EVOCA Opera Touch Owner's manual

INSTALLATION, OPERATION, MAINTENANCE

Translation of original instructions

EN English

Doc. No. H6095EN00

Edition 1 02 - 2023

Opera Touch ESB7-R/US 120V

EVOCA S.p.A.

ad unico socio

Sede amministrativa, operativa e legale: Via Roma 24

24030 Valbrembo (BG) Italia

Tel +39 035 606111

Fax +39 035 606463

www.evocagroup.com

Cap. Soc. € 41.138.297,00 i.v.

Reg. Impr. BG, Cod. Fisc. e P.IVA: 05035600963

Reg. Produttori A.E.E.: IT08020000001054

Cod. identicativo: IT 05035600963

01/11/2022

integration of radio modules

In compliance with the national laws in

force, the manufacturer must check the

compliance of the radio equipment with

the essential requirements of the national

legislation.

The procedure used to check compliance

is at the manufacturer’s discretion.

If a radio module is built in a “non-radio”

equipment, the subject integrating the

module will become the manufacturer of

the end product and it must therefore check

the compliance of the end product with the

essential requirements of the national laws

in force in the country of installation of the

equipment.

As a matter of fact, the integration of radio

modules in other products can inuence

the compliance of the end product with the

essential requirements of the national laws

in force.

definitions according to the law

The manufacturer is a natural person who

or a public body which manufactures radio

equipment and/or electric material or has it

engineered, manufactured or marketed by

putting its own trademark or name on it.

An importer or distributor who places

radio equipment or electric material on the

market by putting its own name or trade-

mark becomes the manufacturer.

An importer or distributor who makes any

change to radio equipment or electric mate-

rial already placed on the market to such an

extent that the said change may condition

the compliance with the listed directives

is held to be the manufacturer and it must

therefore assume the relative obligations

according to the said directives.

Symbology

The following symbols may be present

inside the machines, according to models

(signs of danger)

Attention: dangerous voltage

Power o before removing the

cover

To reduce the risk of re or

electric shock, don’t remove

the cover. No user-servicea-

ble part inside.

Repairs should be done by

authorized service personel

only.

Attention

Danger of crushing your han-

ds

Attention

Hot surface

The signs of danger must be readable

and visible; they shall be neither hidden

nor removed. Damaged or unreadable

labels must be replaced.

Warnings

This document intended for the technical

personnel is made available in the electron-

ic format at the manufacturer’s (reserved

area web site).

for installation

The installation and any subsequent

maintenance operation shall be carried

out by the personnel skilled and trained

on the utilisation of the machine ac-

cording to the rules in force

The use of kits and/or accessories not

type-approved by the manufacturer can not

guarantee the observance of safety stand-

ards, in particular for live parts.

The installer will be the sole person respon-

sible for any damage improper installation

may cause to the machine or to things and

people.

The manufacturer declines all responsibility

for the use of non type-approved compo-

nents.

Assembly and any testing operation

must be carried out by qualied per-

sonnel who have a specic knowledge

of the machine operation from the point

of view of electric safety and health

rules.

The intactness of the machine and its

compliance with the standards of rel-

evant installations must be checked by

skilled personnel at least once a year.

Package materials must be disposed of in

observance of the environment.

For the vending machines of hot drinkts

only

The machine is equipped with an automatic

washing system for the mixers with the rela-

tive water circuit and the brewing unit.

If the machine is not used for some time

(weekends, etc.) even for pauses longer

than two days, it is recommended to enable

the automatic washing functions (e.g. be-

fore starting to use the VM.

for use

The machine can be used by children over

8 years and by people having reduced

physical, sensorial or mental skills under

the supervision of people responsible for

their safety or specically trained on the

use of the machine.

Children shall not be allowed to play with

the machine by the people in charge of

their supervision

Children shall not be allowed to clean or

service the machine.

for the environment

Some tricks will help you to protect the

environment:

-use biodegradable products to clean the

machine;

-properly dispose of all the packages of the

products used to fill and clean the ma-

chine;

-power off the machine during inactivity for

energy saving.

for dismantling and disposal

When dismantling the machine, it is rec-

ommended to destroy the machine rating

plate. The symbol shows that the ma-

chine can not be disposed of as

common waste, but it must be

disposed of as it is established by

the 2012/19/EU (Waste Electrical

and Electronic Equipment - WEEE)

European Directive and by the national

laws arising out of it in order to prevent any

negative consequence for environment and

human health.

