Eurotron IRtec Rayomatic 20 User manual

EUROTRON Instruments S.p.A.

Viale F.lli Casiraghi 409/413

20099 Sesto S.Giovanni (MI) - Ital

Tel. +39-02 248820.1 Fax +39-02 2440286

eurotron

IRtec Rayomatic 20/40

Process Infrared Thermometers

Instruction Manual MM850341 ed.01a

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________2____________________________________________

INTRODUCTORY NOTE

A

TTENTION

: T

HIS MA NUAL IS VALID F OR

IR

TEC

R

AYOMATIC

20/40

WITH SERIAL NUMBER HIGHER THAN

0038294.

This publication contains operating instructions, as well as a description of the principles of operation,

of

IRtec Rayomatic 20/40

IR thermometers.

This information covers all models of the instrument, including the basic equipment and its options and

accessories. This manual is a complete “USER UIDE”, providing step-by-step instructions to operate

the instrument in each of its designed functions.

Eurotron

has used the best care and efforts in preparing this book and believes the information in this

publication are accurate. The

Eurotron

products are subjected to continuous improvement, in order to

pursue the technological leadership; these improvements could require changes to the information of

this book.

Eurotron

reserves the right to change such information without notice.

No part of this document may be stored in a retrieval system, or transmitted in any form, electronic or

mechanical, without prior written permission of

Eurotron Instruments.

IRtec

IR thermometers u ses sophisticated analogic and digital technologies. A ny m aintenance

operation must be carried out by qualified personnel

ONLY

. We recommend to contact our technicians

for any support requirements.

IRtec

is fully tested in conformity with the directive n°89/336/CEE Electromagnetic Compatibility.

Eurotron

shall not be liable in any event, technical and publishing error or omissions, for any

incidental and consequential damages, in connection with, or arising out of the use of this book.

IRtec is a registered trademark of Eurotron Instruments S.p. .

ll right reserved

Copyright © 2000, 01

EUROTRON Instruments S.p.A.

Viale Fratelli Casiraghi 409/413

20099 Sesto San Giovanni (MI) – Italy

Tel.: +39-02 248820.1 – Fax: +39-02 2440286

e-mail: info@eurotron.com

http://www.eurotron.com

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________3____________________________________________

TABLE OF CONTENTS

1

GENERAL DESCRIPTION 5

1.1

Specifications ------------------------------------------------------------------------------------------------ 6

1.1.1

IRtec Rayo atic 20----------------------------------------------------------------------------------------- 6

1.1.2

IRtec Rayo atic 40----------------------------------------------------------------------------------------- 8

1.2

Ordering code-----------------------------------------------------------------------------------------------10

1.2.1

IRtec Rayo atic 20----------------------------------------------------------------------------------------10

1.2.2

IRtec Rayo atic 40----------------------------------------------------------------------------------------11

2

PHYSICAL DESCRIPTION 12

3

PRINCIPLE OF OPERATION 14

3.1

Modular syste s-------------------------------------------------------------------------------------------14

3.2

Basic ele ents ---------------------------------------------------------------------------------------------14

3.2.1

Optical syste ----------------------------------------------------------------------------------------------15

3.2.2

Detectors-----------------------------------------------------------------------------------------------------15

3.2.3

Input stage---------------------------------------------------------------------------------------------------15

3.2.4

Microcontroller----------------------------------------------------------------------------------------------16

3.2.5

Serial co unica tion -------------------------------------------------------------------------------------16

3.2.6

Output stage ------------------------------------------------------------------------------------------------16

3.2.7

Te perature co pensation------------------------------------------------------------------------------16

3.2.8

Power supply------------------------------------------------------------------------------------------------16

3.2.9

Laser pinpointing-------------------------------------------------------------------------------------------16

3.2.10

Laser pinpointing---------------------------------------------------------------------------------------16

4

SIGNAL PROCESSING 17

4.1

Average ------------------------------------------------------------------------------------------------------17

4.2

Peak ----------------------------------------------------------------------------------------------------------17

4.3

Valley---------------------------------------------------------------------------------------------------------18

4.4

Peak-Picker -------------------------------------------------------------------------------------------------18

4.4.1

Peak-Picker with reset ------------------------------------------------------------------------------------18

4.4.2

Peak-Picker delayed --------------------------------------------------------------------------------------19

4.5

Valley-Picker ------------------------------------------------------------------------------------------------20

4.5.1

Valley-Picker with reset-----------------------------------------------------------------------------------20

4.6

Track and Hold ---------------------------------------------------------------------------------------------20

5

UNPACKING 21

6

INSTALLATION 22

6.1

Electrical connection --------------------------------------------------------------------------------------22

6.2

Laser Pinpointing syste s -------------------------------------------------------------------------------23

6.3

Reset input --------------------------------------------------------------------------------------------------24

6.4

Alar s--------------------------------------------------------------------------------------------------------24

6.4.1

Alar output -------------------------------------------------------------------------------------------------25

6.5

E issivity adjust ent -------------------------------------------------------------------------------------26

6.6

Positioning---------------------------------------------------------------------------------------------------26

6.7

Mounting and Align ent----------------------------------------------------------------------------------26

7

MAINTENANCE 28

7.1

Purge Air Supply -------------------------------------------------------------------------------------------28

7.2

Water Supply------------------------------------------------------------------------------------------------28

7.3

Optic cleaning-----------------------------------------------------------------------------------------------28

7.4

Mounting Device -------------------------------------------------------------------------------------------28

7.5

Interconnection Cable-------------------------------------------------------------------------------------28

7.6

Storage-------------------------------------------------------------------------------------------------------28

8

SUPPORT AND ACCESSORIES 29

8.1

Positioning plates ------------------------------------------------------------------------------------------29

8.2

Water cooling jacket---------------------------------------------------------------------------------------29

8.3

Air purge devices-------------------------------------------------------------------------------------------30

8.3.1

Air treat ent equip ent----------------------------------------------------------------------------------32

8.4

Sighting tubes-----------------------------------------------------------------------------------------------32

8.5

Other accessories------------------------------------------------------------------------------------------32

