Forematic PICO PK-550 User manual

www.forematic.com

Sliding gate opener

PICO

Manual edition V1.2

PICO installaon

Page Contents

1Descripon & specicaons

2Set contents

2Responsibilies & consideraon

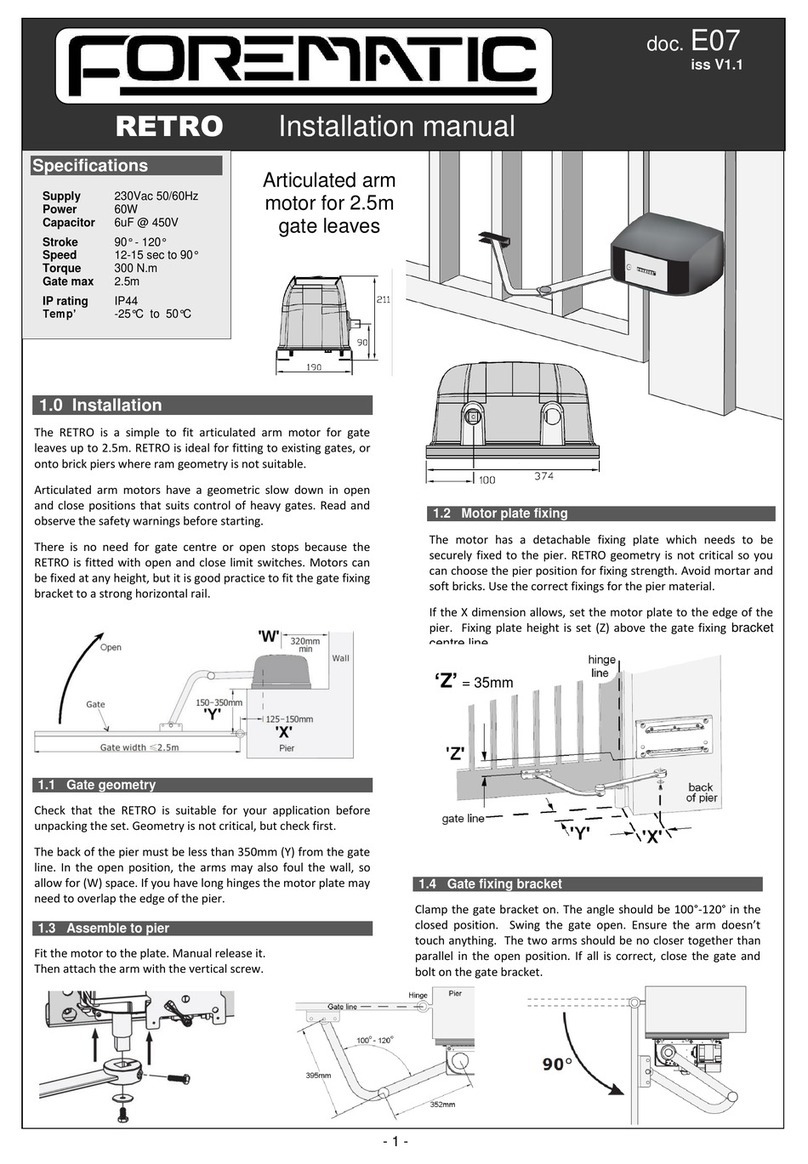

3Gate mounng

4Driveway layout

5Groundwork & cable ducts

6Standard wiring & opons

7Commissioning

8 User instrucons

9 Safety record

10 Safety tutorial

11 Warranty

Descripon

PICO is green and safe for a modern market place. It

will provide long and reliable service if maintained

to these instrucons. PICO features a stall sensor to

reverses the gate when obstrucons are detected.

Speed & pressure are set to meet safety standards.

F550 is designed for domesc gates up to 600kg.

The more powerful F560 is rated for commercial

gates up to 900kg. Both have a high duty cycle for

busy entrances.

