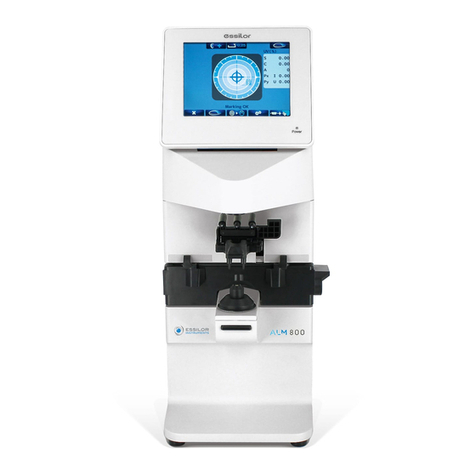

Essilor Instruments TEN 070 User manual

User Manual TEN 070

TEN 070

IMTEN070 V.4

1

1

User Manual TEN 070

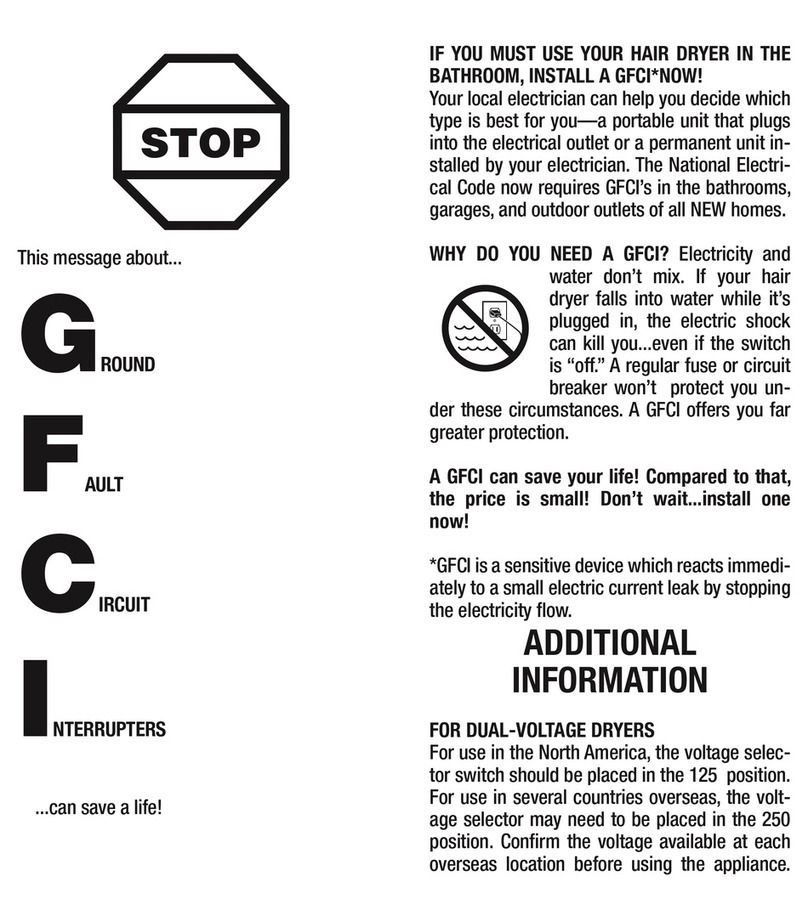

CONTROLS

WIRINGDIAGRAM

4

1 Master switch

2 Power socket

3 Knob for inclination regulation

4/5 Polaroid filter

5

1

3

XS Feed outlet with fuse

QS Luminous master switch I

H Lamp

FU 5x20 Fuse

F1mm2Black wire

N 1mm2Blue wire

2

2

2

User Manual TEN 070

TECHNICAL DATA AND FEATURES

TENSIOMETER

TENSIOMETER

Tensioning test

Machine

Code A2100

Maximum length (A) 155 mm

Maximum width (B) 135 mm

Maximum height (C) 167 mm

Machine weight 0.93 Kg

Feed voltage 230 V ± 10% 120 V ± 10%

Maximum absorption current 0.05 A 0.09 A

Power 6 W 6 W

Frequency 50 Hz 60 Hz

Fuse F 250mA L250V F 250mA L250V

ENVIRONMENTAL WORKING

B

C A

Max altitude 2000 m

Temperature 5 ÷ 40 °C

Max relative humidity 80 %

PROPER USE

TENSIOMETER is utilized for checking stress on mounted lenses

Any other use than that for which the machine has been designed and manufactured described in this

manual is to be considered “IMPROPER USE”.

Therefore manufacturer declines any responsibility for possible damages caused to persons or to the

machine itself.

The machine described above has not been designed to work in an explosive atmosphere or in the presence

of inflammable vapours or liquids. Installation and use of same is therefore forbidden in these

environments.

DANGERS AND RESIDUAL RISKS

Generally speaking, the machine does not give rise to any residual risks

INFORMATION FOR USER

In order to safeguard operator and avoid possible machine damage, it is essential to have studied user manual before

carrying out any operation on same.

PACKING

Packing contains the following:

Body of instrument

Power lead

Instruction, Use and Maintenance Manual

The machine has been designed to be moved by hand, without the necessity of additional lifting devices.

Throughout the period when packed machine remains inactive, awaiting to be put into operation, it is

opportune to position it in a place safe from atmospheric agents.

