eXact PipeCut 410E User manual

PipeCut 280E/410E

System

EN Operating Instructions 5-16

patents: US 7,257,895, JP 4010941, EP 1301311, FI 108927, KR 10-0634113

Exact Tools Oy

Särkiniementie 5 B 64

00210 HELSINKI

FINLAND

Tel + 358 9 4366750

FAX + 358 9 43667550

www.exacttools.com

2

Exact PipeCut 280/410 System

Blade information for Exact PipeCut saws

TCT (tungsten carbide tip) saw blades are for cutting steel, copper, aluminium and all kind of plastics. TCT blades

can be sharpened.

Cermet (ceramic alloy tip) saw blades are for cutting stainless steel, acid proof materials, steel, copper, aluminium

and all kind of plastics. Cermet blades can be sharpened.

Diamond blades are for cutting cast iron only. Diamond blades can not be sharpened.

280E/410E speed control recommendations:

Stainless steel I

Steel II

Cast-iron II

Plastics II

3

A

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

4

Declaration of Conformity

We declare under our sole responsibility that the pipe cutting machine, Exact PipeCut 280E/410E

described under “Technical Data” are in conformity with the following standards or standardization

documents: EN60745-1, EN60745-2-5, EN55014-1, EN 55014-2, EN61000-3-2, EN61000-3-3

according to the provisions of the directives 2014/30/EU, 2006/42/EC.

For more information, please contact Exact Tools at the following address.

The technical file is available at the address underneath.

The person authorized to compile the technical file:

Helsinki, 01.02.2016

Seppo Makkonen, Managing director

Exact Tools Oy

Särkiniementie 5 B 64

FI-00210 Helsinki

Finland

5

Contents The original language of this manual is english English

Contents

Information

6. Technical data

7. Package contents

Safety

8. Safety instructions

Operation

10. Functional description

10. Product features

11. Before operating the tool

11. Connection to the mains power supply

11. Precise setting of the cutting point

11. Setting the pipe on supports

12. Attaching the pipe saw to the pipe

12. Piercing the pipe wall

12. Sawing around a pipe

13. Overload protection and rotation speed control

13. Improving possible misalignment of the cut

13. Model 280E cutting result adjustment

14. Model 410E cutting result adjustment

14. Installing and changing the saw blade

15. Maintenance and servicing instructions

15. Environment/Disposal

15. Guarantee/Guarantee conditions

16. Tips for using Exact PipeCut saws

Exploded view (separate attachment)

Definitions: Safety guidelines

The definitions below describe the level of severity for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result

in property damage.

Denotes risk of electric shock.

6

Information English

Operating, safety, and servicing instructions

Please read this operating, safety, and servicing instructions carefully before using

the pipe saw. Also store this instruction book somewhere accessible to everyone

using the pipe saw. In addition to these instructions, always follow the official work,

health and safety regulations. The Exact PipeCut is meant for professional use only.

Technical data

Model Pipecut 280/PipeCut 410E

Voltage 1 230 V - 240 V / 50 Hz

Power 1750 W

No-Load speed I (low) = 2900/min, II (high) = 3900/min

Intermittent operation 2.5 min ON / 7.5 min OFF (S3 25% 10 min)

Blade diameter 165 mm (6.50”)

Mounting bore 62 mm (2.44”)

Weight 280E 9.0 kg (20 lbs)

Weight 410E 12.1 kg (26 lbs)

Range of use Ø 280E 40 mm – 280 mm (1.6”- 11”)

Range of use Ø 410E 75 mm – 410 mm (3.0”- 16”)

Max. pipe wall steel 10 mm (0.4”)

Max. pipe wall plastics 38 mm (1.5”)

Protection class

/ II

Spindle lock Yes

Speed preselection Yes

Constant electronic control Yes

Overload Protection Yes

Reduced starting current Yes

Vibration 2.84 m/s2

LpA (sound pressure) 90.6 dB(A)

KpA (sound pressure uncertanity) 3 dB(A)

LWA (acoustic power) 103.6 dB(A)

KWA (acoustic power uncertanity) 3 dB(A)

The values given are valid for nominal voltages [U] of 230/240 V. For lower voltage and models for

specific countries, these values can vary.

Please observe the article number on the type plate of your machine. The trade names of the

individual machines may vary. Only for power tools without reduced starting current: Starting cycles

generate brief voltage drops. Interference with other equipment/machines may occur in case of

unfavourable mains system conditions. Malfunctions are not to be expected for system impedances

below 0.36 ohm.

7

Information English

Noise/Vibration Information

Measured values determined according to EN60745.

Wear hearing protection!

Vibration total values (triax vector sum) determined according to EN60745:

Vibration emission value ah=2.84 m/s2, Uncertainty K =1.5 m/s2.

The vibration emission level given in this information sheet has been measured in accordance with

a standardised test given in EN 60745 and may be used to compare one tool with another. It may be

used for a preliminary assessment of exposure.

WARNING: The declared vibration emission level represents the main applications of the tool.

However if the tool is used for different applications, with different accessories or poorly

maintained, the vibration emission may differ. This may significantly increase the exposure level over

the total working period.

An estimation of the level of exposure to vibration should also take into account the times when the

tool is switched off or when it is running but not actually doing the job. This may significantly reduce

the exposure level over the total working period.

Identify additional safety measures to protect the operator from the effects of vibration such as:

maintain the tool and the accessories, keep the hands warm, organize work patterns.

Exact PipeCut 280E/410E pipecutting system,

Package contents:

Please check the package contains the following items:

1. Pipecutting System case

2. Exact PipeCut 280E or 410E pipe saw

3. Cutting supports × 4

4. Operating instructions

5. Hex socket key 5 mm (and 2 mm in 280E) fitted to the machine

6. TCT blade 165 × 62 fitted on the machine

7. DVD-video disc with instructions

OR

1.

2.

3. 4.

5.

6.

7.

8

Safety English

9

Safety English

Support large panels (pipes) to minimise the

risk of blade pinching and kickback. Large

panels (pipes) tend to sag under their own weight.