Remotes use a secure

‘Rolling Code’ paern

that changes each me it

is used. Rolling codes

can’t be copied, ensuring

your home stays secure.

User programming has

been kept simple for the

novice installer. Foresee

make simple hi-tech

products to keep modern

homes secure.

Set contents

PK-550 Standard domesc gate set for 230Vac

supplies. Backup baeries are an oponal extra.

PK-560 Light commercial set with the larger

motor opon. Suitable for oce entrances, small

car parks. Single phase mains supply with

oponal baery backup.

PL-550 Low power set with a baery pack,

charger, and a remote power supply. Charging

can be by a suitable wind turbine or solar panel.

Ideal for sites where a long mains cable would

be dicult or expensive to run.

All sets come with a set of photobeams and two

remote controls. Baery sets operate for up to

10 hours during power cuts. Without baeries,

gates will try to close when power is restored.

Technical Specifications

Supply voltage 220-240Vac F550 motor 300N 120W

Supply rating 2.5A @ 50-60Hz F560 motor 160W

Standby power <10W Motor insulation IP44

Ambient temp -20° to +50° Pinion Mod.4 15 t

Remotes 433MHz 50 max Opening speed 16mm / sec

Duty cycle 25% 20 times/hr Max leaf weight F550 600kg

Temp overload 120 degrees F560 900kg

1

Gates must be robust, well maintained, and on

clean level ground. Keep the gate area clear of

objects. Have the gate properly maintained and

repaired by qualied personnel to maintain the

legal safety requirements. The manufacturer is

not responsible for injury resulng from failure

to meet the requirements in this manual.

Safety consideraons

European standards state the safety measures

that need to be used, depending on applicaon

and perceived risk. The highest rang calls for

photobeams and sensive edges, in addion to

pressure circuits implicit in the control panel.

This highest rang covers a system for use in

private and public spaces, operated by trained or

untrained users, and from autonomous devices

such as mers and vehicle detectors.

The safety secon of this manual idenfys ‘risk’.

Gate design and layout of a can eliminate many

risks, avoiding the need for more safety devices.

Control panel electronic measures do not make

the system compliant on their own.

Set contents

Our set contents are a starng point for your

automac gate. All sets include two remote

controls and a photobeam. Sets do not include

the toothed rack, wiring or a mains isolator.

All major components are inside a sliding gate

motor. Apart from the main supply, there is only

photobeam to wire in. Sliding gates are ideal for

novice installers. Read on for addional safety.

Installer responsibility

An automated gate is a machine that must

comply with the EU Machines direcve. There

are many aspects of compliance that ensure the

gate is safe to users and public. ‘Automac gate’

signs are required on both sides of the gate

warning against risk of contact injury.

The installer must prepare a handover pack to

include details of the installaon, a user guide

and a risk statement. Much of that informaon is

included in this manual, along with guides to

idenfy site specic risks and gate aributes.

Good pracce is essenal for safety and

reliability. Observe electrical standards for

outdoor installaons. The installaon needs to

tested to part P of the building regulaons.

Homeowner responsibility

It is the responsibility of the home owner or site

manager to ensure only trained people operate

the gate, and ensure all those people are aware

of potenal gate hazards.

Person operang a gate must take responsibility

for the safety of people within the hazard area.

Never let children play near gates in moon.

2

Driveway layout

Beware of draw in shear hazards. Vercal barred

gates present a shear with each bar against the

post while opening.

Crush zones greater than 500mm have a higher

tolerance to risk than smaller gaps. Very small

gaps under 8mm are also low risk.

Ground track needs to cover the opening and

the run back. We show the track slightly shorter

than the full opening. This is to let rainwater

drain around the end, otherwise puddles may

form on one side.

The motor base is set opposite the supporng

post. It must be on the inside for safety reasons.

This post also supports the gate at the top.

Fig1 shows a gate opening to the right. Direcon

is set on DIP5. Set ‘ON’ for opening to the le.

Sliding gates are simple. Most gates have wheels

running on steel track embedded in the ground.

The entrance needs to be level and even.

