WWW.EVO-LITE.COM

• [email protected] • 1-888-887-2980 • ©2020 EVO-LITE, LLC • 6240 W 54TH AVE., ARVADA, CO 80002 • V2–3220BEST PRACTICES

// LEDs are bright. Do not look directly at lighted sheet.

// To avoid visible brightness variances due to voltage drop, the

total distance from power source input to the farthest end of any

interconnected sheet should not exceed 6.5 feet (2 meters). See

power input section on page 3.

// DryttheLightSheetsandtheirconnectionwiresbeforeinstalling

them permanently to a substrate. Always test operation before

installing the translucent (forward facing) material.

// Horizontalapplicationsrequireacompletelyatmountingsurface.

Any deviations could result in the forward facing material(s) being

damaged.

// Never slide heavy material over the bumpers, this can cause damage

to the Light Sheet. If a forward facing material needs to be removed,

lift the material, do not drag as this can damage the Light Sheet.

// Do not fold Light Sheets back-to-back.

// Avoidinstallingwheresubjecttocontinuousexing.

// Applicationspecicinstallationguidesareavailableuponrequest.

For the latest product updates, specifications, troubleshooting, product handling, installation & integration advisories, visit www.evo-lite.com.

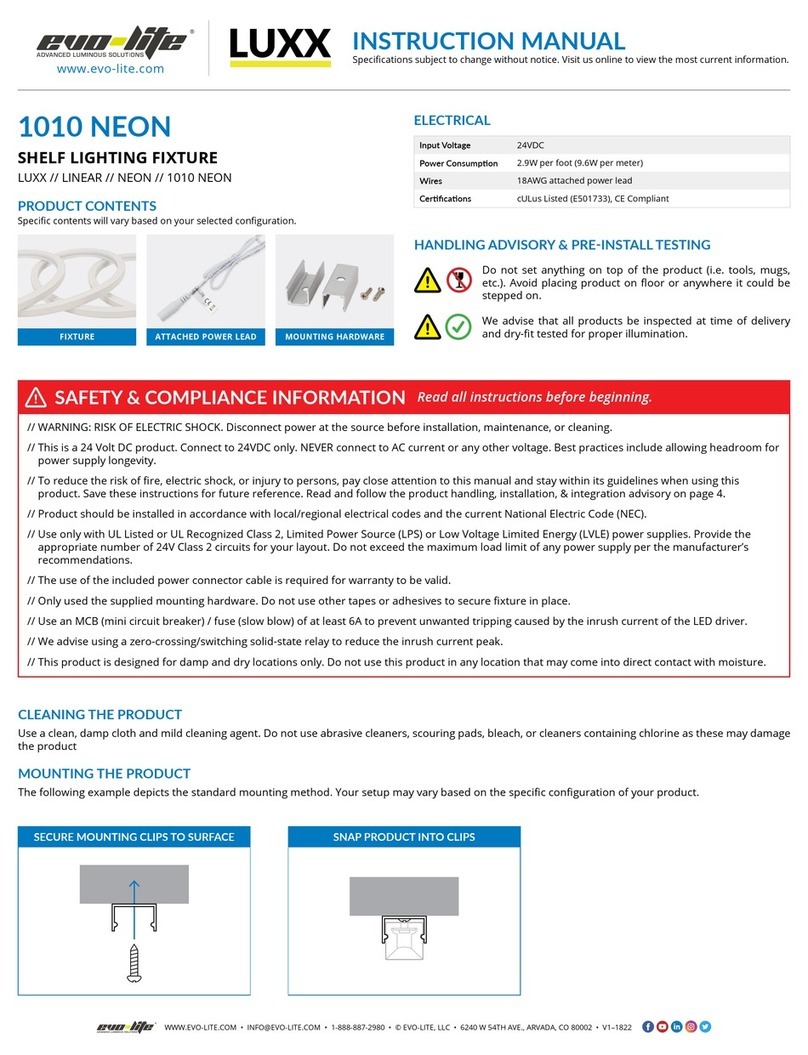

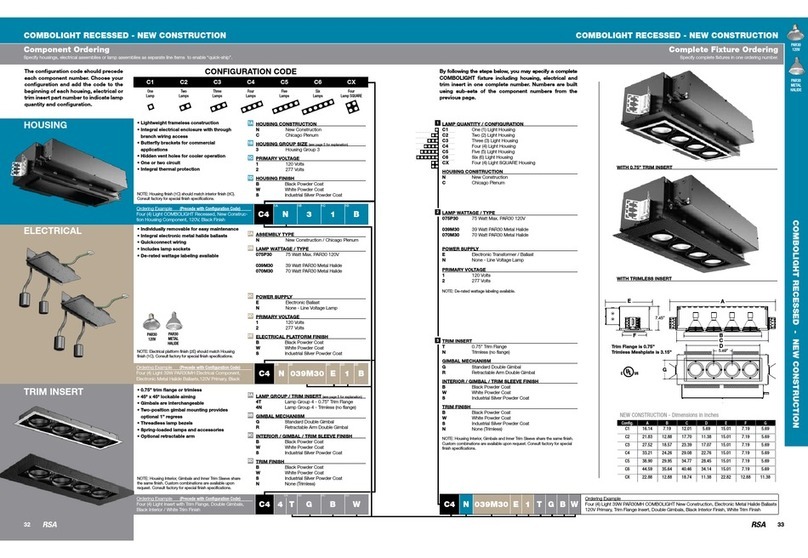

CONTENTS

Each Auragami®Light Sheet package includes one sheet (A), two short wires (B),

two long wires (C) and eight bumpers (D).

SAFETY INFORMATION

Read all installation instructions before beginning.

// Toreducetheriskofre,electricshockorinjurytopersons,paycloseattentiontothismanualandstaywithinitsguidelineswhenusingthis