10

Safety English

Intended Use

PipeCut 280E / 410E:

The PipeCut 280E/410E pipe saw is intended

for use as a pipe fitter’s tool at the installation

site. The PipeCut 280E/410E pipe saw can only

be used to cut round pipes, with a diameter

of 280E: 40 mm – 280 mm (1.6”-11”) or 410E:

75 mm – 410 mm (3”-16”) and a maximum wall

thickness of 10 mm (0.4”) with steel and 38 mm

(1.5”) with plastics. The PipeCut 280E/410E pipe

saw can be used to cut all normal pipe materials,

such as steel, stainless steel, cast iron, copper,

aluminium and plastic. PipeCut 280E/410E

pipe saw is intended for short, intermittent use.

The machine may be loaded for 2.5 minutes

during a 10-minute period (S3 25 %). PipeCut

280E/410E pipe saw is not intended for use

in industrial production. Use pipe holders to

support pipe.

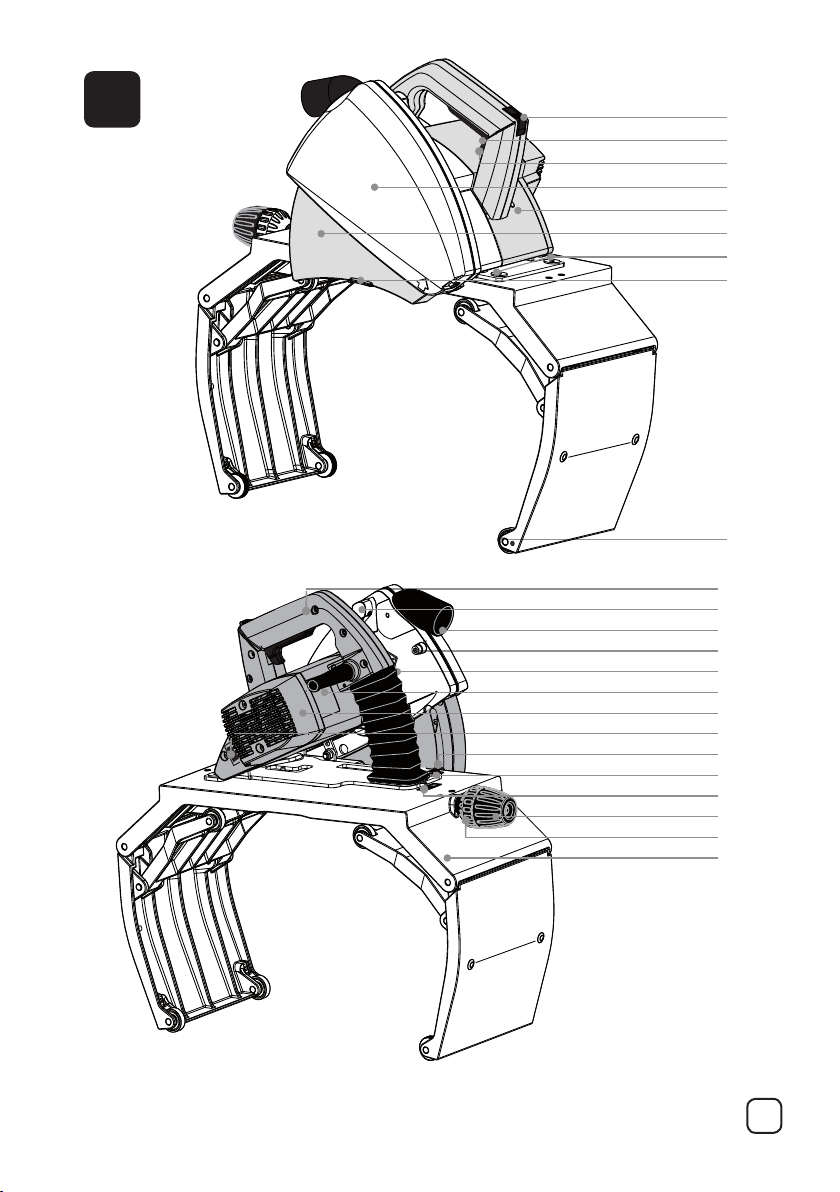

Product Features

While reading the operating instructions, unfold

the graphics page for the machine and leave it

open. This page is folded under the cover of this

manual (page 3). The following numbering of the

product features refers to this illustration.

Figure A

1. UNLOCK button

2. Power switch

3. Power-switch locking lever

4. Blade-guard cover

5. Overload indicator light

6. Moving blade-guard

7. Locking screws of adjustment

(in model 410E)

8. Edge of moving blade-guard

9. Adjustment wheel (in model 280E)

10. Operating handle

11. Chip removal lever

12. Chip removal nozzle

13. Blade-guard screw

14. Spindle-lock button

15. Rating plate

16. Motor unit

17. Speed control

18. Adjusting screw

19. Locking screw of adjustment

20. Pointer of adjustment

21. Gripper adjustment handle

22. Gripper safety

23. Gripper unit

11

Operation English

Exact PipeCut 280E/410E

pipecutting system

operating instructions

Before operating the tool

-Ensure that the motor unit is in the upright

position. The yellow mark of the UNLOCK

button is visible.

- Check that the blade is correctly fitted, in

good condition and suitable for the material

to be cut.

- Ensure the pipe saw guide wheels rotate.

- Ensure the support wheels rotate.

- Check the operation of the lower blade

guard.

- Ensure the pipe is empty.

- Check the position of chip removal lever.