Canlever gates slide across the gateway. They

are more suitable for un-even roads as there is

no contact with the ground.

Gates must slide past the support post, but may

dock with the slam post, either face on, or on

the side of the post. Choice will suit some

designs beer than others.

Gate layout is essenal for a safety. Good design

eliminates risk, so saves needing addional

safety devices. Refer the gate safety page at the

end of this booklet.

The outside photobeam is set to re-open a gate

while it is closing. Another photobeam inside the

gate could have the same funcon, or stop the

gate in either direcon. This would be necessary

to protect the run back space.

Photobeams may be xed to a convenient wall

to save erecng posts. Check their range. Stay

clear of shrubs that may grow to block it.

Fig 3

Fig 1 (opening right — DIP5 OFF)

PICO

3

Fig 2

Groundwork

Fig 4

Dig out a trench for the track foundaons. Lay the drive duct

and support post duct in the trench. Place supports in the

trench to hold the track level and at the right height. Fill with

concrete, then press the track down onto the supports.

Motor height can now be calculated. ’C’ is chosen for the height the

toothed rack screws to the gate. ‘A’ and ‘B’ are xed. Raising motor

base above ground stops water lling the ducts. Dig out the motor

base (approx. 0.5m x 0.5m). Lay the four cable duct taped together.

The spare duct is for future services such as an intercom or loop.

Shuer up the sides if necessary, then ll with concrete. Fit rag

bolts to the motor base. Press into the wet concrete, pulling the

ducts up through the holes provided in the base. Leave for several

days before mounng the motor and gate.

Running cables

All ducts should have draw cords, or be pre-loaded with

the cables. Drive duct needs a cable for the IR1

photobeam and (if ed) a cable for the IR2 photobeam.

The Post duct needs a cable for IR1 Tx. It also takes the

oponal IR2 Tx cable which goes down its own duct to

the end of the track (also known as the run back duct).

A = 25mm

B = 30mm

C > 92mm

Mount the motor and gate. Roll the gate

to each end of travel. and x the two limit

switch brackets to the toothed rack.

4

Fig 5

Fig 6

Fig 7

RIO-P control panel

PICO has two PCBs. The power board connects

the mains supply, baeries and transformer. The

control panel RIO-P has a 10 way user connector

that makes all the accessory connecons for

safety devices and acvaon devices.

ACTIVATION DEVICES [G & C]

Wire in acvaon devices supplement remotes.

Full “gate” opening wires into terminals [G & C].

Remote buons can be programmed for full gate

opening or paral open for pedestrians. FR11 is

a wireless wall buon. FA62 is a wireless keypad.

See user remote programming wireless devices.

SAFETY DEVICES [F & C] or [E & C]

There are two inputs for photobeams or edges.

[F & C] prevents the gate closing (outside photo

-beam). [E & C] input stops the gate opening or

closing (for inside photobeam). In each case, the

gate will re-start aer safety is restored. Encoder

based obstacle detecon is included. If the gate

is slowed by an obstacle, detecon is triggered.

Safety is a synergy of all measures and devices.

See safety tutorial for risks & soluons.

BATTERY PACK

The controller includes a baery charger for two

1.2Ahr baeries giving around 10 hours o grid

support. The RIO-B2 baery pack locates below

the transformer.

Power board STANDARD WIRING

The opener is prewired for internal components.

External components are split into ‘acvaon’ or

‘safety’ devices. To simplify wiring, all examples

opposite use a standard colour scheme. Black is

for COM which is common to all inputs & power.

Use only recommended devices for compability

Unlike acvaon devices, safety device contacts

are ’NC’. More than one device contact on the

same input need to be connected in series. If an

input has no device connected, it needs to be

linked to Gnd. If in doubt, follow the examples

opposite. Safety device power [B] gives +24Vdc

while the motor is running and while open.

This manual advocates star wiring, where a ve

core cable is run to each device. It is simple, but

can result in overcrowded terminal blocks.

