EVOCA Krea Touch Specification sheet

INSTALLATION, USE, MAINTENANCE

Translation of the original instructions

EN English

Doc. No. H5325EN00

Edition 1 04 - 2017

Krea Touch 120V 60Hz

Ed. 11 17

EVOCA S.p.A.

ad unico socio

Sede amministrativa e operativa: Via Roma 24

24030 Valbrembo (BG) Italia

Tel +39 035 606111

Fax +39 035 606463

www.evocagroup.com

Sede legale: Via Tommaso Grossi 2

20121 Milano (MI) Italia

Cap. Soc. € 41.138.297,00 i.v.

Reg. Impr. MI, Cod. Fisc. e P.IVA: 05035600963

Reg. Produttori A.E.E.: IT08020000001054

Cod. identicativo: IT 05035600963

integration of radio modules

In compliance with Article 17 of Direc-

tive 2014/53/EU (RED), the manufacturer

checks whether the radio equipment is in

compliance with the essential requirements

of article 3 of the Directive.

The procedure used to check compliance

is at the manufacturer’s discretion.

If a radio module is built in a “non-radio”

equipment, the subject integrating the

module will become the manufacturer of

the end product and it must therefore check

the compliance of the end product with the

essential requirements of the 2014/53/EU

(RED) Directive.

As a matter of fact, the integration of radio

modules in other products can inuence

the compliance of the end product with the

essential requirements of the Directive.

definitions according to the law

The manufacturer is a natural person who

or a public body which manufactures radio

equipment and/or electric material or has it

engineered, manufactured or marketed by

putting its own trademark or name on it.

An importer or distributor who places

radio equipment or electric material on the

market by putting its own name or trade-

mark becomes the manufacturer.

An importer or distributor who makes any

change to radio equipment or electric mate-

rial already placed on the market to such an

extent that the said change may condition

the compliance with the listed directives

is held to be the manufacturer and it must

therefore assume the relative obligations

according to the said directives.

Symbology

The following symbols may be present

inside the machines, according to models

(signs of danger)

Attention: dangerous voltage

Power o before removing the

cover

Attention

Danger of crushing your han-

ds

Attention

Hot surface

The signs of danger must be readable

and visible; they shall be neither hidden

nor removed. Damaged or unreadable

labels must be replaced.

Warnings

This document intended for the technical

personnel is made available in the electron-

ic format at the manufacturer’s (reserved

area web site).

for installation

The installation and any subsequent

maintenance operation shall be carried

out by the personnel skilled and trained

on the utilisation of the machine ac-

cording to the rules in force

The use of kits and/or accessories not

type-approved by the manufacturer can not

guarantee the observance of safety stand-

ards, in particular for live parts.

The installer will be the sole person respon-

sible for any damage improper installation

may cause to the machine or to things and

people.

The manufacturer declines all responsibility

for the use of non type-approved compo-

nents.

Assembly and any testing operation

must be carried out by qualied per-

sonnel who have a specic knowledge

of the machine operation from the point

of view of electric safety and health

rules.

The intactness of the machine and its

compliance with the standards of rel-

evant installations must be checked by

skilled personnel at least once a year.

Package materials must be disposed of in

observance of the environment.

For the vending machines of hot drinkts

only

The machine is equipped with an automatic

washing system for the mixers with the rela-

tive water circuit and the brewing unit.

If the machine is not used for some time

(weekends, etc.) even for pauses longer

than two days, it is recommended to enable

the automatic washing functions (e.g. be-

fore starting to use the VM.

for use

The machine can be used by children over

8 years and by people having reduced

physical, sensorial or mental skills under

the supervision of people responsible for

their safety or specically trained on the

use of the machine.

Children shall not be allowed to play with

the machine by the people in charge of

their supervision

Children shall not be allowed to clean or

service the machine.

for the environment

Some tricks will help you to protect the

environment:

-use biodegradable products to clean the

machine;

-properly dispose of all the packages of the

products used to fill and clean the ma-

chine;

-power off the machine during inactivity for

energy saving.

for dismantling and disposal

When dismantling the machine, it is rec-

ommended to destroy the machine rating

plate. The symbol shows that the ma-

chine can not be disposed of as

common waste, but it must be

disposed of as it is established by

the 2012/19/EU (Waste Electrical

and Electronic Equipment - WEEE)

European Directive and by the national

laws arising out of it in order to prevent any

negative consequence for environment and

human health.