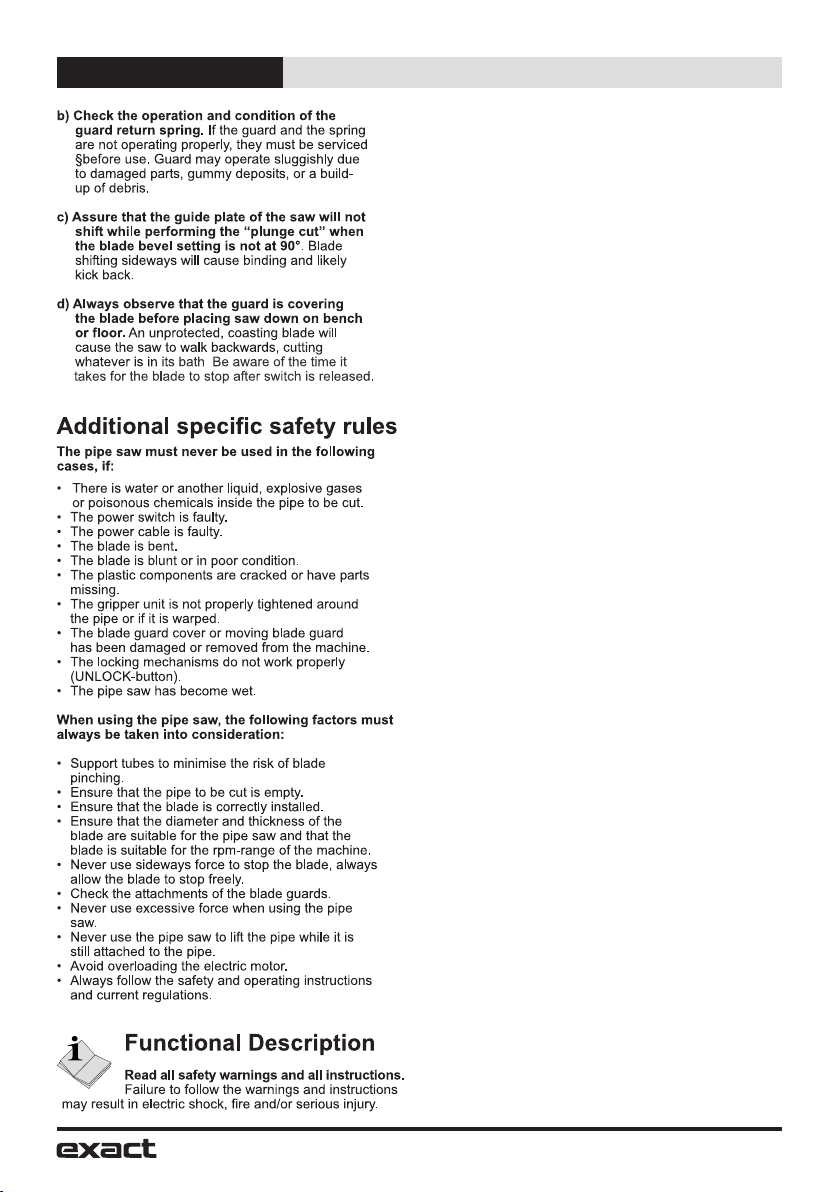

The pipe saw is equipped with a nozzle for

removing chips. When sawing plastic pipes, turn

the chip removal lever (Fig A/11) to “open” position

(Fig B), which opens the hatch in the blade

housing. If you attach a vacuum cleaner to the

chip removal nozzle, most of the plastic chips will

then fly out of the chip removal nozzle (Fig A/12)

and won’t remain inside the blade housing. When

sawing metal pipes, turn the lever to “close”

position (Fig B). The metal chips will drop out from

the bottom of the blade housing. Never attach

a vacuum cleaner when cutting metal pipes!

Connection to the mains power supply

Ensure that the mains voltage is the same as

indicated on the rating plate (Fig A/15). Connect

the pipe saw to the power outlet only after

having checked this.

Precise setting of the cutting point

When you mark the cutting point on the pipe to be

cut, deduct 20 mm from the required dimension

(Easy-to-remember rule: The cutting mark location

requires a measurement of - 20 mm.) (Fig C)

Setting the pipe on supports

Use the system supports when cutting pipes.

This will ensure safe working and optimum

result. Work on flat surface. Place the pipe on

two supports so that the cutting point is between

the supports. Place two more support under both

ends of the pipe. Check that all support wheel

contact the pipe (adjust if required e.g. with

pieces of lumber) (Fig D). When cutting short

and light weight pipes, place the supports so

that the cutting point is outside supports (Fig E).

Support the pipe with your left leg, if required.

Proper arrangements will prevent the blade from

jamming as the pipe is cut through.