5

Fig 8

6

Control terminal funcons

Grey 24Vdc accessory power A

Lamp output , 24Vdc L

Red Safety device power B

Yellow Safety, re-open F

Black Common C

Wh

Blu

Blk

To connect 2 motors

Limit common

Open limit N/C (right)

Close limit N/C (le)

Sync

C

SW2

SW1

Green Full opening input G

Brown Pause either direcon E

Accessories below have NO contacts. FORESEE’s wireless buon

& keypad work on the remote channel so require no wiring.

Exit buon is normally in the property. A keyswitch can

on either side, or for use by authorised persons only (eg teachers)

Acvaon devices that need to be powered all the me

use 24Vac ‘Grey’ power [A]. Safety devices use 24Vdc power [B] ,

only acve while gates are open and are moving.

Keypads are used for friends, family or trusted delivery drivers.

This keypad can accept many codes, and some for single use (less

trusted delivery drivers). Some codes can also be mer enabled.

Smartphone control oers a modern control method with

a device we all carry. A data cable to the house is not necessary

for simple control, but adds features if it is included at this early

stage. They can replace the intercom and addional remotes.

Intercoms require a cable to the house. These two types need

only 2 wires. Intercoms are supplied with their own power supply.

Vehicle exit sensors are placed in the driveway to open

the gate. They must be wired as ‘open only’. This requires the

photobeam yellow wire to be interrupted by the detector.

Activation device wiring

VY805

buon

FA61

Keyswitch

K15

Keypad

202

Audio

502

Video

VD909

vehicle

Sensor

Vehicle sensor

wiring uses a handy

relay. It enables an

open only when the

gate is closed.

This prevents freezing if acvated when part open.

Further wiring plans

There are 2 safety inputs. [F] stops the gate

closing (Fig14). [E] pauses the gate in either

direcon (Fig15). More safety devices may be

added as required. Refer to the safety page for

guidance on the risks.

[F] is the primary beam in Fig10. An inside beam

[E] is recommended. When ed to a return

wall as shown, a person cannot get to the risk

zone without breaking the [E] beam.

Fig12 A safety edge has been added to the le

pier. It is slightly o the gate track. There are

now two devices on [F] wired as Fig16. This puts

[F] Rx on the le. The edge could be ed to the

end of the gate but that would require a wireless

connecon.

Mulple safety contacts must be wired in a chain

(series) on the same input. Photo-beams have a

receiver [Rx] and transmier [Tx]. It helps if the

beam direcon on [F] is the reverse of the beam

direcon on [E].

Fig11 If there is a way to walk around the rst

[E] beam there should be another on the return.

Fig19 shows how to connect the two post items.

Large gaps are considered a people safe haven.

Fig13 Vercal bar gates present draw-in and

shear risk as the bars pass the pier edge. Edge [E]

provides public side protecon. Edge [F] gives

private side protecon. The [F] can wire into the

[F] Tx opposite (Fig17 or Fig20). The [E] edge will

need a new cable.

SAFETY EDGES

DRI safety edges have a 4 core cable

(Blue-yellow-black-red) that needs

power. Fig30 shows the alternave

DCY or DTE edges. Check how much

movement is needed to acvate the

edge when choosing for a applicaon.

Fig 10

7

Fig 12

Fig 13

Fig 11

PICO

Optional

FA31 on

input E

standard

FA31 on

input F

Photobeam

wiring

The first photobeam on F (yellow) is

compulsory. The E input (brown) is

optional. Inputs take

multiple safety devices.

Volt free contacts need

to be wired in series.

Note jumper position !

Beam Fig 16

DRI edge

on the end

of the gate

E or F

power

Beam Fig 17

One DRI

edge on

on a pier

power

Beam Fig 18

Wiring 2 DRI’s

Yellow

NC

Blue

Com

Black

Gnd

Red

Supply

power

Open Timer

A wired switch or mer can hold a gate

open. The N/O contact opens the gate

[G]. The N/C contact stops it closing by

disabling the safety devices on [F]

Fig 21

Fig 14 Fig 15

Beam Fig 20

DCY

or DTE

edges

power

Beam Fig 19

Power

Repeater circuit for ring of

beams. Each Rx enables the

next Tx. Only requires power

on the post.

