9

Instruction manual

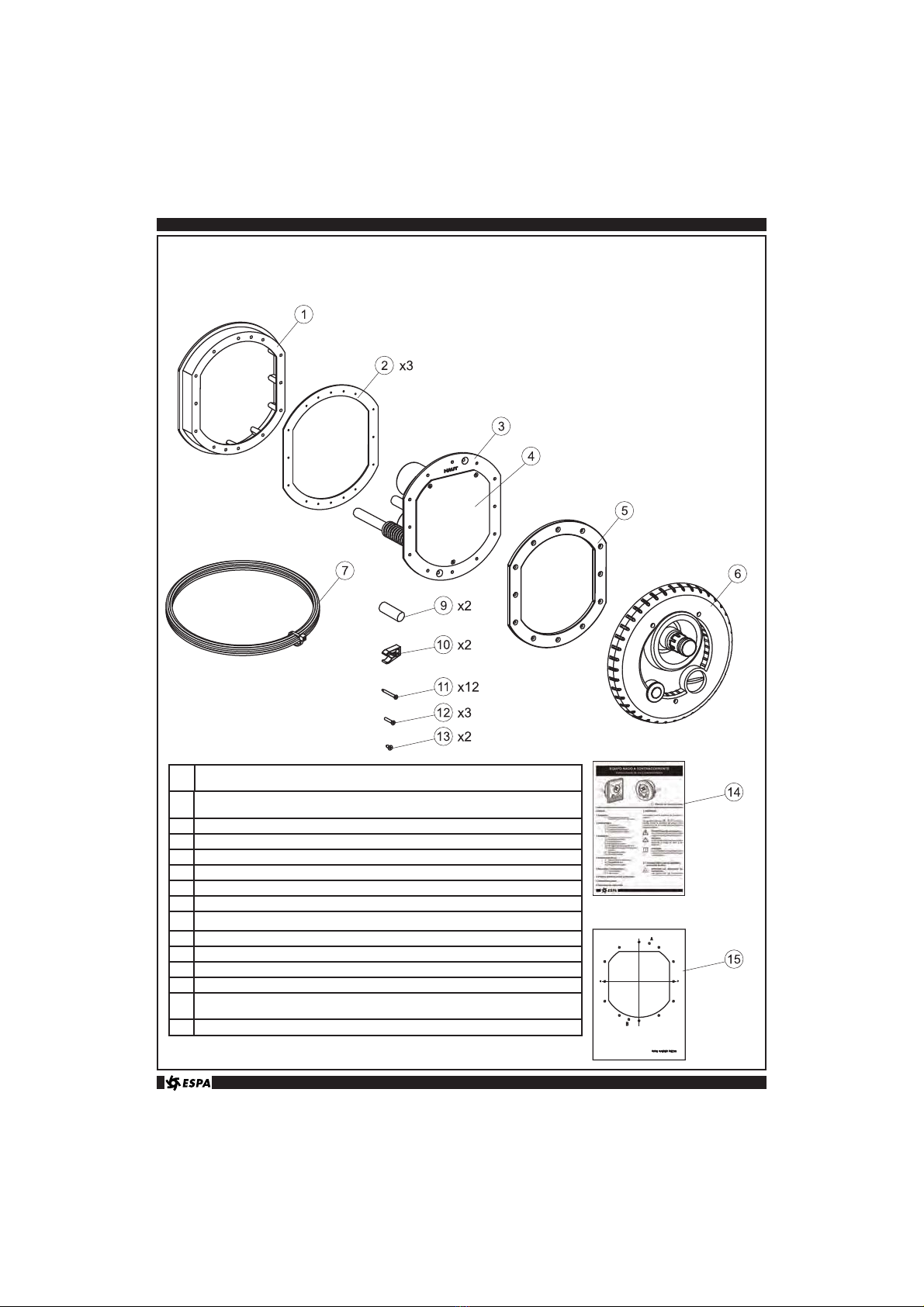

Masonry swimming pools.3.3.