9

SERIAL COMMUNICATION 33

9.1

S art/RS232 adapter-------------------------------------------------------------------------------------33

9.1.1

Connections-------------------------------------------------------------------------------------------------33

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________4____________________________________________

10

CONFIGURATION SOFTWARE 35

10.1

Load configuration -----------------------------------------------------------------------------------------35

10.2

Change the configuration---------------------------------------------------------------------------------35

10.3

Save configuration-----------------------------------------------------------------------------------------37

10.4

Monitor -------------------------------------------------------------------------------------------------------37

11

LOGMAN GRAPHIC SOFTWARE 38

11.1

Start acquisition --------------------------------------------------------------------------------------------38

11.2

Configuration------------------------------------------------------------------------------------------------38

12

LOGMAN LOGGING DATA MANAGER 41

12.1

Progra Archi tectu re--------------------------------------------------------------------------------------41

12.1.1

Toolbars--------------------------------------------------------------------------------------------------42

13

CERTIFICATES 45

13.1

Warranty Ter s --------------------------------------------------------------------------------------------45

13.2

Letter of Confor it y----------------------------------------------------------------------------------------45

APPENDI 46

A1

EMC Confor ity------------------------------------------------------------------------------------------------47

A2

How to deter ine an object e issiv it y --------------------------------------------------------------------49

A2.1

Typical E issi vi ty Values---------------------------------------------------------------------------------49

A2.2

Metals - Typical E iss iv ity Values ---------------------------------------------------------------------50

A2.3

Non-Metals - Typica l E iss iv it y Values --------------------------------------------------------------52

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________5____________________________________________

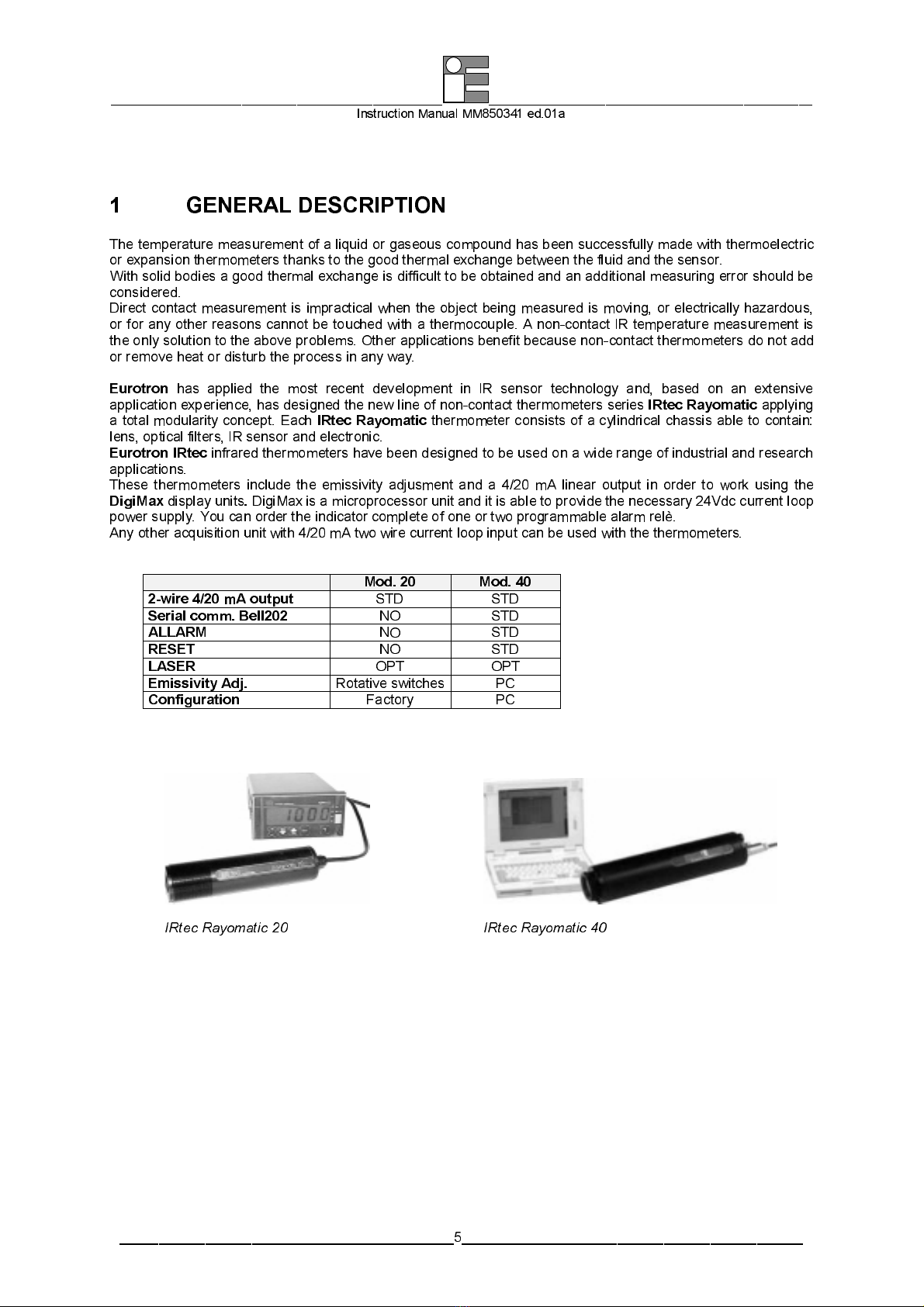

1 GENERAL DESCRIPTION

The te perature easure ent of a liquid or gaseous co pound has been successfully ade with ther oelectric

or expansion ther o eters thanks to the good ther al exchange between the fluid and the sensor.

Wi t h soli d bodies a good ther a l exchange is di ff icu lt to be obta ined and an additio nal easur ing error should be

considered.

Direct contact easure ent is i practical when the object being easured is oving, or electrically hazardous,

or for any other reasons cannot be touched with a ther ocouple. A non-contact IR te perature easure ent is

the only solution to the above proble s. Other applications benefit because non-contact ther o eters do not add

or re ove heat or disturb the process in any way.