8

Remote setting

Seng remotes

You can save up to 16 remotes. There are two

remote channels. Pedestrian channel opens one

gate only. Full opening operates both leaves. You

need to set DIP1 and DIP 2.

Full opening - Press and hold the CODE buon

for 2 secs. DL6 will light. Press a buon on the

remote twice. DL6 now goes out.

Pedestrian opening - Press the CODE buon for

1 secs. DL6 will light. Press the CODE buon

again for 1 secs. Press another remote buon

twice (for ped). DL6 now goes out.

Remote funcon

Assuming an auto-close delay is set, a single

remote buon press will open the gate, pause

for auto-close delay, then re-close. The 4 step

sequence is ;

OPEN—STOP—CLOSE—STOP

Gate moon can be stopped at any point by

pressing a remote or acvang [G]. The next

press reverses direcon. If you want to hold the

gate open, wait unl the gates are almost open,

or just beginning to close, then press the remote

again to pause. Release with another press.

Lamp opons

The mains lamp with internal asher wires to

power board switched by CN2. Alternavely [L]

gives a ashing 24Vdc output for any light. CN2

gives a 24V dc gate in moon output. The N/O

open limit contact can give a gate open output.

Red wire [B] gives 24V when gate is not closed.

Static settings

DIP1 - Remote buon - Full open

Set the funcon of the remote’s second buon.

If DIP1 is ON, both buons can be set for full

opening. If it is OFF, the second buon can be

used for pedestrian, or another gate or door.

DIP2 - Remote buon - pedestrian

Set the funcon of the remote’s second buon.

If DIP2 is ON, a second remote buon can be

set to open one leaf only (pedestrian opening).

DIP3 - So start & stop (set ON)

Aer run me seng has been set, motor

speed ramps up and down at end of travel.

DIP4 - Limit switch sense (set ON)

When limit switches are N/C (default) set DIP4

ON. Change to for special applicaons.

DIP5 - Travel direcon

Set OFF the gate opens to the right, as shown

on pages 3,4, and 7. Set ON to open to the le.

DIP6,7,8 - Auto-close delay

These 3 switches set the delay period. All OFF

disables the auto-close.

DIP switches

DIP6,7,8 Sets auto-close delay (see below)

100 010 110 001 101 011 111

10s 20s 30s 40s 50s 60s 70s

9

are two buttons on the PCB. The CODE

terminal.

You can save up to 16 remotes. There are two

remote channels. Pedestrian channel opens

Press and hold the ‘code’ button for 2 secs.

LED1 will light. Press any button on the remote

FA40

PICO

10

Run time setting

Limit learning

PICO uses encoder feedback from the motor to

monitor movement. On a test run, it measures

the run from limit to limit, from which it sets the

slow down points. In preparaon …...

1. Set the remotes and DIP’s Default is all OFF.

2. Release the clutch. Move the gate to open,

then toclosed posion, ensuring the ’skis’ are

xed to the toothed rack in correct places.

Close the gate, then re-engage the clutch.

3. Safety devices need to be working, or dis-

abled by linking terminal [C] to [F] and [E].

4. You are ready to set run cycle. Power up.

5. Hold ST buon for 5 secs. DL5 will ash.

6. Press ST to start. The gate will open then

stop on the limit switch.

Obstacle detecon is enabled aer the limits are

set. If an obstacle is detected on opening, the

gate stops dead. The gate will close aer the

auto-close delay. If an obstacle is detected while

closing, the gate opens for a second then stops.

Aer the re-close me, the gate will close.

Bi-Parting gates

Two sliding gates can be synchronised on one

entrance. The master motor has acvaon and

safety devices. The slave may provide power.

