EUTHANEX SMARTBOX TT-4000 User manual

AutoCO2System

TabletopSystem

877‐559‐0159TollFreeEuthanexCorp./E‐ZSystemsInc.

610‐559‐0159PhoneP.O.Box3544

610‐821‐3061FaxPalmer,PA18043

www.euthanex.com[email protected]

2

TABLE OF CONTENTS

Disclaimer/SystemOverview____________________ 3

Saftey________________________________________ 4

SystemSetup__________________________________ 5

OperatingtheSystem___________________________10

ProgrammingthePresets________________________14

Troubleshooting_______________________________19

EMC / EMI.

This equipment has been tested and found to

comply with the limits for a Class A Equipment,

pursuant to part 15 of the FCC rules.

IEC 61326-1:2005 / EZ 61326-1:2006

For the customers in Canada:

This Class A Equipment complies with

Canadian ICES-003:2012.

Cet appareil numérique de la classe A est

conforme à la norme NMB-003:2012 du Canada.

3

DISCLAIMER

THIS MANUAL MUST BE READ BEFORE SETTING UP AND OPERATING THE AUTO CO2

SYSTEM. The user should be thoroughly familiar with the contents of this manual prior to using the system with

animals. Only technicians that are properly certified should operate the Auto CO2System.

The user/owner of this equipment shall have the sole responsibility for any damage or injury resulting from

operation that is not in accordance with the authorized instructions. This includes, but is not limited to, operating

the equipment outside of recommended safety levels, variation from specified operating instructions and not

following standard laboratory safety procedures when working with anesthetic agents and volatile compressed

gases.

The system and its components must only be modified or repaired by Euthanex-authorized service technicians.

Improper modification or repair may result in danger to personnel, harm or death to animals and/or equipment

damage. The user/owner of this equipment shall have the sole responsibility for any damage or injury resulting

from improper maintenance and repair that is not done by authorized maintenance and repair personnel.

Parts that have failed, in whole or in part, exhibit excessive wear, are contaminated or are otherwise at the end of

their useful life, should not be used and should be replaced with parts supplied by Euthanex Corporation.

Tampering with the controller unit by unauthorized personnel voids all warranties and specifications. The

manufacturer assumes no responsibility for any malfunction or failure of the unit if tampering is suspected.

TABLETOP SYSTEM OVERVIEW

The SMARTBOX Tabletop Auto CO2System is an advanced automated euthanasia unit that has been developed

specifically for euthanizing small rodents. The system incorporates two key components, the SMARTBOX TT

Controller and the TT Chamber. The system works with preset timings that assure humane and efficient levels of

CO2. The controller has 2 timer settings for operation times for Adult and Neonates. Gas flow rate is set at the

source (fixed flow), while the timings are controlled by the automated controller unit. The controller does not

impact the flow rate, but delivers gas at the rate that is output by the source.

The TT-SB Controller operates in preset automated stages:

1) GasFlowLevelOne:FlowrateissettoconformtotheAVMAguidelinesforhumane

euthanasia.CO2flowsintothetopchamberandanesthetizestheanimalswithminimal

stress.Whiletheanimalsareanesthetized,thegasflowcontinuesandincreasesthe

chamber’sCO2concentrationtoeuthanizinglevel.

2) DwellTime:Gasflowshutsoffandthechamberremainsfullychargedtoassure

euthanasiaofallanimals.

3) ExhaustTime:TheexhaustblowerwillactivateandremoveCo2frominsidethechamber.

(Theexhaustblowerisanoptionalaccessory.)

T

h

s

y

i

n

u

n

pr

m

pe

1.

2.

3.

4.

5.

6.

7.

8.

9.

1

0

1

1

1

2

h

e lightning fla

s

y

mbol within an

n

tended to alert t

h

n

insulated "dan

g

r

oduct's enclosu

r

m

agnitude to con

s

e

rsons.

Read these i

n

Keep these i

n

Heed all wa

r

Follow all i

n

Do not use t

h

Do not clea

n

unit.

Do not bloc

k

Install in ac

c

instructions.

Do not insta

l

as radiators,

unit that pro

d

Do not defe

a

p

olarized or

p

olarized pl

u

wider than t

h

has two bla

d

p

rong. The

w

are provided

p

lug does n

o

electrician f

o

outlet.

