Criterion Series Benchtop User’s Manual

1

TABLE OF CONTENTS

Introduction ...................................................................................................................................................1

1. Precautions in Usage...............................................................................................................................3

1. Precautions in Usage...............................................................................................................................3

1.1. Substances Which Should Not Be Placed Inside the Equipment ....................................................3

1.2. KEEP OUT of the Chamber..............................................................................................................4

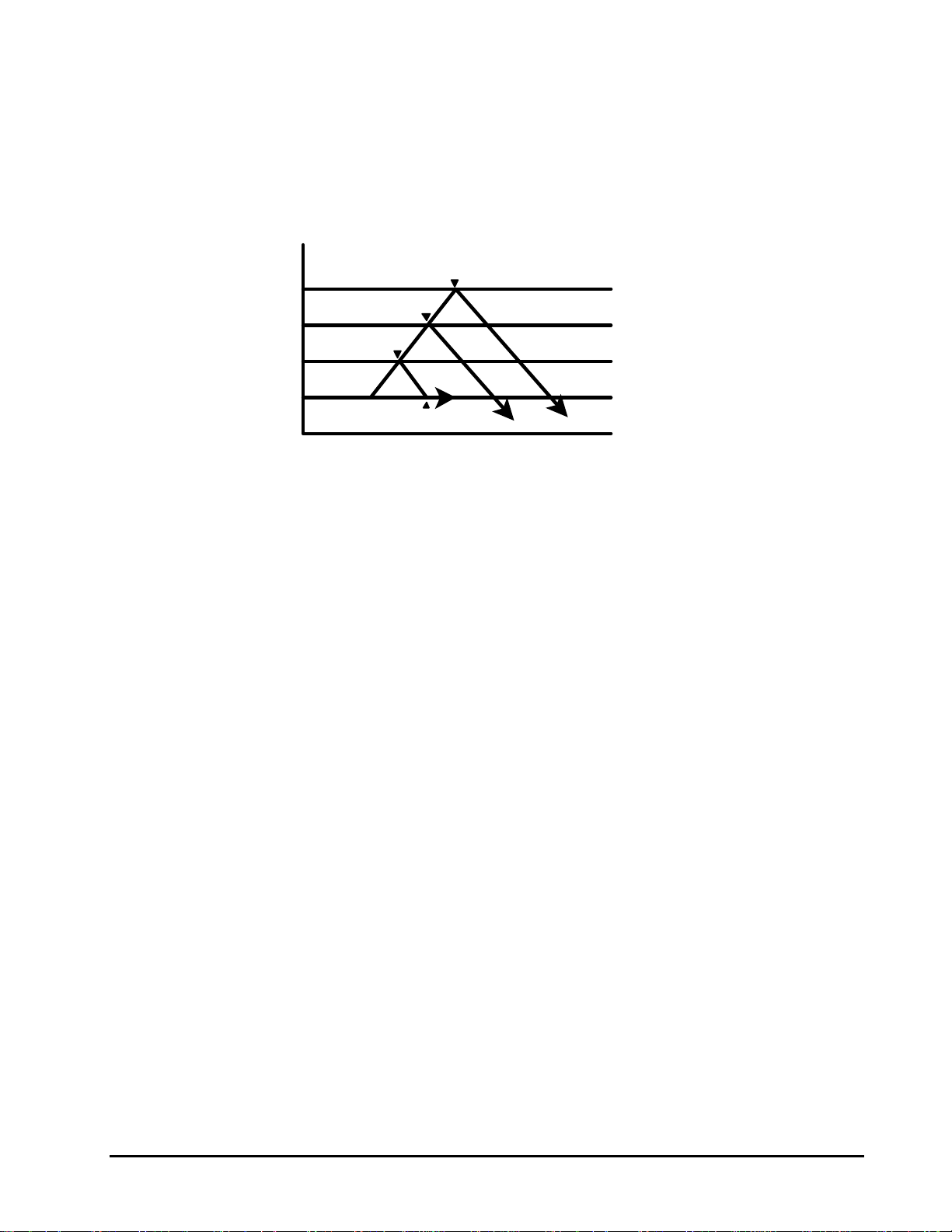

1.3. Specimen Protection (Safety Devices).............................................................................................5

1.3.1. Safety Device Setting Example.................................................................................................6

1.4. Disposing of the Chamber................................................................................................................8

1.5. Other Precautions.............................................................................................................................9

1.6. Global Warming Potential of Refrigerants......................................................................................10

2. Overview ................................................................................................................................................11

2.1. About the Criterion Series ..............................................................................................................11

2.2. Temperature (& Humidity) Control and Instrumentation.................................................................12

2.2.1. Temperature (& Humidity) Control ..........................................................................................12

2.2.2. Watlow Instrumentation...........................................................................................................13

3. Names and Functions of Parts...............................................................................................................15

3.1. Chamber.........................................................................................................................................15

3.1.1. Front........................................................................................................................................15

3.1.2. Left Side ..................................................................................................................................16

3.1.3. Right Side................................................................................................................................17

Table 3.3 Right Side Parts..................................................................................................................17

3.1.4. Test Area (Size 1 chamber) ....................................................................................................18

3.2. Instrumentation Panel.....................................................................................................................19

3.2.1. Instrumentation Panel ..............................................................................................................19

4.1. Installation.......................................................................................................................................21

4.1.1. Installation Site Check..............................................................................................................21

4.2. Power Supply Work........................................................................................................................22

4.2.1. Primary Power Supply Requirements ......................................................................................22

4.2.2. Primary Power Supply Connections.........................................................................................23

4.3. Drainage.........................................................................................................................................24

4.4. Humidity Water Supply (BTL and BTX models only)......................................................................25

Removal of the Water Level Regulator Protection Material...............................................................25

4.4.1. Water Supply Installation..........................................................................................................25

4.4.2. Water Consumption Rate.........................................................................................................26

4.4.3. Water Level Setting..................................................................................................................26

4.4.3.1. Checking Water Level in the Wick Pan.................................................................................26