CODE buon is used to set remotes. ST buon

(step) has the funcon of a remote or input [G].

See page 12 for LED funcons.

FINE ADJUSTMENT

Adjustments set the safe running of the gate.

Follow the order below. Addional acvaon

and safety devices can be wired in aer these

adjustments without the need to re-adjust.

___________________________________

RV. Speed seng, which aects mid travel

safety. Set heavy gates to run slower.

__________________________________

LV. Sets the speed in slow down zone. Set to

close the gate rmly against the post.

__________________________________

Force. Regulates the maximum force applied by

the motor before obstacle detecon kicks

in. Set it high enough to move the gate

reliably, yet sll reverse on an obstacle.

NB Refer to safety tutorial for force test limits.

___________________________________

Further support

Further wiring applicaons, support and fault

nding can be found on our website on the PICO

support page.

Delete all remotes

It is not possible to delete only one

remote. The can delete all remotes

then re-enter the ones you want

to keep. Press and hold the ‘code’

buon for 8 secs.

Fuses

There is one fuse on the power

board. Always replace with a fuse

of equal value. If it fails again, seek

professional advice

Safe operaon

The home owner is obliged to

maintain the system in a safe

state, and keep safety and

maintenance records. Installers must hand the gate

over in a safe state. Use a ‘competent person’ to

keep the gate in compliance with safety direcves.

Maintenance records will be passed to new owners

of the property.

Don’t let children operate or play on the gate. Keep

remotes out of reach of children. Check the safety

device’s funcon of once a month. Do not modify

the gates, as this will require a new safety audit.

Fault nding

In the event of a failure, homeowners should seek

professional help to maintain safety. Our website

PICO support page has fault nding support.

Manual release

The key operated manual release disconnects the

motor from the drive pinion. The lever inside is

protected by a grey slide up cover. Insert the key

and turn clockwise. Pull the lever out and down.

When the lever turns through 90° the gate is be

free to pull open. Be sure to keep the keys in a

place which is accessible from both sided of the

gate. There are two keys per leaf.

There are two remote channels. Pedestrian opening operates one

gate only. Main gate channel opens both. You will need to remove

the covers from the opener, and then remove the main PCB cover.

Add a remote

Press and hold the ‘code’ buon for 2 secs

unl the indicator on the board lights.

Now press the buon on the remote twice.

Usethe buon that you want to operate the

gate. The indicator now goes out. You can

save up to 50 remotes.

For seng a pedestrian gate buon, press the ‘code’ buon for 1

sec, then press it again for another second. Now press the remote

buon twice. This buon will only open the pedestrian gate leaf.

11

User Instrucons

Fig 23

1

2

PICO

There are 7 LED’s on RIO-P

DL5 Flashes in slow down

DL6 Flash indicates a valid remote or that you are

in limit or remote learning mode.

LED3 Indicator for input [F]. On when safe

LED4 Closed limit indicator. O at limit (N/C)

LED5 Open limit indicator. O at limit (N/C)

LED6 Indicator for input [G]. On when acve

LED7 Indicator for input [E]. On when safe

Motor checks - disconnect red & green motor

wires. Connect direct to a 12V baery to check.

Limit switch checks - ick limit switches with a

nger. Check LED4 and LED5 respond.

Safety

DIPs

12

1 2 3 4 5 6 7 8

FORCE % LV % RV %

1 User record

2

3

4

5

6

Input Position Device

F FA31

Installation record complete this table as part of your records

Activation

Input Position Device / code

G

Fault nding

Gate runs slowly - This happens when there has

been a loss of power. The controller needs to re-

nd it’s limits. This is done automacally.

Gate won’t open or close LED4 should be ON to

close. LED5 should be ON to open. LED7 should

be ON to run either way. Check limit switches.

Empty [G]. Does it now work on remotes only?

Check power in, baery voltage & fuses. Isolate

wiring by linking [E & C] and [F & C].

Randomly triggers - There may be a missing

remote. Remove wires from [G]. Does it solve

the problem. Check wiring on acvaon devices.

