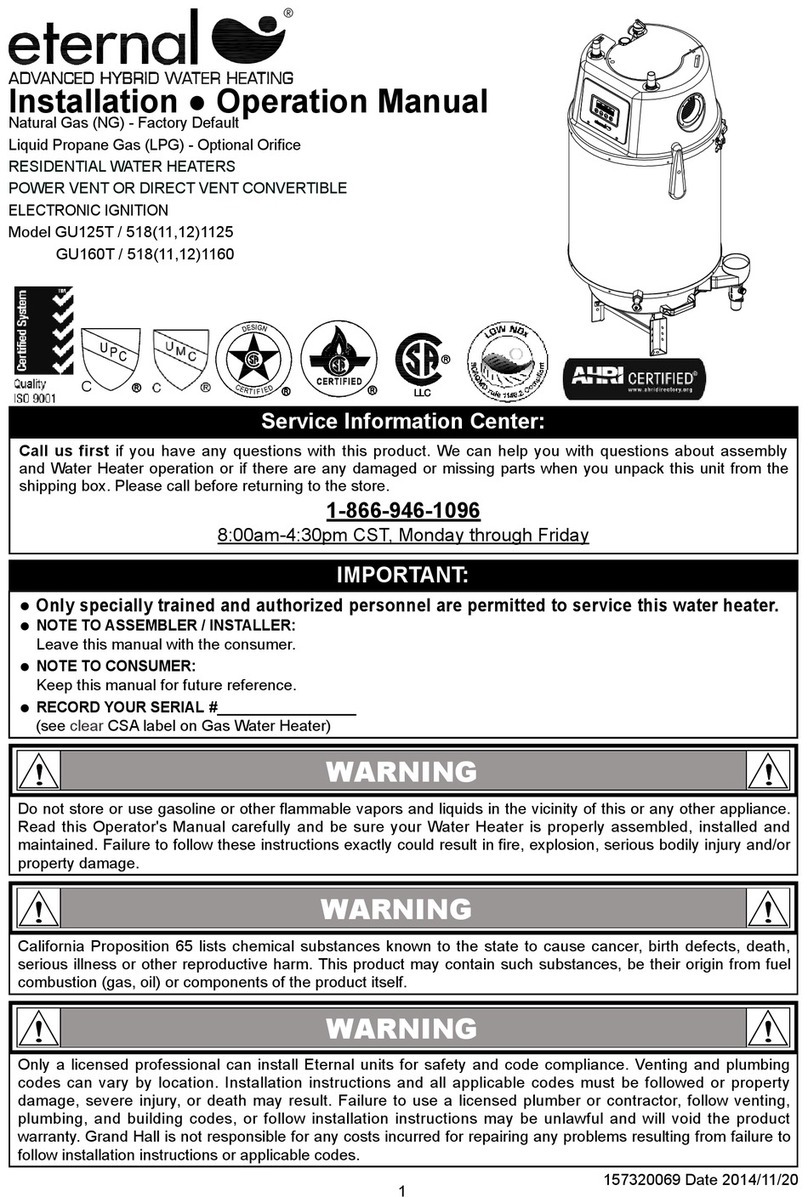

Eternal GU32 User manual

OPERATOR'SMANUAL

NaturalGas(NG)-FactoryDefault

LiquidPropane Gas(LPG)-OptionalConversion

Model

GU32 /501(11,12,21,22)1321

Model

GU28/501(11,12,21,22)1281(Optional)

Model

GU26 /501(11,12,21,22)1261

Model

GU20/501(11,12,21,22)1201(Optional)

IMPORTANT:

ServiceInformation Center:

Callusfirst ifyou haveanyquestionswiththis

product. Wecan helpyou withquestionsabout

assemblyandWaterHeateroperationorifthere

aredamaged ormissingpartswhenyouunpack

thisunitfromtheshippingbox.Pleasecall before

returning tothe store.

1- 866-946-1096

8am-4:30pm CST, Monday through

Friday

Read thisOperator'sManualcarefullyand besure

yourWaterHeaterisproperlyassembled,installed

and maintained.Failuretofollowtheseinstructions

exactlycouldresultinafireorexplosion,serious

bodilyinjuryand/orpropertydamage.

Donotstoreorusegasolineorotherflammable

vaporsandliquidsinthe vicinityofthisoranyother

appliance.

WARNING

! !

1

157020132Date2009/8/5

C

WARNING

!!

CaliforniaProposition65listschemicalsubstances

known tothestatetocausecancer,birthdefects,

death,seriousillness orotherreproductiveharm.

Thisproductmaycontainsuchsubstances,be

theiroriginfromfuelcombustion (gas,oil)or

componentsoftheproductitself.

WARNING

! !

WHATTODOIF YOUSMELLGAS

Do nottry tolightanyappliance.

Do not touchanyelectrical switch;do not use

anyphoneinyourbuilding.

Immediatelycall yourgassupplierfroma

neighbor'sphone.Followthegassupplier's

instructions.

If youcannotreachyourgassupplier,call thefire

department.

Onlyspeciallytrainedandauthorized

personnelare permittedtoservice this

water heater.

Ÿ

Ÿ

Ÿ

Ÿ

NOTETO ASSEMBLER/INSTALLER:

Leavethismanualwiththe consumer.

NOTETO CONSUMER:

Keep thismanualforfuturereference.

RECORDYOURSERIAL# __________________

(see silverCSA labelon GasWaterHeater)

2.

3.

1.

4.

http://waterheatertimer.org/New-water-heater-ideas.html

http://waterheatertimer.org/Which-is-best-hybird-heat-pump-water-heater.html

2

TableofContents

WARNING

! !

