Introduction 5

1 Introduction

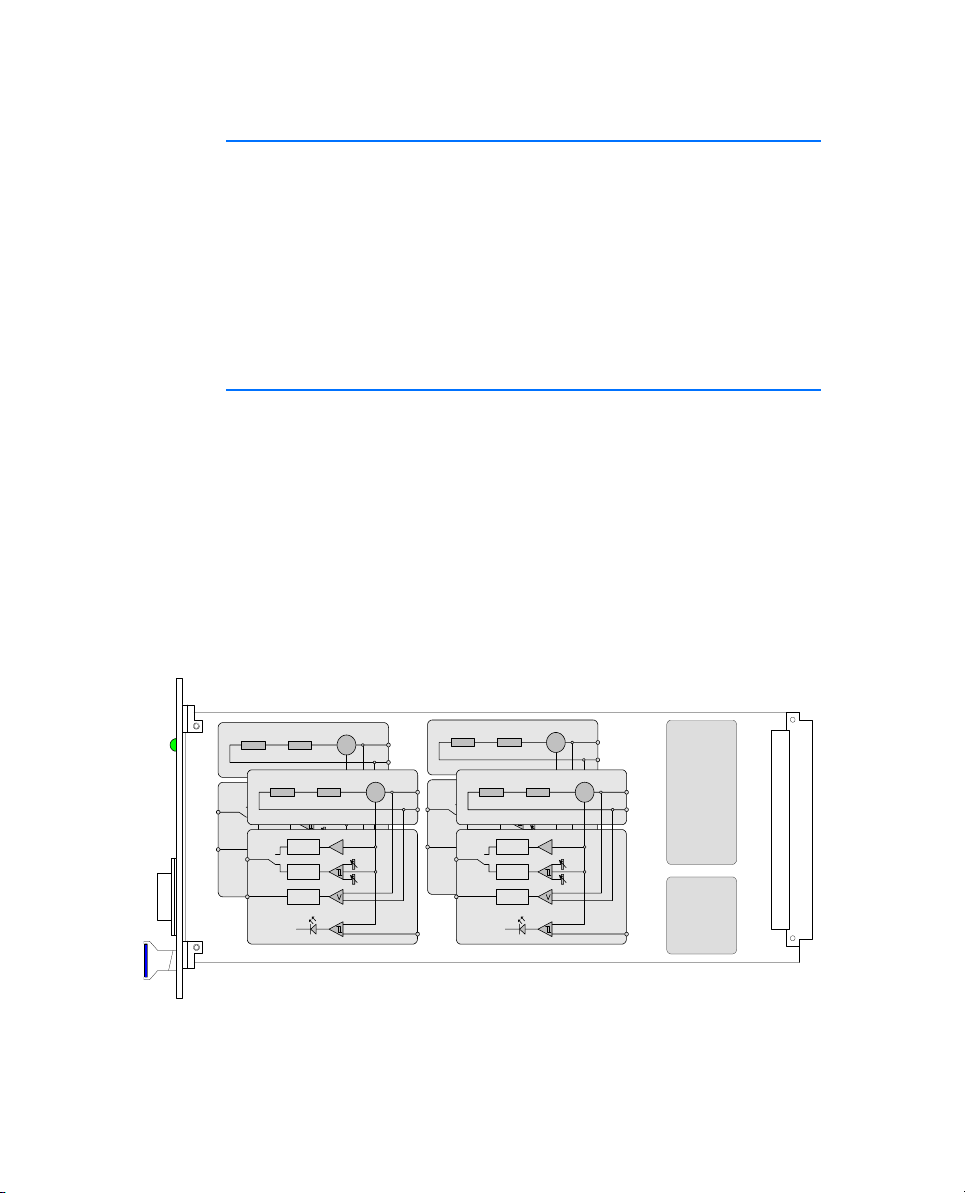

This User’s Guide describes the ES4455.1 Load Board. It consists of the

following chapters:

• "Introduction" on page 5

This chapter – here you will find general information on the ES4455.1

Load Board.

• "Hardware" on page 11

This chapter describes the individual function units of the ES4455.1

Load Board in more detail.

