2

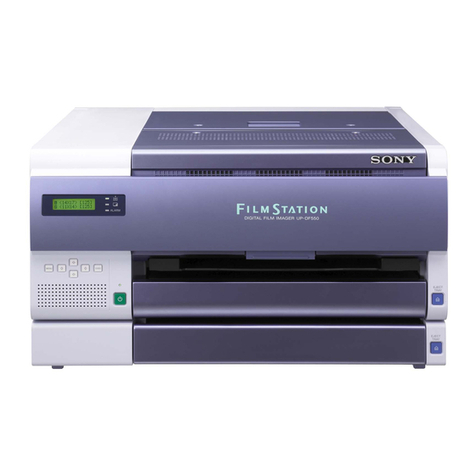

Owner's Record

The model and serial numbers are located at the rear.

Record these numbers in the space provided below.

Refer to these numbers whenever you call upon your

Sony dealer regarding this product.

Model No. ____________________

Serial No. ____________________

To prevent fire or shock hazard, do not expose the unit to

rain or moisture.

To avoid electrical shock, do not open the cabinet. Refer

servicing to qualified personnel only.

THIS APPARATUS MUST BE EARTHED.

For the customers in the U.S.A.

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection again harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference in

which case the user will be required to correct the

interference at his own expense.

You are cautioned that any changes or modifications not

expressly approved in this manual could void your

authority to operate this equipment.

This device requires shielded interface cables to comply

with FCC emission limits.

For the customers in Canada

This unit has been certified according to Standard CSA

C22.2 NO.601.1.

Important safeguards/notices for use in

the medical environments

1. All the equipments connected to this unit shall be

certified according to Standard IEC60601-1,

IEC60950, IEC60065 or other IEC/ISO Standards

applicable to the equipments.

2. When this unit is used together with other equipment

in the patient area*, the equipment shall be either

poweredbyanisolationtransformerorconnectedvia

an additional protective earth terminal to system

ground unless it is certified according to Standard

IEC60601-1.

* Patient Area

3. The leakage current could increase when connected

to other equipment.

4. This equipment generates, uses, and can radiate

frequency energy. If it is not installed and used in

accordance with the instruction manual, it may cause

interference to other equipment. If this unit causes

interference (which can be determined by

unplugging the power cord from the unit), try these

measures: Relocate the unit with respect to the

susceptible equipment. Plug this unit and the

susceptible equipment into different branch circuit.

Consult your dealer. (According to standard

EN60601-1-2 and CISPR11, Class B, Group 1)

Caution

When you dispose of the unit or accessories, you must

obey the law in the relative area or country and the

regulation in the relative hospital.

WARNING

This symbol indicates the equipotential

terminal which brings the various parts

of a system to the same potential.

This symbol is intended to alert the user

to the presence of important operating

andmaintenance(servicing)instructions

in the literature accompanying the

appliance.

R1.5m