The dierentiated collection of the machine

at the end of its life is organised and man-

aged by the manufacturer.

For the correct disposal of the machine

contact the sales point where you have

purchased the machine or our after-sales

service.

The unlawful disposal of the machine im-

plies the application of the administrative

sanctions provided for by the rules in force.

Attention!

If the machine is equipped with a cooling

system, the cooling unit contains HFC-

R134a uoridised greenhouse eect gas

ruled by the Kyoto protocol, the total heat-

ing potential of which is equal to 1300.

for the privacy

Only for the machines having a video ca-

mera and/or webcam.

The video camera and/or webcam for facto-

ry settings is disabled; if enabled, it shoots

soundless imagines without being able to

store them.

The Customer acknowledges that he/she

will become the Holder of the personal data

acquired if the video camera and/or web-

cam built in the equipment is activated.

Starting from that time, the Holder will assu-

me all the relative rights and duties accor-

ding to the provisions in force on the matter.

English

INTRODUCTION 1

transport and storagE 1

in casE of failurE 2

idEntification of thE machinE and its fEaturEs 2

positioning thE vEnding machinE 3

tEchnical fEaturEs 3

variablE combination lock 6

CLEANING AND LOADING 7

switchEs and safEty dEvicEs 7

hygiEnE and clEaning 8

using thE vEnding machinEs of hot drinks 8

coNtrols aND iNformatioN 9

proDuct loaDiNg 9

coffEE bEans 9

instant products and sugar 10

rEfErEncE cup spEcifications 10

cups 10

pErioDical opEratioNs 11

clEaning mixErs and food circuits 11

clEaning thE brEw unit 13

sugar rElEasE 13

dispEnsing compartmEnt 14

mixEr channEls 15

clEaning thE watEr supply tank 15

powEr on 15

sErvicE intErruption 15

wasH cyclEs 15

INSTALLATION 16

door switch 17

connEctivity switch 17

unpacking thE machinE 18

paymEnt systEm assEmbly 18

watEr supply 19

dEcalcifiEr 20

ElEctric connEction 21

nEtwork connEctions 22

mastEr / slavE bank connEction 23

first powEr-oN 24

sanitising for thE first timE 24

opEratioN 25

brEw unit 25

cup sEnsor 26

dispEnsing compartmEnt lighting 27

controlling and adjusting sEttings 27

grindEr-dosErs 27

instant dispEnsing 30

usE of usb kEys 31

connEctivity 31

touch scrEEn 32

Normal opEratioN moDE 32

drink dispEnsing 32

softwarE architEcturE 33

PROGRAMMING 34

accEss to programming mEnus 34

Entry of valuEs 35

Daily actioNs 36

washing and rinsing 36

filling canistErs 36

cash actions 36

slavE machinE rEmotE display 36

sEttiNgs of sElEctioNs 37

arrangEmEnt of sElEctions 37

catEgoriEs 37

products 37

contEnt of thE machinE 42

macHiNE sEttiNgs 43

configuration 43

modify intErfacE strings 44

display sEttings 44

gEnEral display sEttings 44

playlist 45

sEttings of input sEnsors 45

cup sEnsor 45

calibrations 46

output sEttings 47

maintEnancE 48

gEnEral sEttings 48

boilEr paramEtErs 49

prE-dispEnsing sEttings 49

mastEr slavE sEttings 49

macHiNE iNformatioN 50

failurEs 50

statistics 52

favouritEs 52

machinE idEntification numbEr 53

installation datE 53

tEchnical support contacts 53

ENErgy saviNg 53

sEttings 53

EnErgy saving timE bands 54

paymENt systEms 55

protocol 55

pricEs 58

import / Export 59

Export Evadts 59

vidEo 60

imagEs 60

backup 60

logfilE of failurEs 60

systEm 61

Export mEnu trEE 61

display log filEs 61

Export log filEs 61

systEm information 61

import / Export thE translations of strings 61

Export thE sEttings of rEcipEs 61

advancEd functionalitiEs 61

tEchnical fEaturEs 61

filling and Emptying thE boilEr 63

complEtE sElEctions 63

rEstorE sEttings by dEfault 63

schEdulEd EquipmEnt rEstart 63

datE and timE sEtup 63

languagE 63

usErs’ profilEs 64

nEtwork 64

softwarE updatE 65

information 65

coNNEctivity 66

Email sEttings 66

MAINTENANCE 67

gEnEral forEword 67

main switch 68

connEctivity switch 68

brEw unit maintEnancE 69

pErioDical opEratioN 70

