CONTENT

Hardware 4

1 General .................................................................................................................................................4

1.1 Explanation of symbols .................................................................................................................................4

1.2 Safety instructions .........................................................................................................................................4

1.2.1 Intended use ........................................................................................................................................................4

1.2.2 Mounting, start-up and operation .........................................................................................................................5

1.3 Environmental aspects ..................................................................................................................................5

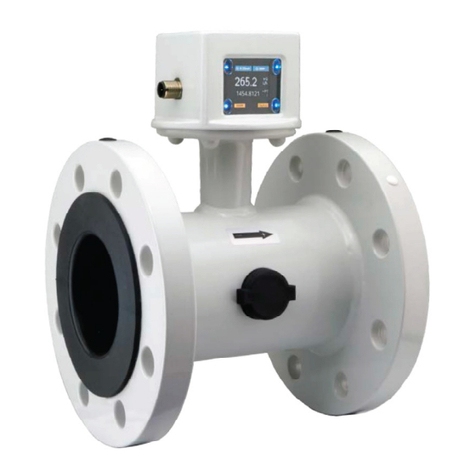

2 Product description ............................................................................................................................6

2.1 Modular design..............................................................................................................................................6

2.1.1 Changing the pipe diameter.................................................................................................................................7

2.2 Functions.......................................................................................................................................................7

2.2.1 Analogue output (OUT 1).....................................................................................................................................7

2.2.2 Switch (alarm) outputs (OUT 1 and OUT 2).........................................................................................................7

2.2.3 Pulse output (OUT 2) and consumption meter.....................................................................................................8

2.2.4 Setting the standard conditions............................................................................................................................8

2.2.5 Lowowcut-off ....................................................................................................................................................8

3 Mechanical installation .......................................................................................................................9

3.1 Installation dimensions ..................................................................................................................................9

3.2 Choosing the appropriate mounting location.................................................................................................9

3.2.1 Process pressure ...............................................................................................................................................10

3.3 Installation position......................................................................................................................................10

3.4 Inlet and outlet measurement path..............................................................................................................11

3.5 Installation of the gauge mounting block .....................................................................................................12

3.5.1 Operating the pipeline without transmitter .........................................................................................................12

3.6 Mounting the transmitter unit into the gauge mounting block......................................................................12

4 Electrical installation ........................................................................................................................13

4.1 Connection diagram ....................................................................................................................................13

4.1.1 Switch and pulse outputs ...................................................................................................................................14

4.2 Bus output (projetcted) ................................................................................................................................14

4.2.1 M-Bus (Meter Bus) (projected)...........................................................................................................................14

4.2.2 Modbus RTU (projected)....................................................................................................................................15

4.3 USBcongurationinterface.........................................................................................................................17

5 Display................................................................................................................................................17

5.1 Measured value display...............................................................................................................................18

5.2 Display menu ..............................................................................................................................................18

6 Error messages .................................................................................................................................20

7 Maintenance.......................................................................................................................................20

7.1 Removing the transmitter from the gauge mounting block..........................................................................20

7.2 Cleaning the sensing head..........................................................................................................................21

7.3 Ordering guide for accessories ...................................................................................................................21

8 Technical data....................................................................................................................................22

8.1 Factory settings of the outputs DN15 / DN20 / DN25..................................................................................23

8.2 Factory settings of the outputs DN32 / DN40 / DN52..................................................................................24

8.3 EU Declaration of Conformance..................................................................................................................25