Ethernet MCOR User manual

User's Manual

Ethernet MCOR (EMCOR) Controller Module

Ethernet MCOR Controller Module User Instructions

This document contains instructions on the use of the EMCOR (Ethernet MCOR Controller Module).

Table of Contents Page

1. Setup Guide...................................................................................................................

2. Table of EMCOR jumper connections...........................................................................

. Figure of jumper connections.......................................................................................

4. EMCOR Controller General Description......................................................................4

5. Table of EMCOR module J1 and J2 signal connections................................................5

6. Table of Crate J and J4 connections to EMCOR J1 connections.................................6

7. Description of EXT INTLK Connection........................................................................7

8. Description of Crate OK Connection.............................................................................7

9. EMCOR Crate USB Diagnostic Application.................................................................7

10. EMCOR Front Panel Description.................................................................................17

11. Remote PCI Register Information................................................................................18

12. Base Address Register Table.........................................................................................19

1 . MCOR Faults Registers Table......................................................................................2

14. EMCOR Module CPU Boot-Up Process Instructions..................................................27

15. Entering and Saving the CPU MAC Address...............................................................28

16. Logging on to the RIOS Server.....................................................................................29

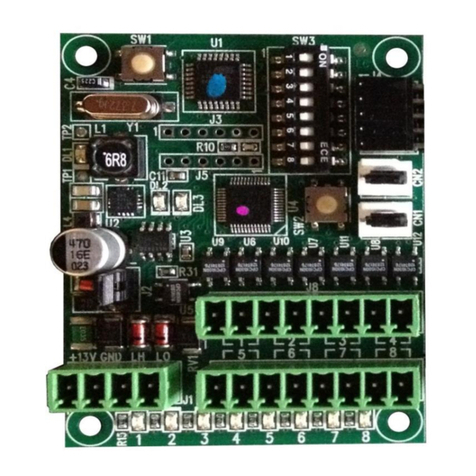

Setup Guide

The EMCOR module is properly configured for use before shipment. The following jumper

configuration guide is for reference only and shows how the module should be configured for normal

use. All testing is performed with the jumpers in the following configuration. Table 1 shows the signal

names and jumper configurations. Figure 1 shows the actual location of the jumpers on the module.

The table below does not reference the jumper on P9, which is installed to ensure a predictable CPU

boot-up process.

The EMCOR module comes equipped with a CPU module attached (non SLAC customers only). The

CPU must go through a boot up process each time power is applied to the crate before the EMCOR

module can be used to control MCOR modules, unless the USB Diagnostic Application is being used.

Instructions for the CPU boot up process, which loads the OS into the CPU module, can be found later

in this document.

Note that due to the amount of heat generated by the CPU module, it is necessary to always make

certain that a blower assembly is installed to the crate and that air flow is constantly available across

the EMCOR and CPU module as a means to remove heat being generated.

Table 1- Table of jumper connections on the EMCOR module

Header/ umper Connection

Pins

Signal 1 Signal 2 Signal 3 Use

P1 1 to 2 +15V_VIN_Crate +15V_V_IN +15V Power

P2 2 to + . V +5V_IN + . V Power

P 1 to 2 +5V_IN_CRATE +5_VIN +5V Power

P4 1 to 2 -15V_IN_CRATE -15V_IN -15V Power

P10 2 to VCCIO + . VCCIO USB Output

VCC

P11 2 to + . VCCIO +5V_IN + . VCCIO

Power

W In +5V_REF1 +5V_REF1 DAC Ref.

W7 In DGND AGND DGND to

AGND

W8 In +5V_REF2 +5V_REF2 DAC Ref.

3

EMCOR Controller Module Description

The EMCOR module was designed to replace the Interface Controller module that resides in slot 00 of

the crate power supply. The EMCOR module will only fit in slot 00 since that is the only location in

the crate with the 2 connectors (P1 and P2) necessary to mate with the EMCOR module. The EMCOR

module will receive the required power needed from the crate power supply via crate connection P1

and EMCOR module connection J2. The EMCOR module will control up to 16 MCOR modules using

a GUI based software such as EPICS and the EMCOR front panel EPICS CA port.

Figure 1--Jumper locations

W7 P2

P10

P3

P4

P1

P11

W3

W8

Note that all of the signal connections for the EMCOR module J1 are identical to the Interface

Controller module J2 connector, but many of the EMCOR J2 connections are not the same as the

Interface Control module J1 connections. The signal names for the EMCOR connections (J1 and J2) are

shown in table 2 below.

