MTS Sensors

R-Series Temposonics®Linear-Position Sensors - Model RD4 Flexible Housing Option

Product Data Sheet, Document Part No.: 551166, Revision A 04/10, 10/11 2

Product specifications

Product overview

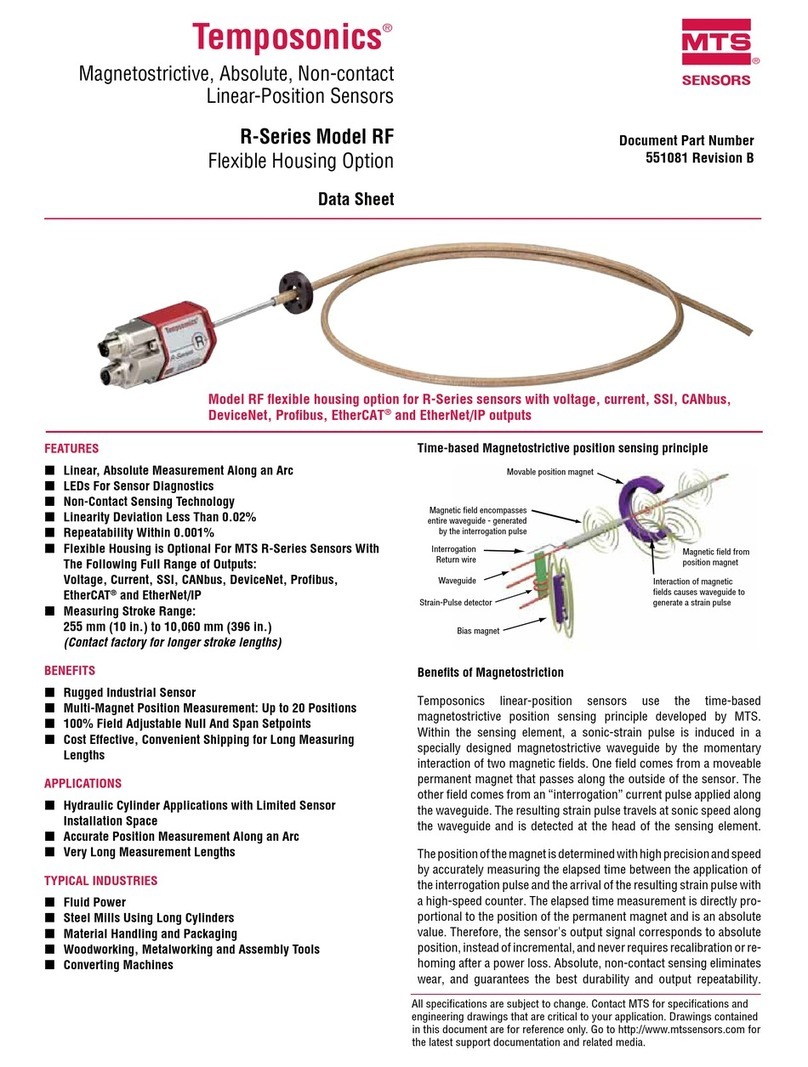

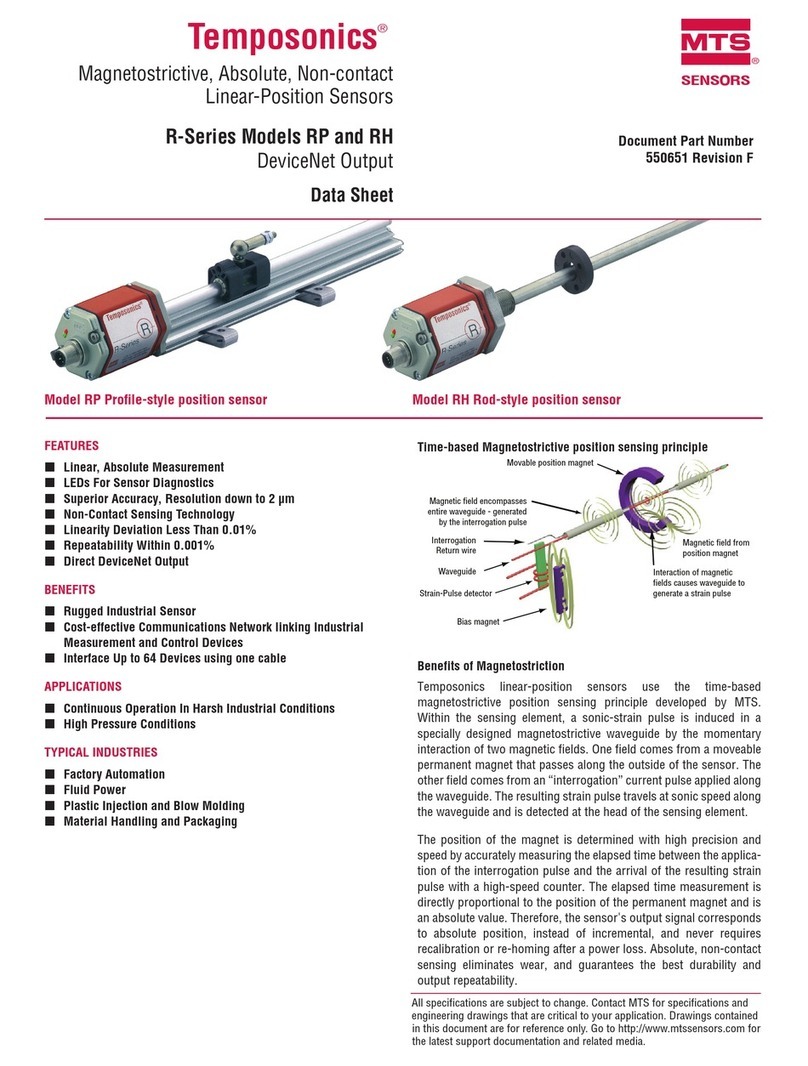

The Temposonics RD4 position sensor provides an added degree of flexibility compared to the standard R-Series rod style sensor package.