Fig B

open closed

Fig C

Cutting point

Cutting mark

Fig D

Fig E

12

Operation English

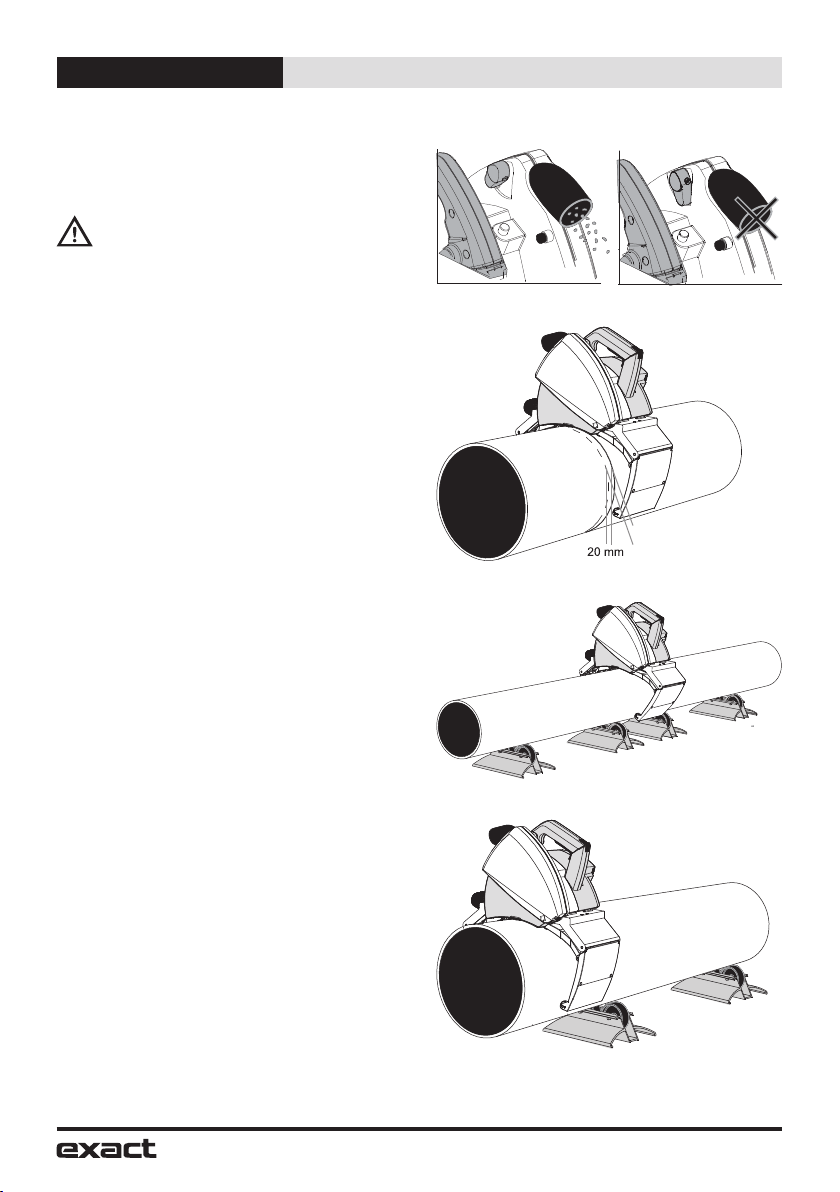

Attaching the pipe saw to the pipe

Open the pipe saw’s gripper unit enough to

suit the diameter of the pipe by rotating the

adjustment handle located at the rear of the saw

(Fig F/1).

Position the pipe saw on top of the pipe so

that the edge of the lower blade guard is at

the cutting mark. Fasten the pipe saw to the

pipe by turning the gripper adjustment handle

until the gripper grips firmly the pipe to be cut

(Fig F/2). Lock the mechanism by turning the

gripper safety (Fig F/3). Hold the pipe in place

and ensure that pipe saw moves freely in the

direction the pipe is fed. For sake of safety

ensure the pipe saw leads are to the left of the

pipe saw. The pipe saw is now ready for cutting.

Piercing the pipe wall

Grip the gripper firmly with your right hand

and place your left foot on top of the pipe

approximately 50 cm from the pipe saw. Turn

the saw until it leans slightly forward (Figure I).

When starting the motor, first of all release the

power-switch locking lever (Fig G/1) and push

the power switch all the way down (Fig G/2).

Before starting to saw, wait until the blade

reaches full speed. Pierce the pipe wall by

pressing pipe saw operating handle downwards

slowly and evenly until the blade has cut through

the pipe wall (at this stage the pipe must not

rotate) and the motor unit is locked in the sawing

position (Fig I /1). Look at the UNLOCK button

during the piercing operation. When UNLOCK

button is locked, i.e. the yellow mark disappears

(Fig H), pipe saw is locked in the sawing

position, and you can safely start sawing around

the pipe.