The dierentiated collection of the machine

at the end of its life is organised and man-

aged by the manufacturer.

For the correct disposal of the machine

contact the sales point where you have

purchased the machine or our after-sales

service.

The unlawful disposal of the machine im-

plies the application of the administrative

sanctions provided for by the rules in force.

Attention!

If the machine is equipped with a cooling

system, the cooling unit contains HFC-

R134a uoridised greenhouse eect gas

ruled by the Kyoto protocol, the total heat-

ing potential of which is equal to 1300.

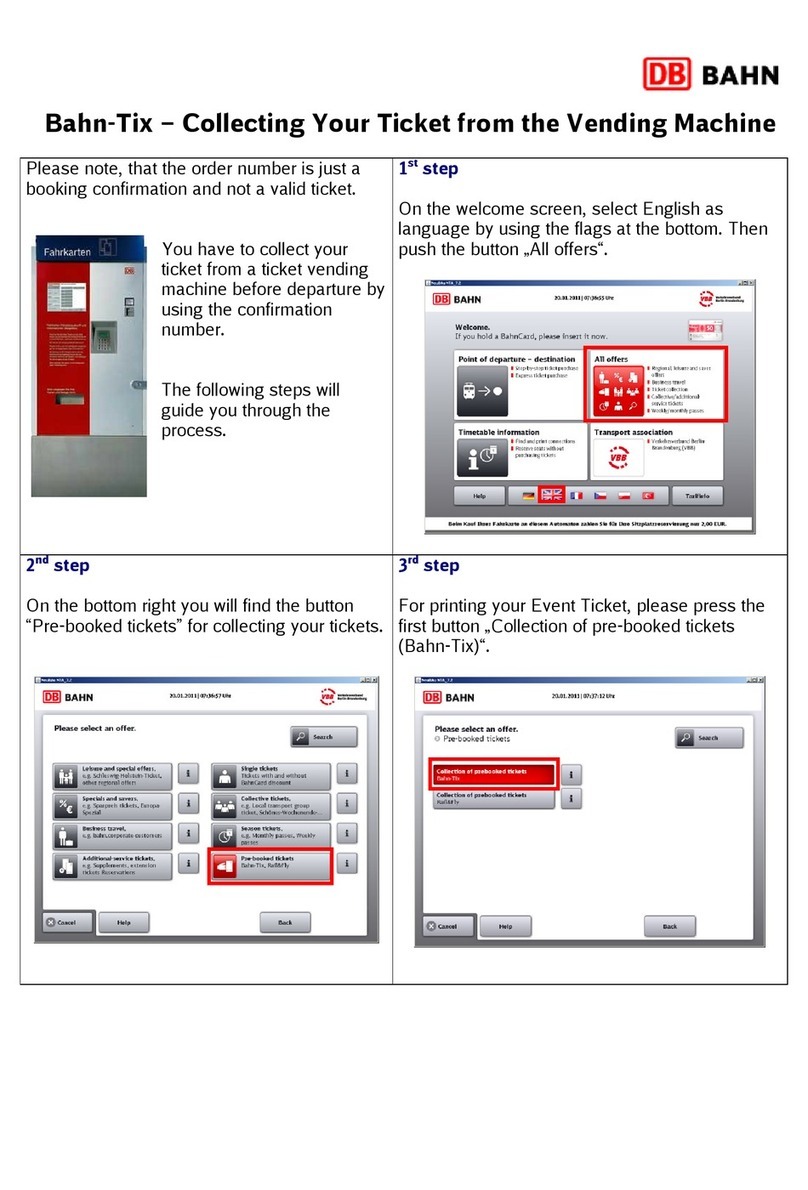

FOREWORD 1

transport and storagE 1

if amalfunction should occur 2

appliancE idEntification and fEaturEs 2

positioning 3

tEcHNical spEcificatioNs 3

powEr consumption 5

variablE combination locks 6

CLEANING AND LOADING 7

main switch and safEty mEasurEs 7

macHiNE saNitisatioN 8

using hot bEvEragEs dispEnsErs 8

coNtrols aND iNformatioN 8

loaDiNg proDucts 9

coffEE bEans 9

instant products 9

prE-ground coffEE 9

intErnally-suppliEd tank watEr 10

pErioDical opEratioNs 10

clEaning thE mixEr and food circuits 11

rEsiduE containErs 12

clEaning thE brEwing unit 13

clEaning thE watEr supply tank 13

switching thE machinE on 13

wasH cyclEs 14

rinsing thE componEnts 14

brEwing unit wash cyclE 14

clEaning thE touchscrEEn 15

sErvicE suspEnsion 15

INSTALLATION 16

main switch 16

door switch 16

connEctivity switch 17

unpacking thE appliancE 17

watEr supply 18

ElEctrical connEction 20

nEtwork connEctions 21

paymEnt systEm 21

iNitial start up 22

first sanitisation 22

opEratioN 23

Es-fb brEwing unit 23

cup sEnsor 24

dispEnsing compartmEnt lighting 24

dispEnsing instant bEvEragEs 24

grindEr-dosEr 25

connEctivity 27

touchscrEEn 27

opEratioN iN Normal usEr status 28

appliancE status 28

softwarE architEcturE 29

PROGRAMMING 30

accEssing thE programming mEnus 30

EntEring valuEs 31

Daily actioNs 32

clEaning and washEs 32

filling thE containErs 32

solid rEsiduE containEr 32

managing monEy 32

sElEctioN sEttiNgs 32

availablE sElEctions 32

availablE sElEctions by catEgory 32

sElEction catEgoriEs 32

bEvEragEs 33

rEcipEs 33

containErs 38

mEchanical layout 38

macHiNE sEttiNgs 38

configuration 38

modifying intErfacE strings 39

customisE thE usEr intErfacE 40

gEnEral display sEttings 40

playlist 40

input sEnsor sEttings 40

cup sEnsor 41

flow mEtEr calibration 41

calibrating thE grindEr 41

calibrating thE motor-dosEr 41

calibrating thE pumps/ solEnoid valvEs 42