Eurotron

has applied the ost recent develop ent in IR sensor technology and, based on an extensive

applica ti on experience, has designed the new line of non- con tac t ther o eters ser ies

IRtec Rayomatic

applying

a total odularity concept. Each

IRtec Rayomatic

ther o eter consists of a cylind r ica l chass is able to co nta in :

lens, optical filters, IR sensor and electronic.

Eurotron

IRtec

infra red ther o eters have been designed to be used on a wide range of indust r ial and research

applications.

These ther o eters include the e issivity adjus ent and a 4/20 A linear output in order to work using the

DigiMax

display units

.

DigiMax is a icrop rocessor un it and i t is able to prov ide the necessary 24Vdc current loop

power supply. You can order the indi cat or co plete of one or two prog ra a ble ala r relè.

Any other acquisi t ion unit with 4/20 A two wire current loo p i nput can be used with the ther o eters.

Mod. 20 Mod. 40

2 wire 4/20 mA output

STD STD

Serial comm. Bell202

NO STD

ALLARM

NO STD

RESET

NO STD

LASER

OPT OPT

Emissivity Adj.

Rotative switches

PC

Configuration

Factory PC

IRtec Rayomatic 20 IRtec Rayomatic 40

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________6____________________________________________

1.1 S ecifications

1.1.1 IRtec Rayomatic 20

•

Measuring ranges:

see par 1.2.1 Table A

•

Accuracy:

@ 23°C ±5°C and

ε

=1.0

IRtec Rayomatic 20-100 and 160:

±0.5% of rdg.

IRtec Rayomatic 20-814 :

±1% of rdg. or ±1 °C whichever is greater

•

Repeatability:

IRtec Rayomatic 20-100 and 160:

± 0.25% of the reading

IRtec Rayomatic 20-814 :

± 0.5% of the reading or ±0.5 °C whichever is greater

•

Response time:

IRtec Rayomatic 20-100 and 160:

28 s (t95)

IRtec Rayomatic 20-814 :

100 s (t95)

•

Type of detector:

IRtec Rayomatic 20-100:

Siliciu

IRtec Rayomatic 20-160:

InGaAs

IRtec Rayomatic 20-814 :

Ther opile

•

Spectral band:

see par 1.2.1 Table A

•

Emissivity:

adjustab le with 2 rotat ive swit ch fr o 0.30 to 1.00

•

Working temperature:

fro -20 to +60 °C (wit hou t cool ing )

fro 0 to +50 °C (for la ser operation )

•

Storage temperature:

fro -30 to +70 °C Sil ic iu and In GaAs detectors

fro +10 to +60 °C Ther opile

•

Output signal:

4/20 A 2 wire current loop – ax load 700

Ω

•

Temperature stability:

±0.1 °C/°C for the band exceeding +18 to +28°C

•

Target pinpointing:

optiona l on-boa rd laser ai in g sys te w ith re ote co and

•

Environmental rating:

IP65 (NEMA-4)

•

Power supply:

4-20mA loop

: fro 12 to 32 Vdc

Laser pinpointing

: 12 to 32 Vdc

•

Dimension / Weight:

ø 45 x 200 - 0.5 Kg

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________7____________________________________________

Note:

•

Nominal target @ 95% energy

•

Optional laser pinpointing system not available on 814-5 and 814-6 models

When the laser pinpointing system is installed, m ltiply the act al target diameter by 1.2

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________8____________________________________________

1.1.2 IRtec Rayomatic 40

•

Measuring ranges:

see par 1.2.2 Table A

•

Accuracy:

@ 23°C ±5°C and

ε

=1.0

IRtec Rayomatic 40-100:

±0.5% of rdg.

IRtec Rayomatic 40-160:

±0.5% of rdg.

IRtec Rayomatic 40-814:

±1% of rdg. or ±1°C whichever is greater

IRtec Rayomatic 40-390:

±1% of rdg.

IRtec Rayomatic 40-460:

±1% of rdg.

IRtec Rayomatic 40-510:

±1% of rdg.

IRtec Rayomatic 40-343:

±1% of rdg. or ±3°C whichever is greater

IRtec Rayomatic 40- 90:

±1% of rdg. or ±2°C whichever is greater

•

Repeatability:

IRtec Rayomatic 40-100:

±0.25% of rdg.

IRtec Rayomatic 40-160:

±0.25% of rdg.

IRtec Rayomatic 40-814:

±0.5% of rdg. or ±0.5°C whichever is greater

IRtec Rayomatic 40-390:

±0.5% of rdg.

IRtec Rayomatic 40-460:

±0.5% of rdg.

IRtec Rayomatic 40-510:

±0.5% of rdg.

IRtec Rayomatic 40-343:

±0.5% of rdg. or ±1.5°C whichever is greater

IRtec Rayomatic 40- 90:

±0.5% of rdg. or ±1.5°C whichever is greater

•

Response time:

IRtec Rayomatic 40-100: 28ms (t95)

IRtec Rayomatic 40-160: 28ms (t95)

IRtec Rayomatic 40-814: 100ms (t95)

IRtec Rayomatic 40-390: 100ms (t95)

IRtec Rayomatic 40-460: 100ms (t95)

IRtec Rayomatic 40-510: 100ms (t95)

IRtec Rayomatic 40-343: 1000ms (t95)

IRtec Rayomatic 40- 90: 1000ms (t95)

IRtec Rayomatic 40-ratio: : 38ms (t95)

•

Type of detector:

IRtec Rayomatic 40-100:

Siliciu

IRtec Rayomatic 40-160:

InGaAs

IRtec Rayomatic 40-814 :

Ther opile

•

Spectral band:

see par 1.2.2 Table A

•

Emissivity:

adjustab le by PC fro 0.30 to 1.00

•

Temperature drift:

±0.1 °C/°C for the band exceeding +18 to +28°C

•

Working temperature:

fro -20 to +60 °C (wit hou t cool ing )

fro 0 to +50 °C (for la ser operation )