0

.Protect the p

on or pinche

d

convenience

where they

e

1

.Unplug this

u

storms or w

h

time.

2

.Refer all ser

v

p

ersonnel. S

e

unit has bee

n

such as pow

e

damaged, li

q

have fallen i

n

unit has bee

n

moisture, do

e

b

een droppe

d

s

h with an arrow

equilateral tria

n

h

e user to the p

r

g

erous voltage"

w

r

e that may be o

f

s

titute a risk of

e

n

structions.

n

structions.

r

nings.

n

structions.

h

is unit near wa

t

n

by s

p

raying liq

u

k

any ventilatio

n

c

ordance with th

e

l

l near any heat

s

heat registers, s

t

d

uce heat.

a

t the safety pur

p

grounding-type

u

g has two blad

e

h

e other. A grou

n

d

es and a third g

r

w

ide blade or th

e

for your safety.

o

t fit into your o

u

o

r replacement

o

ower cord from

d

particularly at

receptacles, an

d

e

xit from the uni

t

u

nit during ligh

t

h

en unused for l

o

v

icing to qualifi

e

e

rvicing is requ

i

n

damaged in an

y

er

-supply cord o

q

uid has been sp

i

n

to the unit, the

n

exposed to rai

n

e

s not operate n

o

d

.

hea

d

n

gle, is

r

esence of

w

ithin the

f

sufficient

e

lectric shock to

t

er.

u

id directly ont

o

n

openings.

e

manufacturer'

s

s

ources such

t

oves, or othe

r

p

ose of the

plug. A

e

s with one

n

ding type plug

r

ounding

e

third prong

If the provide

d

u

tlet, consult an

o

f the obsolete

being walke

d

plugs,

d

the point

t

.

t

ning

o

ng periods of

e

d service

i

red when the

y

way,

r plug is

i

lled or objects

n

o

r

o

rmally, or has

4

o

s

The

e

inten

d

oper

a

the li

t

War

n

Caut

Serv

i

Volta

Press

Tem

p

e

xclamation poi

n

d

ed to alert the

u

a

ting and mainte

n

t

erature accomp

a

n

ing!

To reduce

t

do not exp

o

moisture.

Use line co

Be advised

require the

cord and at

t

shipped wi

t

installation

contact us

f

This equip

m

socket outl

e

should be

e

Do not inst

Do not ope

n

inside.

ion: You are ca

u

modificati

o

manual co

u

this equip

m

i

ce

There are

n

All service

personnel.

ge100‐

2

selec

ure75p

s

p

0to

con

d

n

t within an equ

i

u

ser to the prese

n

n

ance (servicin

g

a

nying the prod

u

t

he risk of fire o

r

o

se this unit to r

a

r

d

supplied wit

h

that different o

p

use of different

t

achment plugs.

t

h the requested

requirements c

h

f

or the correct p

l

m

ent should be

i

e

t and disconne

c

e

asily accessible

.

all in a confine

d

n

the unit - risk

u

tioned that any

o

ns not expressl

y

u

ld void your au

t

m

ent.

n

o use

r

-servicea

b

must be perfor

m

2

40vac50‐60h

z

t)

s

imaxtoinlet

40°C<>10to

8

d

ensation)

i

lateral triangle

i

n

ce of importan

t

g

) instructions i

n

u

ct.

r

electric shock,

a

in o

r

h

the product.

p

erating voltage

s

types of line

The unit was

plug. If the

h

ange please

l

ug.

i

nstalled near th

e

c

tion of the devi

c

.

d

space.

of electric shoc

k

change o

r

y

approved in th

i

t

hority to operat

b

le parts inside.