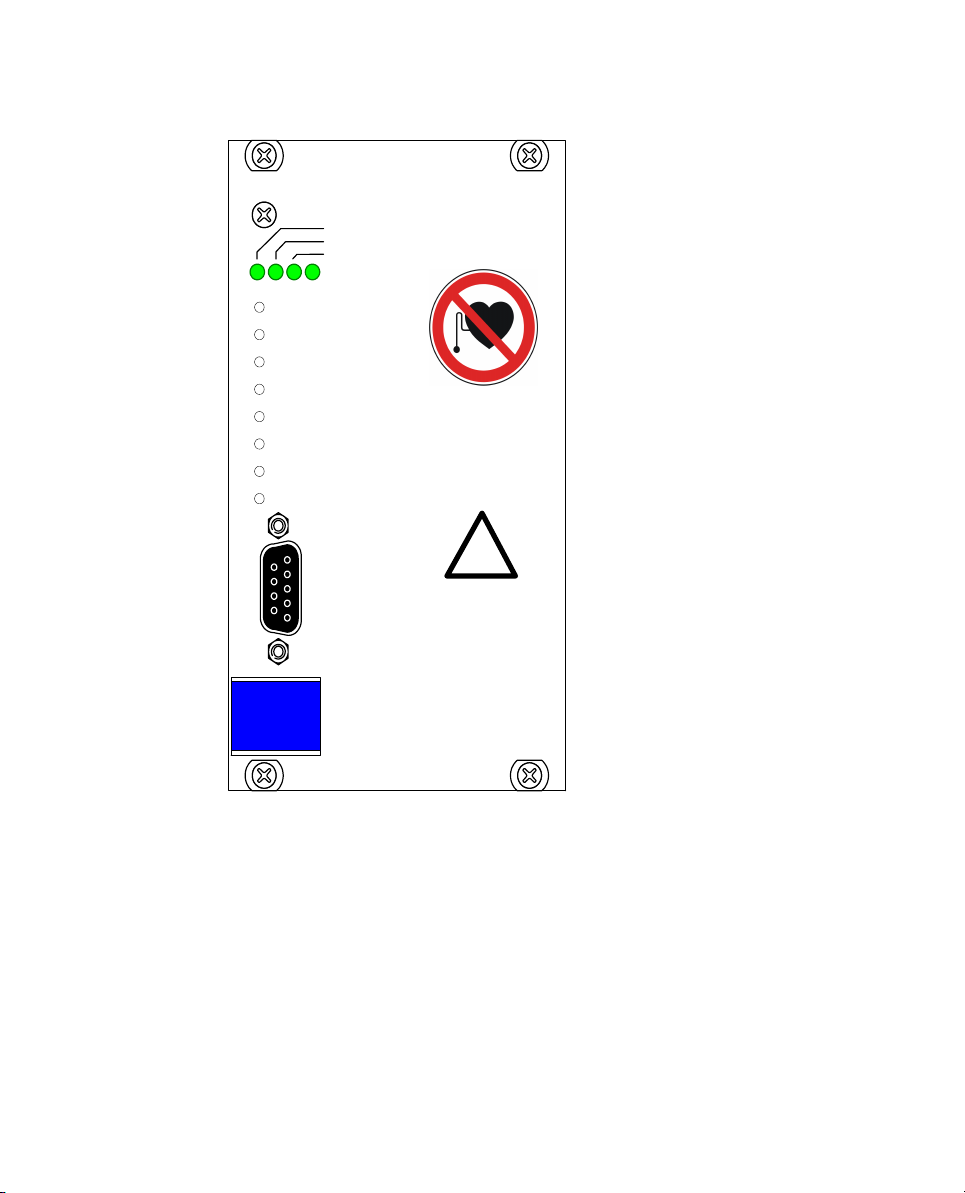

• Pin Assignment and Display Elements

This chapter contains a description of the pins and LEDs on the front

panel of the ES4455.1 Load Board.

• "Accessories" on page 21

This chapter describes the dummy loads available to date which are

assembled as piggybacks on the board of the ES4455.1 Load Board.

• "Technical Data" on page 23

This chapter contains the technical data of the ES4455.1 Load Board.

CAUTION!

Some components of the ES4455.1 Load Board may be damaged

or even destroyed by static discharge. Leave the board in its

transport package until you want to install it.

The ES4455.1 Load Board should only be taken from its package,

configured and installed at a working place that is protected

against static discharge.

WARNING!

The components, connectors and conductors of the ES4455.1

Load Board may carry dangerous voltages. These voltages may

even exist if the ES4455.1 is not installed in the ES4408.1 Load

Chassis or the ES4408.1 Load Chassis is powered off.

Make sure the ES4455.1 is protected against contact during

operation. Disconnect all connectors to the ES4455.1 before

removing the board.