WARNING

Primary SafetyWarning...............................1-3

Pre-InstallationInstructions...............................3

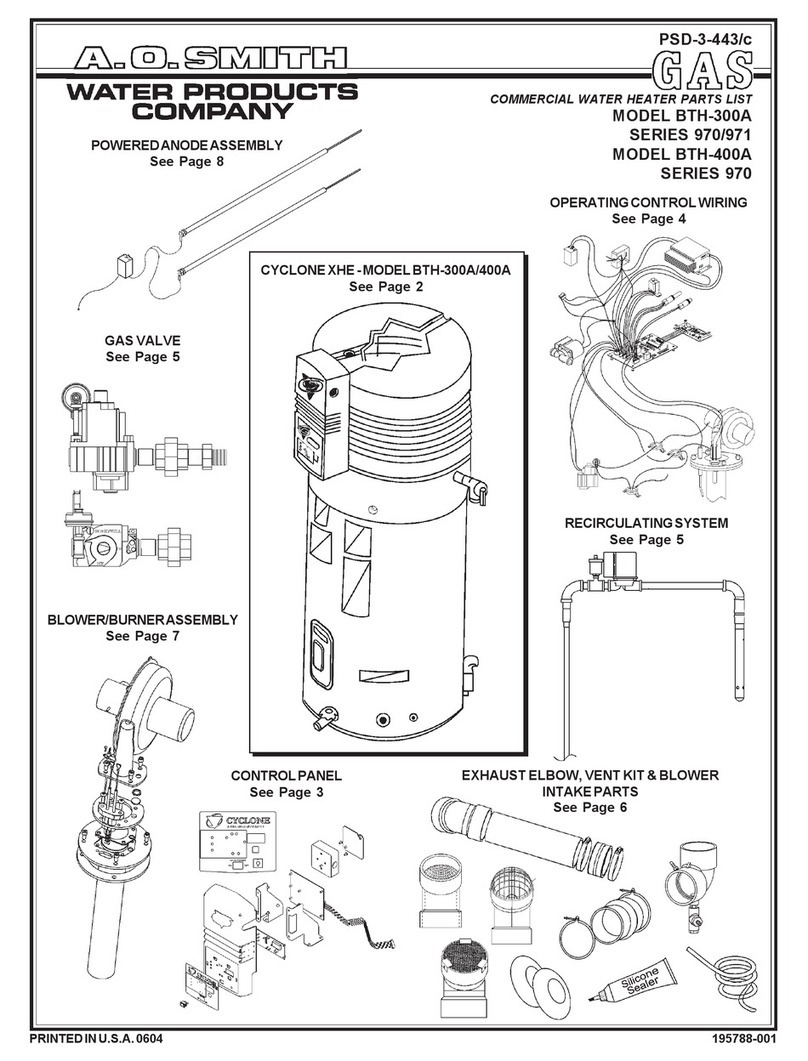

PartsDiagramand ListforGU28/GU32....4-5

PartsDiagramand ListforGU20/GU26....6-7

OperatingInstructions.................................8-9

Use&CareInstructions

Maintenanceand Service............................10

Troubleshooting.............................................11

Specifications................................................12

Installation................................................13-24

GasSupplyPiping....................................25

WaterSupplyConnection...................26-27

ElectricalConnection............................28-30

LiquidPropaneGasConversion.........31-32

PlumbingDiagrams.................................33-34

WarrantyTerms..........................................35

WARNING

! !

Ifyoudetectabnormalcombustion orab-

normalodors,oranearthquake,tornadoor

fire:

1.Turnoff the hotwatersupplyatthe faucet.

2.Turnoff thepowertothe hotwaterheaterby

unplugging.

3.Turnoffgasand wateratthemanualshut-off

valves.

4.Consultthenearestservicepersonnel.

Thiswillhelppreventfire,electricalshockor

damagetothe unit.

DONOTplacecombustiblechemicalsor

materialssuchaslaundry,newspapers,hair

spray,spraydetergent,oil,gasoline,benzene

etc., nearthewaterheaterortheexhaust vent

terminal.

LEAVEthe properclearancebetweenthe

waterheaterandnearbyobjects(trees, timber,

boxesandflammable materialsetc...)

BE SUREtoelectricallyground the unit.

DONOTtouchthe powercordwithwethands.

KEEP powercordfree ofdust.

DONOTuseabrokenormodifiedpowercord.

DONOT bind,bend orstretchpowercord.

DONOTconnectthewaterheatertoasolar

waterheater.

Never usethishotwater heater unlessit

iscompletelyfilledwithwater.

Topreventdamagetothetank,thetankmustbe

filledwithwater.Watermustbe runningfromthe

hotwaterfaucetbeforeturning the maingasvalve

tothe waterheaterto"ON".

! !

WARNING

TurningOff TheAppliance:

Turnoffall electricalpowerbyunplugging the power

cordfromtheoutletifserviceistobeperformed.

Turnthegasshut-off valvelocatedseparatelyof

the waterheatertothe OFF position.

1.

2.

CAUTION

Ifyoudo notfollowtheseinstructionsexactly,

afireorexplosion couldresult causingproperty

damage,personalinjuryorlossoflife.

!!

WARNING

CAUTION

Donot install waterheaterwhereflammable

productswillbestored.

Readandfollow thewaterheaterwarningsand

instructions.Iftheoperator'smanualismissing,

contacttheretailerormanufacturer.

! !

WARNING

! !

DANGER

_Hotwatertemperatureover125 Fcan cause

severeburnsinstantlyordeathfromscalding.

Children,disabled and elderlyareat the highest

riskofbeing scalded.

Temperaturelimiting valvesareavailable,ask

yourserviceprofessional.

Check the temperatureof the running hotwater

byhand beforetakingashower.

Check tosee thatthegassupplied matches

the gastype on the rating plate.

_

_

_

_

WARNING !!

If youdonotfollow theseinstructionsexactly,

afireorexplosion could resultcausing property

damage,personalinjuryorlossoflife.

Pre-Installation InstructionsforYourSafety

C.

D.

3

The installation mustconformwithlocalcodesor,in

the absenceoflocalcodes,withNationalFuelGas

Code, ANSIZ223.1/NFPA 54.

Properlygroundthe unitin accordancewithall local

codesorinthe absenceoflocalcodes,withthe Na-

tionalElectricalCodes,ANSI/NFPA70.

Installation Codes

_

_

OPERATIONINSTRUCTION

STOP! Readthissafetyinformationaboveand inthis

OperatorsManual.

Turnoff all electrical powertothe waterheater.

Do not attempttolighttheburnerbyhand.

Turnthe manualgasvalvelocatedon theoutside of

the unittotheoff position.

Waitfive(5)minutestoclearoutanygas.Ifyousmell

gas,STOP!Follow"B"inthe safetyinformation above.

Ifyou don'tsmell gas,gotonextstep.

Turnthe manualgasvalvelocatedon theoutside of

the unittotheONposition.

Turnon all electrical powertothe waterheater.

Ifthewaterheaterwillnotoperate,followtheinstruc-

tion "ToTurnOffGasWaterHeater"and call your

servicetechnicianorgassupplier.

2.

1. Turnoff allelectricalpowertothe waterheaterifser-

viceistobeperformed.

Turnthemanualgasvalvelocated on theoutsideofthe

unitclockwisetothe off position.

TO TURNOFFGASTO WATERHEATER

Vaporsfromflammableliquidswillexplodeand

catchfire causing death orsevere burns

Donotuseorstoreflammable productssuchas

gasoline,solventsoradhesivesinthe sameroomor

areanearthe waterheater.

Keepflammableproducts

1.Farawayfromwaterheater

2.Inapproved containers

3.Tightlyclosed

4.Outofchildren's reach

Vapors

1. Cannotbeseen

2.Vaporsareheavierthanair

3.Goalong wayon the floor

4.Can becarriedfromotherroomstothemain burner

byaircurrents

Thiswaterheaterdoesnothaveapilot. Itisequipped

withanignition devicethatautomaticallylightsthe

burner.Do not try tolightthe burnerbyhand.

BEFOREOPERATION smell all around the water

heaterarea forevidenceof leaking gas.Besureto

smellnexttothe floorbecausegasisheavierthan

airand willsettleon the floor.

Useonlyyourhandtoturnthegasvalveknob.Never

usetools.Ifthe knob willnotturnbyhand,don'ttry

torepairit. Call aqualifiedservicetechnician.Force

orattemptedrepaircould resultin afireorexplosion.