Caution: Crate connections J and J4 on the back of the crate were designed for use with the C4

Interface Controller, and NOT the EMCOR Controller. Do not make connections to either J or J4 if

you are going to be using the EMCOR controller, as damage to the controller or external connections

could occur. Table has been created as a means to map the EMCOR J2 connections to the crate J and

J4 connections.

Table 2 EMCOR J1 and J2 ignal Connections

2 Signal 2 Signal 2 Signal 1 Signal 1 Signal 1 Signal

A1 +15V_IN_AUX B1 DGND C1 INTLK1+ A1 GND_0 B1 GND_4 C1 GND_8

A2 +15V_IN_AUX B2 DGND C2 INTLK1- A2 +REF_0 B2 +REF_4 C2 +REF_8

A +5V_IN_AUX B -15V_IN_AUX C INTLK2+ A3 AGND B3 AGND C3 AGND

A4 +5V_IN_AUX B4 MAG_FAULT0 C4 INTLK2- A4 MON_0 B4 MON_4 C4 MON_8

A5 DGND B5 MAG_FAULT1 C5 INTLK + A5 MCOR_FAULT0 B5 MCOR_FAULT4 C5 MCOR_FAULT8

A6 DGND B6 MAG_FAULT2 C6 INTLK - A6 FDBK_0 B6 FDBK_4 C6 FDBK_8

A7 -15V_IN_AUX B7 MAG_FAULT C7 INTLK4+ A7 GND_1 B7 GND_5 C7 GND_9

A8 -15V_IN_AUX B8 MAG_FAULT4 C8 INTLK4- A8 +REF_1 B8 +REF_5 C8 +REF_9

A9 +15V_IN_AUX B9 +5V_D C9 MAG_FAULT5 A9 AGND B9 AGND C9 AGND

A10 +5V_IN_AUX B10 AD7_CS C10 MAG_FAULT6 A10 MON_1 B10 MON_5 C10 MON_9

A11 +5V_IN_AUX B11 AD7_DOUTA C11 MAG_FAULT7 A11 MCOR_FAULT1 B11 MCOR_FAULT5 C11 MCOR_FAULT9

A12 +5V_IN_AUX B12 AD7_DOUTB C12 DGND A12 FDBK_1 B12 FDBK_5 C12 FDBK_9

A1 AD6_RESET B1 AD7_BUSY C1 RS2 2_DATA_OUT A13 GND_2 B13 GND_6 C13 GND_10

A14 AD6_FDATA B14 AD7_SCLK C14 RS2 2_DATA_IN A14 +REF_2 B14 +REF_6 C14 +REF_10

A15 AD6_CONVST B15 AD7_REFSEL C15 N/C A15 AGND B15 AGND C15 AGND

A16 AD6_SCLK B16 4KHZ_TRIG_POS C16 N/C A16 MON_2 B16 MON_6 C16 MON_10

A17 AD6_CS B17 AGND C17 DA5_SD0 A17 MCOR_FAULT2 B17 MCOR_FAULT6 C17 MCOR_FAULT10

A18 AD6_DOUTA B18 AGND C18 DA5_RESET A18 FDBK_2 B18 FDBK_6 C18 FDBK_10

A19 AD6_DOUTB B19 DGND C19 DA5_LDAC A19 GND_ B19 GND_7 C19 GND_11

A20 AD6_BUSY B20 DGND C20 DA5_CLR A20 +REF_ B20 +REF_7 C20 +REF_11

A21 AD6_REFSEL B21 +5V_A C21 DA5_SDIN A21 AGND B21 AGND C21 AGND

A22 AD7 RESET B22 +5V_A C22 DA5_SCLK A22 MON_ B22 MON_7 C22 MON_11

A23 AD7 FDATA B23 +5V_D C23 DA5_SYNC A23 MCOR_FAULT B23 MCOR_FAULT7 C23 MCOR_FAULT11

A24 AD7 CONVST B24 +5V_D C24 N/C A24 FDBK_ B24 FDBK_7 C24 FDBK_11

A25 HVDC(F) B25 GND RES+ C25 GND_RES- A25 GND_12 B25 MON_12 C25 AGND

A26 +5V_D (thru R84) B26 BULK ENA IN C26 N/C A26 +REF_12 B26 FDBK_12 C26 MCOR_FAULT12

A27 Water Sum Fault B27 BULK ENA OUT C27 N/C A27 FDBK_15 B27 +REF_1 C27 GND_1

A28 +5V_IN_CRATE B28 +5V_IN_CRATE C28 +5V_IN_CRATE A28 MCOR_FAULT15 B28 MON_1 C28 AGND

A29 DGND B29 DGND C29 DGND A29 MON_15 B29 FDBK_1 C29 MCOR_FAULT1

A30 +15V_IN_CRATE B30 +15V_IN_CRATE C30 +15V_IN_CRATE A30 AGND B30 +REF_14 C30 GND_14