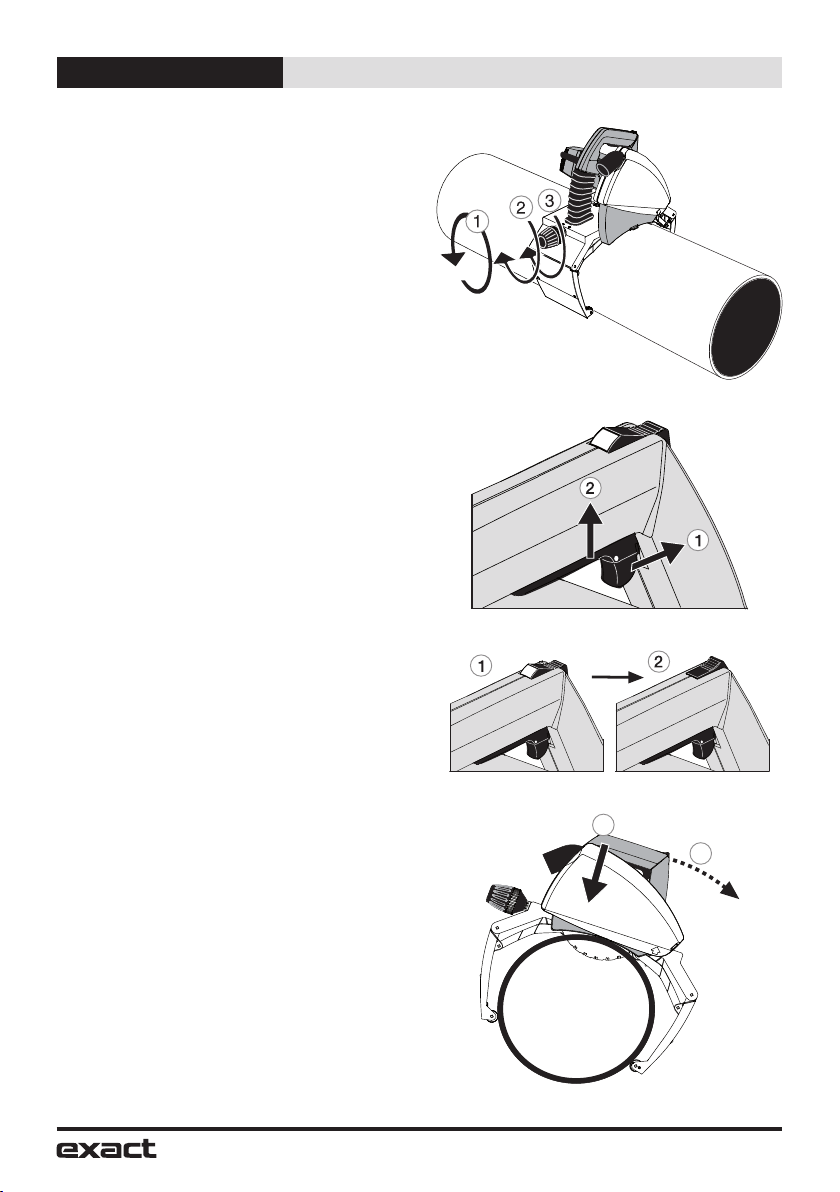

Sawing around the pipe

Start sawing by feeding the pipe saw forward

and fix the pipe with your left foot (Fig I /2). After

that release the pipe (remove your left foot from

the pipe) and turn the pipe saw backwards,

whereby the pipe will also be rotated backwards

(Fig J). Start a new feeding movement, and

feed continuously forward ca. 1/6 of the

pipe’s circumference. Repeat until the pipe is cut

off (Fig K).

Select the sawing / feeding speed as per the

material and the thickness of the wall. Too high

speed can damage the blade, overload the pipe

saw and give a poor sawing result.

Fig F

Fig G

Fig H

Fig I

2

1

13

Operation English

When the pipe is cut off, push the UNLOCK

button forward until the yellow mark is visible

and the locking is released (Fig L/1). Now raise

the motor unit to starting position (Fig L/2).

Release the power switch (Fig L/3). When the

blade has stopped, open the gripper safety

mechanism (Fig L/4) and disengage the pipe

saw from the pipe by loosening the gripper

adjustment handle (Fig L/5). Ensure that the

moving lower blade-guard is lowered into safety

position

Should there be problems during piercing or

sawing, abnormal sounds or vibrations due to

which you have to interrupt sawing before the

pipe is cut through, release the blade by pushing

the UNLOCK button forward until the UNLOCK

button is released, and lift the motor unit up.

Once the problem is cleared, start sawing again.

Never start the motor, when the motor unit is

locked in sawing position or teeth of the blade

contact the pipe to be sawn.

Overload protector and rotation speed

control

The saw has a two-speed rotation speed control

(Fig A/17). When sawing stainless or acid-proof

steel use the lower rotation speed l. When

sawing other materials use the faster rotation

speed ll. The saw also has an overload protector

which switches the power off automatically in

an overload situation. The motor part has a red

indicator light (Fig A/5), which flashes alerting

you to the overload and is lit continually when the

overload protector has been triggered. If the light

begins to flash, the motor must be cooled down.

Stop sawing and allow the motor to cool down.

You can speed up the cooling process by running

the motor without loading it. When the motor has

cooled down sufficiently, the light will stop flashing

or turns off and you can continue sawing.

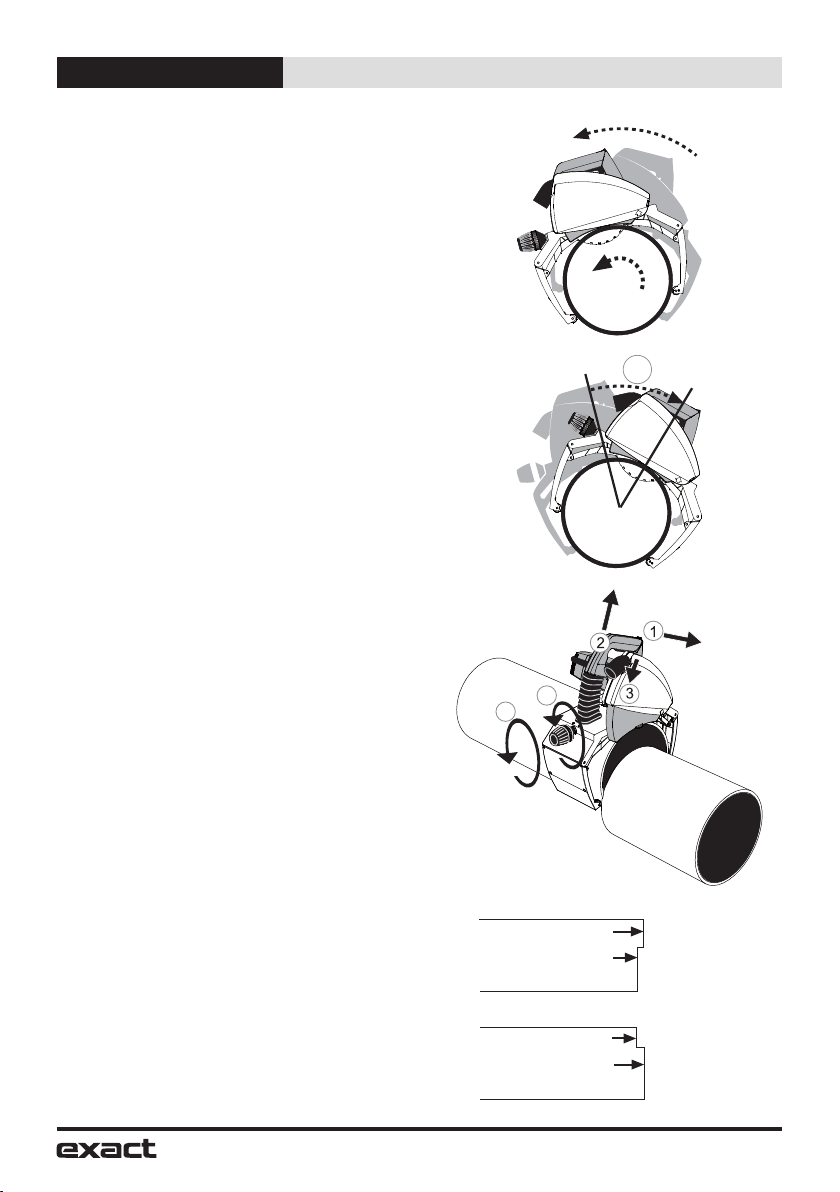

Improving possible misalignment of the cut

The cut is affected by many factors, e.g. the

size of the pipe, the material, the wall thickness,

the quality of the pipe’s surface, the roundness,

welded seams, blade condition, feed rate,

operator’s experience. For this reason the saw

may move to left or right cusing unperfect cut

(see Fig M). Cutting result can be improved as

following with models 280E and 410E.