Donotusethiswaterheaterif anypart hasbeen

underwater.Immediatelycall aqualified servicetech-

niciantoinspectthewaterheaterandtoreplaceany

damagedparts.

B.

A.

WHATTODOIF YOUSMELLGAS

Immediatelycall your gassupplier fromaneighbor's

phone.Followthegassupplier'sinstructions.

Ifyoucannotreachyourgassupplier,callthefire

department.

Donot trytolight anyappliance.

Donot touchanyelectricalswitch.

Donot useanyphoneinyour building.

-

-

2.

3.

1.

4.

5.

6.

7.

8.

WARNING: Do notinstall waterheaterwhereflam-

mableproductswillbe stored.

Readandfollowthewaterheaterwarningsand

instructions.If theoperator's manual ismissing,

contacttheretailerormanufacturer.

Thehotwateroutlettemperatureofthewaterheater

isfactoryset122 F(50 C).

WARNING: Usethiswaterheateratyourownrisk.

Thesetoutletwatertemperaturecancausesevere

burnsinstantlyordeathfromscalds.Testthe water

beforebathingorshowering.Do notleavechildren or

theinfirmwithoutsupervision.

4

PartsDiagramsforModelGU28,32/501(11,12,21,22)1(28,32)1

5

PartsListforModelGU28,32/501(11,12,21,22)1(28,32)1

KEY DESCRIPTION Part# QTY

18 VentCap Assembly(ExhaustTop Included) 301080190 1

KEY DESCRIPTION Part# QTY

19 Side VentTerminator 151010187 1

KEY DESCRIPTION Part# QTY

1Panel,Front 302040001 1

2Panel,Rear 302040002 1

3Panel,Left 302040003 1

4Panel,Right 302040004 1

5Panel,Top/Front 301040005 1

6Panel,Top/Rear 301040006 1

7Panel,Bottom 151010009 1

8Control Panel Assembly 301080170 1

9Temperatureand PressureRelief Valve 194010281 1

10 Exhaust CollarAssembly 301070230 1

11 Drain ValveAssembly 305070273 1

12 Plug 601020001 2

13 PowerWireAssembly 192010143 1

14 WaterFitting Cap 155010059 4

15 Exhaust Flange 307040540 1

16 Packing, Top 152010227 1

17 Drain Cap 155010288 1

OptionalPartsForOutdoorModel

OptionalPartsForHorizontalVentingTermination

PartsDiagramsforModelGU20,26 /501(11,12,21,22)1(20,26)1

6

7

OptionalPartsForOutdoorModel

KEY DESCRIPTION Part# QTY

18 VentCap Assembly(ExhaustTop Included) 301080190 1

PartsListforModelGU20,26/501(11,12,21,22)1(20,26)1

OptionalPartsForHorizontalVentingTermination

KEY DESCRIPTION Part# QTY

19 Side VentTerminator 151010187 1

KEY DESCRIPTION Part# QTY

1Panel, Front 301040001 1

2Panel, Rear 301040002 1

3Panel, Left 301040003 1

4Panel, Right 301040004 1

5Panel, Top/Front 301040005 1

6Panel, Top/Rear 301040006 1

7Panel, Bottom 151010009 1

8Control Panel Assembly 301080170 1

9Temperatureand PressureReliefValve 194010281 1

10 Exhaust CollarAssembly 301070230 1

11 Drain ValveAssembly 305070273 1

12 Plug 601020001 2

13 PowerWireAssembly 192010143 1

14 WaterFitting Cap 155010059 4

15 Exhaust Flange 153010226 1

16 Packing, Top 152010227 1

17 Drain Cap 155010288 1

8

Thiswaterheaterdoesnothaveapilot.Itisequipped

withanignitiondevicewhichautomaticallylightsthe

burner.Do nottry tolightthe burnermanually.

Beforeoperating, makesurethat agasleakisnot

evident bysmellingtheareaaroundtheunit. Be

suretosmellnexttothefloorbecausegasisheavier

thanairandwill settleonthe floor.

Useonlyhandtoturnthe gasvalveknob.Neveruse

tools.If the knob will notturnbyhand,do nottry to

repairit,call aqualified servicetechnician.Forceor

attempted repaircould resultinafireorexplosion

duetothegasleakage.

Donotusethiswaterheaterifanypart hasbeen

underwater.Immediatelycall aqualifiedservicetech-

niciantoinspectthe waterheaterandtoreplaceany

partsthathavebeen underwater.

Do notinstall the unitstanding directlyon

combustiblesurface.

OperatingInstructions

STARTINGTHESYSTEM

Foryoursafety,readbeforeoperating

NORMALOPERATION

To turnon yourwater heater

To turn off yourwaterheater

Openahotwatertap.

Burnerwill ignite;the indicatorwill lighton front

controller.

Mixcoldwatertogetthedesiredwatertemperature

attap.

Maximumtemperatureofhotoutlet canbe setby

controlleron the frontofthe unit.

1.

2.

3.

4.

Closethehotwatertap and the waterheater'sburner

willturnoffautomatically.

1.

WHATTO DOIFYOUSMELLGAS

-Donot trytolightanyappliance.

-Donot touchanyelectricalswitch.

-Donot useanyphoneinyour building.

Immediatelycallyourgassupplierfromaneighbor's

phone.Followthegassupplier'sinstructions.

Ifyou cannotreach yourgassupplier,callthefire

department.

-

-

STARTINGUP

Oncetheunithasbeenproperlyinstalled,checkthe

gasand waterconnectionsforleaks.

Check forproperventilation and combustible airsupply

tothe waterheater.Purgethegasandwaterlinesto

removedebris;then followthesestepstoturnon your

unit.

Closethe manualgasshut-offvalvelocated on the

gasline.

Fullyopenthemanualwatershut-offvalveon the wa-

tersupplyline.

Toensurecompletefillingofthe heatexchangertank,

allow airtoexit byopeningthenearesthotwater

faucet.Allowwatertorun untilaconstantflowisob-

tained.Thiswillletairoutofthewaterheaterand

piping.

Openahotwatertap tocheck thatwaterwillflowto

thattap.Then closethe hotwatertap.

Fullyopenthemanualshut-off gasvalve.

Pluginthe120VAC/60Hzpowersupplytothewater

heaterand turnon the unit.

Open tapandenjoyendlesshotwater!

1.

2.

3.

4.

5.

6.

7.

Donotdrinkwater thathas beeninside

theunitforextendedperiod oftime.Do

notdrinkthefirstuse ofhotwater from

theunitin themorning.

!! CAUTION

Never usethishotwaterheater unlessit

iscompletelyfilledwithwater.

Thetankmustbefilledwithwater.Watermust

flowfromthehotwaterfaucetbeforeturning"ON"

gastothe waterheater.