Gate stops before fully open or closed - The stall

sensor maybe detecng on a rough spot. Check

the track and wheels. Increase FORCE pot.

LED3 ashes 4 mes - cannot nd the limit.

Overview

The gate installer builds a machine on site. The

machine must be declared safe by the builder and

comply with the EU Machinery Direcve. Parts for

the machine must be compliant and used as

directed by the manufacturer. Standards require

good design and good working pracces. Finished

machines must be declared safe. Handover to a

responsible person includes documentaon and

training to maintain the machine’s safety for users

& public. The latest DHF TS011 Code of Pracce

can be found at www.dhfonline.org.uk

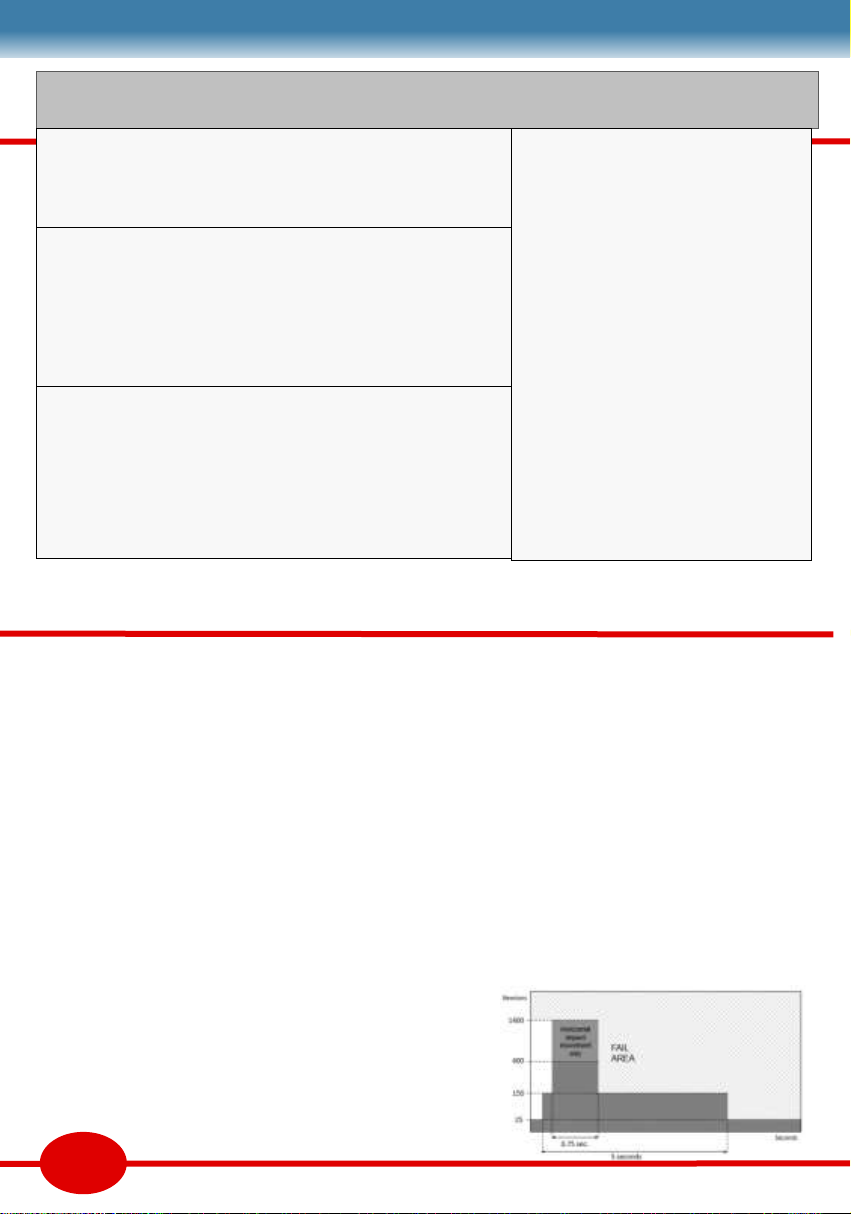

Force tesng

EN12445 explains the method of tesng the

impact forces of a gate. The crux is a graph of

acceptable forces from the point of impact.