calibrating cold watEr 42

output sEttings 42

maintEnancE 43

gEnEral sEttings 43

hEating unit paramEtErs 44

mixEr anti-lock 44

English

macHiNE iNformatioN 44

faults 44

statistics 47

favouritEs 47

machinE idEntification 47

installation datE 47

tEchnical support contact information 47

ENErgy saviNg moDE 48

sEttings 48

timE framEs 49

paymENt systEms 49

common paramEtErs 49

validator 50

ExEcutivE 50

mdb 51

pricEs 53

import/ Export 54

Eva-dts 54

vidEos 54

imagEs 54

backup 55

logfilE Errors 55

systEm 55

Export mEnu trEE 55

viEw logfilE 55

Export logfilE 55

systEm information 55

import/Export string translations 55

Export rEcipE sEttings 55

advancEd fEaturEs 55

componEnt tEst 56

sEnsor and input dEvicE tEsts 56

output dEvicE tEsts 56

touchscrEEn tEst 56

filling and Emptying thE hEating unit 57

machinE paramEtEr tEsts 57

rEstorE factory sEttings 57

languagE 57

usEr profilEs 58

nEtwork 58

softwarE updatE 60

information 60

coNNEctivity 60

Email sEttings 60

MAINTENANCE 61

gEnEral introduction 61

main switch 61

door switch 61

connEctivity switch 62

maintaining thE brEwing unit 62

pErioDical opEratioNs 64

sanitisation 64

circuit boarDs 67

activation board 68

cpu board 69

Expansion card for paymEnt systEms 70

hEating unit control board 70

ElEctric panEl 70

powEr supply board 71

hEating unit thErmal protEction 71

installing and/or updating softwarE 72

APPENDIX 73

04-2017 5325 00 1

Foreword

The technical documentation forms an

integral part of the appliance and must

therefore accompany any movement or

transfer of ownership in order to allow

the various operators to further consult

the documentation.

Before installing and using the appliance,

the document contents need to be scrupu-

lously read and understood, as the manual

provides important information regarding

installation safety, provisions of use and

maintenance work.

Some illustrations of this manual might

show details or parts which deviate from

those of the machine without changing the

basic information whatsoever.

The manual is divided into three chap-

ters.

Chapter 1 describes the loading and rou-

tine cleaning operations to be performed

in the areas of the appliance which can be

accessed via a key-operated door, without

needing to use other tools.

Chapter 2 contains the instructions need-

ed for a correct installation and the informa-

tion required to optimise the appliance's

performance.

Chapter 3 describes the maintenance

work which requires the use of tools to ac-

cess potentially dangerous areas.