product. Save these instructions for future use. READ AND FOLLOW THE PRODUCT HANDLING, INSTALLATION & INTEGRATION ADVISORY

ON PAGE 4. DISCONNECT POWER AT THE SOURCE BEFORE CUTTING OR ALTERING THE LIGHT SHEET(S) IN ANY WAY. DO NOT CONNECT

LIGHT SHEETS TO AC CURRENT. USE ONLY WITH 24V DC INPUT POWER.

// Products should be installed in accordance with these instructions, current local/regional electrical codes and/or the current National Electric

Code (NEC).

// Use only with UL Listed or UL Recognized Class 2, Limited Power Source (LPS) or LVLE (Low Voltage Limited Energy) power supplies. Provide the

appropriate number of 24V Class 2 circuits for your layout. Do not exceed the maximum load limit of any power supply per the manufacturer’s

recommendations.

//ToretainClass2complianceperULregulations,donotinterconnectmorethaneightfullLightSheets(88wattstotal)inanyconguration.

EachLightSheetconsumes11wattsofpower(0.46Aat24VDC).InordertoconnecteightLightSheets,conrmthatthecombinedpower

consumption is never more than 88 watts total. The Light Sheet’s FPC (Flexible Printed Circuit) design and integrated connection blocks have a

96W/4Aat24VDCcapacity.DonotexceedthecapacityoftheFPCandconnectionsblocksinanyconguration.

// This product is rated IP65 and can be used in wet locations, but not where water may accumulate.

// When using any type of mechanical fastener, make sure the fastener head does not penetrate the Auragami Light Sheet. Any penetrations of the

Light Sheet must be made inside the smaller of the two concentric circles marked on the sheet.

