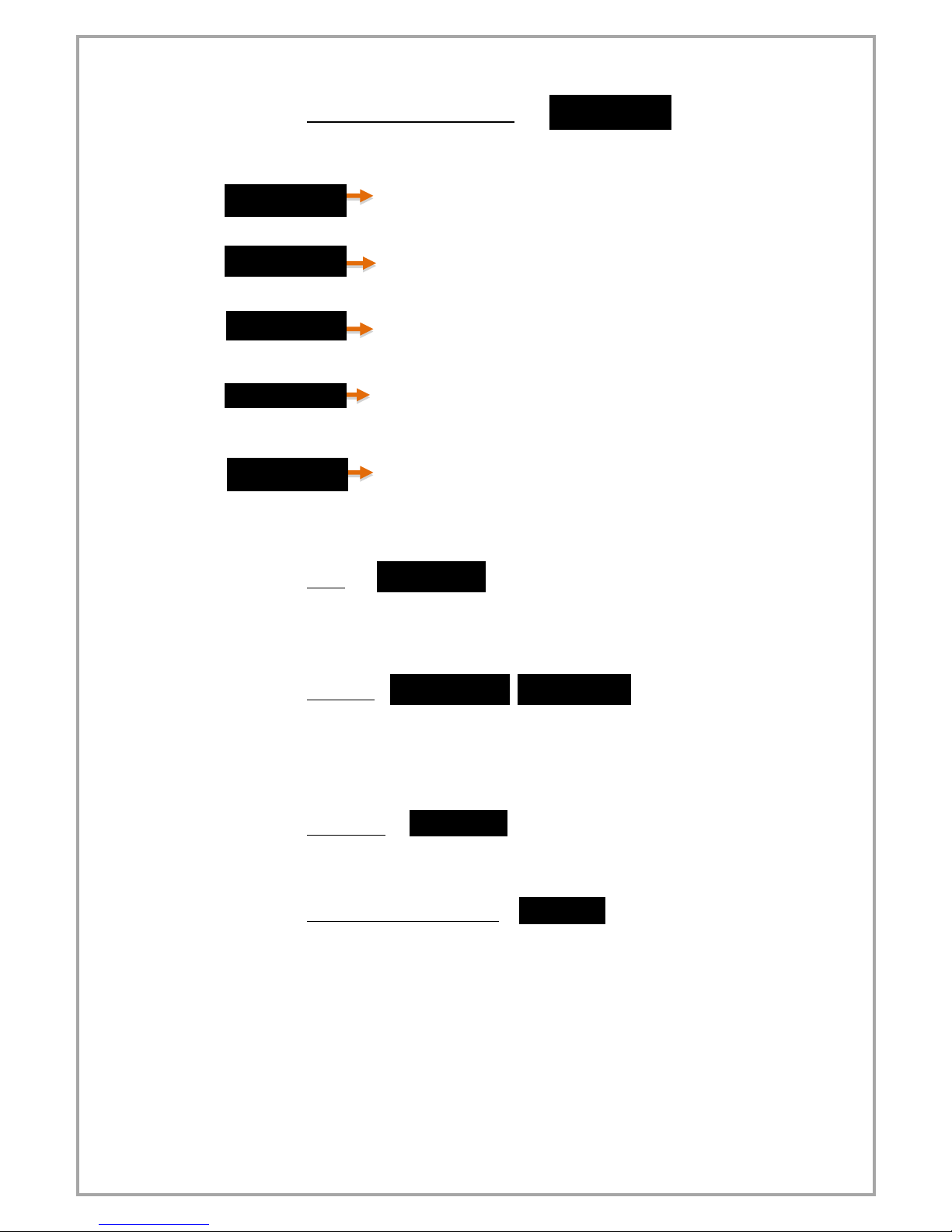

6.1.1.1 Entering the Set Value

The first relay output activates and sets the value of the lit LED of the status SET1.

(Keep it pressed)

The decimal point

starts flashing. Use

the UP and DOWN

keys to select the

decimal point.