The operations described in Chapter 2

and Chapter 3 must solely be carried

-

edge of the appliance's operation both

from an electrical safety and hygiene

point of view.

TRANSPORT AND STORAGE

traNsportatioN

Special care must be taken when handling

the appliance in order to avoid causing

damage to the appliance and people.

When handling the appliance, there is a

Move the appliance using lifting equip-

ment that is suitable for the size and

-

ing equipment can use the equipment.

Avoid:

-Tipping over and/or tilting the appliance;

-Dragging or lifting the appliance with ropes

or similar;

-Lifting the appliance with lateral grips;

-Shaking or tossing the appliance and its

packaging.

storagE

The storage environment needs to be dry

and of a temperature between 0 and 40°C.

If the appliance freezes, it must be condi-

tioned in environments with temperatures

between 0 and 40°C.

Wait until the appliance's temperature

reaches the same temperature as its sur-

rounding environment before switching it

on.

it to dry completely before switching on the

appliance.

204-2017 5325 00

IF A MALFUNCTION SHOULD

OCCUR

In most cases, technical problems can be

solved by means of small interventions; we

therefore suggest that this manual is read

carefully before contacting the manufac-

turer.

If the anomalies or malfunctions cannot be

resolved, please contact:

Evoca S. p. A.

Via Roma 24

24030 Valbrembo

Italy - Tel No. +39 035606111

APPLIANCE IDENTIFICATION AND

FEATURES

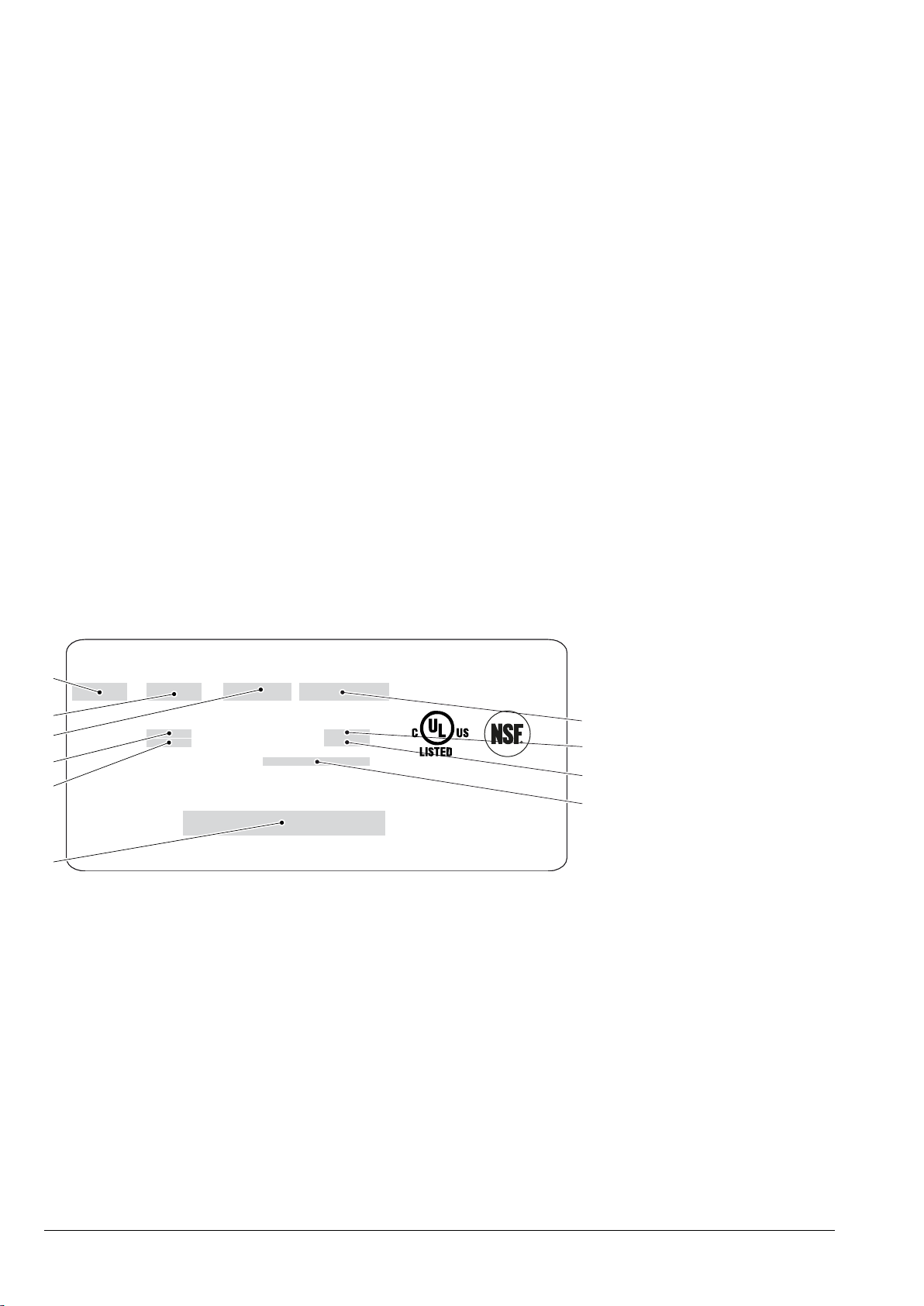

from the plate placed inside the machine on

the right side.

-

ognised by the manufacturer and contains

all the information that allows the manufac-

turer to quickly and safely provide all kinds

of technical information and easily manage

the spare parts

TYPE/TYPECODE/CODE MODEL/MODEL SERIAL NR/SERIAL NR

CALDAIA/BOILER SOLUBILI/SOLUBLE

PRESSIONE/PRESSURE Mpa

CAPACITAí/CAPACITY dm3

PRESSIONE ACQUA RETE/MAINS WATER PRESSURE

TENSIONE/VOLTAGE FREQUENZA/FREQUENCY

POTENZA/POWER CORRENTE/CURRENT

WPOTENZA/POWER

CAFFE/CAFE VAPORE/VAPOUR

XX

1

2

3

4

5

6

7

8

9

10

Fig. 1

1. Product code

2. Type

3. Model

4. Operating voltage

5. Absorbed power