m

ed by qualifie

d

z

1ampMax(a

u

8

5%RH(no

i

s

t

n

s

e

c

e

k

i

s

e

d

u

to

SYSTEM SETUP

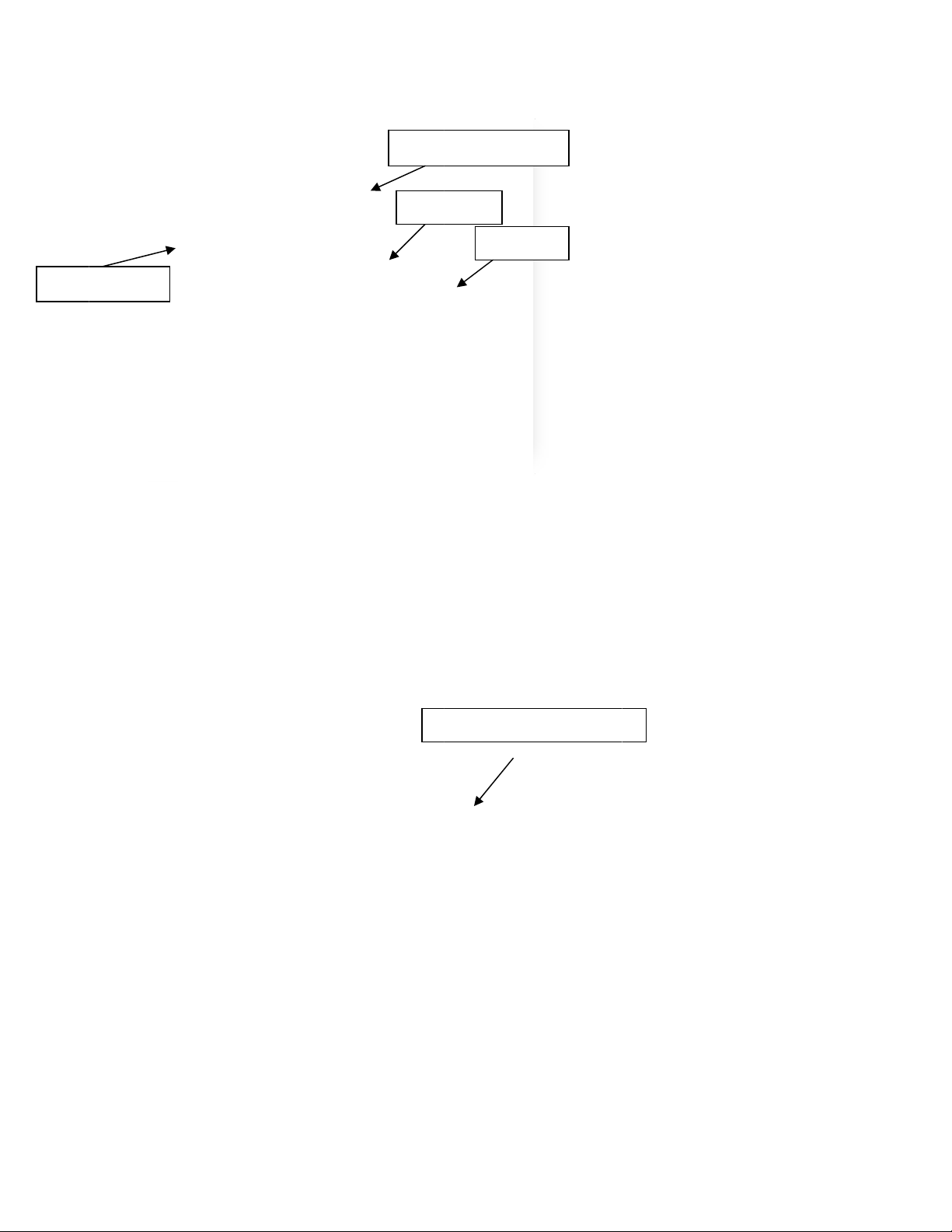

1) TheSMARTBOXTTcontrollerisattachedtotheTabletopchamberutilizingthefourholesonthe

rightsideoftheChamber.

2) Alignthethreadednutinsertsofthecontrolboxwiththefourholesontherightsideofthe

chamber.InserttheM4screwsandusecautiontighteningthemtopreventdamagetothe

chamber.

Screwmountsonchamberside

6

1) Attachthesupplied1/2”checkvalveontotheleftsideofthechamber.Thevalveisthreaded

andwillscrewintothechamberwall.Attachthesupplied1/2”hoseontotherightsideoftop

chamber.Thishoseiscomingoffoftheexhaustblowerunit.

The4”hosefromtheblowerunitcanbedrapedtothefloor,setintoahoodoritcanbeattachedto

houseexhaust.

