Page 2of 58

Contents

Note: This manual describes the features, functions and operation of the Multiphoton Detection Unit (MDU) and

associated devices. Before use, carefully read this manual, directions for all accessories, all precautionary information

and specifications.

1.0 Introduction...............................................................................................................................................4

1.1 Handling Scientifica equipment –precautions.........................................................................................4

1.2 The Scientifica Multiphoton Detection Unit (MDU)...................................................................................5

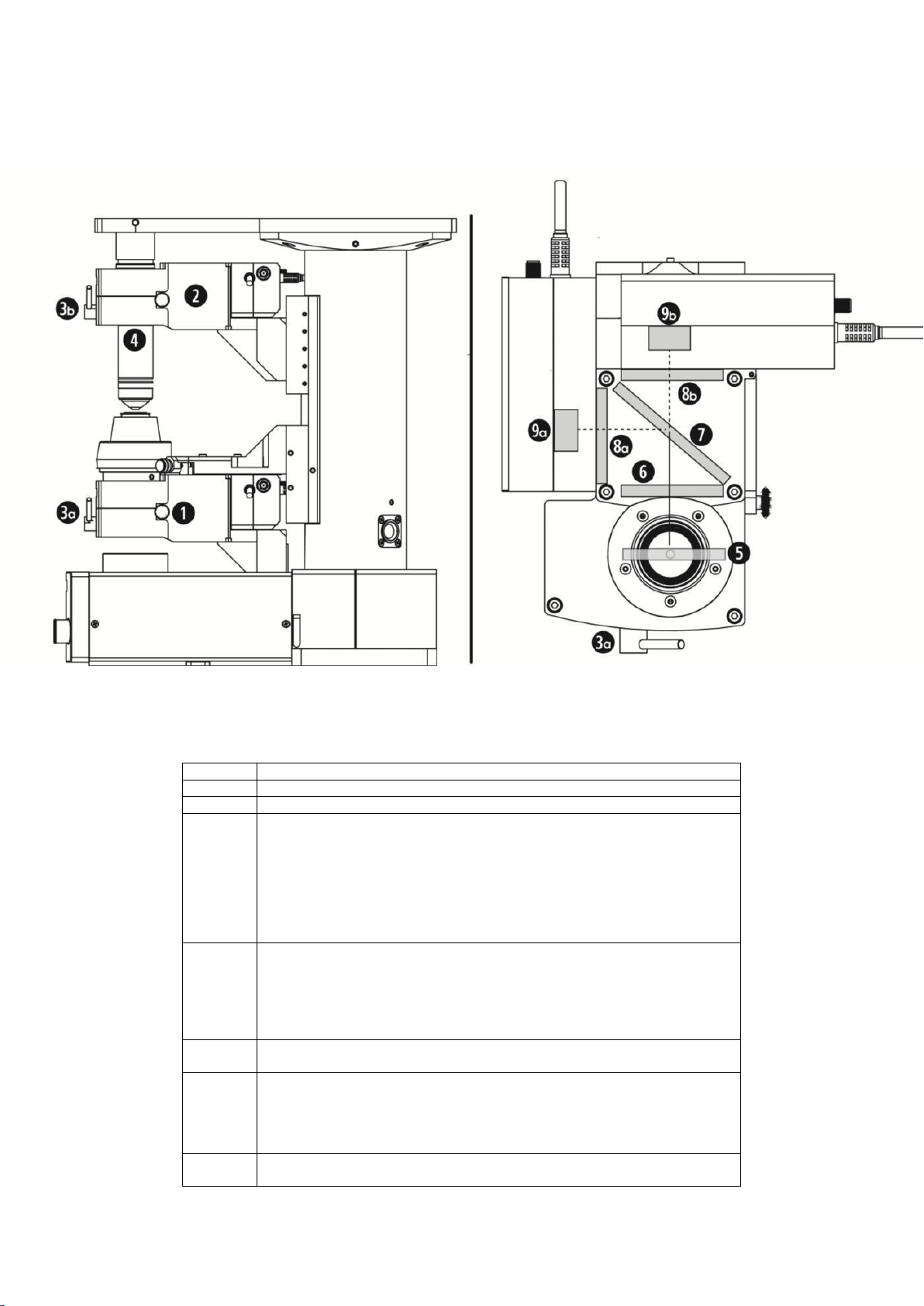

1.2.1 Product overview..............................................................................................................................5

1.2.2 Product Walkthrough........................................................................................................................7

2.0 Packing List...............................................................................................................................................8

2.1 Standard items........................................................................................................................................8

2.1.1 Optical block features.....................................................................................................................10

2.1.2 Detector module features ...............................................................................................................12

2.1.3 Control racks..................................................................................................................................14

3.0 Mechanical setup....................................................................................................................................16

3.1 Fitting the above-stage MDU to the SliceScope ....................................................................................16

3.2 Above-stage variant (fixed objective).....................................................................................................18

3.2.1 Checks and preparation .................................................................................................................18

3.2.2 Fitting Objectives............................................................................................................................18

3.2.3 Direct objective attachment ............................................................................................................19

3.3 Above-stage variant manual with manual objective changer (in vivo)....................................................20

3.4 Above-stage variant with Motorised Objective Changer (MOC).............................................................22

3.4.1 Checks and Preparation.................................................................................................................23

3.4.2 Fitting a DIC Prism .........................................................................................................................23

3.4.3 Removing the rear PMT module.....................................................................................................23

3.4.4 Removing the detection module and bracket from the MOC...........................................................24

3.4.5 MOC Variant Reassembly..............................................................................................................26

3.4.6 Re-assembly of the rear PMT module ............................................................................................28

3.4.7 Installation of MOC variant onto the SliceScope.............................................................................28

3.4.8 Objective installation.......................................................................................................................29

3.5 Substage variant ..................................................................................................................................30

3.5.1 Preparation.....................................................................................................................................30

3.5.2 Installation of substage variant onto SliceScope.............................................................................32

3.5.3 Fitting the Condenser to substage variant ......................................................................................34

3.6 Filter Cube Installation...........................................................................................................................35

3.6.1 Filter Cube Population....................................................................................................................35

3.6.2 Fitting the cube to the carrier.........................................................................................................35

3.6.3 Installation in the Optical Block.......................................................................................................36

3.6.4 Extraction of the filter cube and carrier ...........................................................................................37

4.0 Optical System Preparation ...................................................................................................................38

4.1 Transmission Viewing ...........................................................................................................................38

4.2 Transmitted Laser Imaging....................................................................................................................38

4.3 Laser Beam Delivery.............................................................................................................................38

4.4 Control Software and Data Acquisition..................................................................................................39

5.0 Electrical setup .......................................................................................................................................40

5.1 Electrical setup - controller connections ................................................................................................40

5.1.1 Typical electrical configuration for complete system.......................................................................41

6.0 Operation.................................................................................................................................................42

6.1 Powering up the system........................................................................................................................42

6.1.1 Before switching on........................................................................................................................42

6.1.2 Switch-on routine............................................................................................................................42