.

Press and hold the UP and DOWN

keys to move to the next step. To

enter a negative (-) value, press

the DOWN key to come to one of

the non-digitized steps.

When PRG key is

pressed and entered,

the value input screen

opens. Enter the

desired value using

the UP and DOWN

keys.

.

The new S-LO value you confirmed with the PRG key has been

set. Press UP to move to S-HI.

13

6.1.1.2 Relay Output Funtion Selection

This function selection determines when the relay output will be activated and

deactivated according to the set values.

6.1.1.3 Delay

It specifies in seconds how long the relay output will remain active after it is

activated. If '0' is entered as a zero value, the relay output will remain active until it

changes conditionally.

6.1.1.4 Hysteresis

Due to the unstability in decimal value read on the connected sensor, you can enter

the hysteresis value to prevent the relay from being turned on and off at any time,

so that the set value you set for the relay will be activated and deactivated as low as

Hysdn and above Hysup.

6.1.1.5 Offset value

If you want to add offset to the entered set value, this menu is used. If all set values

are selected forward or negative by the specified offset value, they are shifted back.

6.1.1.6 The default state of the relay

Depending on the factory settings of your device, the relay is normally closed and

activated with the specified setpoint and functions. Use the Cond option on the Out-

1 menu to activate the default in the default position and turn off with the specified

setpoint and functions. The factory setting NC (NormallyClosed) is the option that

the relay is normally closed, NO. (Normally Open) indicates that the relay is normally

open.

.

.

The relay is activated when the value read in the device

increases by increasing Set-1 value.

The relay is activated when the read value in the device is

between Set-1 and Set-2.

The value read in the device is activated whenever the

set-1 value increases or decreases.

The value read in the device activates the relay whenever

the Set-1 or Set-2 value increases or decreases.

The value read in the device is activated when the value

of Set-1 or the value of Set-1 is increased or decreased by

every level such as 2,3,4,5 ....

14

6.1.2 2., 3., 4. Relay Output Settings (OUT-2-3-4)

In this menu you can set the relay outputs 2, 3 and 4 of your EPA300. Complete

settings 5.1.1. The 1 st relay output described in chapter is the same as the OUT-1

settings.