A31 -15V_IN_CRATE B31 -15V_IN_CRATE C31 -15V_IN_CRATE A31 +REF_15 B31 MON_14 C31 AGND

A32 SYNC BUS B32 INH_BUS C32 RESET_BUS A32 GND_15 B32 FDBK_14 C32 MCOR_FAULT14

Table 3 Crate J3 and J4 connections to EMCOR J1 connections

EMCOR 2

Pin

Signal Name Corresponding

Crate 3 Pin

EMCOR 2

Pin

Signal Name Corresponding

Crate 4 Pin

A1 +15V_IN_AUX A1 A1 AD6 RESET A1

A2 +15V_IN_AUX A2 A14 AD6 FDATA A2

A +5V_IN_AUX A A15 AD6 CONVST A

A4 +5V_IN_AUX A4 A16 AD6 SCLK A4

A5 DGND A5 A17 AD6 CS A5

A6 DGND A6 A18 AD6 DOUTA A6

A7 -15V_IN_AUX A7 A19 AD6 DOUTB A7

A8 -15V_IN_AUX A8 A20 AD6 BUSY A8

A9 +15V_IN_AUX A9 A21 AD6 REFSEL A9

A10 +5V_IN_AUX A10 A22 AD7 RESET A10

A11 +5V_IN_AUX A11 A2 AD7 FDATA A11

A12 +5V_IN_AUX A12 A24 AD7 CONVST A12

B1 DGND B1 B1 AD7 BUSY B1

B2 DGND B2 B14 AD7 SCLK B2

B -15V_IN_AUX B B15 AD7 REFSEL B

B4 MAG FAULT0 B4 B16 4KHZ TRIG POS B4

B5 MAG FAULT1 B5 B17 AGND B5

B6 MAG FAULT2 B6 B18 AGND B6

B7 MAG FAULT B7 B19 DGND B7

B8 MAG FAULT4 B8 B20 DGND B8

B9 +5V_D B9 B21 +5V_A B9

B10 AD7 CS B10 B22 +5V_A B10

B11 AD7 DOUTA B11 B2 +5V_D B11

B12 AD7DOUTB B12 B24 +5V_D B12

C1 INTLK1+ C1 C1 RS2 2 DATA OUT C1

C2 INTLK1- C2 C14 RS2 2 DATA IN C2

C INTLK2+ C C15 N/C C

C4 INTLK2- C4 C16 N/C C4

C5 INTLK + C5 C17 DA5 SD0 C5

C6 INTLK - C6 C18 DA5 RESET C6

C7 INTLK4+ C7 C19 DA5 LDAC C7

C8 INTLK4- C8 C20 DA5 CLR C8

C9 MAGFAULT5 C9 C21 DA5 SDIN C9

C10 MAGFAULT6 C10 C22 DA5 SCLK C10

C11 MAGFAULT7 C11 C2 DA5 SYNC C11

C12 DGND C12 C24 N/C C12

EXT INTLK connection 1 Description

Crate connection J1, which is a BNC connector on the back of the crate labeled "EXT INTLK", must

be configured correctly for normal operation of the crate. As is currently the case with the Interface

Controller module, a closed switch must be present across J1 or an MCOR fault will be generated.

The signal name for this connection is 'Water_Sum_Fault'. An open switch will cause +5V on the

water_sum_fault circuits which will generate a fault condition and disable all MCOR modules.

Crate OK connection 2 Description

When properly configured this BNC connection may be used as a dry contact output to enable/disable a

properly configured Bulk Power Supply output.

A properly equipped power supply used as the bulk supply must have a connection available that will

enable the output of the supply with a short across the applicable pins. Consult the operator's manual

of the power supply in use for more specific information.

Event Receiver (EVR)

Currently these functions have not yet been implemented.

Fast Feedback

Currently the Fast Feedback function has not yet been developed.