2) AttachtheCO2supplyfromthecontrolboxtothechamber.Thebraidedhoseisalready

attachedtothechamber,justplacethequickdisconnectfittingtothestemonthebacksideof

theTTController.

5)Attac

tank

t

TheE

regul

a

htheheated

t

hreadsbefo

r

A‐285Electr

i

a

torwilllike

l

regulatorto

r

eattaching

r

i

callyHeated

l

yresultinfr

o

theCO

2

tank

r

egulator.Us

Regulatoris

o

zenCO

2

lin

e

7

.Itisrecom

m

eawrencht

o

requiredto

o

e

s.

m

endedthat

o

tightenthe

o

peratethe

s

Teflontape

b

mountedre

g

s

ystem.Usi

n

b

eusedonth

g

ulator.Not

e

n

ganon‐hea

t

eCO

2

e

:

t

ed

CO

2

T

a

6)Plug

t

turn

o

press

press

contr

o

clock

w

7)Attac

SMA

R

a

nkValve

t

heregulator

o

nandoffhe

urefromthe

urereduces

a

o

lsflowoutp

w

iseorcoun

t

hthetubing

b

R

TBOXTTco

n

intoanACo

u

atasneeded

CO

2

tank.A

f

a

ccordingly.

T

utincubicf

e

t

erclockwise.

b

etweenthe

n

troller.Thei

n

u

tlet.There

g

tomaintain

C

f

ulltanktypi

c

T

heregulato

r

e

etperhour(

CO

2

regulat

o

n

putintothe

Tank

P

Flow

C

O

8

g

ulatoristhe

C

O

2

tempera

t

c

allyrunsat

8

r

flowoutput

CFH).Theo

u

o

routputhos

e

controlbox

u

P

ressureGau

g

Gauge

Valve

B

O

2

Inputinto

rmostaticall

y

t

ure.Thelar

g

8

00lbsPSI.

A

isindicated

o

u

tputiscont

r

e

tothe“CO

2

u

tilizesaqui

c

g

e

B

ar

ControlBox

y

controlledt

o

g

ergaugein

d

A

sthetankis

o

nthesmall

e

r

olledbytur

n

IN”onbott

o

c

kconnectfit

o

automatica

d

icatesthe

used,theta

n

e

rgauge.It

n

ingthevalv

e

o

mofthe

ting.

lly

n

k

e

bar

9

8)PlugblowercontrolcordintotheSMARTBOXTTcontroller.

Plugblowerunitacintomainpowersource.

Blowerunitonlyoperateswhenexhaustcycleisengagedbycontroller.

Ventexhaustclosetoroomreturnvent.

9)PlugACcordfromSMARTBOXTTcontrollerintoACpoweroutlet.

10)Turnonmainpower,readylightwillcomeon.

Setupisnowcomplete.

10

OPERATING THE SYSTEM

1)PresstheOnswitchthatisonthebottomofthecontroller.Thegreen“READY”lightwillturnon.

2)Releasethethreelatchesonthefrontofthechambertoopenthelid.

On

/

OffSwitch

11

3)Thechamberisnowreadytobeloaded.Cageswithwirebarlidscanbestackedintwolayers.

ATT‐8100chambercanaccommodateupto8standardmousecages.ATT‐4000chambercan

accommodateupto6standardmousecages.Numberofcagesaccommodatedwillvarybased

uponactualcagesize.Donotattempttoplacemorecagesthenwillcomfortablyfitintothe

chamber.

NOTE:Cagesshouldbesetaskewtoallowoptimalpenetrationofgastothelowercages.

CO

2

T

a

4)After

fully

s

5)Open

gaug

e

a

nkValve

thechambe

r

s

ecured,asli

g

thegasflow

e

shouldber

e

r

isloaded,cl

o

g

htgasleak

m

fromtheCO

2

e

ading800P

S

o

sethelida

n

m

ayoccur.

2

tankbytur

n

S

Iifthetank

i

Ta

12

n

dsecurethe

n

ingthetank

i

sfull,lessif

i

nkPressure

G

FlowGaug

e

Valv

e

threelatche

valveknobc

o

i

tisnotafull

G

auge

e

e

Bar

stoseal.If

t

o

unterclock

w

tank.

t

helatchesa

r

w

ise.Thelar

g

r

enot

g

ePSI

13

6)Openthegasflowoutoftheregulatorbyturningthe“T”barcounterclockwise.Thisbeginstheflow

ofgastothecontroller.Settheregulatorflowrateat50CFHfortheTT‐8100or33CFHfortheTT‐

4000.

