80703B_MHW_2850T/3850T_02-2019_ENG2

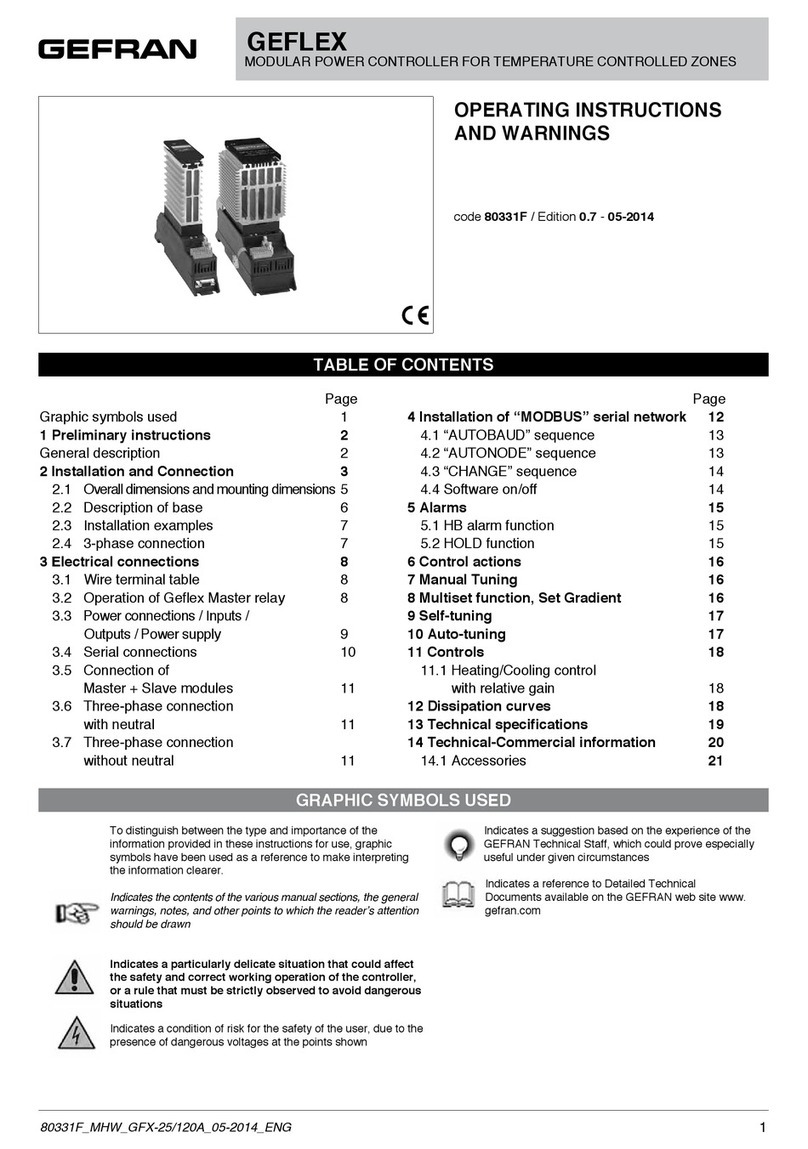

TABLE OF CONTENTS

4.14.2.9. Temperature Information ...................................74

4.14.2.10. Information System Message............................74

4.14.3. DATA TIME sub-menu................................................74

4.14.4. PROGRAM CLOCK sub-menu ..................................75

4.14.5. PROGRAMS MGR sub-menu ....................................75

4.15. SETUP Menu........................................................................76

4.15.1. HW CFG sub-menu....................................................76

4.15.1.1. I/O terminal exchange .......................................76

4.15.1.2. F-MIX analog input configuration ......................77

4.15.1.3. F-MIX analog output configuration....................78

4.15.1.4. F-MIX digital input configuration .......................78

4.15.1.5. F-MIX digital output configuration.....................78

4.15.1.6. F-EU16 digital input configuration.....................79

4.15.1.7. F-EU16 digital output configuration ..................79

4.15.2. ALARM CFG sub-menu .............................................80

4.15.3. SETUP MGR sub-menu .............................................80

4.15.3.1. “Controller model” SETUP ................................80

4.15.3.2. SETUP MGR......................................................81

4.15.3.3. IMAGE ...............................................................82

4.15.3.4. “Controller model” RESET ................................82

4.15.4. PID CFG sub-menu....................................................82

4.15.4.1. PID configuration procedure .............................82

4.15.4.2. PID base configuration ......................................83

4.15.4.3. PID advanced configuration ..............................83

4.15.4.4. PID limit configuration .......................................84

4.15.4.5. Configuration of PID Gradient ...........................85

4.15.4.6. PID valve configuration......................................85

4.15.4.7. PID alarm configuration.....................................85

4.15.4.8. PID HB alarm configuration...............................86

4.15.4.9. PID variable configuration .................................87

4.15.4.10. PID synoptic configuration ................................89

4.15.5. VAR CFG sub-menu...................................................90

4.15.6. USER CFG sub-menu................................................90

5. Custom pages ................................................91

5.1. Examples of custom pages..................................................91

5.1.1. Example of Pit Kiln.....................................................91

5.1.2. Example of a Food Steriliser......................................91

5.1.3. Example of Kiln heat processing ...............................91

5.2. Go to the menu page ...........................................................92

5.3. Creating a custom page.......................................................92

5.3.1. Screen coordinates....................................................92

5.3.2. Creating and editing a component ............................92

5.1.4. Example of autoclave.................................................92

5.3.2.1. Precision component configuration ..................93

5.3.2.2. Color..................................................................93

5.3.2.3. Overlapping components ..................................93

5.3.3. LED Component ........................................................93

5.3.4. Edit Text component ..................................................93

5.3.5. Text component .........................................................94

5.3.6. Note component ........................................................94

5.3.7. Progress Bar component...........................................94

5.3.8. Data View component................................................95

5.3.9. Data Set component..................................................95

5.3.10. Button component .....................................................95

5.3.11. Image component......................................................96

5.3.12. Change page component ..........................................96

5.4. Custom page creation tutorial..............................................97

5.4.1. Page Creation Procedure...........................................97

5.4.2. Adding Bar Graphs ....................................................98

5.4.3. Adding Data View.......................................................98

5.4.4. Adding a Data Set......................................................99

5.4.5. Adding LEDs ..............................................................99