EMCOR Crate Diagnostic Application

This is a Windows based GUI application primarily used as a diagnostic application to monitor and

reset certain faults, set and monitor MCOR channels, and turn on/off a properly configured bulk power

supply. A USB male Type A connection attached to a PC with a USB male Type B connection attached

to EMCOR connector J9 is required for use with this application.

The application may be used as soon as the crate has been powered up and can be used whether the

CPU boot process has been completed or not. If the CPU boot up process is not going to be performed,

both the serial and Ethernet cables (J7 and J5) do not need to be connected. Once the crate is powered

up and the power-up sequence of the EMCOR module has completed, a green (OK) LED on the

EMCOR module should be slowly flashing. A red LED on the MCOR module(s) may also be flashing

(assumes that the bulk supply is connected and enabled, and a closed switch across the crate J1

connector) which would indicate a fault on the MCOR module(s).

The application may now be opened and the main panel shown in screen shot 1 will appear.

To remove the fault(s) associated with any MCOR modules during the power up sequence, (assuming

there are any) click on the 'Faults' tab on the main panel. The 'Faults' panel will open up (screen shot

2). After the 'Refresh' tab of the 'Faults' panel is clicked, all faults associated with the MCOR modules

will show up in red ( a fault indication on this screen will correspond to a flashing red LED on the

indicated channel MCOR module). In screen shot 2 only one module is showing in red since the crate

is only populated with one MCOR module (channel 7). The fault can be cleared by checking the

'MCOR Reset' box and then clicking on the 'Refresh' tab. Note that the 'Faults' display shows two types

of faults, Latched and Immediate. The only way to clear a 'Latched' fault is with the software 'MCOR

Reset' selection. An 'Immediate' fault can be cleared by using the EMCOR front panel Reset button.

The 'Faults' display should now appear as shown in screen shot , with all MCOR faults appearing in

green as shown on the panel, and no flashing red LEDs as shown on the MCOR module(s). It should be

noted at this time that even though the 'Faults' panel displays 'Magnet' and 'External Interlock' faults,

they are not active on the EMCOR module at this time (have not been implemented) and will not

display faults. Once the fault(s) of the MCOR modules has been cleared, the EMCOR module and

MCOR modules are ready to be programmed per the instructions below.

The application is ideally suited for configuring the current setting on any MCOR module and then

determining if the output setting matches the desired setting. The following instructions can be used as

an example to set an MCOR module's current setting and then reading the value back to confirm that

the setting was properly performed. The screen shots below will aid in the use of the application.

From the main panel of the application click on the 'DAC' button.

Screen shot 1- Main Panel

8

Screen shot 2- Faults Panel with fault

Screen Shot 3- Faults Panel with no faults

Screen Shot 4-Channel Pulldown

Screen Shot 5-DAC Panel

Select the channel to be set from the 'Channel' pull-down (Screen shot 4) at the top left of the DAC

panel. Next, set the 'DAC Full Scale Current' setting from the 'Full Scale Current' table below. This

setting will be based on the type of MCOR module being used (for an MCOR 12 module as an

example, '12. 0768' would need to be entered in the 'DAC Full Scale Current' window). Once this

value has been set, you must then hit the 'Enter' key. Use the same table to determine the Monitor ADC

and Feedback ADC settings and enter those values using the 'Enter' button as well. Once those values

have all been entered, click the 'Configured' box at the bottom of the panel. Then set the 'Set Point' to

the desired value of current and hit the enter or return key (note that there must be a load connected to

the output on the back of the crate before any current will flow). The 'Set Point' window cannot be set

to a value unless the 'Configured' box has been checked. Click on the 'Refresh' button for the changes

to take effect on the panel display. Select the 'ADC' panel (from the main panel). This panel (screen

shot 5) will enable the user to monitor any settings made and determine that the output is the same as

what was requested (after clicking the 'Refresh' button). The 'DAC' panel also displays the Feedback

and Monitor current values for the channel selected.

Note that a ramp rate for the current to reach full level can be set by entering the desired value in the

'Ramp Rate' window (DAC Panel). The 'Ramp Mode' box must be displayed for the setting to take

effect after the enter button is pressed. The value entered in the ramp rate window is in amps/second.

The alternative to 'Ramp Mode' is the 'Immediate' Mode.

