4

Table of Contents

Micro-Trak Warranty.............................................................................................................................................................................3

Table of Contents ..................................................................................................................................................................................4

Component Parts and Assembly Hardware.....................................................................................................................................5

DrillMaster System Layout - Mounted Single Section ...................................................................................................................6

DrillMaster Wiring Diagram - Mounted Single Section .................................................................................................................7

DrillMaster System Layout - Drawn Multi Section..........................................................................................................................8

DrillMaster Wiring Diagram - Drawn Multi Section........................................................................................................................9

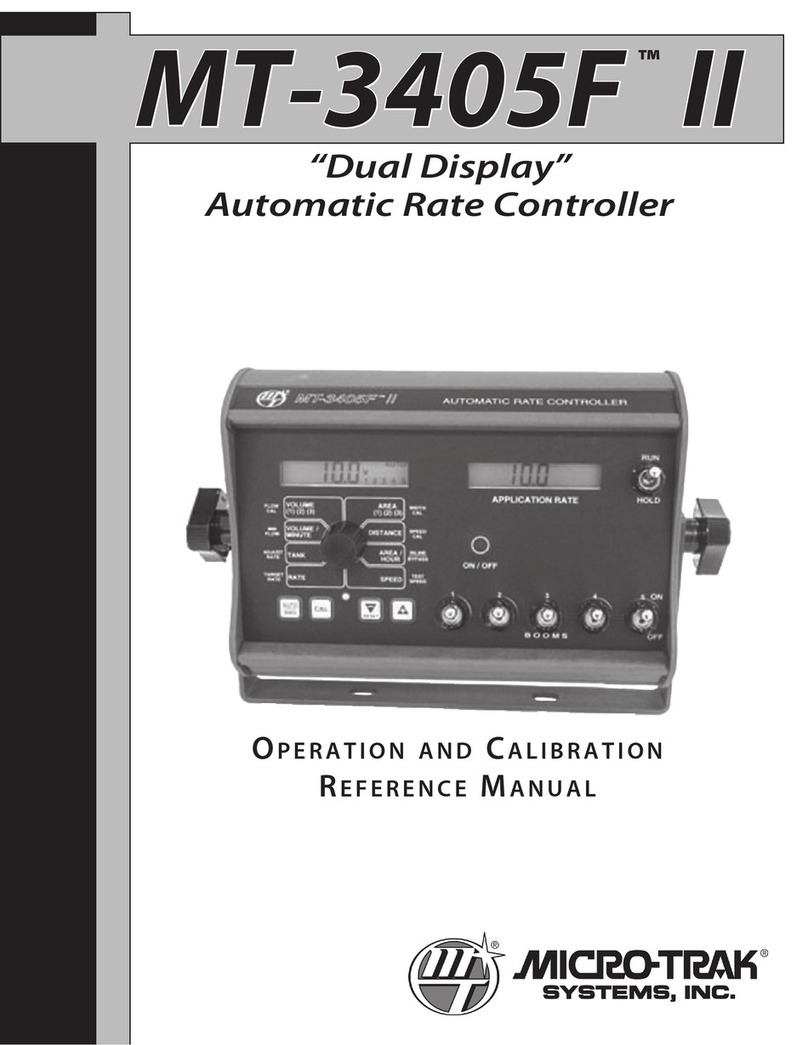

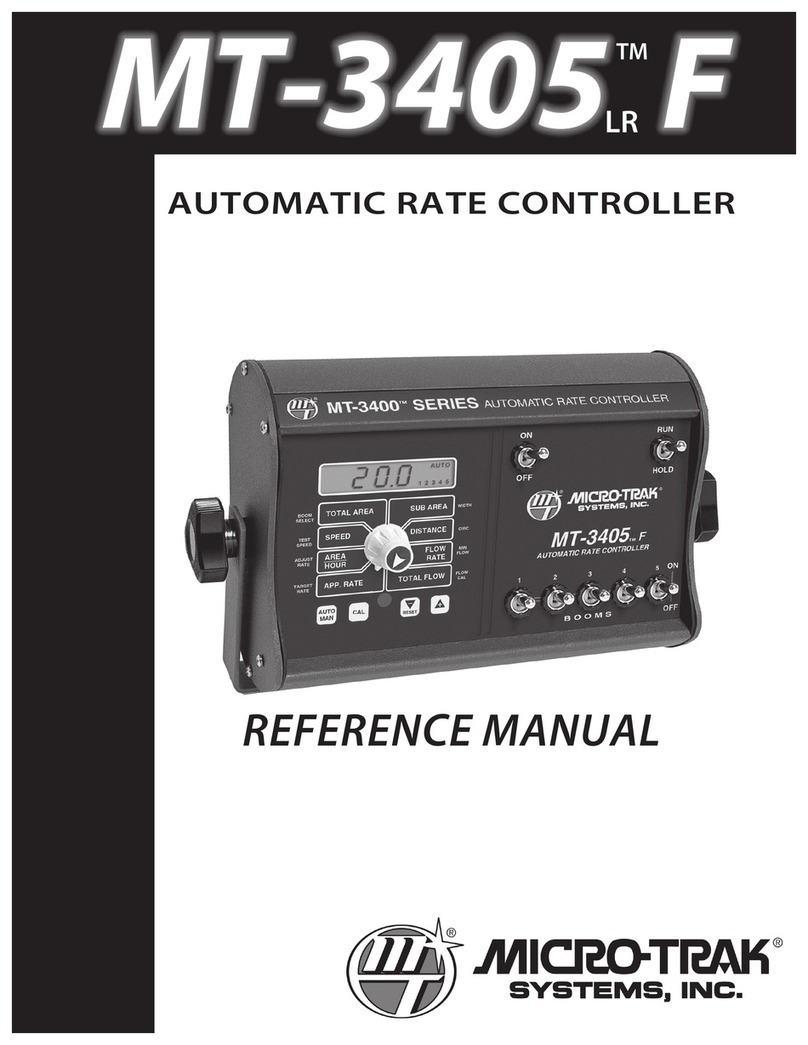

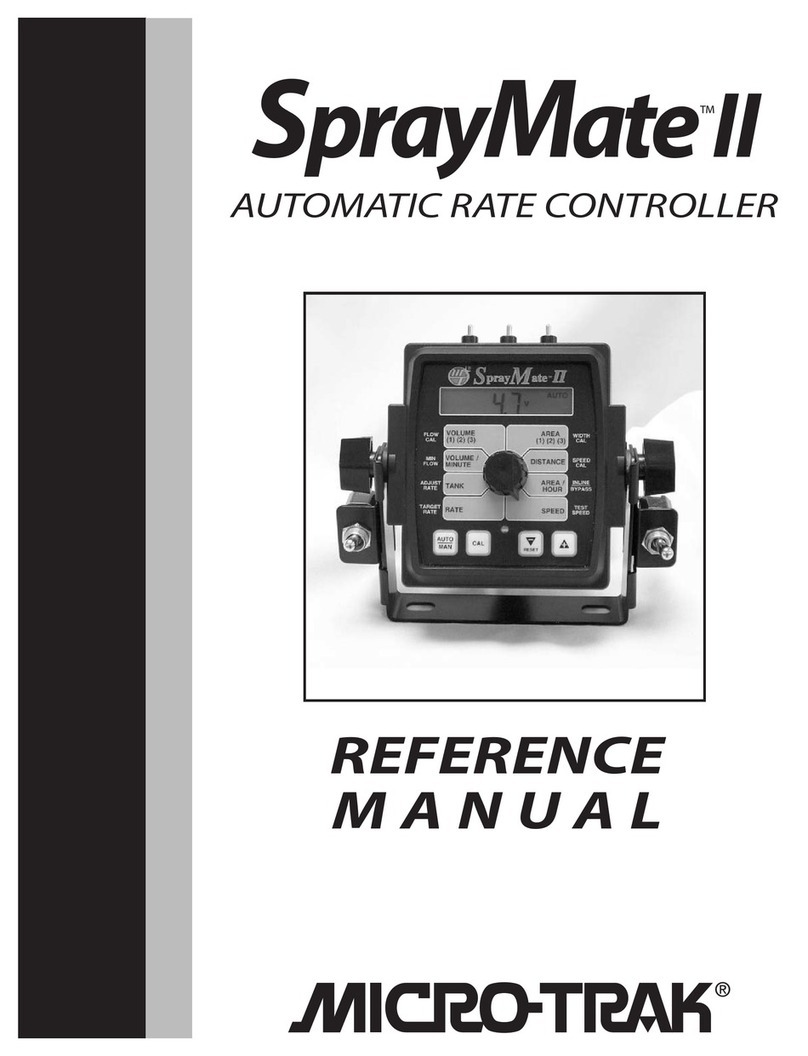

DrillMaster Seed Rate Controllers....................................................................................................................................................10