sanitising 70

ElEctronic boards 73

cpu board 74

actuation board 75

boilEr control board 76

currEnt rEgulator board 76

powEr supply unit 76

fan rEplacEmEnt 77

boilEr hEat protEction 77

softwarE installation and/or updatE 78

APPENDIX 79

02-2023 6095 00 1

Introduction

The technical documentation supplied

is an integral part of the equipment and

it must therefore accompany the equip-

ment whenever it is either moved or

transferred to enable the various opera-

tors to consult it.

Before starting to install and use the ma-

chine, it is necessary to carefully read and

understand the content of the documenta-

tion since it can supply important informa-

tion on installation safety, utilisation rules

and maintenance operations.

The manual is divided into tree chap-

ters.

The is intended to describe

the ordinary lling and cleaning operations

that shall be carried out in areas of the ma-

chine that can be accessed with the simple

use of the door key, without using any other

tool.

The second chapter contains the instruc-

tions for correct installation as well as the

information necessary for optimal utilisation

of the machine performance.

The third chapter is intended to describe

the maintenance operations involving the

use of tools for access to potentially dan-

gerous areas.

The operations described in the second

and third chapter must be carried out

only by the personnel who have a spe-

-

tion from the point of view of electric

safety and health rules.

TRANSPORT AND STORAGE

traNsport

To avoid any damage to the equipment and

any injury to the people, the equipment

must be handled with great care.

While handling, there is the danger of

crushing one's hands and/or feet: never

shoes.

Handle the equipment by using lifting

means suitable for the size and the

weight of the equipment (e.g. lifting

Lifting means may only be used by per-

Please avoid:

-overturning and/or tilting the equipment;

-dragging or lifting the equipment by means

of ropes or alike;

-lifting the equipment by its sides;

-shaking or impacting the equipment and

its package.

storagE

The storage area must be dry and its tem-

perature lie between 32 and 104 °F

If the equipment should freeze, condition it

at a temperature between 32° and 104 °F.

Wait for the temperature of the equipment

to adjust to the room temperature before

powering it on.

Before powering on the equipment, please

wait for the humidity condensate (if any) to

dry completely.

202-2023 6095 00

IN CASE OF FAILURE

In most cases, any technical problem can

be solved by carrying out minor operations.

As a consequence, we suggest carefully

reading this manual before contacting the

manufacturer.

In case of failures or malfunctions that can

not be solved, please apply to:

Evoca S. p. A.

Via Roma 24

24030 Valbrembo

Italy - Tel. +39 035606111

IDENTIFICATION OF THE

MACHINE AND ITS FEATURES

Every single machine is identied by a spe-

cic serial number that can be found on the

rating plate arranged inside.

The plate is the only one recognised by the

manufacturer and it contains all the data

that enable the manufacturer to supply

technical information of any kind in a quick

and safe manner and to facilitate the man-

agement of spare parts.

TYPECODE MODEL SERIAL NR

BOILER SOLUBLE

PRESSURE Mpa

CAPACITY dm3

MAINS WATER PRESSURE

VOLTAGE FREQUENCY

POWER CURRENT

WPOWER

CAFE VAPOUR

1

2

3

4

5

6

7

8

9

10

Fig. 1

1. product code

2. type

3. model

4. operating voltage

5. absorbed power

6. boiler data

7. serial number

8. operating voltage frequency

9. current

10. water network features

02-2023 6095 00 3

POSITIONING THE VENDING

MACHINE

The machine is not suitable for installation

outdoors. It must be installed in a dry room

and far from any source of heat at a tem-

perature ranging from 41 °F to 93 °F. It can

not be installed in a room where water jets

are used for cleaning (e.g. large kitchens,

etc.).