11

Full Scale Current Table

MCOR DAC Monitor ADC Feed-Back ADC DAC Full Scale Setting

0 0A 0A 0A 0.7692A

20 20A 20A 20A 20.5128A

12 12A 12A 12A 12. 0768A

9 9A 9A 9A 9.2 076A

7.5 7.5A 7.5A 7.5A 7.692 A

6 6A 6A 6A 6.15 84A

2 2A 2A 2A 2.05128A

1.5 1.5 1.5A 1.5A 1.5 846A

1 1 1A 1A 1.02564A

Screen Shot 6- ADC Raw Panel

12

The 'Register' Panel (screen shot 7) allows all 16 crate channels to be monitored for the following (top

to bottom) parameters:Note that readings do not automatically update. 'Refresh' must be utilized for

updated results.

■ Set Point

■ Current Set Point

■ Monitor ADC Reading

■ Monitor Average ADC Reading

■ Monitor Ripple Measurement (in uA)

■ Feedback ADC Reading

■ Feedback Average ADC Reading

■ Feedback Ripple Measurement (in uA)

■ Full scale DAC Set Point Current

■ Full scale Monitor ADC Read Back Current

■ Ramp Rate (amps/sec)

■ Samples per Average

■ Configuration/Status Register

■ Full scale Feedback ADC Read back Current

Screen Shot 7- Registers Panel (Channel Parameters)

13

The 'Bulk Supply' Panel is shown in screen shot 8 below. This panel is used for enabling/disabling an

external bulk supply only. The bulk supply must support being remotely enabled/disabled, which is

accomplished by the crate via the 'Crate OK' connection on the back of the crate. This connection is a

BNC connector (J2) which is a dry contact (relay) output. When enabled ('PS On/Off' box checked) a

short is placed across the enable connection of the power supply pins to turn the output of the bulk

supply on. The user must consult the manual of the specific power supply in use to determine the

connections necessary for this function. BiRa Systems can help with this if necessary.

It is necessary to configure the bulk supply properly to ensure that the supply comes up in the correct

state so that the output of the supply does not come on until commanded. The bulk supply voltage,

Over Current, Over Voltage protection must be set up locally and cannot be controlled by the EMCOR

module. The power supply should be set up so that when powered on the output is enabled but the

output is not on. Note that it is not necessary to remotely access the bulk supply output. The bulk

supply may be used manually by the user if desired.

Screen Shot 8- Bulk Supply Panel

The USB application can also be used for monitoring the Xilinx (FPGA) temperature and voltage.

From the main panel select 'XMON' and the panel shown in screen shot 8 will appear. The current

values of the 1.0V and 2.5V supply voltages and the temperature of the part will be shown upon

clicking the 'Refresh' button.

Screen Shot 9- Xilinx Monitor

To monitor the EMCOR board voltages select the 'V MON' tab from the main panel. Screen shot 10 is

representative of this panel after clicking the 'Refresh' button.

Screen Shot 10 EMCOR Board Voltages Panel

15

16

For System information the 'Sys Info' tab can be used as shown in screen shot 11.

Screen Shot 11- Sys Info Panel

The front panel of the EMCOR module is shown below. The J9 connector is used for USB

communication. The P9 connector (JTAG) is used for programming of the FPGA, which is done by

BiRa Systems and should never need to be accessed by the user. The jumper that can be seen in the P9

connector is for stability of the boot-up process and should not be removed. The EVR connector is not

active at this time. The EPICS CA (J5) connector is for Ethernet communication. The COM (J7)

connection port is used for serial communication. CPU RST (S2) is a switch that when activated will

reset the CPU, which will cause a re-boot of the module to occur. The Fast Feedback function is not

active at this time.

EMCOR Front Panel

17

Remote PCI Register Information

The tables below contain detailed information on the EMCOR Registers. Refer to the following tables

for use in accessing data from the EMCOR module.

Some of the registers may not be active since some of the features of the EMCOR module have not yet

been incorporated.

The registers may be accessed by a GUI that resides on the PC that contain the CPU boot-up software,

and is a LINUX based OS.

Should it be necessary or desirable to access the PCI Registers, the following instructions should be

used. The following instructions assume that the CPU boot-up process has completed normally (see

boot-up instructions below).

Open up a terminal on the LINUX based machine used for the boot up process, and enter the following,

being careful to make the entries exactly as shown.

"cd emcor-python-package/Python-RemotePCI-GUI". Once this information is entered you are in

the correct directory to access the function. Next, enter "python pyrpci_gui.py", which is the actual

python based GUI. In order to access a desired register it is first necessary to enter the IP address

(172.16.0.100) at the top of the GUI, and then hit the connect button. A screen shot of the register is

shown here.