•

Storage temperature:

fro -30 to +70 °C Sil ic iu and In GaAs detectors

fro +10 to +60 °C Ther opile

•

Digital communication:

Bell 202 superi posed on 2-wire current loo p

RS232 with optional adapter

•

Output signal:

4/20 A 2 wire current loop – ax load 700

Ω

•

Target pinpointing:

optiona l on-boa rd laser ai in g sys te w ith re ote co and

•

Environmental rating:

IP65 (NEMA-4)

•

Power supply:

Loop: fro 12 to 32 V dc

Laser pinpointing: 12 to 32 Vdc

•

Dimension / Weight:

ø 45 x 200 - 0.5 Kg

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________9____________________________________________

Note:

•

Nominal target @ 95% energy

•

Optional laser pinpointing system not available on 814-5 and 814-6 models

•

When the laser pinpointing system is installed, m ltipy the act al target diameter by 1.2

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________10____________________________________________

1.2 Ordering code

1.2.1 IRtec Rayomatic 20

cat. 1130 - A - B - C – D – E - F

Table A B CWL

φ

target/distance Range

100-1 0.9

µ

6 @ 500 600 to 1600°C (1100 to 2900°F)

100-2 0.9

µ

16 @ 1000 600 to 1600°C (1100 to 2900°F)

160-1 1.6

µ

6 @ 500 300 to 1300°C (570 to 2350°F)

160-2 1.6

µ

3 @ 300 300 to 1300°C (570 to 2350°F)

160-3 1.6

µ

2 @ 100 300 to 1300°C (570 to 2350°F)

814-1 8-14

µ

21 @ 600 -25 to 1000°C (-15 to 1800°F)

814-5 8-14

µ

80 @ 1000 0 to 800°C (32 to 1450°F)

814-6 8-14

µ

10 @ 65 0 to 400°C (32 to 750°F)

Table C Signal output

2 4÷20 A 2-wire current loop

Table D Pinpointing system

0 None

1 built-in laser pinpointing

Table E Electrical connection cable

1 2 long - 2 wires shilded

2 8 long - 2 wires shilded

9 Special lenght

Table F Report of Calibration

0 None

1 Eurotron NIST or EA traceable certificate with data

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________11____________________________________________

1.2.2 IRtec Rayomatic 40

cat. 1140 - A - B - C – D – E - F

Table A B CWL

φ

target/distance Range

100-1 0.9

µ

6 @ 500 600 to 1600°C (1100 to 2900°F)

100-2 0.9

µ

16 @ 1000 600 to 1600°C (1100 to 2900°F)

160-1 1.6

µ

6 @ 500 300 to 1300°C (570 to 2350°F)

160-2 1.6

µ

3 @ 300 300 to 1300°C (570 to 2350°F)

160-3 1.6

µ

2 @ 100 300 to 1300°C (570 to 2350°F)

814-1 8-14

µ

21 @ 600 -25 to 1000°C (-15 to 1800°F)

814-5 8-14

µ

9 @ 300 0 to 1000°C (32 to 1800°F)

814-5 8-14

µ

3.5 @ 140 0 to 1000°C (32 to 1800°F)

814-5 8-14

µ

80 @ 1000 0 to 800°C (32 to 1450°F)

814-6 8-14

µ

10 @ 65 0 to 400°C (32 to 750°F)

22C-1 ratio 20 @ 1000 600 to 2000°C (1100 to 3630°F)

22C-2 ratio 6 @ 600 300 to 1 300°C (570 to 2350°F)

343-1 3.4

µ

26 @ 500 100 to 400°C (210 to 750°F)

390-1 3.9

µ

17 @ 550 600 to 1300°C (1100 to 2350°F)

460-1 4.6

µ

17 @ 550 400 to 1600°C (750 to 2900°F)

510-1 5.1

µ

17 @ 550 150 to 1300°C (300 to 2350°F)

510-2 5.1

µ

8.5 @ 300 800 to 2000°C (1470 to 3630°F)

790-1 7.9

µ

17 @ 550 40 to 600°C (104 to 1100°F)

Table C Signal output

2 4÷20 A 2-wire current loop with superi posed serial co unicat ion

Table D Pinpointing system

0 None

1 built-in laser pinpointing

Table E Electrical connection cable

1 2 long - 6 wires shielded

2 8 long - 6 wires shielded

9 Special length

Table F Report of Calibration

0 None

1 Eurotron NIST or EA traceable certificate with data

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________12____________________________________________