6. Heating unit details

7. Serial number

8. Operating voltage frequency

9. Current

10. Water mains properties

04-2017 5325 00 3

POSITIONING

The appliance is not suitable for outdoor

installations. It must be installed in a dry

environment, with a temperature between

35.6° F and 89.6° F and cannot be installed

in environments where jets of water are

used for cleaning (e.g. large kitchens, etc.).

The appliance must be positioned next to

a wall and in such a way that the back of it

is at a minimum distance of 4 cm from the

wall in order to allow regular ventilation.

Under no circumstances should the ma-

chine be covered with cloths or similar.

The appliance must be placed on a level

surface.

The maximum incline must not exceed 2

degrees; level it up using the adjustable

feet if necessary.

The appliance satisfy the requirements

NSF only when are used 3.93 inches

feet

Positioning on top of a cabinet

The appliance can be placed on a table or

other suitable support (the recommended

height is 32 inches).

We suggest using, where possible, the

appropriate cabinet, where you can place

the waste container, the water supply tank

and, in the event of very hard water, the

descaler.

TECHNICAL SPECIFICATIONS

DimENsioNs

Height 25.59 inches

Width 16.25 inches

Depth 22.25 inches

Depth with door open 33.75 inches

Weight 90 Lbs

25.59

16.25

33.46

43.31

22.25

33.75

Fig. 2

ElEctrical coNNEctioN

Frequency 60 Hz

Maximum power* 1150 W

* Please refer to the nameplate.

boilEr

20.29 oz capacity with 1100 W heating ele-

ment.

lEvEl of NoisE

The level of continuous, equivalent, weight-

ed acoustic pressure is less than 70 dB.

watEr supply

Water supply from mains with water pres-

sure between 7.3 psig e 123.3 psig (5 and

8.5 Bar).

The appliance's software has been de-

signed to control the water supply from an

internal tank (optional kit).

404-2017 5325 00

EsprEsso aDjustmENts

-Coffee grain size

-Coffee dose

-Water dose

frEsH brEw aDjustmENts

-Pre-ground product dose

-Water dose

-Infusion time

iNstaNt aDjustmENts

-Instant powder doses

-Water dose

tEmpEraturE aDjustmENt

Sets the temperature of heating unit via the

software.