The RD4 design utilizes a separate electronics housing and interconnection cable to allow installation of the sensor rod into small spaces.

By relocating the electronics, the head of the sensor rod is reduced to its minimal size. This makes the RD4 ideal for use with clevis mount

cylinders or any space limited cylinder application. Also, the RD4 sensor can be used for applications that require remote mounting of the

sensor electronics due to environmental factors, such as, high temperatures or high levels of shock and vibration.

The RD4 interconnection cable exits the head of the sensor rod and connects to the electronics housing. The electronics housing, along with its

mounting block, can be configured with either a side cable connection or a bottom cable connection. The side cable connection is

for use with threaded rod styles; 'M', 'T', 'C' and 'D'. These threaded rod styles provide for easy sensor installation into a standard

threaded port opening on the top of the cylinder end cap.

The bottom cable connection is for use with the pressure-fit rod style (i.e. style 'S'). The rod style 'S' requires an appropriately machined cavity

in the cylinder end cap to house the head of the sensor rod. Also, a hole going through the end cap is needed to channel the interconnection

cable to the electronics housing that mounts on the side of the end cap. Proper design and careful sensor installation is required to assure

the correct fit and o-ring sealing. MTS factory assistance is recommended when designing for the rod style 'S' in all new RD4 applications.

Output options

R-Series Model RD4

Product Overview, Output and Specifications

The R-Series Model RD4 sensor is available in voltage, current, SSI,

CANbus, DeviceNet, Profibus, EtherCAT®and EtherNet/IP outputs. Important specification note:

For R-Series model specific specifications, consult the individual data

sheets applicable to the sensor output(s) for your application.

Parameters Specifications

OUTPUT

Measured

output

variables:

Position, velocity, simultaneous multi-

position and velocity measurements.

(Measured output variables depend on the

complete sensor model used.)

Resolution: Output dependent

Update times: Output dependent

Linearity

deviation:

< ± 0.02% full stroke (minimum ± 50 μm)‡

‡For rod style 'S' the linearity deviation

can be higher in the first 30 mm (1.2 in.) of

stroke length.

Repeatability: < ± 0.001% full stroke (minimum ± 2.5 μm)

Hysteresis: < 4 μm, 2 μm typical

Outputs: Voltage, current, SSI, CANbus, DeviceNet,

Profibus, EtherCAT and EtherNet/IP

Measuring

range: 25 to 5080 mm (1 to 200 in.)

ELECTRONICS

Operating

voltage:

+24 Vdc nominal: -15% or +20%

Polarity protection: up to -30 Vdc

Over voltage protection: up to 36 Vdc

Current drain: Output dependent

Dielectric withstand voltage: 500 Vdc

(DC ground to machine ground)

ENVIRONMENTAL

Operating

conditions:

Operating temperature:

-40 °C (-40 °F) to +75 °C (+167 °F)

Relative humidity: 90% no condensation

Parameters Specifications

EMC test‡:Electromagnetic emission:

IEC/EN 50081-1

Electromagnetic susceptibility:

IEC/EN 50082-2

IEC/EN 61000-4-2/3/4/6, level 3/4

criterium A, CE qualified

‡Sensor rod and interconnection cable is

mounted inside a hydraulic housing or

metal housing.

Shock rating: 100 g (single hit)/

IEC standard 68-2-27 (survivability)

Vibration rating: 10 g/10 to 2000 Hz, IEC standard 68-2-6

(operational)

WIRING

Connection type: Connector or integral cable (output dependent)

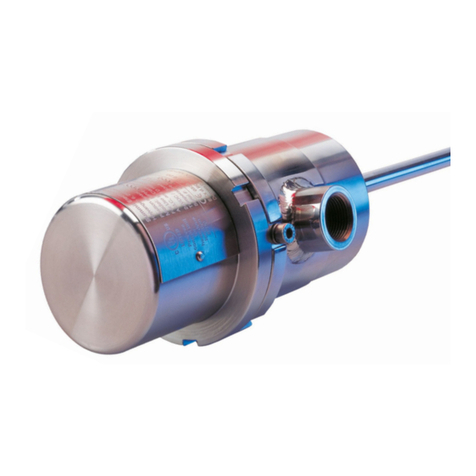

ROD STYLE SENSOR (MODEL RD4)

Electronic head: Aluminum housing with diagnostic LED

display. (LEDs located beside connector/

cable exit)

Sealing: Sensor electronics: IP 67 (with profession-

ally mounted housing and connectors)

Sensor rod head with interconnection

cable: Threaded style (IP 65) and pressure

fit style (IP 30)

Sensor rod: 304L stainless steel

Operating

pressure:

350 bar static, 690 bar peak

(5000 psi, 10,000 psi peak)

Mounting: Any orientation. Threaded flange M18 x

1.5 or 3/4 - 16 UNF-3A or non-threaded

pressure fit

Typical mount-

ing torque: 45 N-m (33 ft. -Lbs.)

Magnet types: Ring magnet, open-ring magnet or magnet

float