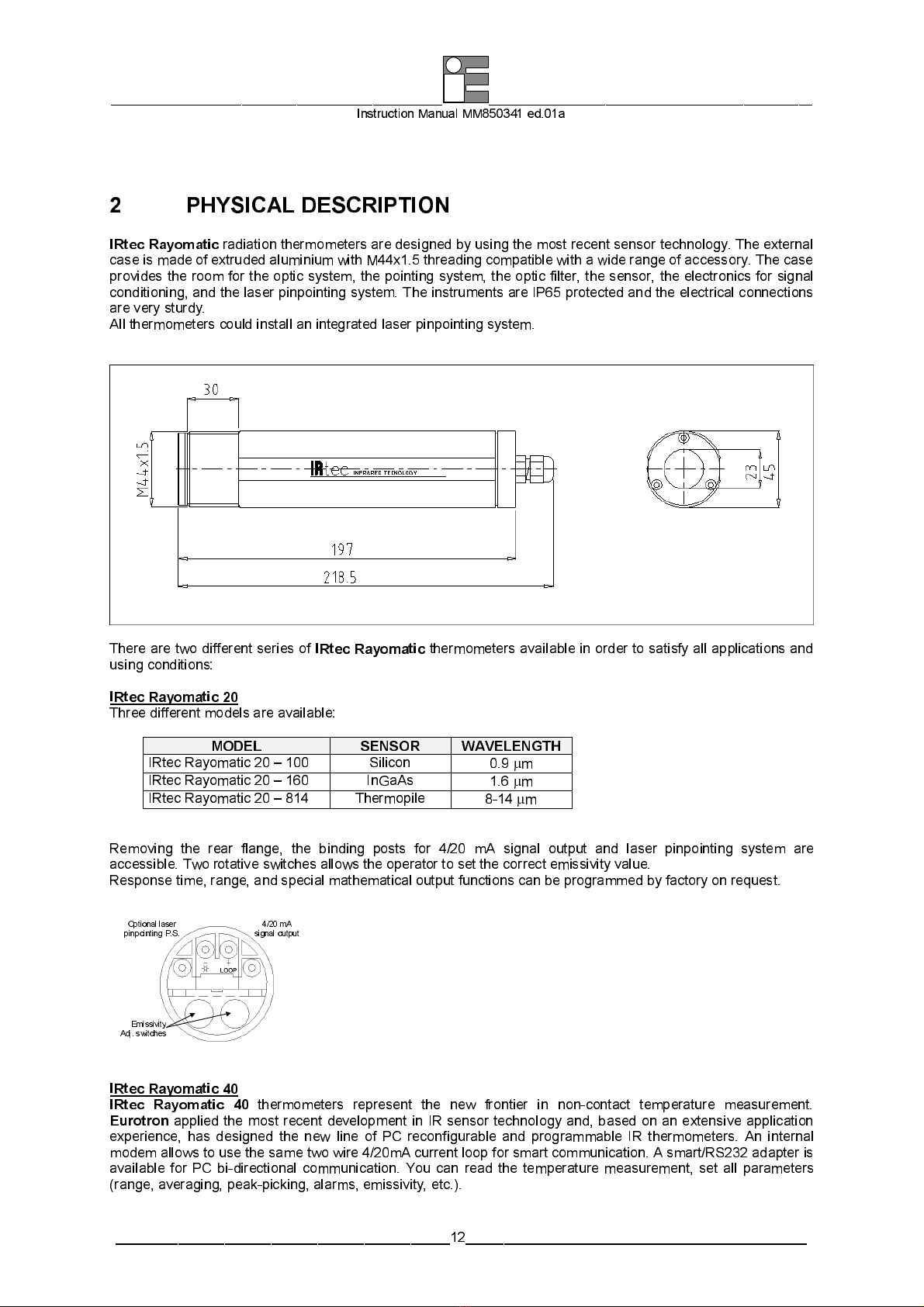

2 PHYSICAL DESCRIPTION

IRtec

Rayomatic

radiation ther o eters are designed by using the ost recent sensor technology. The external

case is ade of extruded alu iniu with M44x1.5 th reading co pat ib le with a wide range of accessory. The case

provides the roo for the optic syste , the pointin g syste , the opt ic fi lter , the sensor , the electronics for signa l

condit ion ing, and the l aser p inpo int ing sys te . The in st ru ents a re IP65 pro tected and the electrica l con nectio ns

are very sturdy.

All ther o eters could install an integrated laser pinpointing syste .

There are two different series of

IRtec Rayomatic

ther o eters available in order to satisfy all applications and

using conditions:

IRtec Rayomatic 20

Three different odels are avai lab le:

MODEL SENSOR WAVELENGTH

IRtec Rayo atic 20 – 100 Silicon 0.9

µ

IRtec Rayo atic 20 – 160 InGaAs 1.6

µ

IRtec Rayo atic 20 – 814 Ther opile 8-14

µ

Re oving the rear flange, the binding posts for 4/20 A signal output and laser pinpointing syste are

accessible. Two rotative switches allows the operator to set the correct e issivity value.

Response ti e, range, and special athe atical output functions can be progra ed by factory on request.

Emissivit

y

Adj. switches

Optional laser

pinpointing P.S. 4/20 mA

signal output

IRtec Rayomatic 40

IRtec Rayomatic 40

ther o eters represent the new frontier in non-contact te perature easure ent.

Eurotron

applied the ost recent develop ent in IR sensor technology and, based on an extensive application

experience, has designed the new line of PC reconfigurabl e and progra ab le IR ther o eters. An interna l

ode a l lows to use the sa e two wire 4/20 A current loop for s art co unic at ion . A s a rt /RS232 adapter is

available for PC bi-directional co unication. You can read the te perature easure ent, set all para eters

(range, averaging , peak-pi cki ng, alar s , e issi vi ty , etc.) .

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________13____________________________________________

Two auxiliary lines can be progra ed a nd used for funct ion and ala r reset and to drive alar relè .

Four different odels are ava i lab le:

MODEL WAVELENGTH

IRtec Rayo atic 20 – 100 0.9

µ

IRtec Rayo atic 20 – 160 1.6

µ

IRtec Rayo atic 20 – 814 8-14

µ

IRtec Rayo atic 20 – X/Y X/Y

µ

HW Reset

Optional laser

pinpointing P.S. 4/20 mA

signal ou tput

A la rm output

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________14____________________________________________