5.4.6. Adding Text ................................................................99

5.4.7. Adding an image......................................................101

6. SERVICE PAGES...........................................103

6.1. Variable selections .............................................................103

6.2. Active alarm .......................................................................103

7. Examples and application notes.................105

7.1. Multi kiln control.................................................................105

7.1.1. Managing parameter groups....................................105

7.1.2. Configuration Procedure..........................................105

7.2. Building programs with default segments (TEMPLATE).....106

7.2.1. Program composition with TEMPLATES..................106

7.2.2. Configuration Procedure..........................................106

7.3. Correction of linear inputs and outputs..............................107

7.3.1. Calibration of input...................................................107

7.3.2. Correction of input ...................................................107

7.3.3. Correction of output.................................................107

7.4. Alarms ................................................................................108

7.4.1. Generic alarms.........................................................108

7.5. Control................................................................................109

7.5.1. Control actions.........................................................109

7.5.1.1. Proportional, Derivative and Integral action influ-

ence on the controlled process feedback .......109

7.5.2. Self-Tuning...............................................................109

7.5.3. Cascade control.......................................................109

7.5.3.1. Tuning two PIDs configured for cascade control ..

110

7.5.4. Ratio control.............................................................110

7.6. Motorised valve control......................................................111

7.6.1. Valve control parameters .........................................111

7.6.2. Valve control mode ..................................................111

7.7. Practical configuration examples.......................................113

7.7.1. Loop configuration...................................................113

7.7.2. Configuring a LOOP controller with input equal to the

average value of 3 variables ....................................115

7.7.3. 2-curve setpoint profile............................................119

8. Maintenance .................................................123

8.1. Gasket replacement...........................................................123

8.2. Configuration cloning.........................................................123

8.3. Cleaning .............................................................................123

8.4. Disposal .............................................................................123

8.5. Troubleshooting..................................................................124

8.5.1. LED signals ..............................................................124

8.5.2. System signals.........................................................125

9. 2850T-3850T configuration in GF_eXpress .....

127

9.1. Target Selection..................................................................127

9.2. Offline Target Configuration ...............................................128

9.3. Online Target Configuration................................................129

9.3.1. HW and functional options of the target aligned with

those of the configurator..........................................129

9.3.2. HW and functional options of the target not aligned

with those of the configurator..................................130

9.4. Making changes to the configurator ..................................131

9.4.1. “PROGRAMMER EDITOR” section..........................132

9.4.1.1. “GETLogic” section ........................................132

9.4.1.2. “GRAPHICS” section ......................................133

9.4.2. “LOOP” section........................................................134

9.4.3. “GETview” section ...................................................134

9.4.3.1. MANAGEMENT OF GRAPHIC COMPONENTS ...

134

9.4.4. “USERS” section......................................................135

9.4.5. “CFG HARDWARE” section.....................................136

9.4.6. “SETUP” section......................................................136

9.4.7. “ENERGY” section...................................................137

9.4.8. “VARIABLES” section ..............................................137

9.4.9. “PARAMETERS” section..........................................138