The machine must be installed near a wall,

but in such a way that the back is min. 1,57

inch far from the wall in order to provide for

regular ventilation; in no case, it shall be

covered with any piece of cloth or alike.

The maximum inclination shall not exceed

2 degrees. If necessary, level it by using the

adjustable feet.

TECHNICAL FEATURES

23.62

47,24

29,13

49,21

72,04

Fig. 2

Weight 297 lb

Voltage 120 VAC

Frequency 60 Hz

Maximum power 1850 W

NoisE lEvEl

The continuous sound pressure level is

below 70 dB.

402-2023 6095 00

watEr supply

Supplied by the network, the water pres-

sure of which lies between 7,25 psi and

123,28 psi.

The machine software can manage the

water supply from an internal tank (optional

kit).

cups

Machine Capacity: 85 cups per turret / 340

total

The capacity has been measured with the

reference cup specified on page 10 and

may vary if different cup models are used.

For machine proper functionning, the cups

used must have the same specifica-tions

than the reference cups.

paymENt systEm

The machine can be electrically arranged

for the systems with an Executive, BDV and

MDB protocol and for the assembly of 24

Vdc validators.

The space is not only arranged to accom-

modate the coin mechanism, but also to

assemble the most widespread payment

systems (optionals).

salEs pricEs

A dierent price can be set for every single

selection.

The sales price is the same for all selec-

tions according to the standard setup.

coiN box

Made of sheet iron. Cover and lock avail-

able as accessories.

EsprEsso rEgulatioNs

-Coffee granulometry

-Coffee dose

-Water dose

iNstaNt rEgulatioNs

-Instant powder doses

-Water dose

tEmpEraturE rEgulatioN

The boiler temperature can be set up via

software.

approvals

-Cup presence

-Water presence

-Coffee presence

-Coffee unit position

-Liquid waste empty

-Operation temperature reached

safEty DEvicEs

-door switch

-connectivity disable micro switch with

open door

-manually resettable boiler safety thermo-

stat

-air-break float jam

-anti-flood solenoid valve

-float controlling liquid waste full

-boiler probe short-circuit / interruption

control

-protection with board and coin mechanism

supply transformer fuse

timE-basED protEctioN for:

-Pump

-Coffee unit ratio-motor

-Coffee dispensing

-Grinder

-Column shift motor

HEat protEctioN of:

-Ingredient motors

-Coffee unit ratio-motor

-Coffee release electromagnet

-Pump

-Whipper motors

-Grinder motor

02-2023 6095 00 5

caNistEr capacity

the machine may have dierent canister

combinations.

The indicative product quantity they can

contain is:

Coee beans (ES version) 7,05 Lb.

canister capacity

Coee

instant

1.8 Lt.

2.5 Lt.

4.5 Lt.

6 Lt.

0,9 Lb

1 Lb.

2 Lb.

3 Lb.

Chocolate

instant

2.5 Lt.

4.5 Lt.

6 Lt.

4 Lb.

7 Lb.

9,9 Lb.

Milk

instant

2.5 Lt.

4.5 Lt.

6 Lt.

1,5 Lb.

2,64 Lb.

3.74 Lb.

Tea

Instant lemon

2.5 Lt.

4.5 Lt.

6 Lt.

4,4 Lb.

7,7 Lb.

11 Lb.

Sugar 2.5 Lt.

4.5 Lt.

6 Lt.

4,4 Lb.

7,7 Lb.

11 Lb.

Ginseng 2.5 Lt.

4.5 Lt.

6 Lt.

3,96 Lb.

-

-

Broth

instant

2.5 Lt.

4.5 Lt.

6 Lt.

3,08 Lb

5,51 Lb.

7,71 Lb.

accEssoriEs aND kits

Accessories and kits can be mounted on

the machine to vary performances thereof.

The accessories and kits that can be ap-

plied on the equipment are made available

at the manufacturer’s.

The accessories and kits are supplied with

mounting and testing instructions that shall

be strictly followed to preserve the machine

safety.

The installer is the sole person responsi-

ble for any damage improper installation

may cause to the machine or to things and

people.

Important !!!