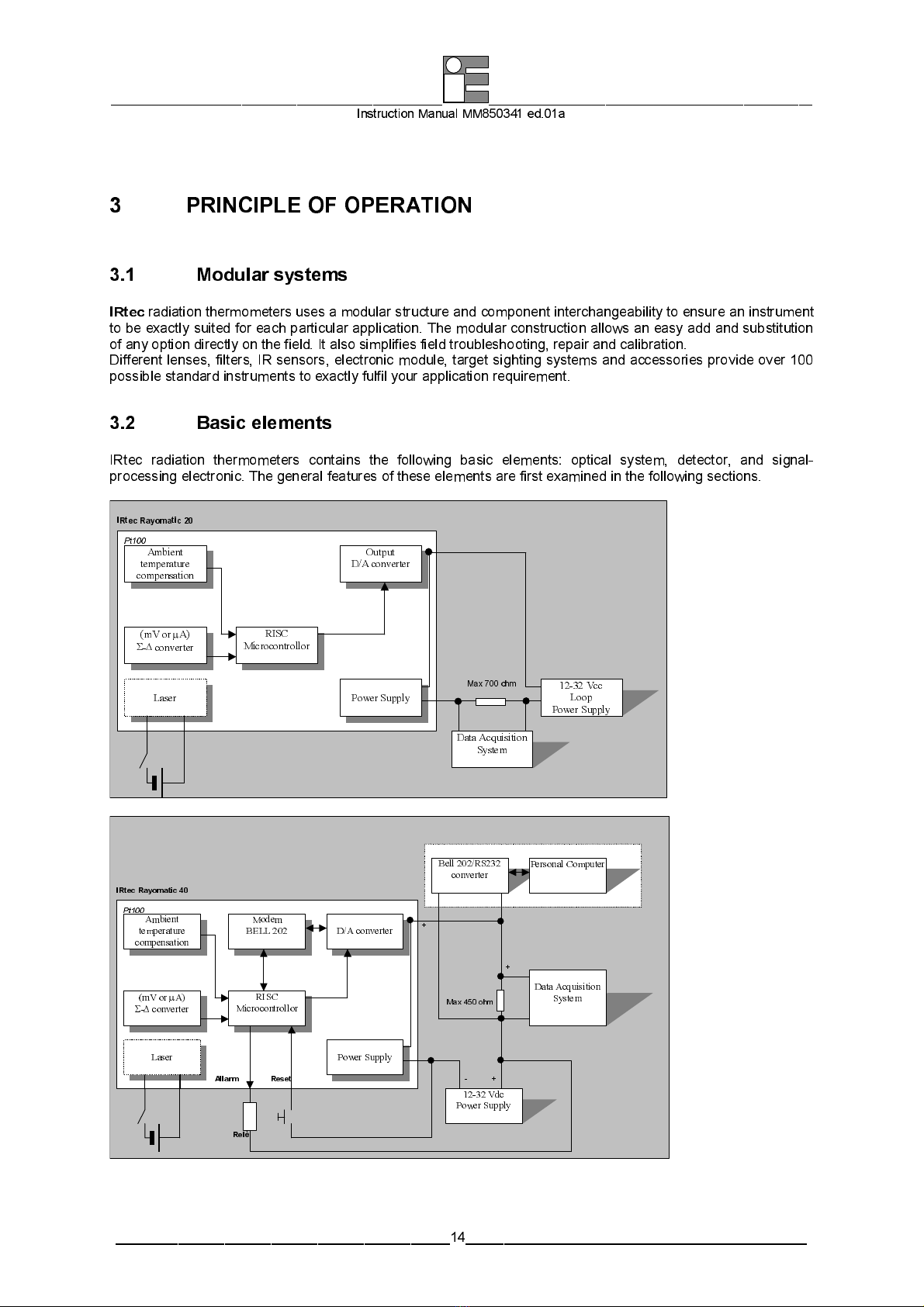

3 PRINCIPLE OF OPERATION

3.1 Modular systems

IRtec

radiation ther o eters uses a odular structure and co ponent interchangeability to ensure an instru ent

to be exactly suited for each particular application. The odular construction allows an easy add and substitution

of any option direct ly on the field. I t also si pl i fies f ield tro ubl eshooting , repair and cal ib rat ion .

Different lenses, filters, IR sensors, electronic odule, target sighting syste s and accessories provide over 100

possible standard instru ents to exactly fulfil your application require ent.

3.2 Basic elements

IRtec radiation ther o eters contains the following basic ele ents: optical syste , detector, and signal-

processing electronic. The general features of these ele ents are first exa ined in the following sections.

Ambient

temperature

compensation

(mV or

µ

A)

Σ

-

∆

converter

RISC

Mi crocontrollor

Power Supply 12- 2 Vcc

Loop

P ower Supply

Data Acquisition

System

O utput

D/A converter

IRtec Rayomatic 20

Pt100

Laser

M ax 700 ohm

Ambient

temperature

compensation

(mV or

µ

A)

Σ

-

∆

converter

RISC

Microcontrollor

Power Supply

12- 2 Vdc

Power Supply

Bell 202/RS2 2

converter Personal Computer

Reset

Modem

BELL 202

D/A converter

IR tec Rayomatic 40

Pt100

Laser

Allarm

Max 45 0 o hm

Data Acquisition

System

- +

+

+

Relè

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________15____________________________________________

3.2.1 O tical system

The detector is positioned at a focus distance of a high quality lens. The lens for s an i age of the source in the

plane of the detector. The size of the cone of radiation accepted fro an axial point of the target and, the

irrad iance at the detector, is deter ined b y the clear aperture of the lens, while the active area o f the detector

deter ines the f ield of view. The lens and detector then act as the aperture and field stop of the syste

respectively.

3.2.2 Detectors

Thermopile

A ther opi le contain a large nu ber of ther ocouples in a very s all area. The ther ocouples are connected

together and the output is the difference between the a bient te perature (cold junction) and the te perature

collected by the optical syste (hot junction).

Inspite of la rge nu ber of ther ocouples, the signal outpu t is very s all: few

µ

V/°C. The response ti e of the

detector is very long because the detector ust be war i ng up (or coo led) by the collected energy.

The waveband is deter ined by an add it iona l op t ica l f i lter chose by Eurot ron for the speci fic app li cat ion . Th is

soluti on per its to reduce distu rbs due by at osphere absorpti on and to axi ise t he output signa l.

Photodiode

Both Siliciu and InGaAs photodiode principle is co pletely different fro ther opile: the collected energy is

transfor ed in a electron flow. The result is a current proportional with the incident energy.

This trans for a t ion is very fas t (onl y few

µ

S). This ti e the response ti e of the easuring syste is li ited by

electronics: high resolut ion and low energy con su pt ion , ak e it a lit tle bi t slower.

The waveband is deter ined by the phys ica l charac teris t ic of the sensor.

Ratio detectors

Special IR ap pl ica t ions could no t be so lved us ing the stan dard onochr o at ic ther o eters. A ratio detector

could be the solution.

Typical proble s which wil l cause an inco rrect reading inc lud e:

•

s all objects e.g. to s all to fill the target area

•

s oke, dust or stea which obscure the line of sight

•

dirty windows in the process

•

e issivit y of the produc t changes (due to changes in al loy or surf ace condi tio n) .

A ratio detector is a sing le chip tw in detector wi th di fferent worki ng wavelengths. The rat io of the two si u lta neous

easure ents is independent fro e issivity and the result is the correct target te perature.