!! CAUTION

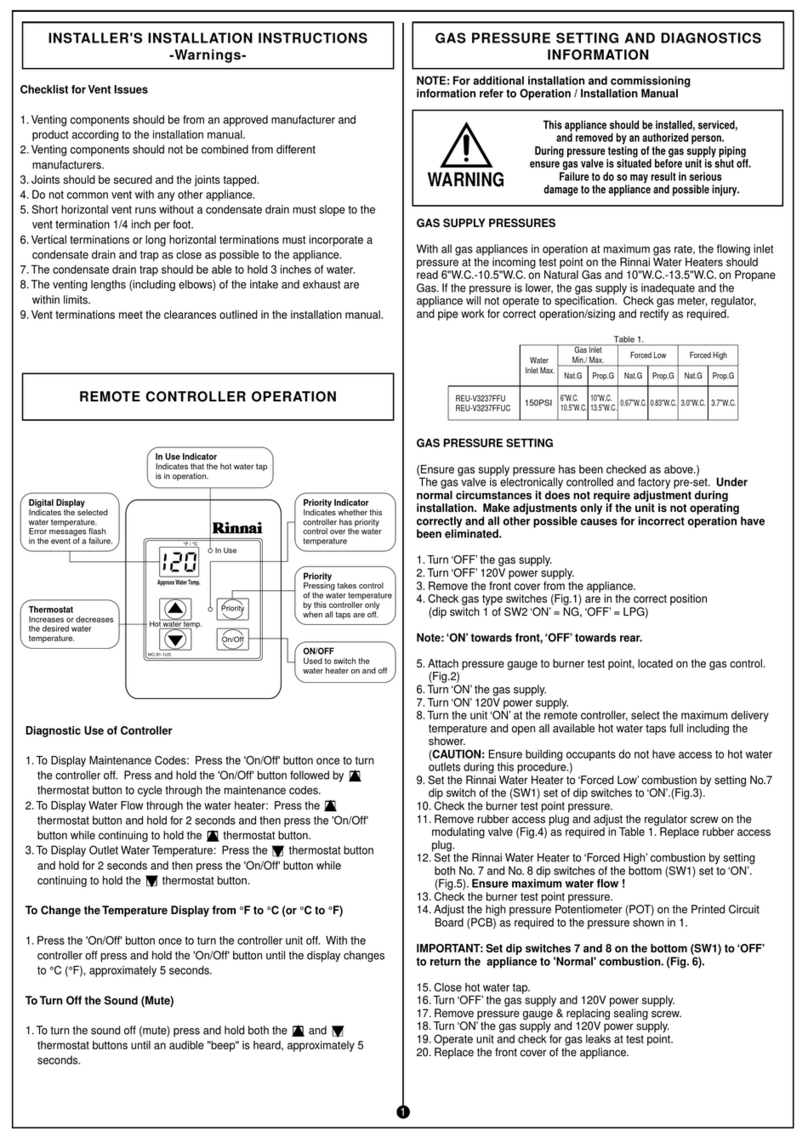

HowToUse TheFrontControlInterface

9

WaterTemperatureTimetoProduceaSeriousBurn

120 Morethan 5minutes

125 1.5to2minutes

130 About30seconds

135 About10seconds

140 Less than 5seconds

145 Less than 3seconds

150 About1.5seconds

155 About1seconds

DANGER

! !

Hotwaterheatertemperatureover125 Fcan

causesevereburnsinstantlyordeathfrom

scalding.

Children,disabled and elderlyareatthe highest

riskofbeing scalded.

Feelwatertemperaturebeforebathing orshow-

ering.

Temperaturelimiting valvesareavailable,aska

professionalperson.

_

_

_

_

Toswitchthewater heaterON: fromOFFcondition

Pressthe PowerButton.

-Thetemperatureselectedwillbeindicatedonthe

Digital Monitor.

-TheONIndicatorwilllightup.

Whenrunningthewaterbyopeningthewatertap,

thewaterheaterwillstarttheburnerautomatically

andtheDigital Monitorwill show theactualwater

temperature.When watertapsareclosed,the unit

will stop the burnerand theDigitalMonitorwill show

thesettemperature.

Toswitchthewaterheater OFF:

Pressthe PowerButton.

-The temperatureselected on theDigitalMonitorwill

goout.

-TheONIndicatorwill turnoff.

Toadjustwatertemperature:

Press the "HOT"or"COLD"TemperatureSetting

ButtonwithunitON.(Temperaturesettingisonly

adjustablewhen the waterheaterisnotinuse.)

The maximumwatertemperaturesetting can be

limitedbyDIPswitches.Thismanualsettingoverrides

adjustabletemperaturesettingsonthefrontpanel.

PleasecallGrandHallUSAforDIPswitchsetting

instructionsifneeded.

1.

2.

1.

1.

2.

Maintenance and Service

10

SYSTEMSANDPARTSCHECK

Theunitshouldbecheckedonceayearorasneces-

sarybyacertifiedand trained technician. Ifrepairsare

needed, the repairs shouldbe donebyacertifiedand

trained technician.

The following systemsand partsshouldbe checked at

leastonceayear.

Venting system

Burner

Manualoperation ofthepressurereliefvalvetoen-

surecorrectoperation.

Periodiccleaningofthewaterstrainer.

Removethethermistorfromheatexchangerand

checkformineralcoating.Amineral coating onthe

thermistorrequirescleaning.

WARNING !!

Turnoffthe electricalpowersupply,themanual

gascontrolvalve,and the manualwatercontrol

valvebeforeservicing.

CAUTION

! !

Avoid contactwithhotwaterreleasedfrom

thereliefvalve.

NOLUBRICATION: Nolubricationisrequiredfor

thewaterheater.

Service&Cleaning OfTheBurner:Onlyspecially

trained and authorizedpersonnelarepermittedtoser-

vicetheburner.

Maintenance and Service

BURNERIGNITION:Waterheaterhasautomaticig-

nition system.Onceyou openahot watertap, the

computerelectronicallyignitestheburners.Youcan

seetheburnerflamevia flameinspectionhole.

FlameInspection

Hole

3.

4.

1.

2.

SedimentBuild-up:Unlikeatypicalstorage tank,

thisheaterhasaselfcleaning systeminitiated

bythe flowofwater. Build up ofsediment infaucet

aerators,showerheadsand screenscouldimpair

waterflowandcausethewaterheatertodeliver

less thanitsfull output, ortoshutdowncompletely.

Checkanyofthesescreensorshowerheadson

yourfaucetsperiodicallyandcleanasnecessary.

PhysicalDamage:If the waterheaterhasbeensub-

jected tofire,flood,orphysical damage,turnoffthe

manualgasshutoffvalveanddonotoperatethewa-

terheateragainuntil it hasbeen checked byquali-

fied personnel.

TemperatureSetting:Hotterwaterincreasesthe

riskofscalding injury.

VentingSystemInspection:Avisual inspection

shouldbe madeontheventingsystematleastonce

ayear.

_

_

Besurethe venting isproperlyconnected topre-

ventescapeofdangerousflue gaseswhichcould

causedeadlyasphyxiation.

Obstructionscouldcauseimproperventing.The

combustionand ventilation airflowmustnotbe

ob-structed.

Damageordeteriorationwhichcouldcauseim-

properventing orleakage ofcombustion

byproducts.

_

5.