The use of accessories and kits not type-

approved by the manufacturer can not

guarantee the observance of safety stand-

ards, in particular for live parts.

The manufacturer declines all responsibility

for the use of non type-approved compo-

nents.

Assembly and any subsequent test-

ing operation must be carried out by

from the point of view of electric safety

and health rules.

602-2023 6095 00

VARIABLE COMBINATION LOCK

Some models are supplied with a variable

combination lock.

The lock is complete with a silver key, with

the standard combination, for opening and

closing.

It is possible to customise the locks by us-

ing a kit made available as an accessory

and intended to change the lock combina-

tion.

The kit is composed by a change key

(black) of the current combination as well

as by change (gold) and use (silver) keys of

the new combination.

Sets of change and use keys with other

combinations can be supplied upon re-

quest.

Moreover, further sets of use keys (silver)

may be requested by specifying the combi-

nation stamped on the keys.

usual opening operations since this

To change the combination:

1. Open the door of the equipment to avoid

having to force the rotation;

2. Slightly lubricate by using a spray inside

the lock;

3. Insert the current change key (black) and

turn it until you reach the change posi-

tion;

4. Remove the current change key and

insert the change key (gold) with the new

combination;

5. Turn the change key slightly several

times without completing the rotation

6. Turn it until you reach the close position

and remove the change key.

The lock has now assumed the new combi-

nation.

no longer used.

time, it is recommended to lubricate the

Other types of lubricants may trap dirt

Fig. 3

02-2023 6095 00 7

Chapter 1

Cleaning and Loading

The machine is not suitable for installation

outdoors. It must be installed in a dry room

at a temperature ranging from 41 °F to 93

°F. It can not be installed in a room where

water jets are used for cleaning (e.g. large

kitchens, etc.).

Before cleaning and loading, wash

your hands and wear disposable

gloves: the use of gloves is not remov-

ing the need for hand hygiene.

SWITCHES AND SAFETY DEVICES

Door switcH

Whenever you open the door, a special

switch will power o the electric installation

of the equipment to allow the user to carry

out the ordinary lling and cleaning opera-

tions described here below in totally safe

conditions.

All the operations requiring the ma-

chine to be directly connected to a

source of electricity when the door is

open must be ONLY carried out by the

coNNEctivity switcH

On opening the door, a special switch will

deactivate the connectivity components of

the equipment.

When the door is open, the drives of func-

tional units and/or remote control are disa-

bled.

All the operations requiring the

machine to be directly connected to

a source of electricity and the con-

nectivity functions to be active when

the door is open must be ONLY car-

1

2

3

4

5

6

7

89

Fig. 4

1. Waste bucket full

2. Dispensing compartment

3. Door switch

4. Mobile nozzles

5. Brew unit

6. Cup stacker

7. Canister

8. Mixer

9. Connectivity switch

802-2023 6095 00

USING THE VENDING MACHINES

OF HOT DRINKS

The dispensers of drinks in open canisters

may be only used for selling and dispens-

ing drinks obtained by:

-Brewing of products such as coffee and

tea;

-Reconstituting instant or freeze-dry

packed products;

These products shall be declared as “suit-

able for automatic dispensing” in open

canisters by the manufacturer.

Dispensed products shall be consumed

immediately. Under no circumstance

for later consumption.

Any other use shall be considered as im-

proper and thus potentially dangerous.

HYGIENE AND CLEANING

This manual shows the potential criti-

cal points and gives the instructions

necessary to control any bacterial pro-

liferation.

On the basis of the health and safety

rules in force, the operator of the vend-

ing machine shall apply the self-control

procedures established according to

the provisions of the HACCP (Hazard

-

tive and the national laws.

At the time of the installation, it is nec-

essary to completely sanitise the water

circuits and the parts in contact with

-

terium that may have built up during

storage.

It is recommended to use sanitising prod-

ucts to clean the surfaces, even if not di-

rectly in contact with foodstus.

Some parts of the machine can be dam-

aged by aggressive detergents.

The manufacturer disclaims all responsibil-

ity for any damage caused by the non-ob-

servance of the above or the use of aggres-

sive or toxic chemical agents.

before carrying out any maintenance

operation requiring the disassembly of

components.

02-2023 6095 00 9

CONTROLS AND INFORMATION

The controls and information for the user

are arranged outside.