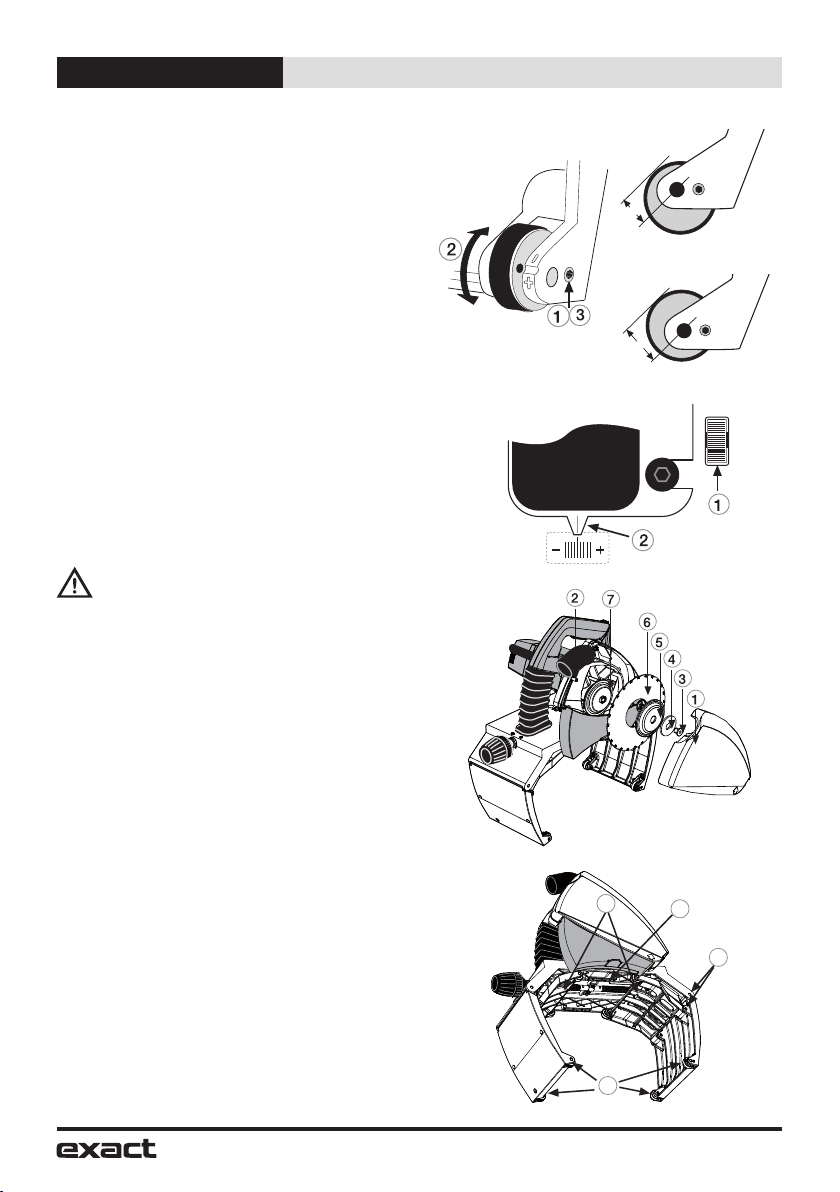

Model 280E cutting result adjustment

The model 280E gripper unit has 8 guidance

wheels. One of those is called adjustment wheel

(Fig A/9). Note that the adjustment of this wheel

applies only to the actual pipe size and material,

and the wheel may have to be readjusted as the

blade is worn.

Fig J

Fig K

1/8

Fig L

4

5

Fig M

a

b

start of the cut

end of the cut

start of the cut

end of the cut

Saw has moved from right to left

Saw has moved from left to right

14

Operation English

To adjust the wheel, loosen the locking screw

(Fig N/1) and turn the wheel centre clockwise or

counter clockwise to the desired position (Fig N/2),

and lock the wheel again (Fig N/3). If the saw

has moved from right to left (Fig M/a) rotate the

center part of the adjusting wheel so that the “d” is

smaller (Fig N/a). If the case is like in Fig M/b do

like shown in Fig N/b. Remember to lubricate the

adjusting wheel at regular intervals.