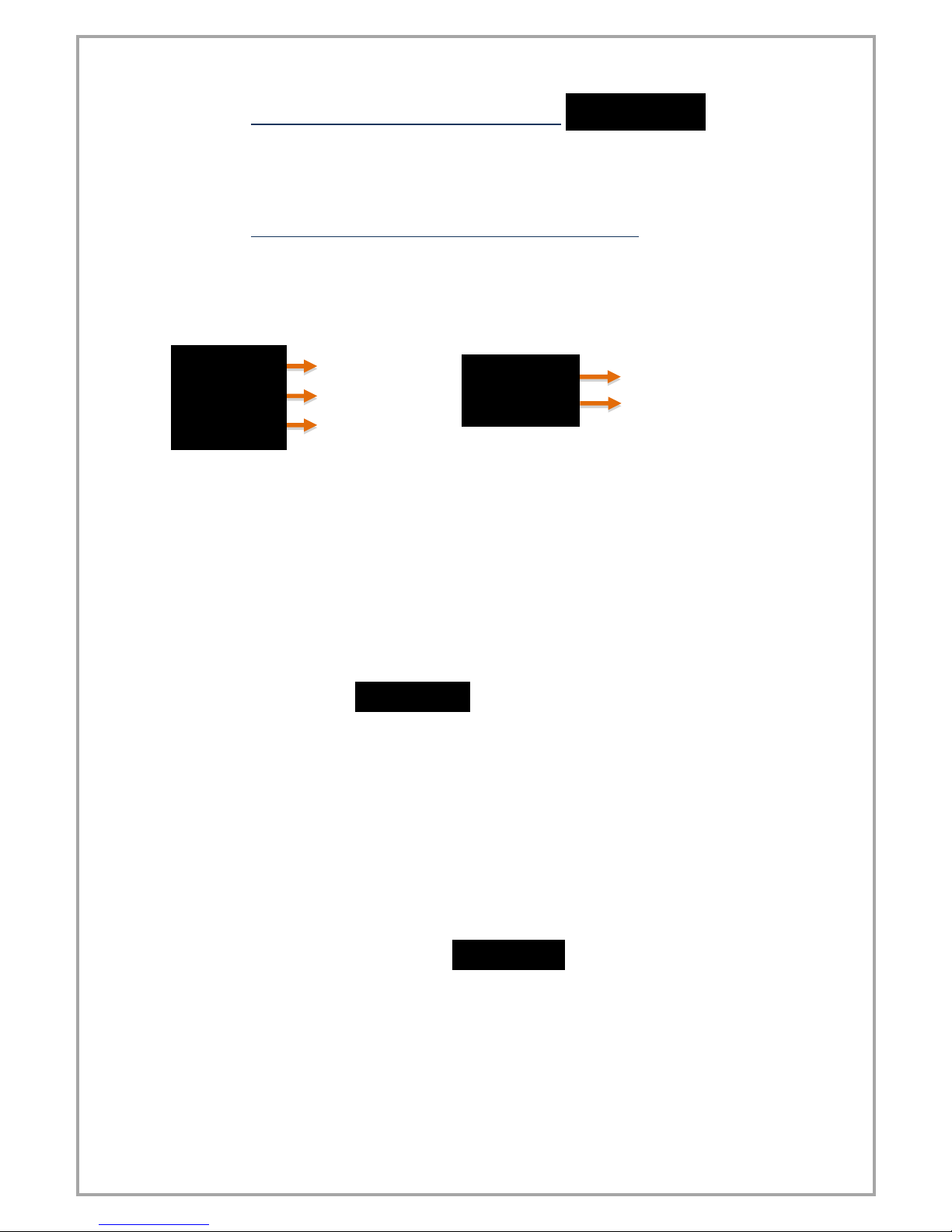

6.1.3 Current and Voltage Analog Output Settings (ANLOG)

If your EPA300, which is manufactured specifically for your order, has an analog

output module, you can make the necessary settings from this menu.

Select the analogue output from the TYPE menu:

From the COND menu, select whether the analogue output module is active or not.

Use ON to activate or OFF to activate.

From InvrS menu, you can choose which value to increase or decrease according to

the sensor reading on the analogue output. This option, which is OFF by default,

provides an analog output that increases or decreases in proportion to the value

read at the sensor. If you turn this ON, the value read out at the sensor will increase

while the value at the analog output will decrease, ie an inversely proportional

output will be provided.

Wave Form (VAVE.F.)

The waveform of the output signal can be selected from the Vave.f menu. There are

4 options in the menu: Liner, Sin, Cos, Trian. When the liner option is confirmed with

the PRG key, a linearly increasing waveform is obtained in the specified scale range.

When the Cos option is confirmed with the PRG key, a waveform in the form of a

waveform that starts from zero and completes a complete cosine wave is obtained

at the scale interval specified. When the Sin option is confirmed, a waveform in the

form of a waveform that starts at the peak value of the sine wave and completes a

complete sinusoidal wave in the determined scale range is obtained. When the

triangle option is selected in the same way, a triangle wave is obtained in the scale

interval determined at the exact middle value corresponding to the top.

Analog Output Scale Setting (Scale)

In the device with the analogue output feature, SCALE mode in this menu must be

ON to set the output signal to the desired scale range. S-LO started appearing on the

analogue menu afterwards. And S-HI. Options and scale values can be entered.

0.5 - 4.5 Volt

0 –20 mA

0 - 10 Volt

4 - 20 mA

0 - 5 Volt

.

.

.

.

.

15

6.1.4 UART and CANopen Digital Output Settings (DGTAL)

WARNING: After changing the UART or CANopen settings, you need to restart the

device for the changes to take effect.