ENablE sigNs

-Water present

-Coffee present

-Brewing unit in position

-Liquid residue container is present

-Liquid residue container is empty

-Heating unit temperature reached

safEty mEasurEs

-Door switch

-The microswitch disables connectivity

when the door is open

-Heating unit safety thermostat has a man-

ual reset

-Air-break float jams

-Anti-flooding solenoid valve

-Full liquid waste container float

-Short circuits control/heating unit probe(s)

cut in

-Main electrical circuit fuse.

couNtDowN protEctioN DEvicE of tHE:

-Brewing unit gearmotor

-Grinder

-Pump

tHErmal protEctioN DEvicE of tHE:

-Brewing unit gearmotor

-Coffee-releasing electromagnets

-Grinders

-Motor-doser

-Motor mixer

-Pump

04-2017 5325 00 5

coNtaiNEr capacity

-

tion.

The quantities shown are indicative only

and have been experimentally obtained

from the manufacturer; they can vary de-

pending on the product that is used.

container capacity

beans

3.6 L 1.2 kg

Instant

1 L

2 L

3.6 L

0.3 kg

0.55 kg

-

Instant

hot chocolate

1 L

2 L

3.6 L

0.85 kg

1.5 kg

-

Powdered

milk

1 L

2 L

3.6 L

0.37 kg

1.5 kg

-

Instant

tea

1 L

2 L

3.6 L

1.1 kg

1.65 kg

-

French

vanilla-infused

1 L

2 L

3.6 L

1.1 kg

1.5 kg

-

accEssoriEs aND kit

-

sories and kits in order to vary its perfor-

mance.

The accessories and kits which can be

used with the appliance are available from

the manufacturer.

The accessories and kits are supplied with

installation and test instructions, which

should be scrupulously followed in order to

maintain the safety of the appliance.

The party that performed the installa-

tion is responsible for any damage that

may occur to the appliance, or to things

and people due to incorrect installation.

Important!

Accessories and kits which have not been

approved by the manufacturer, may not

comply with the safety standards, most

especially in regards to live parts.

The manufacturer declines any responsibil-

ity if non-approved components are used.

The installation and subsequent test

operations must be performed by quali-

of the appliance's operation both from

an electrical safety and hygiene point of

view.

When the vending machine is not provided

with credit mechanism and it shall be in-

be added permanently:

The credit mechanism can be used are one

at the following:

-manufacturer MARS and designation MEI

CF7512 or

-manufacturer MARS and designation MEI

VN2712U or

-manufacturer MARS and designation MEI

VN2762RU5M, or

-manufacturer USA Technologies and des-

ignation G9,

and Vender is not to be operated without

credit mechanisms

604-2017 5325 00

VARIABLE COMBINATION LOCKS

Some models are supplied with variable

combination locks.

The lock is supplied with a silver-coloured

key that has a standard combination, which

is used for opening and closing the lock.

It is possible to customise the locks using a

kit, available as an accessory, which allows

the lock combination to be changed.

The kit is composed of a change key

(black) for changing the standard combi-

nation, change keys (gold) and use keys

(silver) for changing and using the new

combinations.

Change and use key packs with other com-

binations can be supplied on request.

Furthermore, other use key (silver) packs

can be requested specifying the combina-

tion printed on the keys.

To change the combination:

1. Open the door of the appliance to avoid

having to force the rotation;

2. Lightly lubricate the inside of the lock

with a lock spray.

3. Insert the current (black) change key and

rotate it to the change position;

4. Extract the current change key and insert

the change key (gold) with the new com-

bination;

5. Slightly turn the change key several

times without fully rotating the key;

6. Rotate the key to the closing position and

remove the change key.

The lock has now assumed the new combi-

nation.

-

er be used.

-

-

ing properly over time.

Other types of lubricants can trap dirt

Fig. 3

04-2017 5325 00 7

Chapter 1

Cleaning and loading

The device must operate at a room tem-

perature between 2 and 32°C.