18

Once the GUI has been accessed, the specific address of the register with the desired data must be

entered, and a read of the register executed. The data is in a 2 bit hex format which must then be

converted to a decimal equivalent. Information in the tables below will indicate what format the data

is in (generally signed or unsigned integer) and the units of the data.

As an example of how to convert the data to usable information, suppose that one wanted to know what

the Set point requested value was for channel 7. The BAR (Base Address Register) tells us that the

Channel Control Registers reside between address 0x00000000 to 0x00000 C0. The EMCOR channel

registers table tells us that the base address for channel 7 is 0x000001c0. Since the channel settings

registers table shows us that the information we're looking for (Set Point Requested) has an offset of

0x00, we would enter the address 0x000001c0 into the GUI and request a read of the information in

this register. In this case the data in the register reads 0x000f4240. The channel settings register tells us

this data is a signed integer format with units of uA. When translated to decimal, the result is 1000000,

or the equivalent of 1amp, which is the current set point for channel 7.

The BAR 0 (Base Address Register) Memory Map of the EMCOR Registers is shown below.

BAR 0 Address

0x00000 –

0x00 C0

Channel Control Registers

0x00400 –

0x004 C

Bulk Supply Registers

0x00440 –

0x0047C

MCOR ADC Control Registers

0x00480 –

0x004BC

Fault Registers

0x004C0 –

0x004FC

Waveform Capture Registers

0x00500 –

0x005 C

Interlocks and Magnet Faults

0x00540 –

0x0057C

MCOR Voltage Monitor

0x00580 –

0x005BC

Xilinx System Monitor

0x005C0 –

0x005FC

MCOR System Information

0x00600 –

0x0067C

512 Bytes Transceiver data

0x00680 –

0x006BC

Interrupt Registers

0x006C0 –

0x006FC

MCOR EVR Control Registers

0x01000–

0x017FE

EVR Register Interface from USB (No BAR)

0x01800 –

0x01FFF

EVR Data Buffer Memory from USB (No BAR)

0x40000 –

0x7FFFC

Waveform Memory

19

The Table below shows the offset of each of the 16 channels.

MCOR Channel Registers

Channel Base

0x0000 Channel 0

0x0040 Channel 1

0x0080 Channel 2

0x00C0 Channel

0x0100 Channel 4

0x0140 Channel 5

0x0180 Channel 6

0x01C0 Channel 7

0x0200 Channel 8

0x0240 Channel 9

0x0280 Channel 10

0x02C0 Channel 11

0x0 00 Channel 12

0x0 40 Channel 1

0x0 80 Channel 14

0x0 C0 Channel 15

The Tables below shows how each channel is configured.

Channel Settings Registers

Offset Reg

0x00 0 Set Point Requested. The Channel

will not respond to setpoint

commands unless the configure bit is

set.

Int 2 in uA

0x04 1 Current Set Point

0x08 2 Monitor ADC Reading

0x0C Monitor Average ADC Reading

0x10 4 Monitor Ripple Measurement

0x14 5 FeedBack ADC Reading

0x18 6 FeedBack Average ADC Reading

0x1C 7 FeedBack Ripple Measurement

0x20 8 Fullscale DAC SetPoint Current

0x24 9 Fullscale Monitor ADC ReadBack

Current

0x28 A Ramp Rate Int 2 uA/sec

0x2C B Samples per Average UInt 2

0x 0 C Configuration/Status Register

0x 4 D Set Configuration Register

0x 8 E Reset Configuration Register

0x C F Fullscale FeedBack ADC ReadBack

Current

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

MS Sedco

MS Sedco TDM installation instructions

Dynojet

Dynojet PCV F Installation Instructions and Technical Information

Beko

Beko Bekomat 14 Instructions for installation and operation

Motorline professional

Motorline professional MCS01 User& installer's manual

Purified Air

Purified Air UV-O 500 Technical and Operations Manual

Strahman

Strahman BI-TORQ FL-BT-149 Series Operation and maintenance manual

Lenze

Lenze E82ZAFSC010 Mounting instructions

Warren rupp

Warren rupp Sandpiper HDB1 1/2 Service & operating manual

Quectel

Quectel FC905A user manual

Roger

Roger EDGE1 Series Instruction and warnings for the installer

cias

cias MICRO-RAY-CARD8 installation manual

Hitachi

Hitachi SU-1000 operating instructions