If your device has a USB port, use MyPanelMeter, which you can download from our

website to check your device. Check the user manual of the program.

6.1.4.1. UART Settings

If you are communicating with your device via RS-485 or RS-232; You can make the

necessary settings here. You can select the communication protocol, baudrate,

parity, address and period information. For the MODBUS Protocol address

information, see the relevant booklet.

6.1.4.2. CANopen Ayarları

Here you can configure the baud rate, Node ID, Heartbeat, PDO etc. of your device

related to the CANopen protocol.

For more information on CANopen, see the EPA300-CANopen booklet.

6.1.5 Keypad Setting (SOUND)

When you press any key on your device, you can turn the beep sound on and off from this

menu. Use ON to turn the sound on, OFF to turn it off.

6.2 Calibration Menu [CALIB]

6.2.1 Specifying Scale Values (SCALE)

When your device is calibrated to its factory settings, it operates at a value range

of 0-100. That is, the smallest reading on the sensor shows 0 on the screen and 100

on the screen. You can change this scale from this menu.

Use the S-LO for the minimum value of the scale, and the S-HI menus for the

maximum value. To change the value, press the PRG key. After specifying the value

with the UP and DOWN keys, press the PRG key again to locate the decimal point.

Then press the PRG key to confirm the value.

You can use the Fctor menu to expand this scale by multiplying it by a fixed

factor. The number of this factor, which is the default value of 1, is multiplied by the

values of S-LO and S-HI to determine the scale value.

For example; When you set the S-LO value to 1, the S-HI value to 20 and make

the factor 4, your device will run in the 4-80 value range.

WARNING: Changing the scale value does not change the calibration of your

device, it only indicates the displayed value range on the screen. For the calibration

of the instrument, 6.2.2.

16

6.2.2 Manual Calibration Method Determination (CALOP)

Your device has been automatically calibrated during production. If you do not, you

can do this calibration according to the sensor. You need to select the calibration

method from this menu.

In the 2-point calibration option, only the maximum and minimum points are

selected. With the multiple calibration option, you can calibrate your device at up to

10 different points. For example; If the length of the sensor is 40 cm and you want to

calibrate at 5 different points, these points are; There must be 0 cm, 10 cm, 20 cm,

30 cm, and 40 cm points at which the sensor starts.

Select the FCAL option if you want to calibrate your device to factory calibration

again.

6.2.3 Number of Calibration (CL.CNT)

In this menu that appears when you select the segmented calibration option, you

can specify the number of points you want to calibrate the device. It's a maximum of

10.

6.2.4 Automatic Calibration (START)

From this menu 5.2.2. You can start your automatic calibration by pressing the PRG

key according to the selected calibration method in the section. During the

calibration that will start according to your chosen meta; You can see the calibration

point to be determined on the first line by the ignored segment number and on the

second line the unprocessed value read on the sensor. You can scroll through the

segments, ie the calibration points, with the UP and DOWN keys. You can confirm

the segment you want to specify with the PRG key while the sensor is in position for

calibration. DONE will appear on the screen for a very short period of time.

6.3 Display Menu [DISP]

6.3.1 Choice of decimal point location (POINT)

In the value that appears on the display in run mode, you can set the position of the

decimal point in this menu. This value, which is '2' in the factory settings, indicates

how many decimal places to display after a call. If you select '0', only the whole

number appears on the screen.