3

3

User Manual TEN 070

UNPACKING

Once packaging has been removed no damage must be evident. On the contrary, Service Centre must be

informed.

Disposal of packaging material will be carried out by customer in compliance with the regulations in force

in the country where the machine is used.

PRE-ARRANGEMENT TO BE CARRIED OUT BY CUSTOMER

The user installs machine in suitable rooms, equipped with electrical system in compliance with regulations in force.

Installation must be carried out in well-ventilated environments, dry and illuminated in compliance with current

legislation.

INSTRUCTIONS FOR USER

CONNECTION AND START-UP

Before carrying out connection, assure that mains voltage corresponds to that on machine plate and that

master switch is on “0” (zero) position.

Position the instrument on a perfectly horizontal surface so as to guarantee an adequate stability; after having assured

that the master switch is on “0” (zero) position, connect feed cable as per the circuit diagram inserting same first in

machine side and subsequently into outlet.

START-UP

Start-up of machine is carried out by a voluntary action on master switch and is evidenced by the warning light on the

front of the machine.

STOP MODES AND EMERGENCY STOP

It is possible to obtain the normal stop function of machine by bringing master switch onto position “0” (zero).

The general emergency stop function may be obtained by disconnecting the feed cable from outlet.

After an emergency stop or stoppage due to an anomaly or lack of electricity, always put master switch

onto position “0” (zero).

WORK EXAMPLES

Start up machine

Position the lens mounted on frame, between the two filters of the machine

(1)

Example of stressed lens (2) 1

Slacken the knob positioned on the back side of the unit, in order to

regulate the angle of the machine, and extract the foot according to needs,

then tighten the knob for blocking the foot in the desired position; this

operation gives the possibility to optimize the reading position. (3)

3 2

MAINTENANCE

Any modification causing an effect on operation or safety of machine, may only be carried out by manufacturer’s

technicians or by technicians formally authorized by same. On the contrary, Essilor declines any responsibility for

changes or damages which may subsequently occur.

Essilor declines any responsibility for improper use of machine, for damages caused by operations not treated in this

manual or which are unreasonable.

All ordinary and extraordinary maintenance operations are to be carried out with machine off, isolating

same from power by disconnecting feed cable.

EXTRAORDINARY MAINTENANCE

Extraordinary maintenance is intended that carried out when machine stops due to break-down of mechanical or

electrical parts.

For safety reasons final user is not permitted to carry out extraordinary maintenance operations. Contact

Essilor or authorized Service Centre.

4

4

User Manual TEN 070

INSTRUCTIONS TO OBTAIN ASSISTANCE AND SPARE PARTS

For any communication with Service Centre, to be contacted c/o our offices, always quote machine type, serial number

and year of manufacture written on label, which determine identification of each single machine and, whenever

possible, specify the nature of the problem encountered or defect present on machine.

In order to guarantee a perfect machine operation, it is necessary that possible replacement of pieces are exclusively

carried out with original spare parts having identical characteristics.

MACHINE CLEANING

Utilize a slightly damp cloth and non-aggressive detergent products.

Before carrying out this operation assure that machine is effectively in stop condition, disconnecting feed

cable from mains.

Infiltration of liquids may damage the electrical part of machine.

DIAGNOSTIC

Anomaly: Lamp does not switch on

Possible cause ACTIVITY

It is possible to replace the fuse present in the socket drawer (*)Fuse interrupted

Master switch broken Contact Service Centre

Lamp broken Contact Service Centre

(*) In order to check condition of the fuse it is necessary to bring

master switch to position “0” (zero), disconnect feed cable,

open small drawer.

MACHINE DEMOLITION AT END OF USEFUL LIFE

The symbol with a crossed bin indicates that equipment must be collected separately from

other wastes. The differentiated refuse collection of equipment at the end of useful life is

organized and handled by manufacturer. The user who wants to dispose of material will have

to contact manufacturer and follow the procedures that same has adopted for separate

collection.

A proper differentiated collection of equipment helps avoiding possible negative effects on

environment and health and favours re-utilization and/or recycling of materials composing

equipment.

Unauthorized disposal of product by possessor will lead to application of fines, in compliance

with regulations in force in the country where equipment is used.

DIRECTIVE REFERENCES AND STANDARDS APPLIED

Mandotory directives

Reference Title

UE Directive no. 2014/35/UE Low voltage (DBT)

UE Directive no. 2014/30/UE Electromagnetic compatibility (EMC)

UE Directive no. 2011/65/UE Restriction of the use of certain hazardous substances in electrical and electronic

equipment (RoHS)

Voluntary standards

Reference Title

EN ISO 12100

(2010)

Machinery safety – fundamental concepts - General design principles

Part 1 – Basic terminology/methodology

Part 2 – Technical principles

EN 61010-1 (2010) Safety prescriptions for electric measurement, control and laboratory equipments

Equipment for measurement, control and laboratory use – Electromagnetic Compatibility

prescriptions

EN 61326-1 (2013)

Essilor Instruments USA

8600 W. Catalpa Avenue, Suite 703

Chicago, IL 60656

Phone: 855.393.4647

Email: [email protected]

www.essilorinstrumentsusa.com

5

5

Table of contents

Other Essilor Instruments Measuring Instrument manuals