All messages are displayed on the touch

screen of the machine.

6

7

8

9

10

11

5

1

2

3

4

Fig. 5

1. Lower aesthetic panel

2. Dispensing compartment

3. Lock

4. Touch screen

5. Upper aesthetic panel

6. Advertising space

7. Space for bill validator

8. Advertising space or cashless systems

9. Coin return button

10. Coin insert

11. Coin return

PRODUCT LOADING

that they have been preserved accord-

ing to the producer's instructions for

storage and holding temperature.

date.

The products shall be declared as “suitable

for automatic dispensing” in open canisters

by the manufacturer.

Products may even be loaded if canisters

are partially full.

COFFEE BEANS

It is advisable to use good quality cof-

fee beans to avoid any malfunction of the

equipment due to the presence of impuri-

ties.

1. open the canister cover.

2. fill with coffee beans.

3. make sure that the canister shutter is

open

10 02-2023 6095 00

INSTANT PRODUCTS AND SUGAR

It is advisable to use quality instant prod-

ucts to avoid any malfunction of the equip-

ment due to the presence of impurities.

1. open the instant powder canister cover.

2. fill with instant powder

3. close the cover carefully.

-

ing.

have loaded are not lumpy.

MAX

Fig. 6

REFERENCE CUP

SPECIFICATIONS

Fig. 7

CUPS

The cup dispenser shelf has got a double

articulated joint intended to improve the

accessibility to the cup dispenser for lling

columns.

To load the columns, act as follows:

-Open the machine door

-Pull the shelf to release the dispensing

compartment

-Turn the shelf to the outside

-Remove the cover from the cup stacker;

-Load the cups

1

2

Fig. 8

1. Cover

2. Cup column

Capacity 12 oz

Height 114.50 mm

Diameter 81.20 mm

Weight 8.50 g

Type Vending

Line Single Wall

Material PE Coated Paper

02-2023 6095 00 11

PERIODICAL OPERATIONS

This manual shows the potential criti-

cal points and gives the instructions

necessary to control any bacterial pro-

liferation.

On the basis of the health and safety

rules in force, the operator of the vend-

ing machine shall apply the self-control

procedures established according to

the standards of the HACCP (Hazard

-

tive.

Clean and sanitise the machine and the

parts in contact with the foodstus, as it

is described by the following paragraphs,

whenever you load products or more fre-

quently and according to the utilisation of

the machine, the inlet water quality and the

products in use.

It is necessary not only to remove any pow-

der residue from the parts outside brewers

and mixers, in particular in the funnel area,

but also to sanitise the parts in contact with

the mixer drink.

It is absolutely forbidden to direct water

CLEANING MIXERS AND FOOD

CIRCUITS

Whenever products are loaded and/or

weekly or more frequently, according to the

use of the machine, the inlet water quality

and the products in use, sanitise the mixers.

The parts to be cleaned are: powder de-

posit drawers, mixers and the conduit in-

tended to dispense instant drinks

It is absolutely forbidden to use water

3

5

2

1

6

4

Fig. 9

1. Powder funnel

2. Splash-guard ring

3. Water conveyor

4. Mixer impeller

5. Powder port

6. Rear cover

12 02-2023 6095 00

To clean the mixers, act as follows:

1. open the cover of mixers and lift the pow-

der ports as far as the retainer;

2. detach the instant drink tube from the

water funnel connection

3. rotate the ring nut intended to fasten the

water funnel counterclockwise and re-

move the mixer from the machine

4. separate all components (the funnels of

instant products, water funnels, convey-

ors, powder deposit drawers)

5. remove the mixer impeller;

Fig. 10

6. dip the components into a container with

the sanitising solution you have prepared

before for about 20 minutes, wash and

make sure that you have mechanically

removed visible residues and films by

using, if necessary, pipe cleaners or

brushes;

7. re-assemble the impellers

8. re-position the mixer.

Make sure that the water funnel is prop-

erly inserted.

9. rotate the ring nut intended to fasten the

water funnel clockwise to secure the

mixer to the machine

after having assembled the parts, act

as follows, any way:

-wash the mixers and add some drops of

the sanitising solution into the various fun-

nels.