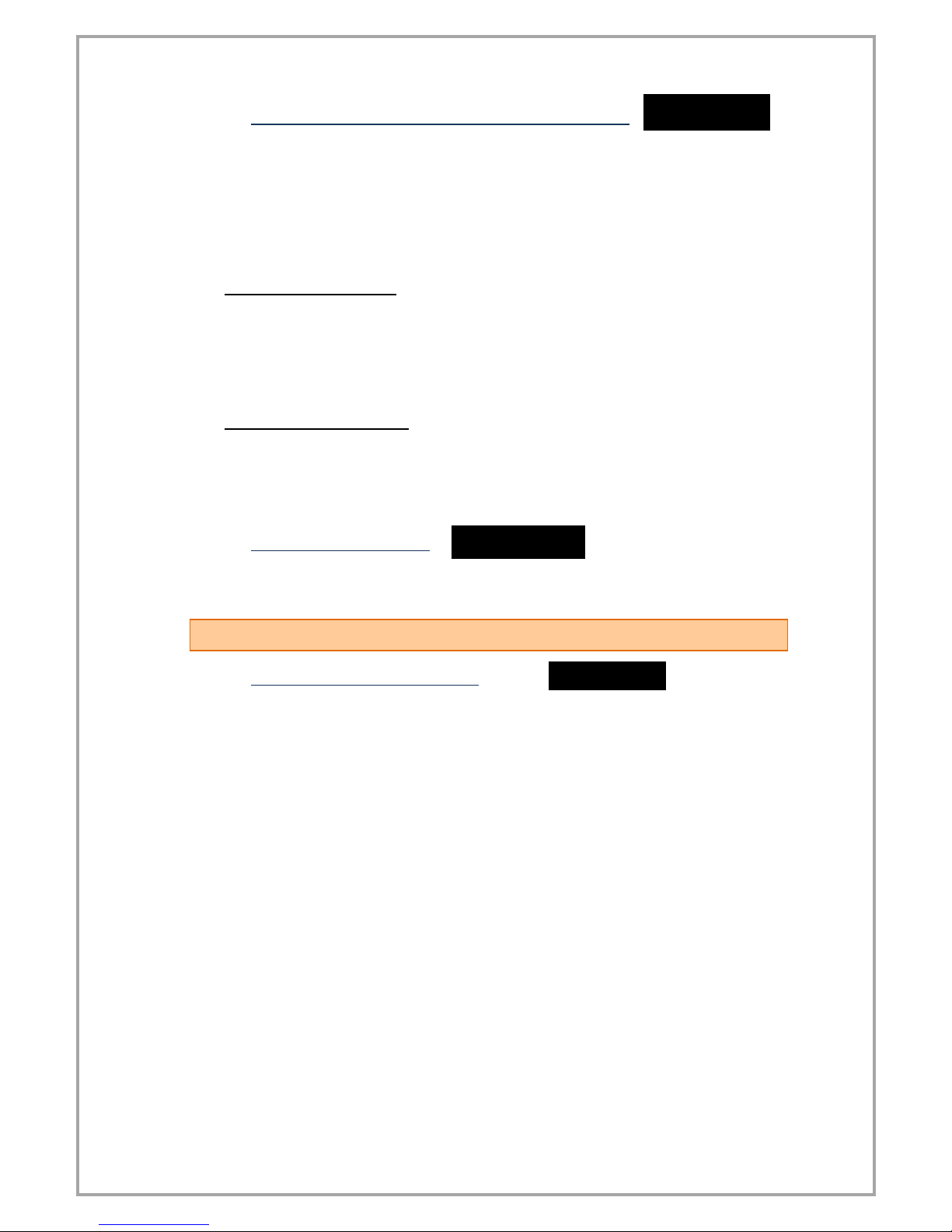

6.3.2 Tare Functain Settings (TARE)

In this menu you can define the Tare Function and its properties.

From the EVENT menu you can select the Tare Function type:

.

.

Factory calibration (Default)

2 point calibration

Segmented calibration

.

.

.

17

When the unit is in operation mode, each time the UP key is pressed;

In the PrSet option, you can specify the value to be equalized when the Tare key is

pressed.

If your EPA300, which is specially manufactured according to your order, has the

Digital Tare Input module, you can make settings from the INPUT menu under the

Tare menu.

The EDGE option determines which edge of the edge signal coming from the Tare

function is activated. RISE for rising edge, FALL for falling edge. For example; When

you connect this signal to a button, the RISE option activates the tare when the

button is pressed and the FALL option when the button is released after the button

is pressed.