Preparatory work.a)

Place the section to be embedded (16) with its

protective plate (17) fixed in the metal mesh which

acts as a framework for the concrete.

Put it in position, bearing in mind that there must

be a distance of approximately 400 mm between

the centre of the section to be embedded and the

maximum height of the swimming-pool.

Position the surfaces of the part in a perpendicular

manner at the base of the swimming-pool.

The surface of the section to be embedded (16),

indicated by the letter S in (Fig. J), must be

aligned with the surface of the concrete once it

has been sprayed, so that the front plate (6) is

well placed once the ceramic wall-tiles have been

fixed in place. (Fig. J)

Once the concrete has been sprayed, remove the

protecting plate (17) and clean the surface of the

embedded section (16).

Attach the foam gasket (2) to the embedded

section (16).

Introduce the front section (3) into the embedded

section (16) and join together with screws (18)

(Fig. K)

Ensure that the rear body (3) is in correct position.

The word “HAUT” must be at the top part. (Fig. E)

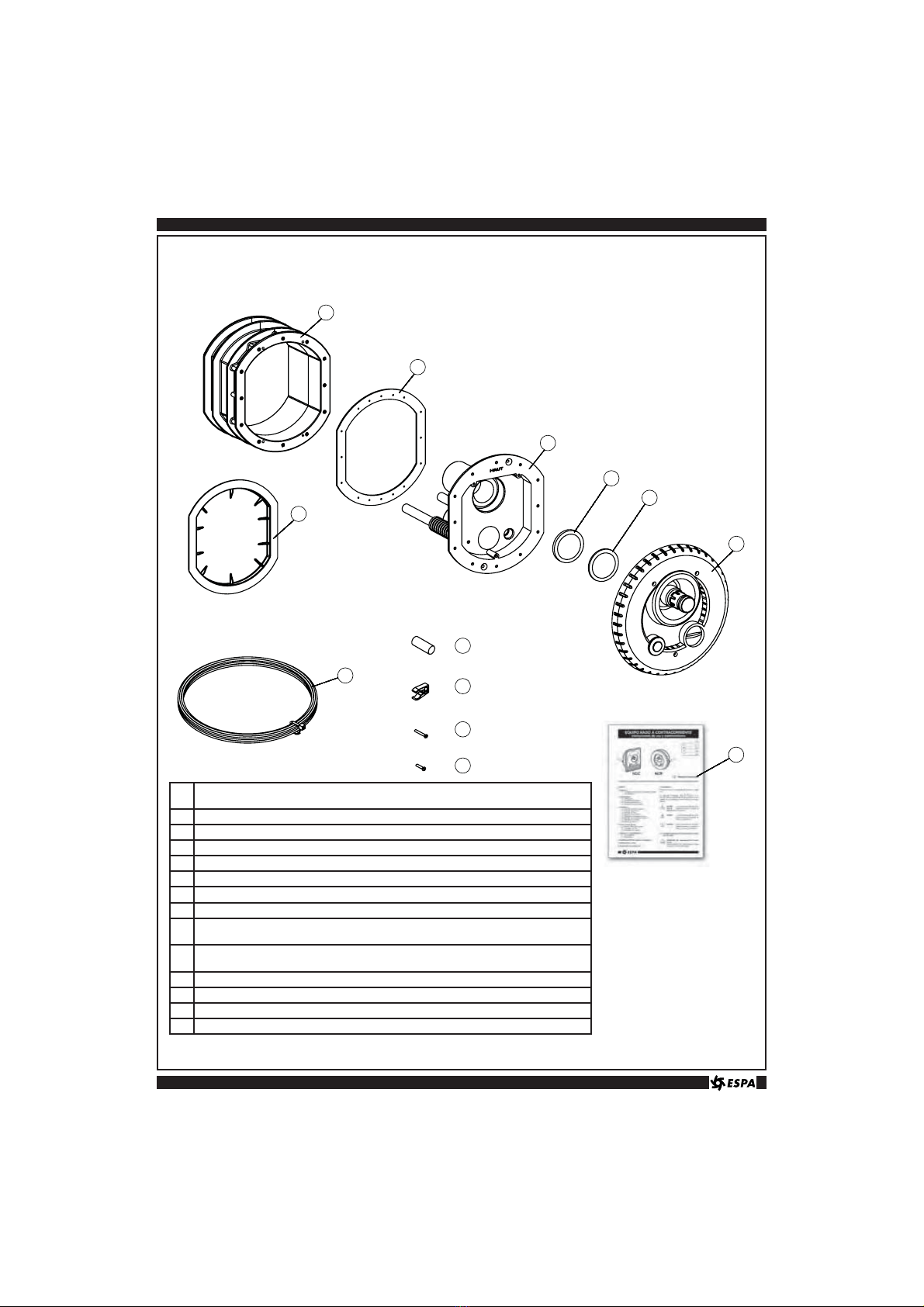

Fitting front plate.3.4.

Pass the capillary pipe (7) through the hole in the

rear body (3) until it emerges from the end of the

hose on the side of the connections to the pump.

(Fig. N)

Fit the capillary pipe (7) by pressing it into the

pressure switch and ensuring that it is securely

connected.

Offer the front plate (6) up to the rear body (3),

ensuring that the rubber gasket is in place before

fixing the unit with the 3 M5 screws (12).

For sprayed concrete swimming-pools, place

joints no.(19) and/or (20) as necessary to adjust

the jet of the front plate (6).