Safety device applicaons

Safety devices such as sensive edges and photo

beams are to stop, and if necessary, reverse the

gate movement in the “Risk Zone”. Applicaons

necessary for safety are primary devices. Other

applicaons that contribute to safety, but are

not necessary are supplementary devices. Some

devices are only rated for supplementary safety

use. Primary devices need to be Cat2 or Cat3 as

dened by EN954-1.

Gate Safety Code of Pracce

Installaon record

Installaon Sengs

DIPs

POTs

Safety

ON ON ON ON ON ON ON ON

FORCE % LV % RV %

Authorised Users

1

2

3

4

5

6

7

8

Input Posion Device

IR1 FA31

Acvaon

Input Posion Device / code

13

Crush hazards marked C1 to C3

Crushing is between a moving part and a staonary

part. It is most signicant below 500mm when it

may be up to 400N for less than 750ms. Moving

part needs to be less than 25N within 5 secs.

Impact zones marked R1 to R3

Impact refers to a moving object striking a person

outside the crush zone. This is 1400N for less than

750ms. There could be a temporary object (a car) in

the R zones, hence the use of photobeams.

Safety distances marked S1 & S2,

At least one photobeam 300—700mm high must

supplement force limitaon. Spacing between the

beams and the limit of the moving part must be less

than 200mm. Nominal spacing between vercal

gate bars is 100mm. Safety must be eecve to H,

the maximum height of the moving part, or 2.4m,

whichever is the least.

Edited from DHF TS 011 Code of Pracce

‘Draw in’ or Shear Gaps where a body

part could be drawn in are not allowed. Limbs have

dierent nominal sizes. Finger gaps need to be less

than 8mm (D2), arms less than 100mm etc. A solid

inll sliding gate needs to be less than 8mm from

the post. Vercal bars on sliding gates (D2) present

mulple shear risks against the supporng post.

Entrapment Ez is an area where a

person can be entrapped without being in contact

with the gate. Entrapment is not permied unless a

manual release is provided inside the zone.

Finger traps F1 is a nger trap as a result

of poor hinge design. Designs must ensure moving

gaps are under 100mm, and either under 4mm or

over 25mm, and the gap changes by less than 20%.

Motor PSR is not an acceptable nger trap soluon.

‘Hold to run’ speed of a closing gap in a crush zone

must be less than 0.5m/s. Gates must stop within

50mm in the crush zone, or 100mm at mid travel.

14

RETRO

Complete your home security with

a Foresee gate automation set

PICO

sliding gate motors for

confined spaces, sloping

drives, and sharp corners

AVANTI

Warranty

Warranty covers defects to the Foresee product proven attributable

to a material or manufacturing fault during the warranty period. We

will repair, or refund, or replace faulty product with a similar fault

free product at our discretion. We do not accept costs for

dismantling, installation, or for carriage. Parts replaced under

warranty are the property of the warrantor.

Warranty only covers damage to the contract object. A warranty

card and a dated proof of purchase through an authorized agent is

required. Warranty covers safe reliable function of this set for 3

years from the date of purchase.

The warranty period for Radio Equipment is 24 months. The period

for replacement parts is 6 months or to the end of the current

warranty period, which ever is longer.

Warranty exceptions

The warranty does not cover damage caused through:

Wear & Tear or Improper Installation or Negligent Care or lack of

Maintenance or Misuse or Water ingress or Abnormal

Environmental Influences or Mechanical damage during Transport

or damage through improper Installation or Additional Surface

Protection treatment or mis-repair by Non-qualified or Incompetent

Persons or unapproved parts or Removal of Product Identification.

PRIMO

Garage door opener

This manual suits for next models

2

Other Forematic Gate Opener manuals