CleanUp:The flueoutletandtheairintakeholeson

the bottomsidesofthe waterheatershouldbe checked

frequently.Cleanasneeded toprevent theentryof

water,insects,rodentsorotherforeignmaterialssuch

asfallenleavesanddustthatcould causeblockages.

Donot obstructtheflowofcombustionairandex-

haustairflow.

Water Strainer:Thewaterstrainershouldbe

checked atleastonceayear.It protectsvalvefrom

dirt,andpipescale.Self-cleanbyopeningvalve

orplugconnectedtoablow-offoutlet.

11

TROUBLESHOOTING

Thisunithasthe abilitytocheckitsownoperationcontinuously.Ifanerroroccurs,amessagewill flashonthedigital

monitorofthefrontpanel.

Thisassistswithdiagnosing theerror,and mayenable you toovercomeaproblemwithout aservicecall.Please

quotethe code displayedwhen inquiringaboutservice.

NOTE: Inallcasesyou maybe abletoclearthe ErrorMessage simplybyturning the hot watertapOFF, then ON

again. Ifthisdoesnot cleartheErrorMessage, try pushing the ON/OFF button OFF, then ONagain. If the Error

Message still remains,contactourservicecenteroryournearestserviceagentand arrangeforaservicecall.

1-866-946-1096

8am-4:30pm CST, Monday through Friday

Troubleshooting

CodeDisplayedFaultRemedy

E1

E2

E3

E4/E5

E6/E7

E8/E9

E11

E12

E13

E14

E15

E16

E17/E18

E19/E20

E21

E22

E24

E27

E28

E30/E31

E34

E35

E36

E37

E38

E39

E40

E41

E42

E43

E46

Remainingflamedetected

Ignitionfailure

Weakflameorabnormalcombustion

Anoutletthermistoropen/short

AH/Ethermistoropen/short

Aninletthermistoropen/short

ADCmotorfailure

Watertemperaturetoo hot

No filledwaterintankorpressureswitchfailure

Acontrollerfailureconcerninganinletthermistor

AcontrollerfailureconcerningaH/Ethermistor

Acontrollerfailureconcerninganoutletthermistor

Aburnerthermistorshort/open

Asecondaryairholethermistorshort/open

Avent condition isnotnormal

Temperaturetoohigh on aburnerthermistor

Mixingcontrol valveisnotconnected

Mixingcontrolvalveinitializationfailure

Powerlineofmain gasvalveisopen

Rotation ofaDCfanistoohigh/low

Carryovergasvalveisnotconnected

Modulation gasvalveisnotconnected

Acontrollerfailureconcerninggasvalve

CommunicationfailurewithSUBCPU

Subsidiary RAMfailure

AcontrollerfailureconcerningSubsidiaryflamesignal

MainRAMfailure

Acontrollerfailureconcerningflamesignal

MainROMfailure

Main MUXerror

DetectionofOxygen depletion

Callservicecenter

Check gasline,igniter,flamerod

Gaslinenotsupplyingenough gas

Checkoutletthermistorand wiring

CheckH/Ethermistorand wiring

Checkinletthermistorand wiring

Call forreplacementmotor

Check flowsensororCPU

Check watertankorpressureswitch

Callservicecenter

Callservicecenter

Callservicecenter

Check burnerthermistorand wiring

Check airholethermistorandwiring

Checkventconditionforbackflow

Call forreplacementthermistor

Checkmixingvalvewiring

Callforreplacementvalve

Checkwiring,thermostatand fuse

Call forreplacementmotor

Checkcarryovergasvalvewiring

Checkmodulationgasvalvewiring

Callservicecenter

Callservicecenter

Callservicecenter

Callservicecenter

Callservicecenter

Callservicecenter

Callservicecenter

Callservicecenter

Callservicecenter

12

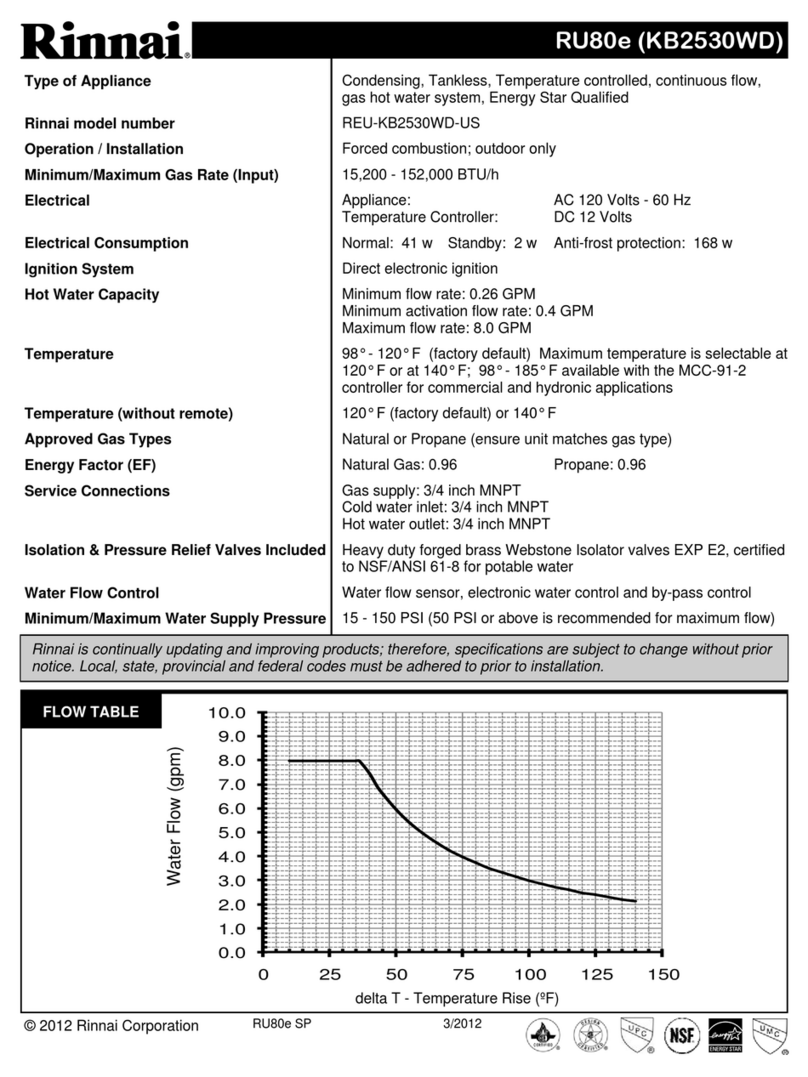

EternalHybridWaterHeaterTechnicalSpecifications

GU20 (Optional) GU26 GU28(Optional) GU32

501(11,12,21,22)1201 501(11,12,21,22)1261 501(11,12,21,22)1281 501(11,12,21,22)1321