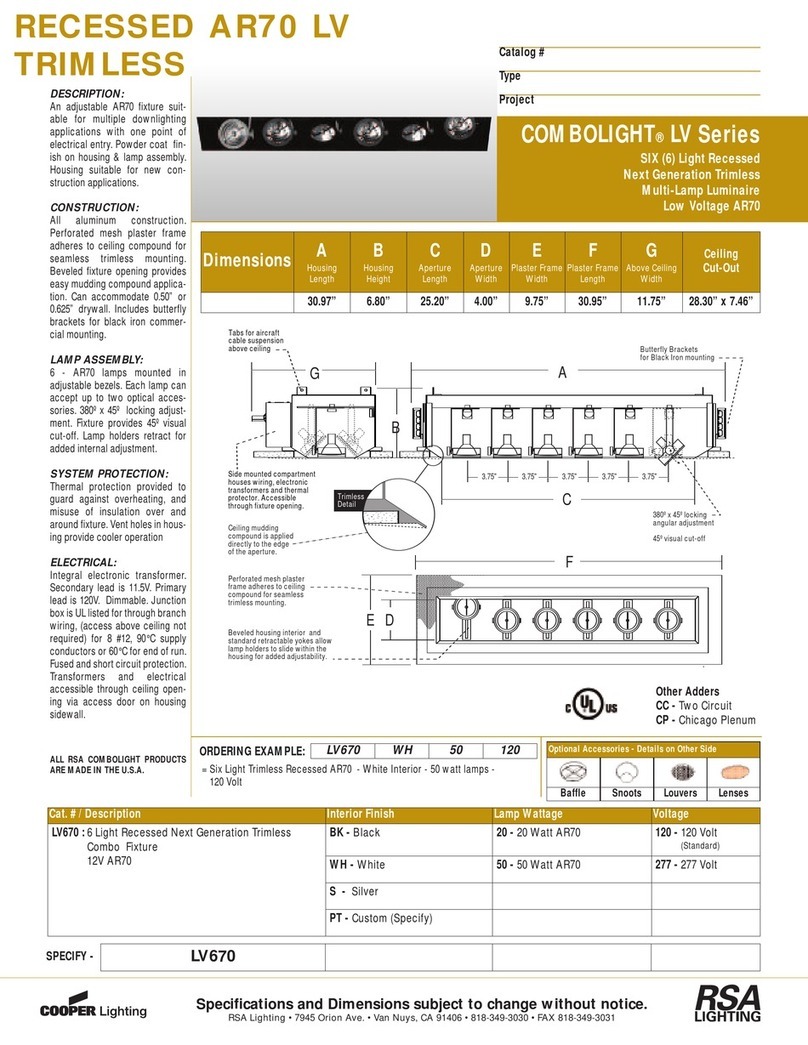

PART DESCRIPTION QTY

AAuragami®Light Sheet (19.80” x 9.25” / 503.5 mm x 235 mm) with

3M®adhesive backing and 12 integrated connection blocks 1

PART ACCESSORY PACK (INCLUDED: AG1-24-RGBW-AP) QTY

B20 AWG short sheet-to-sheet connection wires 3.26” (83 mm) 2

C20 AWG long sheet-to-sheet connection wires 5.86” (149 mm) 2

DProtective bumpers with silicone adhesive backing 8

A B

C

D

AURAGAMI®LIGHT SHEET

SHORT SHEET-TO-SHEET

CONNECTION WIRES

LONG SHEET-TO-SHEET

CONNECTION WIRES

* Not to Scale

PROFILES

Each bumper

can support

up to 400 lbs

(199kg)

Bumper with silicone

adhesive backing

Integrated 5-pin connection

block (TYP. of 12)

RGBW LIGHT SHEETS

0.35” (9mm)

(when bearing

weight)

including Light

Sheet thickness

3/8” Nominal

0.25”

(6.5mm)

including

Light Sheet

thickness

1/4” Nominal

BEST PRACTICES

Do not set anything on top of Light Sheets (i.e. tools, mugs, etc.).

DonotsetLightSheetsontheoorwheretheycouldbestepped

upon or where anything can be dragged or set upon them. Light

Sheets can be damaged unless properly handled.

Due to possible unforeseen issues with shipping and handling,

we advise that all Light Sheets be inspected at time of delivery

anddry-ttestedforproperilluminationpriortomountingand

again before the forward facing material is installed.

For troubleshooting guidance, please visit www.evo-lite.com

FLEXIBLE LED LIGHT SHEET | RGBW

ITEM #: AG1-24-RGBW SERIES (RED, GREEN, BLUE, WHITE)

INSTRUCTION MANUAL

BACKLIGHTING // LED SHEETS // AURAGAMI®// RGBW

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTIFICATION

PHYSICAL

Cut/Fold Line

Spacing 0.99” (25.18 mm) short axis / 0.925” (23.5 mm) long axis

Coverage 1.27 ft20(.118 m2) per sheet / up to 10.18 ft2(0.94 m2)

per Class 2 guidelines

Operang Temp. -30˚C(-22˚F)~+50°C(+122°F)

POWER & CONTROLS

Compable with full range (100% - 0%), icker-free power and control components.

Please contact Evo-Lite for opmal soluons to t your requirements.

ELECTRICAL

Input Voltage 24 Volt DC - Constant Voltage

Input Power 11 W per sheet

Connecvity Up to eight sheets via integrated connection blocks (not to exceed 88 W)

Cercaon ULListed(E495221),CECompliant(EMCandLVD),RoHSCertied,IP65

SPECIFICATIONS

24V

IP65

DIMMABLE

+−

83 mm (3.26”)

PROTECTIVE BUMPERS

9 mm

(0.35”)

12.8 mm (0.50”)

149 mm (5.86”)