In the FILTR option, you can specify how many milliseconds the modulated signal is

to be controlled. By default, this value is 100 ms.

6.3.3 Screen Refresh Rate (REFRS)

Indicates how many milliseconds the value displayed on the screen will be refreshed.

By default this value is 100 ms; To reduce or reduce the on-screen vibrations, or

reduce the duration of your device's response to movement of the sensor.

ZERO: Then the value read on the sensor is equal to zero and the

Tare state LED is lit.

PRESET: Then, the value read on the sensor is equalized to the

specified value and the Tare status LED is lit.

REPEATED ZERO: The first time it is pressed, the value read on the

sensor is equal to zero and the Tare status LED is lit. When it is

pressed later, the read value returns to the state before the key is

activated and the Tare status LED is turned off.

REPEATED PRESET: When pressed for the first time, the value read

on the sensor is equal to zero and the Tare status LED is lit. When

it is pressed later, the read value returns to the state before the

key is activated and the Tare status LED is turned off.

.

.

18

6.3.4 Blocking the on Screen Volatility (FILTR)

Your EPA300 is programmed to display the signals received from its connected

sensor in the most accurate way on the screen by processing them with special

algorithms. But; You can solve this problem by filtering from this menu in the event

of a trembling of the value displayed on the screen due to various reasons such as

noise in the vicinity, disturbances in the sensor. There are three different filtering

methods for this:

1. AVRGE (Average Calculation):

When you activate this filter by turning the STATE option ON, your device will

refresh the value that appears on the display after you have read as many values

from the sensor as you would select COUNT. For example; COUNT will default to

500, and your device will refresh the value on the screen after you have taken 500

samples from the sensor, that is, after reading it, taking the average of these values.

Accordingly, increasing COUNT will reduce flicker on the screen; But your device will

slow the response of the sensor to its rapid movement.

2. LQE(Lineer Quadratic Estimation):

You can also activate this filter, also known as a thick filter, by turning the STATE

option ON. If you decrease the default COVARIANCE of 500, the flicker on the screen

will decrease; But your device will slow down the reaction of the sensor to its rapid

movement.

3. HYS (hysteresis):

You can activate the hysteresis filter by turning the STATE option ON. With this filter,

which has two parameters named Delta and A.Error, the value read from the sensor

is not reflected on the screen until it changes to Delta. When the sum of the non-

reflected values on the screen is equal to A.Error, the display is updated with the

average of these values.

6.4 Secure Menu [SECUR]

6.4.1 Hide Menu (HIDE)

You can hide the menus ON you do not want the operator to see your device to use

them.

All menus except Secure are hidden.

The Output menu is hidden.

The Calib menu is hidden.

The Display menu is hidden.

The Quick Set change menu is hidden. See. 5.3.

.

.

.

.

.

19

6.4.2 Menu Lock (LOCK)

If you have not set a password before, you will see NPASS in the display when you

enter this menu. Press the PRG key to set the desired password here. Then use the

DOWN and UP keys to select the menus you want to lock. Definitions of Menüler

5.4.1. It is the same as in the Menu Hiding section.

6.4.3 Set Password (PASS)

Use this menu item to set a password or to change the password you have

previously set. If no password was previously set; When you enter this menu, the

display will show NPASS. Press the PRG key to set the desired password here. If the

password has already been set; The display shows PASS? Will appear and you will be

asked to enter this password. After inputting the password, the display will show

NPASS. You can specify your new password here and confirm it with the PRG key.

6.4.4 Return to Factory Setting (FTRY)

You can return your EPA300 to factory settings from the time box you desire. Press

the PRG key to return to the factory settings. Here you are going to face the PASS?

You need to enter 12345, which is the factory password, not the user password you

specified on the password screen.

6.4.5 Restart the Device (RESET)

In any case, press the PRG key to come back to this menu to restart your device. The

device will automatically power off and on and start working.

NOTE: The EPA 300 can be used with the instrument panel only, without the need

for relay outputs.