7)Thesystemhastwopresettimersforspeciesselection.Pressupfor“ADULTS”ordownfor

“NEONATES”onthefrontofsidecontrolbox.Thered“RUN”lightindicatestheeuthanasiacycleis

operating.

8)Duringthefirstinitialrun,adjusttheregulatorflowrateto50CFPH.Thisadjustmentwillassurea

humaneprocess.Animalswillfirstbeanesthetizedwithminimalstressandtheneuthanizedwhile

asleep.Exceedingthisflowratemayintroducestresstoanimalsandresultinoperationoutsideof

AVMAguidelines.(Thisregulatoradjustmentistypicallyonlyrequiredthefirsttimeusingthe

systemandwhenafullCO2tankisfirstputonline.)

9)Thesystemwillcyclethroughtwostages:

Stage1Charging:Gasflowsthroughthechamberfor8:30minutes,fullychargingthechamber

withCO2.

Stage2Dwell:GasflowstopsandthechamberremainsfullychargedwithCO2for5minutes.

Stage3Exhaust:Blowerwillactivatefor3.5minutes,chamberwillunlockandreturntoready

state(green).

StartToggle

Adult

Neonates

CHA

N

Recom

m

Corpora

t

Factory

s

The fo

1.Relea

2.Thes

t

3.Toch

4.Press

N

GING

T

m

ended flow

t

ion an

d

are

d

s

ettings for

p

llowing i

s

sethelatch

t

t

art‐upscree

angethepre

s

thedownb

u

T

HE SY

S

rates and pr

e

d

esigned to

p

resets are:

s

the

p

r

o

t

oopenthec

o

nappearson

s

etcycletim

e

u

tton,tomov

S

TEM P

R

e

set times

w

comply wit

h

Adult

C

Dwell:

Dwell:

Exhau

s

o

cedure f

o

o

ntrollerdo

o

thePLC.

e

s,pressESC.

ethearrow

t

14

R

ESET

S

w

ere determi

n

h

the latest

g

C

harging:

Adult

Neonates

s

t

o

r chang

o

r.

Theoption

s

t

o:>“SetPa

S

:

n

ed with ex

t

g

uidelines o

f

8:30 mi

n

5 minut

e

59 minu

t

3:30 mi

n

ing the

p

s

creenwilla

p

ram.”Press

O

t

ensive testi

n

f

the AVM

A

n

utes

e

s

t

es

n

utes

p

reset ti

m

p

pear.

O

K.

n

g done by

E

A

Panel on E

u

m

es:

E

uthanex

u

thanasia.

5.Thec

a.U

b.U

c.A

Note: O

n

6.Repe

a

7.After

syste

m

Repeata

b

ursorwillbli

n

setheup/d

o

setheright/

l

fterthedesi

r

n

ly the T =

0

a

tsteps5an

d

allthetimer

s

m

isnowrea

d

b

ovefortime

n

kforthe“T”

o

wnkeystoi

n

l

eftkeysto

m

r

edtimeisse

t

0

0:00m will

d

6tosetdw

e

s

havebeen

s

d

ytooperat

e

r2.

settings.

n

creaseorde

m

ovethecurs

o

t

,pressOK.

be set. Th

e

e

llandexha

u

s

et,pressthe

e

withthene

w

15

creasethev

a

o

rtothenex

t

e

Ta = 00:0

0

u

sttimes,ifn

ESCbuttont

w

lyprogram

m

a

lue.

t

numberyo

u

0

is not a pr

o

ecessary.

wicetoretu

r

m

edtimes.

C

u

wouldliket

o

grammable

r

ntotheho

m

C

loseandlatc

ochange.

function.

m

escreen.Th

hthedoor.

e

16

FseriesIDECorSiemens:

1.Releasethetwolatchestoopenthecontrollerdoor.

2.TheclockscreenisonthePLC.

3.Tochangethepresetcycletimes,pressESC,thenOK.Theoptionscreenwillappear.

4.Pressthedownbutton,tomovethearrowto:“>Program”.PressOK.