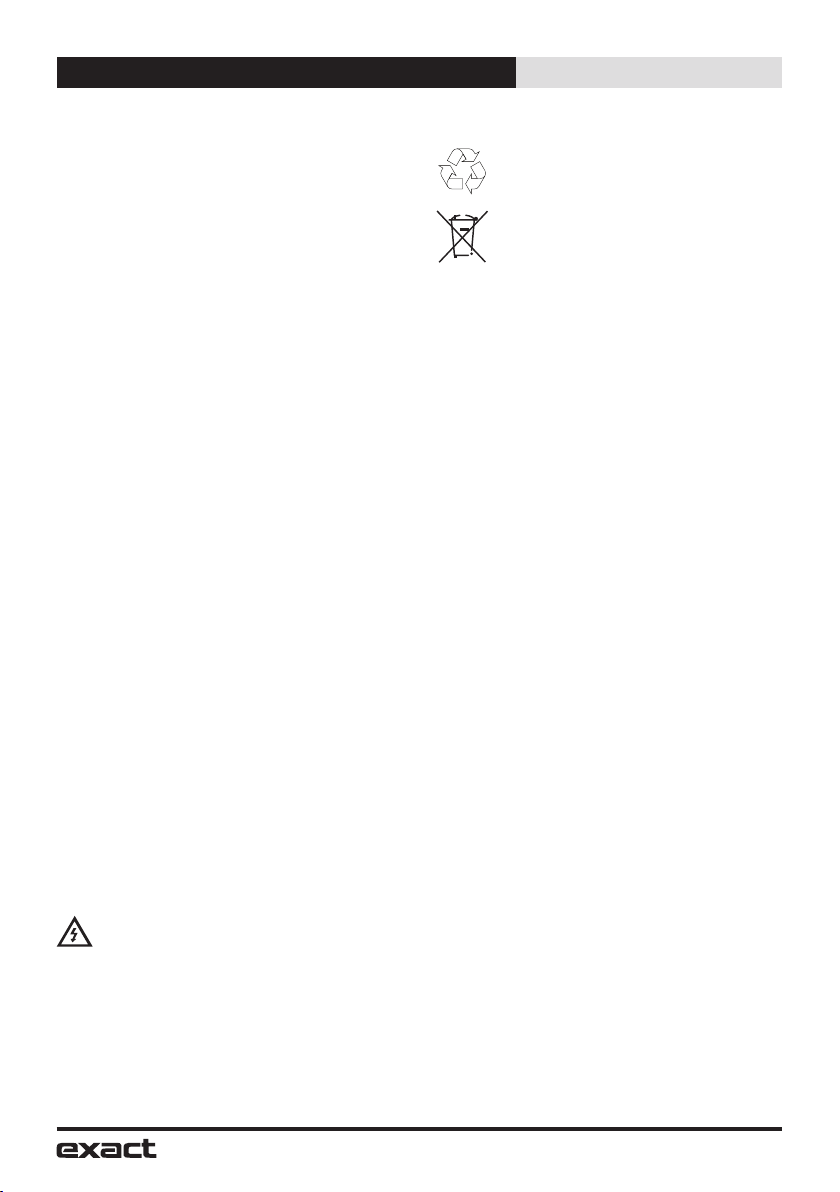

Model 410E cutting result adjustment

In model 410E the angle of whole motor unit is

changed to improve the cutting result: Loosen

3 locking screws of adjustment (Fig A/7 + A/19).

If the saw has moved from right to left (Fig M/a)

rotate the adjusting screw (Fig A/18, O/1) so that

the pointer (Fig A/20, O/2) moves to the left (-).

If the case is like in Fig M/b. rotate respectively

to the right (+). After adjusting tighten the

3 locking screws of adjustment. Note! There is

some backlash in the adjusting screw before the

pointer starts to move.

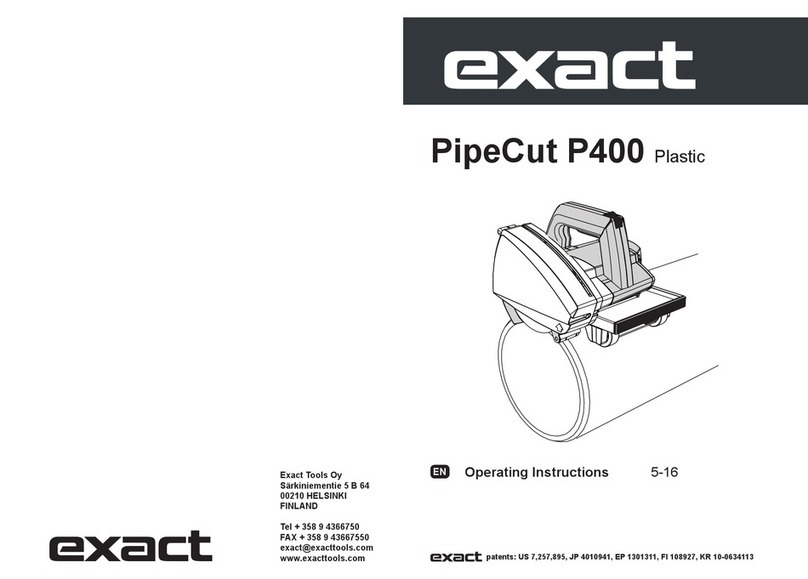

Installing and changing

the saw blade

WARNING: To reduce the risk of injury,

turn unit off and disconnect it from

power source before installing and

removing accessories, before adjusting or

when making repairs. An accidental start-up

can cause injury.

Remove the power plug from the socket. Check

that the motor unit is locked in the upper position.

Remove the blade guard cover (Fig P/1) by

opening the screw (Fig P/2). Press the spindle-

lock button (Fig A/14) and simultaneously rotate

the blade by hand until the spindle-lock button

drops a further distance of about 7 mm. Now the

rotation of the blade is prevented. Use the blade

key to open the blade attachment bolt. Remove

the securing bolt (Fig P/3), the washer (Fig P/4),

the blade flange disc (Fig P/5), and the blade

(Fig P/6).

Before installing a new blade, check that both

blade flange discs are clean. Place a new or

sharpened blade on the back flange disc (Fig P/7),

so that the marked side of the blade is facing

outwards and the arrows on the blade are facing

in the same direction as the rotation direction

markings on the inside of the blade case. Ensure

that the new blade goes right to the bottom in

the back flange disc. Put the blade flange disc,

the washer, and the securing bolt back in place.

Press the spindle lock button and tighten the blade

securing bolt. Put the blade guard cover back in

place and tighten the finger bolts.

Fig N

d

a

d

b

Rotate wheel so that dis smaller

Rotate wheel so that dis bigger

Fig O

Fig P

Fig Q

1

2

3

4

15

Maintenance, Environment, Guarantee English

Maintenance and

servicing instructions

Remove the power plug from the socket

before servicing or cleaning the pipe saw. All

maintenance operations carried out on the pipe

saw’s electrical components must be carried out

at an approved service agency.

Blade

Check the condition of the blade. Replace

a bent, blunt, or otherwise damaged blade with

a new one. Using a blunt blade can overload the

pipe saw’s electric motor. When you notice that

the blade is blunt, do not continue sawing with

it, as the blade may become so badly damaged

that it will not be worth sharpening. A blade in

sufficiently good condition can be sharpened

a few times by a professional sharpening

company.