Installation

Fluesystem

Operation

Min

Max 145,000BTU/Hr 180,000BTU/Hr 199,000BTU/Hr 236,000 BTU/Hr

NG

LP

NG

LP

Min 0.9"WC 0.9"WC 0.5"WC 0.5"WC

Max 1.6"WC 2.4"WC 1.8"WC 2.5"WC

105mA 131mA 107mA 126mA

CO

NOx

FlueTemp

0.1-12.8gpm 0.1-15.8gpm 0.1-17.5gpm 0.1-20.8gpm

Gas

Coldwater

Hotwater

T&P Valve, FlameRod, ThermalFuse(307F), RemainingFlame Detector, Fan RPMDetector, FreezeProtection(-

4F), Vent BlockageDetection, Thermostat Switch(194F),Thermostat Switch(221F), IgnitionPrevention,GFCI

LeakageBreakerw/3Afuse, MixingValve, UserSelectableMaximumTemperatureLock

47,500 BTU/Hr

7.0mm

5.2mm

9.0mm

6.5mm

166.1

145.6

196.2

172.9

100,102,104,106,108,110,112,114,116,122,131,140(default),149,158,167(15steps)

120 Volts60Hz

3/4inchesNPTFemale

17.3x33.5x22.8

60db

17.3x40.9x22.8

20.5x38.3x24.8 20.5x45.7x24.8

Standby-8watts,Maximum -84watts Standby-8watts, Maximum-105watts

WaterFlowSensorw/Built-inDisplay

TankThermistor, Inlet Thermistor, Outlet Thermistor, BurnerThermistor, AirThermistor

SimulationFeedforwardandFeedbackw/Electronically ControlledMixingValve

86%

3.8gal 6.4gal

Connections

WaterTemperatureSensing

OrificeSize

MaximumValveCurrent

ManifoldPressure

Electrical Consumption

Operatingwaterpressure

WaterHolding Capacity

PackagedWeight(lbs)

PackageDimensions(WxHxD)

SafetyDevices

Model Number(CSA)

Maximum NoiseLevel 48db

WaterFlowSensing

WaterTemperatureControl

Under100PPM

Under55PPM

IndoororOutdoor

ForcedExhaust PowerVent

15to150Psi

WithorWithoutRemoteControls

Direct Electronic IgnitionandAutomatic FlameSensing

Current ControlledDoubleStageNegativePressureFull ModulationGasValve

SingleOrificeFuelInjectionPre-MixingCylindricalMetalFiberInfraredBurnerw/FullModulation

3.5-10.5"WC

8.0-14"WC

Under185F

UnitWeight (lbs)

GasInput

GasSupply

Pressure

Combustion

Analysis

TemperatureSettings

Thermal Efficiency

Model Name

Ignition

Type

FlowCapacityRange

GasValve Type

BurnerSystem

UnitDimensions(WxHxD)

ElectricalPowerSupply

T&PValve,FlameRod,ThermalFuse(307F), RemainingFlameDetector, FanRPMDetector,Freeze

Protection(-4F),VentBlockageDetection, ThermostatSwitch(194F),ThermostatSwitch(221F),

IgnitionPrevention, GFCILeakageBreakerw/3Afuse,Mixing Valve,UserSelectable Maximum

TemperatureLock.

13

Onlyspeciallytrained and authorized technicians

arepermitted toservicethiswaterheater.

Unpack the unitcarefullyandmakesurethatall

accessoriesareputasidesothattheywill not

be lost.

Operator'smanual

WarrantyCard

AdditionalParts

Inspectthe waterheaterforpossibleshipping

damages.

Installation Preparation

PROFESSIONALINSTALLATIONREQUIRED

Unpacking YourEternal Water Heater

Ÿ

Ÿ

Ÿ

Checkthemarkingsoftheratingplateon thewater

heatertobecertainthetype ofgasbeingfurnished

correspondstowhatthe waterheaterisequipped

for.

Donot connectthiswaterheatertoafuel typenot

inaccordancewiththerating plate

WATERHEATERPLACEMENT

AdditionalSafetyInstructions

2. Ifventedthrough anoutside wallorthroughthe roof

using4"ventpiping thetotalventrun cannotexceed

35feetwithone90elbow.Ifmoreelbowsarere-

quired theventing distancemust be reduced 5feet

forevery90elbow.

Ventpiping shouldslope downwardtowardsthe out-

sideifcondensatecollectorisnotused. Horizontal

runsrequireadequatesupportat3feet intervals

andvertical runssupportedat5feetintervals.

Condensation maybecreated at timesasthe com-

bustiongasesexittheventcap.Discolorationofsur-

facesinproximitytothe ventcap mayoccur.

Carefullychoosethelocation forthe newheateras

placementisaveryimportantconsiderationforthe

safetyofthe occupantsinthe building and forthe

most economicaluseoftheappliance.

Whetherreplacing anold waterheaterorputting

thewaterheaterinanew location,considerthe

following criticalpoints:

Thelocationselected shouldbe asclosetothe

venttermination pointaspossible,and centered

withinthe waterpiping systemforbesthot wa-

terdelivery.All waterheaterscan leak.Do not

installwithoutadequatedrainage provisions

wherewaterflowcan causepropertydamage.

1.

3.

2.

1.

4.

5.

6.

4.

Forotherthan directventappliance,the

appliancemustbe located ascloseaspossible

toachimneyorgasvent.

The applianceshouldbe located inanarea

whereleakageofthetankorconnectionswill

notresultindamagetotheareaadjacentto

the applianceortolowerfloorsofthe structure.

Whensuchlocationscannotbe avoided,itis

recommended thatasuitabledrainpanbe

installed underthe appliance.The pan mustnot

restrictcombustionairflow.

Theminimuminlet gaspressuremust be within

thevalue specifiedbythemanufacturerand the

minimumvaluelistedisonlyforthepurpose

ofinputadjustment.

Ifawaterheaterisinstalledinclosedwater

supplysystem,suchasone having abackflow

preventerinthecoldwatersupplylineanda

thermalexpansion tankisrequired,contactthe

watersupplierorlocalplumbinginspectoron

howtocontrolthissituation.

TheTemperatureandPressure(T&P)reliefvalve

mustbe certified asmeeting the requirementof

theStandardforReliefValvesandAutomaticGas

Shut-offDevicesforHotWaterSupplySystems

ANSIZ21.22/CAN1-4.4.Thevalvemustbemarked

withamaximumsetpressurenottoexceed the

marked hydrostaticworking pressureofthe wa-

terheater(150psi)and adischargecapacitynot

lessthanthe waterheaterinput rateasmarked

on therating plate.

Fortanktypewaterheaters,the reliefvalve

mustbeinstallednearthe hotwateroutlet.

WARNING

! !

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

CAUTION

! !

BeforecommencingtheInstallation

Check thatitisinaccordancewithrelevant

buildingandmechanicalcodes,aswellasany

localorstateorfederalregulations.

3.

Read the Safetyguidelinesinthebeginning of

thismanual.

The internal computercontrolledregulatorispre-

setbythe manufacturerand shouldnotbead-

justed byuser.

Maintainproperspacearound the unitforservic-

ing.Install the unitsothat itcanbe connected

orremovedeasily.

The electricalconnectionrequiresameansfor

switchingoffthe powersupply.