Every ratio ther o eter has a li it as to how uch signa l can be lost. Th is is referred as t he reducti on ra t io that

can vary up to 90% without effecting the easure ent accuracy. To be also kept in consideration that the loss in

signal can co e fro 3 sources:

•

low e issivi ty of the target

•

object too s all to f il l the co ne of visi on

•

obstruction caused by stea , s oke, dirt and dirty windows

In all the above condition a ratio ther o eter will operate with better accuracy than any onochro atic

ther o eter. The IRtec “Rayo atic” ther o eters was designed to operate with spectral bands with li ited

te perature coefficient.

3.2.3 In ut stage

Is the ost i portant part of the ther o eter. It should be able to interface the detector to the icro-controller.

IRtec Rayo atic series uses different kind of detectors (ther opile, photod iode, and ra t io detectors) with dif ferent

operating specifications.

•

Ther opile odels needs electronics with high i pedance input and very low drift.

•

Photodiode odels needs fast electronics .

•

Ratio odels needs electronics able to drive a double detector.

For the best odula ri ty of the easuring syste , Euro tron has developed special configu rab le electronics to eet

all require ents.

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________16____________________________________________

3.2.4 Microcontroller

Microcontroller has to anage all ther o eter functionality. It should be fast, with low absorption, with integrate

e ory, serial interface, etc.

Eurotron’s IRtec Rayo ati c use a R ISC processor with intern al re-wr ita ble FLASH e ory.

3.2.5 Serial communication

This odule is included in

IRtec Rayomatic 40

only. This odule consist of a special ode to i ple ent serial

co unica t ion on the ther o eter.

The s art IRtec Rayo at ic l ine uses a digi ta l co unic at ion ethod superi posed on the 2 w ire 4-20 A loop to

co unica te with PC, lap- top and/or handheld co unica to rs.

The co unicat ion capab i li ty also eans that a PC can be used both for re o te calibra tio n and tra ns i tter

operative ode configuration.

The digital protocol operates using the frequency shift keying (FSK) principle, which is based on the Bell 202

co unica t ion sta ndar d where si ne waves are superi posed on the dc analog signa l to gives si u ltaneous

analog and dig ital co unica tion

Te perature unit , peak hold , e issiv it y, average ca n be p rog ra ed thro ugh the dig ita l port using either a PC or

a dedicated co unica tor.

3.2.6 Out ut stage

This odule is based by a D/A converter to transfor t he te perature easure ents fro the icrocontroller

digita l for at to the cur rent s igna l. The sign al output fro t he ther o eter is a 4/ 20 A on 2-w ire cur rent loop

linear with the te perature range.

3.2.7 Tem erature com ensation

All IR detector are a bient te perature sensible. Detectors easure the difference between detector and target

energy. To obtain the correct value of target te perature, it is necessary to easure the detector te perature

and add it to the detector easure ent. A Pt100 is ounted on the detector and icroco ntroller reads the

te perature and akes the co p uta tion.

3.2.8 Power su ly

A power supply s tage is bu il t- in the ther o eter for adaptin g the current loop supp ly ( f ro 12 to 32 Vdc) to al l

digital and analogue circuits.

3.2.9 Laser in ointing

IRtec Rayo atic ther o eters can be optionally equipped with a laser pinpointing syste to si plify aligne ent

operation.

When target has s all and cr it ica l di ensi ons the laser ai i ng syste can be activated by operator to check and

adjust appropriate align ent of ther o eter.

A separate (12-32 Vdc ax. 100 A) power supply input all o ws operator to use it only when necessary.

3.2.10 Laser in ointing

IRtec Rayo atic ther o eters can be optionally equipped with a laser pinpointing syste to si plify align ent

operation.

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________17____________________________________________

4 SIGNAL PROCESSING

When a radiation ther o eter is e ployed in an on-line syste , its signal ay be subjected to large fluctuations.

Ti e function facilities are useful to retain the signal levels that are ore likely to represent the true target

te perature.

Eurotron IR ther o eters can be fa cto ry pre-set wi th one of the signal p rocessi ng facil i ties: averag ing , T rac k &

Hold, Peak, Valley, Peak-Picking, Valley-Picking, etc.

IRtec Rayomatic 40

functions can be progra ed fro user by using a Personal Co puter, a Bell202/RS232

adapter and a configuration software.

IRtec Rayomatic 20

Average function can be p rogr a ed by fact ory only .

4.1 Average

Rapid te perature fluctuations about a true ean value can ake the ther o eter output unsuitable for

recording and cont ro l. In t hese cases the average fun ct ion c an be used to p rov ide a s oo thed s igna l . The ou tpu t

signal Avu is given by:

Avu =Avp + (M – Avp) * 2

∆

T / D

where:

M

= Actual te perature

Avu

= Output average

Avp

= Previous average

∆

T

= sa pling ti e

D

= Da ping in seconds (progra able)

Temperature

Temperature with constant D>0

Range 0..99

Actual temperature

(D=0)

Time

4.2 Peak

The Peak function holds a axi u te perature and retain i ts unt il a h igher va lue appear o r an external reset

signal appear to decay the output to the current te perature easure ent.

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________18____________________________________________

4.3 Valley

The Valley function holds the ini u te perature and retain its until a lower value appear or an external reset

signal appear to increase the output to the current te perature easure ent.

4.4 Peak-Picker

The peak-picker function holds a peak signal and allows it to decay slowly until the arrival of the next peak. It is

used in such appli cat ion s as ro l lin g il ls where the signa l is o ccas iona l ly lowered by stea , s oke, water

droplets, etal scale, etc. When Peak-Picker function is progra ed, the 4/20 A output will follows the

athe atical expression below:

U = Peak – (PickDec * 2

∆

T)

dove :

U

= output signal

Peak

= peak signal

PickDec

= D ecay rate °C/sec (progra able)

∆

T

= sa pling ti e

Temperature

Time

Decay rate (PickDec)

Programmable (0.0 to 1999.9 °C/S)

4.4.1 Peak-Picker with reset

When the Peak-Picker with reset function is selected, the external reset input is used to force the signal output to

the current te perature easure ent.