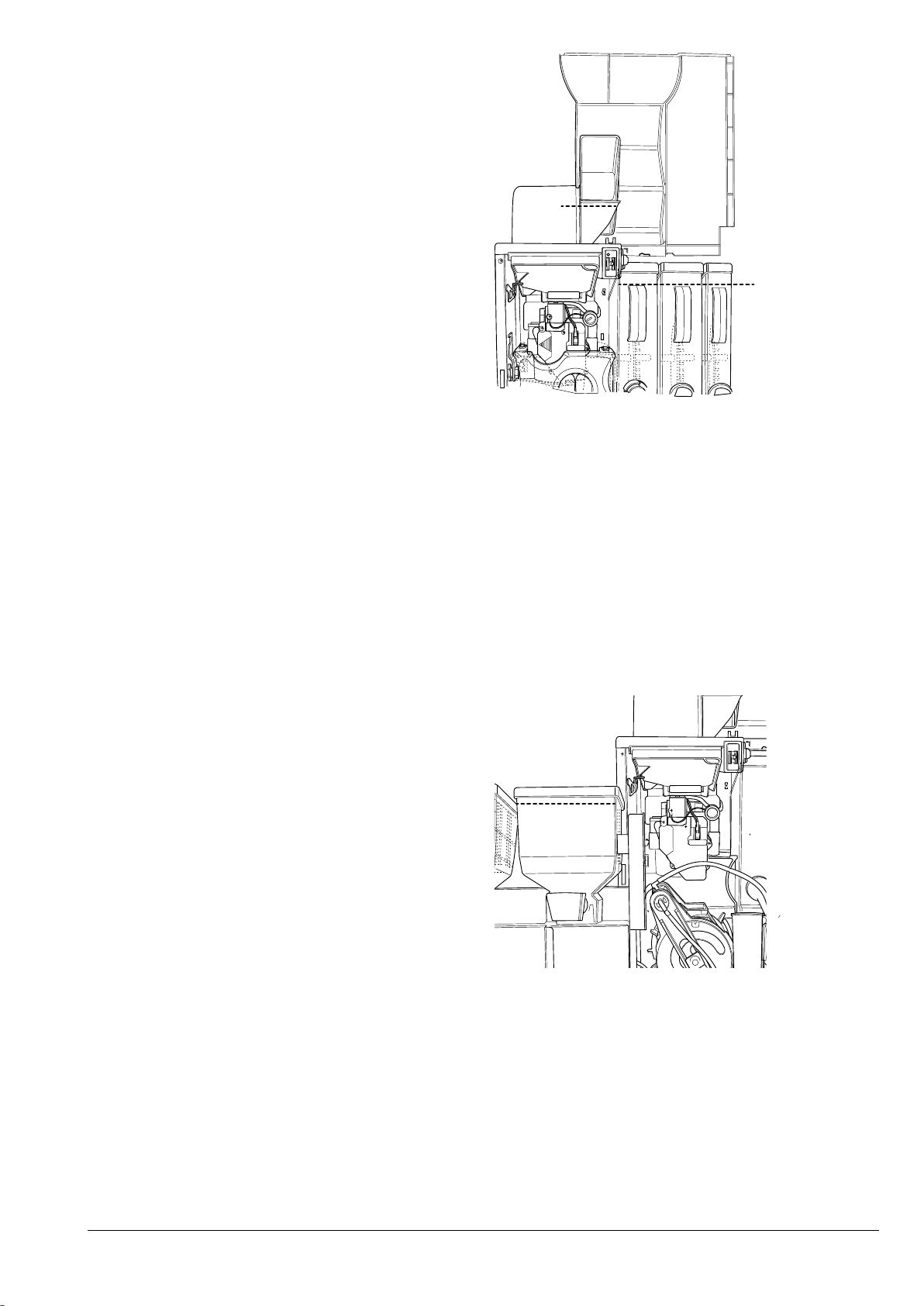

MAIN SWITCH AND SAFETY

MEASURES

maiN switcH

power to the appliance and is positioned

on the left side, close to the solid residue

container.

When carrying out normal cleaning and

product loading tasks, the appliance does

via the main switch, the residue container

must be removed.

Door switcH

With the door open, live-parts cannot

be accessed.

Normal product loading and cleaning op-

erations can be carried out in complete

safety.

All operations which require the ma-

chine to be switched on and the door

open, must EXCLUSIVELY be performed

this condition entails.

coNNEctivity switcH

disconnects the appliance’s connectivity

components.

When the door is open, the functional

groups and/or remote control function is/

are disabled.

All operations which require the

appliance to be switched on, the con-

nectivity functions active and the door

open, must EXCLUSIVELY be performed

this condition entails.

7

11 12 13

10

1

23456

8

9

Fig. 4

1. Connectivity switch

2. Main switch

3. Liquid residue container

4. Mixer

5. Diffuser nozzle

6. Brewing unit

7. Solid residue container

8. Pre-ground coffee container

9. Instant powder container

10. Coffee bean container

11. Door switch

12. Upper panel

13. Instant powder containers

804-2017 5325 00

MACHINE SANITISATION

points and includes information about

controlling the possible growth of bac-

teria.