Avoid installingtheunitinanareawithhighlev-

elsofdust,sand,ordebris.Theseparticlesmay

clog the airventorimpairthefunction ofthe fan,

leadingtoimpropercombustion.Regularmain-

tenanceisneeded.

Donotinstalltheunitwheretheexhaustventis

pointingintoanyopeningin abuildingorwhere

the noisemaydisturbneighbors.

12/

T&PValveand ExhaustCollarInstallation

Loosen2screwsholdingthe FrontPanelatthe

bottom, pushthe paneldownandtowardsyourself

toremove. Takethe accessoryboxoutofthefront

ofthe unit. Thisboxcontains:

T&P ReliefValvex1

ExhaustCollarx1

ORing(G95)x1

MeshScreenx1

DrainCapx1

SelfTappingScrew(T4x16)x5

AttachtheFrontPanelandpushthe panelup.

Securewiththepreviouslyremovedscrews.

Priortoinstalling theExhaustCollar,please

securetheO-Ringbetweenthe ExhaustFlange

and botton ofExhaustCollarwithT4screws.

1.

14

2.

3.

T&PValveand ExhaustCollarInstallation

Install the ExhaustCollarand securewithM4

screws.

InstalltheT&PReliefValveonthesideofunit.

MakesuretheT&PReliefissecuredtoprevent

waterleak.

VentCapInstallation(ForOutdoorInstallation)

4.

15

InstalltheVentCap onthe ExhaustTop.Secure

the VentCapbyusing clamporscrewonthe

ExhaustTop.

1.

5.

16

Thisunitistobe installed onafloor.

Donotinstallthe unitstandingdirectlyoncombus-

tible surface.

STANDINGINSTALLATION

OUTDOORINSTALLATION

Installation Codes :

Followalllocalcodes,orintheabsenceoflocalcodes,

followthe codesforinstallation ofgasburningappliances;

National fuelgascode ANSIZ221.23.Foroutdoorinstalla-

tion,do notremovethe ventcapfromthe top ofthe appliance.

Locatethewaterheaterinanopen,unroofedarea,and

maintainthefollowing minimumclearancesfromcombus-

tible materials.

Clearances

Ifthisunitisinstalledunderan overhang,theremustbea

24"clearancefromthe topoftheunittotheoverhang,and

thesurroundingareamustbeopenin frontand onthesides

oftheunit.

OutdoorInstallation

OUTDOOR INDOOR

A-Fromtopofwaterheater 24inches 36inches

B-Fromfrontofunit 24 inches 4 inches

C-Fromsidewallflueorvent connector inany direction -- 6inches

D-Fromback ofunit 2inches 2inches

EL -Fromleft side ofunit(gaspipingside) 12 inches 6 inches

ER-Fromrightsideofunit 2inches2inches

FL-Floor combustible combustible

A-Fromtop of waterheater

B-Fromfrontofunit

C-Fromside wall flue orventconnectorinanydirection

D-Frombackofunit

FL-Floor

EL-From left side ofunit(gaspiping side)

ER-Fromrightside ofunit

WARNING

! !

Do nothavethe flue terminalpointing towardan

opening intothe building.Do notlocateyour

heaterinapitoranylocationwheregasand

watercanaccumulate.

WARNING

! !

Do notinstall the waterheaterwherewater,

debrisorflammable vaporsmayget intotheflue

terminal.Thismaycausedamagetothewater

heater.

!

Donotinstalltheheaterventterminatorwithin

4ft. ofanyairintakeopening intoanybuilding.

SimilarCanadianregulationsforbidthe unitfrom

being installed within10 ft. ofanyopeningintoany

building.

WARNING

!

DANGER

! !

Improperinstallationcancausenausea oras-

phyxiation fromcarbonmonoxideandfluegases

whichcouldresultinsevereinjury ordeath.For

installation inaltitudesabove4,500 feet, contact

themanufacturerforinstallationinstructions.

17

Maintenance and Service

INDOORINSTALLATION

Install4"ventpipedirectlyon flue outlet.

Thewaterheatershould belocatedin anarea where

enough airisavailable forpropercombustion and

ventilationofthesurrounding area.Follow thelatest

editionofANSIZ223.1andanyyourlocalcodesthat

areapplicable.

EternalisaCategoryIIIventedapplianceand

manufacturer'sventilation specificationsshouldbe

followed.

Ingeneraltheserequirementsspecifythatifthe unit

isinstalled in aconfined space,theremust be per-

manentairsupplyopenings.

CombustionAirSupply:

IndoorInstallation

Improperinstallation can causenauseaoras-

phyxiation fromcarbon monoxide and flue gases

whichcouldresultin severinjury ordeath.For

installation inaltitudesabove4,500feet, contact

themanufacturerforinstallation.

CAUTION

!!

WARNING

Airsupplyfromoutsidebuilding:

When combustion airissupplied directlythrough an

outsidewallsuchasintakelouversopeningsintothe

dwelling, eachopening shouldgiveaminimumfree

areaofonesquareinchper15,000 Btu/hourof the

totalinput ratingsof allappliancesintheenclosed

area.

Airsupplyfrominsidebuilding:

When combustionairissuppliedfrominsidethebuild-

ing,eachopeningshouldgiveaminimumfreearea of

one squareinchper3,750 Btu/hourofthetotalinput

ratingsofall appliancesin the enclosed area.These

openingsshouldneverbe less than40 sq.in.

64sq.in.eachforGU32/501(11,12,21,22)1321

54sq.in.eachforGU28/501(11,12,21,22)1281

48sq.in.eachforGU26/501(11,12,21,22)1261

40sq.in.eachforGU20/501(11,12,21,22)1201

MINIMUMRECOMMENDEDAIRSUPPLYTO

WATERHEATER

INSTALLATIONDIAGRAM

Waterheatercapacity Outsideairarea Insideairarea

Max.236,000BTU 16sq.in. 64sq.in.

Max.199,000BTU 14sq.in. 54sq.in.

Max.180,000BTU 12sq.in. 48sq.in.

Max.145,000BTU 10sq.in. 40sq.in.

WaterHeaterCapacityMinimumRequiredAirVolume

Max.236,000BTU 3,150cu.ft

Max.199,000BTU 2,655cu.ft

Max.180,000BTU 2,400cu.ft

Max.145,000BTU 1,950cu.ft

The minimumrequired inside airvolumeshouldbe 50

cu.ft perevery3,750Btu/hour.

18

Mounting ProcedureforCommercial/Foodservice

CaulkingMethod:

Applycaulkingalongthe bottomedgeofthe unit.

Makesurethecaulkiswatertightandappliedevenly

between unitand flatsurfacetopreventseepage from

accumulating underneaththeunit.

Mounting on raisedplatformorstand:

Installtheunitonawaterheaterstandthatraises

theunitatleast6”fromthefloorwhereseepagecan

accumulateunderneaththeunit.