.

20

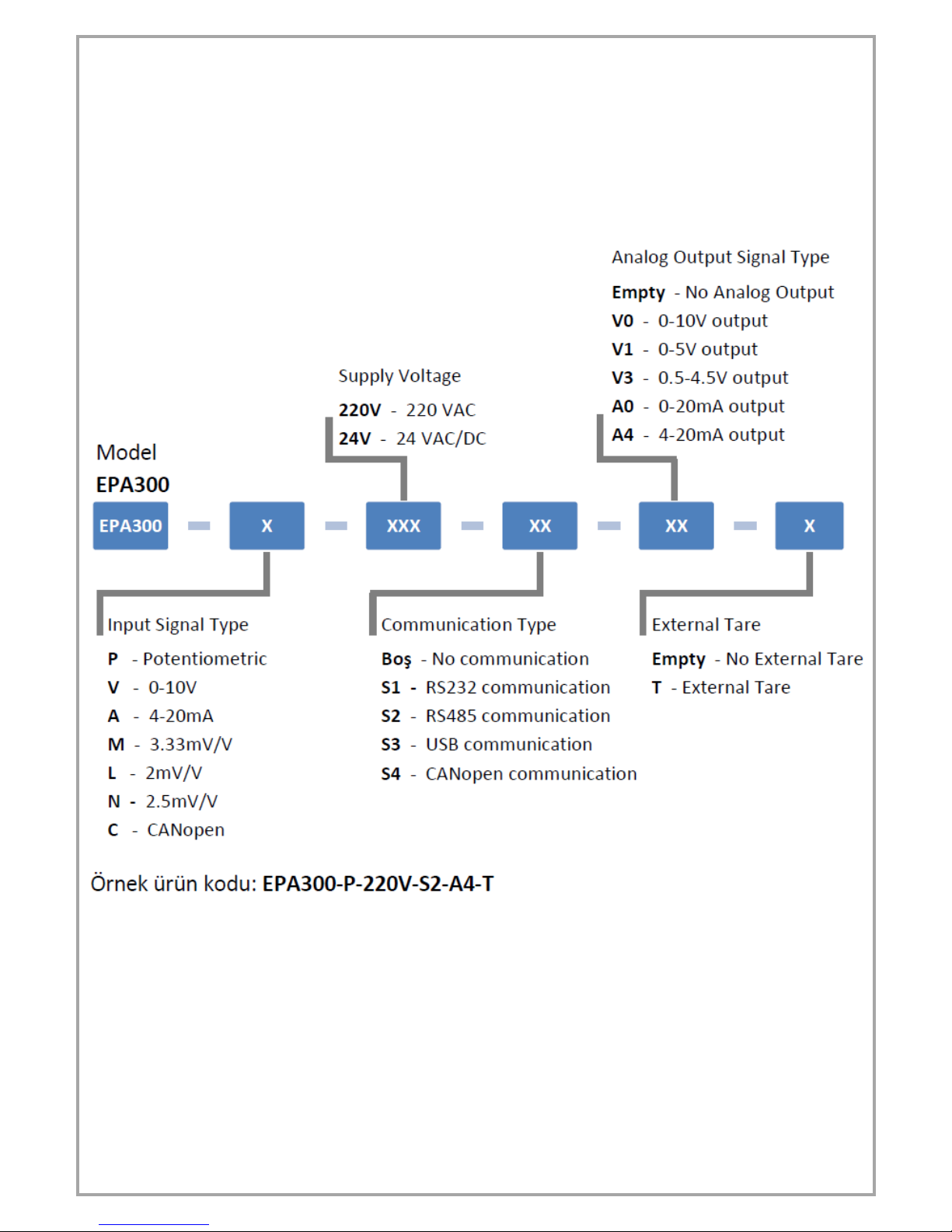

Order Coding:

When ordering your EPA 300 process controller, you can use the following coding format.

Other manuals for EPA300

1

Table of contents

Other Eskon Controllers manuals