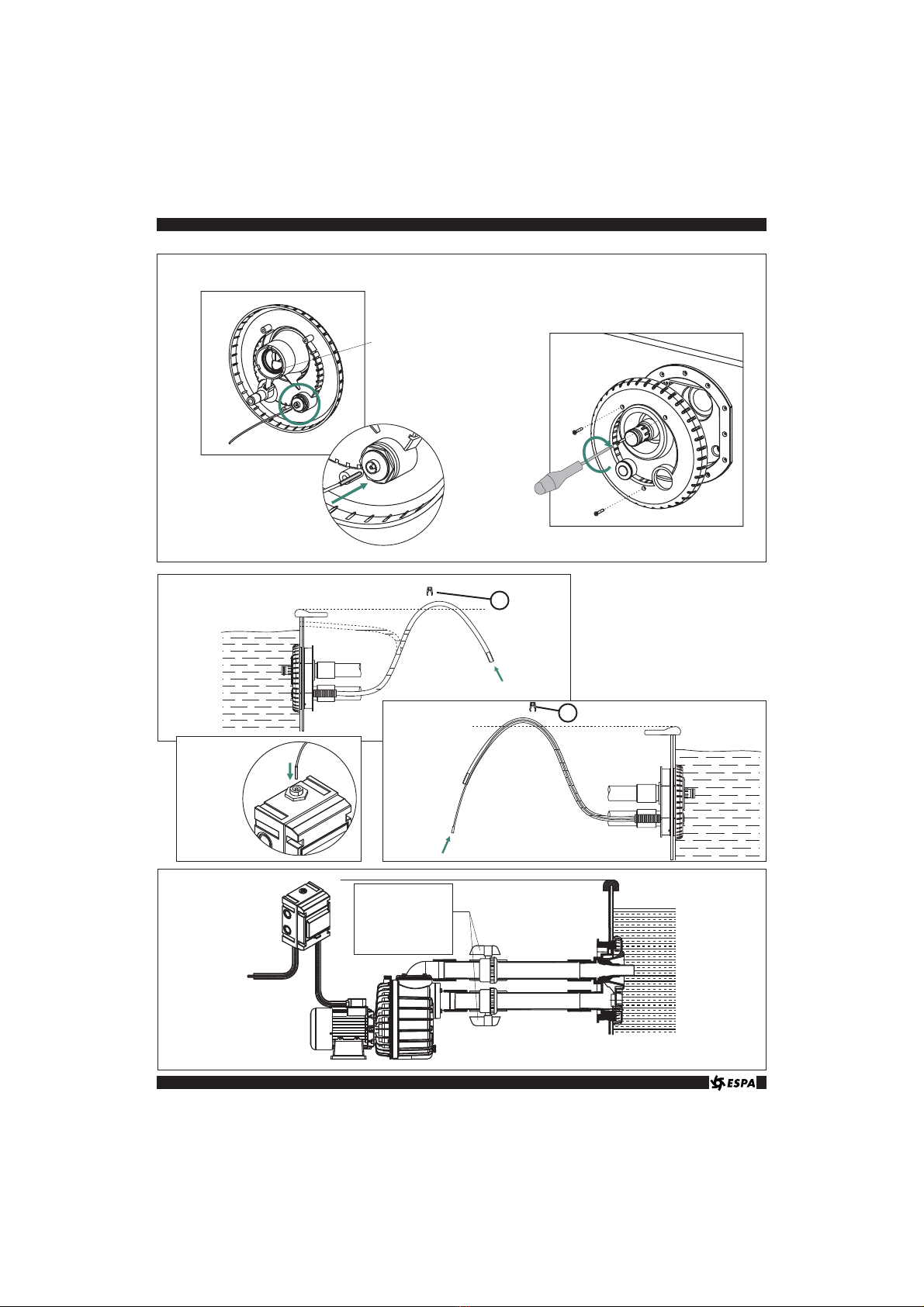

Fitting the air hose.3.5.

The hose must be attached to the wall to form an

air trap, or at a level above the maximum height

of the swimming pool, so as to avoid emptying the

pool. Alternatively, it can be attached to the wall at

a height between the waterline and the maximum

height of the pool. Use a securing staple (10) to

ensure correct fitting.

Mount the filter (9) on the end of the hose in order

to prevent dirt entering. (Fig. P)

Fitting the pressure switch.3.6.

The hose must be attached to the wall to form an

air trap, or at a level above the maximum height

of the swimming pool, so as to avoid emptying the

pool. Use a securing staple (10) to ensure correct

fitting.

Cut the hose to the right length to reach the

panel (8) and mount the filter (9) on the end of

the hose in order to prevent dirt entering.

The maximum length to ensure correct operation

of the pressure switch is 25 metres. It is advisable

to cut the capillary pipe to just the right length to

reach the panel (8), ensuring that the connecting

pipe is passed through again. (Fig. Q)

Connect the capillary pipe (7) to the pressure

switch, ensuring that it is firmly connected.

(Fig. R)

Fitting the pump.3.7.

Pump installation and assembly must be carried

out by an authorised installer.

General safety warnings.a)

The equipment must be fitted following

current safety regulations for installing

swimming pools, and particularly standard

IEC 60364-7-702 and the special regulations

for each application.

The pump must be installed on a flat surface

and attached to the floor.

To ensure the safety of persons, the pump

must be installed at least 3.5 metres from the

swimming pool.

The mains electricity supply must be protected

by an automatic power-supply cut-out device,

a residual current circuit-breaker switch (Δ fn)

not exceeding 30 mA.

Fitting the pipes.b) (Fig. S)

The connection pipes to the pump for

distances of up to 3.5 metres must have a

minimum diameter of DN63. For distances of

up to 5 metres from the swimming pool piping

of DN75 must be used, and DN90 piping for

distances of more than 5 metres.

Flow valves must be fitted in the discharge

and suction pipes, so that the pump can be

removed for maintenance without draining the

swimming pool.

Particular care must be paid to ensure that

water cannot enter the pump motor or other

electrically powered parts of the installation.