-rinse the parts abundantly to remove any

residue of the solution in use.

All the operations requiring the ma-

chine to be directly connected to a

source of electricity must be ONLY car-

Table of contents

Other EVOCA Vending Machine manuals

Popular Vending Machine manuals by other brands

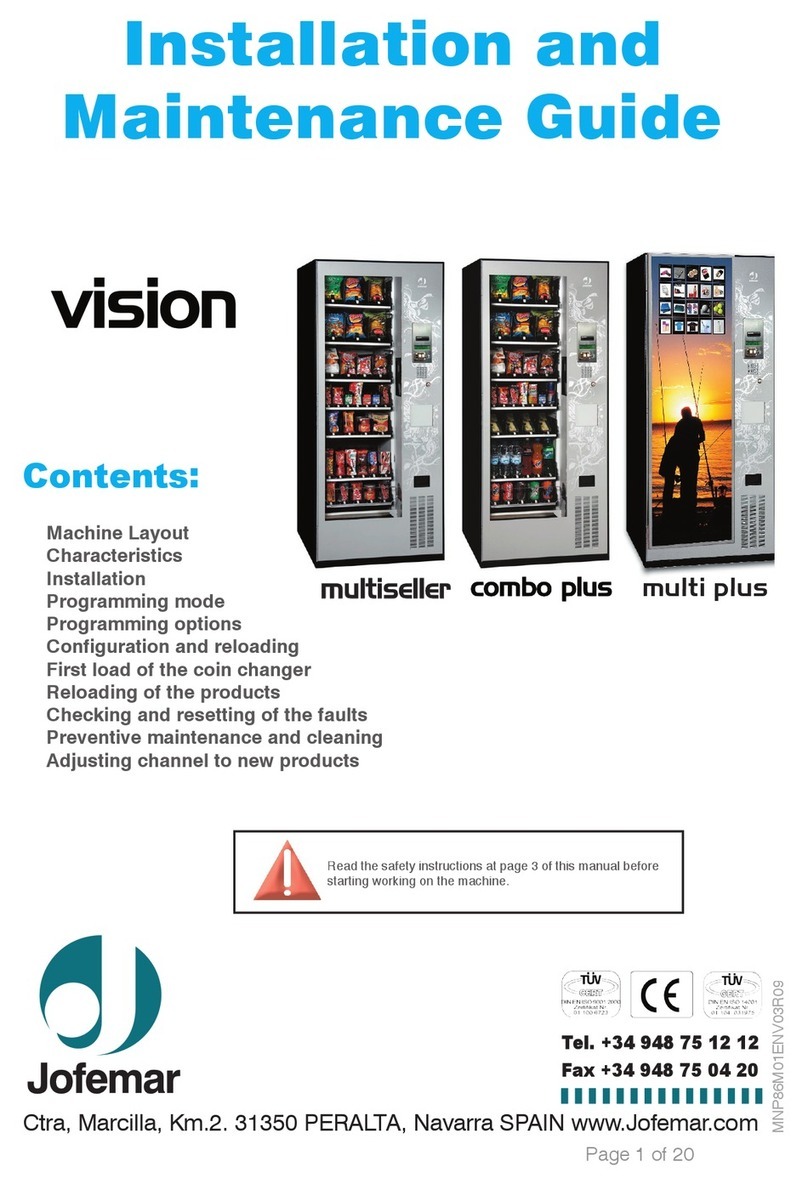

Jofemar

Jofemar vision multiseller Installation and maintenance guide

VeriFone

VeriFone UX301 installation guide

Cafection

Cafection EMBLEM Service & installation manual

Westomatic

Westomatic Sigma Touch Operator's & installation manual

Goldmedal

Goldmedal 5300 instruction manual

Elektral

Elektral Tru-VEND Maxi-Kafe Instructions for use & maintenance manual

COFFEtek

COFFEtek Neo + Operator's guide

Crane

Crane P Series manual

Sanden

Sanden Vendo Vue SXY 30 manual

Crane

Crane Dixie-Narco Glassfront BevMax 3 5800 Installation & setup guide

Necta

Necta Zenith Fresh Brew Instant Installation, operating and maintenance manual

CribMaster

CribMaster ProStock Removal and Replacement