Gripper unit

Clean the gripper unit regularly with compressed

air. Lubricate the gripper’s wheel axles (Fig Q/1)

and its joints (Fig Q/2). Also clean and lubricate

the gripper’s trapezoidal screw (Fig Q/3) and the

two worm screws on it (Fig Q/4).

Blade guard

When you have sawn plastic pipes and then

intend to start sawing metal pipes always clean

the inside of the blade guards. Hot particles

derived from sawing metal will burn plastic

particles, which may release toxic smoke. Make

it a rule to clean the blade guard regularly, and

pay special attention to keep the moving blade

guard movement from becoming hampered.

Lubricate the axis of the moving blade guard

regularly.

Motor

Keep the motors cooling vents clean.

Plastic parts

Clean the plastic parts with a soft rag. Only use

mild detergents. Do not use solvents or other

strong detergents as they may damage the

plastic parts and paint surfaces.

Power cable

Check the condition of the power cable regularly.

A faulty power cable should always be replaced

at an approved service agency.

Correct use and regular servicing and cleaning

will ensure the continued operation of the pipe

saw.

Environment

Separate collection. This product

must not be disposed of with normal

household waste. When your Exact

PipeCut machine is worn out, do not

dispose of it with normal household

waste. This product must be recycled

separately. Separate recycling of used

products and packaging facilitate

recycling and recovery of materials. Reusing

of recycled materials helps prevent pollution of

environment. According to local regulations it

is possible to deliver household appliances to

municipal rubbish depositories or to the dealer

when buying a new product.

Guarantee

Warranty terms valid from 01.01.2015

If the Exact PipeCut Saw becomes unusable

due to material or manufacturing defects within

the Warranty Term or *Extended Warranty

Term at our discretion we will repair the Exact

PipeCut Saw or supply an entirely new or factory

reconditioned Exact PipeCut Saw at no charge.

Warranty Term / *Extended Warranty Term

The Exact Tools Warranty Term is for 12 months

from date of purchase. *By registering on-line

(exacttools.com/Warranty Registration) you

will receive an additional 12 months Warranty

Term for FREE. Warranty registration must be

completed within one month of purchase.

Password for registration is: 1yearmore

The Warranty is only valid if:

1.) Copy of a dated purchase receipt is returned

to the Authorized Warranty Repair Center or

has been uploaded to our website at the time

of warranty registration.

2.) The Exact PipeCut Saw has not been

misused.

3.) No attempt has been made by non-approved

persons to repair the saw.

4.) The Exact PipeCut Saw has been used in

accordance with the operating, safety, and

servicing instructions provide in the manual.

5.) The Exact PipeCut Saw has been delivered

to an Authorized Warranty Repair Center

within the term of the warranty.

16

Tips English

Note: The Exact PipeCut Saw is to be shipped

to the Authorized Warranty Repair Center freight

prepaid. If the Exact PipeCut Saw is repaired

under Warranty the return shipment will be made

freight prepaid. If the Exact PipeCut Saw is not

repaired under Warranty the return shipment will

be made freight collect.

Please Note: The following items or services

are excluded from Warranty claims:

- Saw Blades

- Overload Protection Fuse

- Carbon Brushes

- Gripping Unit Wheels

- Blade Flange

- Attachment Flange

- Pulling Flange Washer

- Normal Wear and Tear

- Errors Due to Misuse or Accident

- Water, Fire and Physical Damage

- Power Cords

- Adjustment of Adjustment Wheel

- If a wrong type of generator has been used

as power source

Tips for using Exact

PipeCut saws

Diamond blade should only be used for cutting

cast iron pipe. It is not recommended to cut cast

iron with TCT or Cermet blades.

Clean the inside of the blade guards after cutting

plastic pipe.

Smaller pipe is easily cut by rotating the pipe

by hand either on a table or on the floor. Please

note: rotate pipe towards you when rotating by

hand and be careful not to rotate too fast.

Check the condition of the blade regularly.

The cutting procedure is divided into two stages;

first saw through the pipe wall, then complete

the cut by sawing around it.

Do not overload the saw by cutting continuously.

The saw will be overheated and the metal parts

can become burning hot. This will also damage

the motor and the blade. The rule is 2.5 minutes

in use and 7.5 minutes rest.

Keep the feeding speed constant. This will

extend the lifetime of the blade. For example

cutting time for a steel pipe diameter of 6’’

(170 mm), and a wall thickness of 1/5’’ (5 mm),

is 15-20 seconds, and for a cast-iron pipe

diameter of 4’’ (110 mm), with a wall thickness of

1/6’’ (4 mm) is 20 to 25 seconds.

Always keep the motor unit in the upright

position. The yellow mark of the unlock button is

then visible. Never place the Pipe Cut Saw on

the pipe in the locked / cutting position.

Factors that affect the lifetime of the saw

blade:

• material of the pipe

• correct blade type for material being cut

• correct motor speed setting

• wall thickness of the pipe

• feeding speed

• smoothness of the pipe

• user’s general skills

• cleanness of the pipe

• rust on the pipe

• welded seam in the pipe

• blade speed

Factors that affect the straightness of the

cut:

• condition of the saw blade

• wall thickness of the pipe

• feeding speed

• smoothness of the feed

• user’s general skills

• cleanness of the pipe

• roundness of the pipe

• gripper unit too loose or too tight

• blade assembled too tight

Due to continuous product development,

the information in this instruction book may

change. We do not give separate notification

of changes.

Please see more information at our web-site

www.exacttools.com

This manual suits for next models

1

Table of contents

Other eXact Cutter manuals

eXact

eXact PipeCut+Bevel 170E User manual

eXact

eXact PipeCut P400 User manual

eXact

eXact PipeCut 170 User manual

eXact

eXact PipeCut 170 User manual

eXact

eXact PipeCut 170 User manual

eXact

eXact PipeCut 220 INOX Series User manual

eXact

eXact PipeCut 360 system User manual

eXact

eXact PipeCut 280E System User manual

eXact

eXact Pipecut 280 Pro Series User manual

eXact

eXact PipeCut V1000 User manual