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________19____________________________________________

rese

t

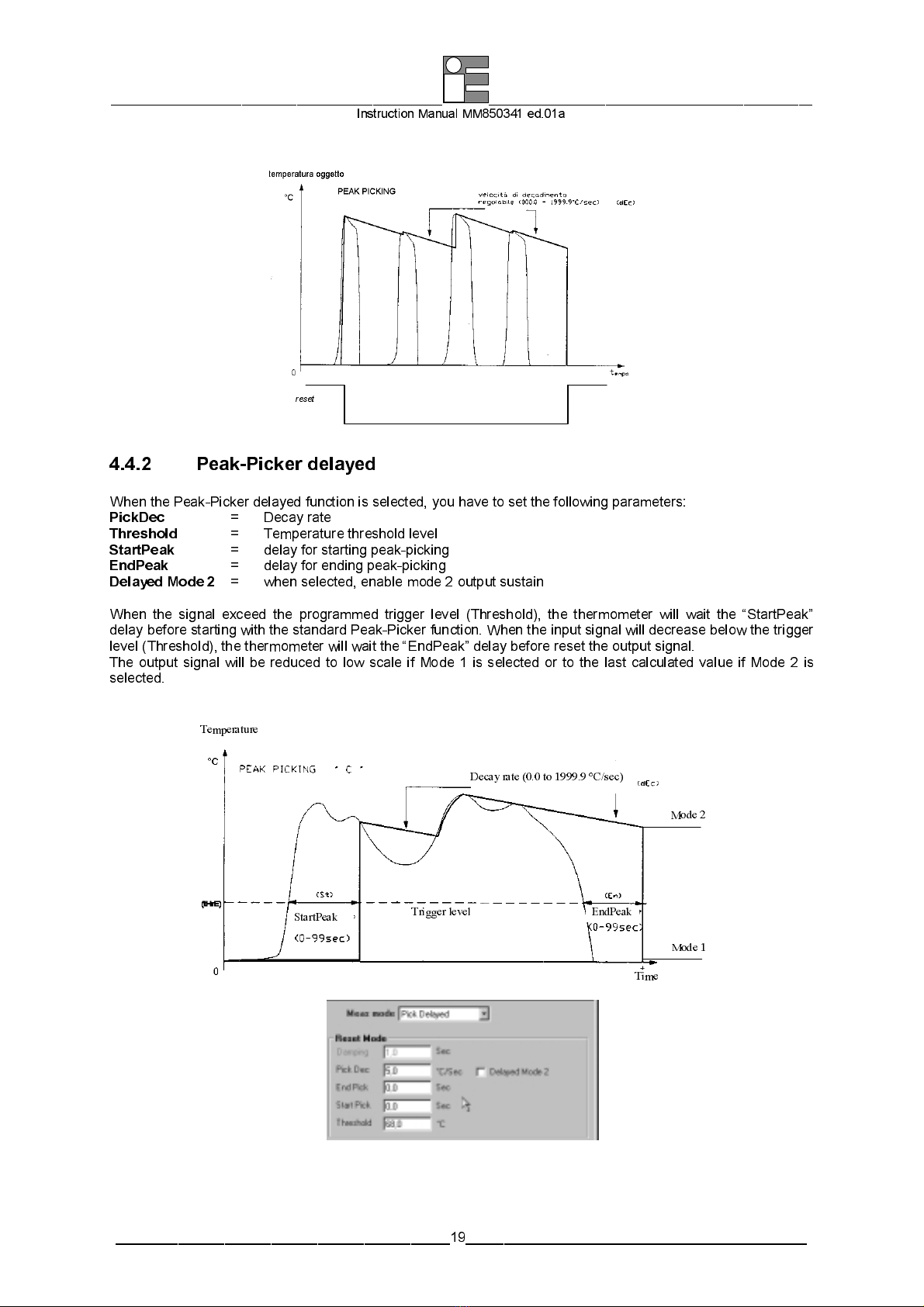

4.4.2 Peak-Picker delayed

When the Peak-Picker delayed function is selected, you have to set the following para eters:

PickDec

= Decay rate

Threshold

= Te perature threshold level

StartPeak

= delay for starting peak-picking

E dPeak

= delay for ending peak-picking

Delayed Mode 2

= when selected, enable ode 2 output sustain

When the signal exceed the progra ed trigger level (Threshold), the ther o eter will wait the “StartPeak”

delay before starting with the standard Peak-Picker function. When the input signal will decrease below the trigger

level (Threshold), the ther o eter will wait the “EndPeak” delay before reset the output signa l .

The output signal will be reduced to low scale if Mode 1 is selected or to the last calculated value if Mode 2 is

selected.

Temperature

Time

Decay rate (0.0 to 1999.9 °C/sec)

Trigger level

StartPeak E dPeak

Mode 1

Mode 2

________________________________________________ _______________________________________________

Instruction Manual MM850341 ed.01a

___________________________________________20____________________________________________

4.5 Valley-Picker

Reverse the Peak-picker function principle to describe the Valley Picker.

U = Valley + (PickDec * 2

∆

T)

where :

U

= output signal

Valley

= Valley signal

PickDec

= Increasing rate °C/sec (progra ab le)

∆

T

= sa pling ti e

4.5.1 Valley-Picker with reset

Reverse the Peak-Picker with reset function principle to describe the Valley-Picker with reset.

4.6 Track and Hold

The track (sa ple) and Hold func t ion al lows s oothed signal s to be ob tai ned fro inter i t tent events. These ay

origina te fro objects on a conveyor belt or targets where the view is periodic al ly obscu red by rotat ing achinery .

The output sa pl ing is act iva ted by a co and signa l received by an external switch tha t can be actuated by the

belt or rotating ach inery itself. The outpu t is held when the swi tch is operated unt i l t he next co and i s

received.

Time - temp o

Temp.

R

eset

Track & Hold

This manual suits for next models

1

Table of contents

Other Eurotron Thermometer manuals