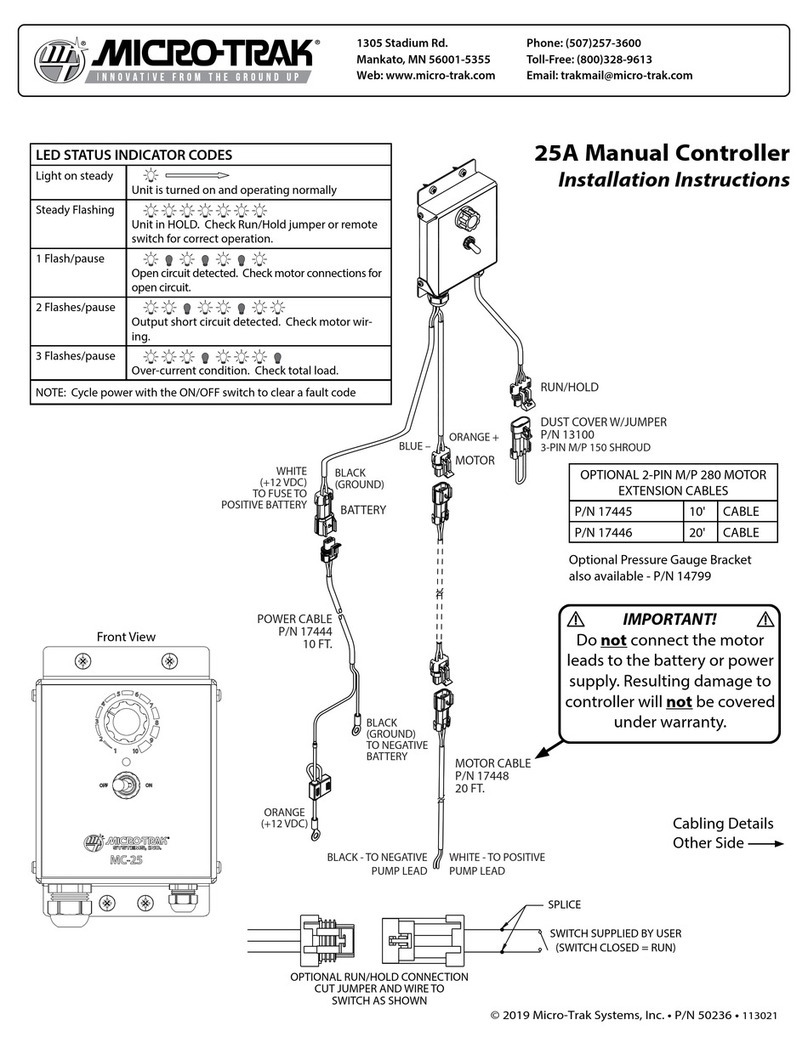

Installation......................................................................................................................................................................................11-13

Mounting the Display Console........................................................................................................................................................................ 11

Attaching the Power and Run/Hold Control Switches...........................................................................................................................11

Electrical Installation ...........................................................................................................................................................................................12

Speed Sensor Options ........................................................................................................................................................................................12

Remote Run/Hold................................................................................................................................................................................................. 13

Care and Maintenance .......................................................................................................................................................................13

DrillMaster Console Functions..........................................................................................................................................................14

Calibration ......................................................................................................................................................................................15-18

Selecting Measurement Units .................................................................................................................................................................................. 15

Entering Calibration Values ........................................................................................................................................................................16-17

Factory-loaded Calibration Values................................................................................................................................................................. 17

Speed Cal for Radar or GPS............................................................................................................................................................................... 18

Determining the Speed Cal ..............................................................................................................................................................................18

“Special” Calibration.....................................................................................................................................................................19-21

“Special” Cal - Page 1 and Two Values ......................................................................................................................................................... 19

Factory-loaded “Special” Calibration Values.............................................................................................................................................. 19

Entering “Special” Calibration Values - Page 1.......................................................................................................................................... 20

Entering “Special” Calibration Values - Page 2.......................................................................................................................................... 21

Operation........................................................................................................................................................................................22-26

Console Switches and Buttons........................................................................................................................................................................ 22

Console Switches and Inputs........................................................................................................................................................................... 23

General Information ............................................................................................................................................................................................24

Rotary Positions ....................................................................................................................................................................................................24

Resetting System Counters............................................................................................................................................................................... 25

Clearing System Counters................................................................................................................................................................................. 26

Pre-Field System Checkout ...............................................................................................................................................................26

Troubleshooting............................................................................................................................................................................27-30

Message/Warnings...............................................................................................................................................................................................27

General .....................................................................................................................................................................................................................28

Checking Individual Components..................................................................................................................................................................29

Checking Console Inputs................................................................................................................................................................................... 30

Appendices.....................................................................................................................................................................................31-38

Appendix A: Fine Tuning Speed/Distance Calibration Value With Run/Hold Switch Kit Installed.......................................32

Appendix B: Cal Test Fine Tuning Calibration Values............................................................................................................................33

Appendix C: Meter Cal Fine Tuning Calibration Values........................................................................................................................34

Appendix D: Bin Level Sensor Kit Installation........................................................................................................................................... 35

Appendix E: Radar Adapter Cables............................................................................................................................................................... 36

Appendix F: Conversion Chart........................................................................................................................................................................37

Appendix G: Replacement Parts List............................................................................................................................................................38