Description:

IncompliancewithNSF-5standard,waterheaters

should bemountedin awaythat seepagecannot

accumulateundertheunit.GrandHallrecommends

eitherapplyingwatertightcaulking alongthe bottom

edgeoftheunitwiththe floorsurface,orinstallEter-

nalinconjunction withawaterheaterstandorplat-

formthatwould raisethe unitatleast6”offthe floor.

CondensateDrainInstallation

VERTICAL TERMINATION HORIZONTALTERMINATION

CONDENSATEDRAINREQUIREMENTS

WARNING

! !

Ifthe condensatecollectorisnotused,the drain

pipemustbecappedtopreventexhaustgases

andcondensatefromenteringthe building.The

Drain Capissuppliedontheappliance.

Thecondensatecollectormustbeusedin horizontal

teminationsifaverticalriseintheventsystemexceeds

5ft.

Regionsofcoldclimatewillcreatemorecondensatein

theventsystem. The condensatecollectorshould be

used incoldclimates.

If morethanoneelbowisusedinthe verticalsection

the condensatecollectormustbe used.

19

Allvertical terminating ventinstallations.

Horizontalterminatingventinstallationsifaverticalriseintheventsystemexceeds5ft.Ifmorethanone elbow is

used intheverticalsection,acondensatecollectormustbe used.

TheExhaustCollarofthiswaterheaterhasabuilt-in condensatecollector. Use1/2"IDvinyltubetoconnect

condensatedrain port.Do notusecopperpiping foranyportion ofthe condensatedrain.

The condensatetrapmustcontainaminimumof3inchesofwater.

Disposeofcondensateperlocal codes.

Condensateformationcan occurinhighefficiencypowerventappliances.Topreventcondensatedamage,aconden-

satedrainmustbe installed underthefollowingconditions:

When the condensatecollectorisused,pleasefollowtheseinstructions.

HorizontalTerminationWithoutUsing TheCondensateCollector

VENTING INSTRUCTION

ExhaustFansand Ventilation

Thewaterheaterisequippedwithacombustible air

detectortomeasurewhetherthereisenough airfor

propercombustion.Ifthereisnot, the waterheater

willnotwork untilsufficentairisprovided.

Anyequipment,whichusesairfromanenclosed

space, candepletethe airfromthatarea.Thiscan

resultinexhaustflowingfromthe fluetotheenclosed

space,whichcouldresultin theaccumulation of

dangerousexhaustfumesinthe spacewherethe

waterheaterisinstalled.

Additionalairmust besupplied tocompensatefor

anyexhausteffect.

Ifafanblowerisused tosupplyairtothe waterheater

room,theinstallershould makesureitdoesnotcre-

atedrafts,whichcouldcauseunwanted shutdowns.

Ifablowerisnecessary toprovideadequatecom-

bustionairtothe waterheater,aswitchorequiva-

lentdevicemustbewiredintothewaterheatercon-

troltopreventthewaterheaterfromfiringunlessthe

blowerisoperating.

Thiswaterheatermustbe ventedin accordancewith

"VentingofEquipment"section ofthe latestedition

oftheNationalFuelGasCode,ANSIZ223.1andall

aapplicable localbuildingcodes.

ExhaustVentingInstallation

EXHAUST VENTINGINSTALLATION VENTINGCONNECTION

20

WARNING !!

Improperventing of thisappliancecan resultin

excessivelevelsofCarbonMonoxide,whichcan

causeseverepersonalinjuryordeath.

The vent systemmust be gastight. Allseamsand

jointsmustbe sealedwithsiliconesealantoradhe-

sivetape havingaminimumtemperatureratingof

400F.

Wheninstalling the ventsystem,all applicablena-

tional andlocalcodesmustbefollowed.If thimbles,

firestopsorotherprotectivedevicesaregoingtobe

installedwhichwillpenetrateanycombustibleor

noncombustibleconstruction,be suretofollowall

applicablenationaland localcodes.

Fanassistedappliances:Followtherequirementas

indicatedin thelatesteditionofANSIZ233.1/NFPA

54.

Horizontal exhaustvent connectorsmust pitched

downwardtotheterminalifcondensatecollectoris

notused,atleast1/4"perfootoflength.Single wall

ventconnectorsmust be atleast6"fromadjacent

unprotected combustible surfaces.Jointofventcon-

nectors should besecurelyfastenedbysheetmetal

screwsorotherapprovedmethod.

Theentirevent systemmust not exceed the size

specifiedintable.

VENTING LENGTH

Generalrulesforventingsystem

Placethewaterheaterascloseaspossibletothe

vent.

Theventcollaronthewaterheatermustbe fastened

directlytoanunobstructed ventpipe.

Donotweld theventpipetothe waterheatercollar.

The weightofthe stack must notreston the water

heater.The flue must be easilyremovablefornor-

mal serviceandinspection oftheunit.

Thewaterheatermustnotsharecommon ventwith

afireplace,wood stoveorotherappliances.

Avoidterminatingthewaterheaterventnearanyair-

conditioning orair-supplyfans.

Avoidusing anoversized ventpipe orusing extremely

longrunsofthepipe.Thismaycauseexcessive

cooling and condensationofflue exhaust gases.

The venting systemmustbe installed inamanner

whichallowsinspectionduringtheinstallation ofthe

ventingpipesand jointsaswell asperiodicinspec-

tionafterinstallationasrequiredbyANSIstandards.

1.

2.

3.

4.

5.

6.

7.

Foreachelbowadded,deduct5feetfrommaxi-

mumventlength.Forexample,30 ft.isthemaxi-

mumtotaldistanceiftwoelbowsareused.

Ÿ

Ÿ

Diameter 4 inches

Max. No. ofElbow 3 ea

Max. Verticalor Horizontalrun inLength40 ft

When thehorizontalventrunexceeds5feet the

following criteriamustbeobserved:

Ÿ

Ÿ

Ÿ

Ÿ

VENTINGCLEARANCES

12"minimumfromthe ground,9"fromceiling over-

hangs.

Thepowerventoutletterminalshallterminateat

least36"aboveanyforcedairinletlocatedwithin

10feet.

Thepowerventoutletterminalshallterminateat

least 4feet below,4feet horizontallyfromor1

foot aboveanydoor, window orgravityairinlet

intothe building.

VENTINGTROUGHROOF-CLEARANCES

Thepowerventoutletterminalshallterminateat

least12"abovetheroofsurface.

Thelocation selectionmustprovideclearance

forservicingandproperoperationofthewater

heater.

Ÿ

Supporttheventrunat3feetintervalswithover-

headhanger.

Pitchdowntheventruntowardtheventterminal

at arateof1/4inchperevery footofhorizontal

runifcondensatecollectorisn'tused.

This manual suits for next models

3

Table of contents

Other Eternal Water Heater manuals

Eternal

Eternal GU125T User manual

Eternal

Eternal GU145 (S)/ 508 User manual

Eternal

Eternal GU32DV User manual

Eternal

Eternal GU32DV User manual

Eternal

Eternal GU145 Series User manual

Eternal

Eternal GU145 Series User manual

Eternal

Eternal ECHNK01 User manual

Eternal

Eternal GU145/508111145 User manual

Eternal

Eternal GU100/508111100 User manual