5.Pressthedownbutton,tomovethearrowto:“>SetParameter”.PressOK.

6.Thepasswordscreenappears.Usetheup/dwandRt/Ltarrowtoinputpassword"CLUTCH"thenhit

OK

6.Timerselectscreenappears.Thisscreenismaybedifferentthatthepicturebasedontheprogram

loaded.

17

*Usetheup/downkeystomovetothevaluetochange.

*Press“OK”andthescreenwillchange.Presstherightarrowuntilslargeboxwillbeoverthetimer.

*Press“OK”andtheboxwillbecomesmallandoverthefirstvalueofthetimer.

*Usetheright/leftkeystomovethecursortothenumberyouwouldliketochange.

*Usetheup/downkeystoincreaseordecreasethevalue.

*Usetheright/leftkeystomovethecursortothenumberyouwouldliketochange.

*Afterthepropertimeisset,pressOK.Theboxwillchangebacktolarge.

Note:onlytheT=00:00mwillbeset.TheTa=00:00isnotaprogrammablefunction.

6.Aftersettingthetimers,pressthe“ESC”buttontoreturntothemainscreen.

Usetheupkeytomovetostart,hit"OK"button,useleftarrowtomovetoYes,Hit"OK"button.

TheLabControlUnitisnowreadytooperate.Closeandlatchthedoor.

18

Operational Parameters

TT-8100

Factory settings for presets are: Adult Charging: 8:30 minutes

Dwell:Adult 5minutes

Dwell: Neonates 59 minutes

Exhaust 3:30 minutes

CO2

Set regulator to 50CFH

Flow meter to 25LPM

TT-4000

Factory settings for presets are: Adult Charging: 8:30 minutes

Dwell:Adult 5minutes

Dwell: Neonates 59 minutes

Exhaust 3:30 minutes

CO2

Set regulator to 33CFH

Flow meter to 16LPM

The heated regulator can be left plugged in since it is

thermostatically controlled and will shut off when the heat is

not required.

19

TROUBLESHOOTING

Before any service is done that would require opening the unit it must be disconnected from the

power source. If your location has lockout-tagout protocols please follow them.

System will not turn on:

1) Makesurepowercordisproperlypluggedin.

2) Makesurethepowerswitchonthebackoftheunitisturnedinthe“ON”position.

Gas is not being delivered to the chamber or the flow rate is not

correct:

1)Checkthatyourgassupplyhasnotrunout.

2)CheckthattheCO2tankvalveisfullyopen.

3)CheckthattheconnectionsfromthegassupplyregulatortothecontrollerCO2inputis

properlymated.

4)Checkthatthegrayhoseinsidethecontrollerisconnectedtothechamberinputfitting.

5)Checkthattheregulatorisopenandsetto50CFH.

6)Checkthattheelectricheater,inlinefromthegassupplytotheregulator,isoperating.The

heaterrunsintermittently,switchingonwhenheatisrequired.Ifthegasisnotadequately

heated,itwillnotflowproperly.

Not all animals are being euthanized after the completion of gas

cycle:

1)Checkthatallconnectionsintheentiresystemareproperlyattached.

2)Checkthatyourgassupplyhasnotrunout.

3)Checkthattheregulatorisproperlysetat50CFH.

4)Itmaybenecessarytorevisesettingsfortheparticularspeciesthatyouarehavingdifficulties

with.Tryextendingflowanddwelltimes.Seepage14forinstructionsonchangingpresets.

Note; If the unit does not have the exhaust blower option , the blower time needs to be set at 00:00

If this troubleshooting guide does not resolve your problem, contact Euthanex Tech Support

1‐877‐559‐0159TollFreeEuthanexCorp./E‐ZSystems

610‐559‐0159PhoneP.O.Box3544

610‐821‐3061FaxPalmer,PA18043

www.euthanex.com[email protected]

This manual suits for next models

2

Other EUTHANEX Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

PerkinElmer

PerkinElmer RamanStation 400 Series Getting started guide

Isotech

Isotech Saturn 877 User maintenance manual/handbook

Star Lab

Star Lab ErgoOne user manual

3D Histech

3D Histech TMA Grand Master 3.2 user guide

Bionova

Bionova IC10/20FR manual

Thermo Forma

Thermo Forma 3920 Operating and maintenance manual