Under the current health and safety

regulations, the operator of the appli-

ance must apply the self-control pro-

the HACCP (Hazard Analysis Critical

legislation.

Frequently, and depending on how often

the machine is used and the incoming

water quality, as well as the products used,

the appliance must be thoroughly sanitised

to ensure that hygienic products are dis-

pensed.

The sanitisation must be performed using

disinfectants, taking care to mechanically

swabs and/or brushes.

USING HOT BEVERAGES

DISPENSERS

(e.g. plastic cups, ceramic cups, jugs)

The machines that dispense beverages

into open containers must be used ex-

clusively for the sale and distribution of

-Brewing products such as coffee and tea;

-The reconstitution of instant or freeze-

dried products.

These products must be declared by the

manufacturer as “suitable for automatically

dispensing” into open containers.

The dispensed products need to be

consumed immediately. They must un-

Any other use is considered improper and

therefore potentially dangerous.

CONTROLS AND INFORMATION

The controls and information for the user

are located on the door.

All of the messages are displayed on the

touchscreen.

1

2

3

4

5

6

Fig. 5

1. Liquid residue container

2. Dispensing unit

3. Door lock

4. Touchscreen

5. Coffee bean container*

6. Upper panel

* Not fitted on instant models.

04-2017 5325 00 9

LOADING PRODUCTS

they have been stored in compliance

with the manufacturer instructions re-

garding storage and the storage tem-

perature.

expiration date.

The products must be declared by the

manufacturer as “suitable for automatically

dispensing” into open containers.

Products may also be loaded with partially-

full containers.

COFFEE BEANS

For espresso models.

It is recommended to use high-quality cof-

fee beans in order to avoid appliance failure

due to the presence of impurities.

1. Open the door and lift up the top panel.

2. Open the container’s lid.

3. Fill the container with coffee beans.

4. Check that the container’s shutter is

open.

INSTANT PRODUCTS

It is recommended to use high-quality

instant products in order to avoid appliance

failure due to the presence of impurities.

1. Open the door and lift up the top panel.

2. Open the lid of the instant powder con-

tainer.

3. Fill the container with instant powder.

4. Carefully close the lid.

Avoid compressing the powder in order

not contain any clumps.

MAX

MAX

Fig. 6

For ES-FB models.

It is recommended to use high-quality pre-

failure due to the presence of impurities.

1. Open the container’s lid.

2. Rotate the shelf outwards.

3. Fill the container with pre-ground coffee.

4. Carefully close the lid.

5. Reposition the shelf.

MAX

Fig. 7

10 04-2017 5325 00

WATER

For models with an internally-supplied wa-

ter tank only.

on and the water empty warning appears,

the following is required:

1. Empty the tank of any residual water.

2. Sanitise it whilst taking care to mechani-

cally remove residues and visible films

with swabs or brushes, if necessary.

To restore service:

1. Fill the tank with clean drinking water

which is clear and impurity-free.

2. Connect the tank to the appliance.

3. Confirm the appliance's reset operation.

PERIODICAL OPERATIONS

points and includes information about

controlling the possible growth of bac-

teria.

Under the current health and safety

regulations, the operator of the appli-

ance must apply the self-control proce-

HACCP (Hazard Analysis Critical Con-

For each product load or more frequently,

depending on how often the appliance is

used, the incoming water quality, and the

products used, it is necessary to clean and

sanitise the appliance and parts in contact

with the food, by proceeding as described

in the following paragraphs.

Apart from the external parts of the brewing

units and mixers which need to be cleaned

of any powder residue, particularly in the

funnel area, the parts of the mixer which

are in contact with the drink should also be

sterilised.

Under no circumstances should jets of

water be directed at the appliance for

cleaning.

Table of contents

Other EVOCA Vending Machine manuals

Popular Vending Machine manuals by other brands

Dixie Narco

Dixie Narco HVV 276E Assembly

NZR

NZR ZMZ 0205 manual

Automatic Products

Automatic Products Showcase 748 operating manual

SIX Payment Services

SIX Payment Services Worldline DAVINCI III Integration guide

Westomatic

Westomatic H2O Hydration Station Installation & maintenance guide

COFFEtek

COFFEtek Neo + Operator's guide