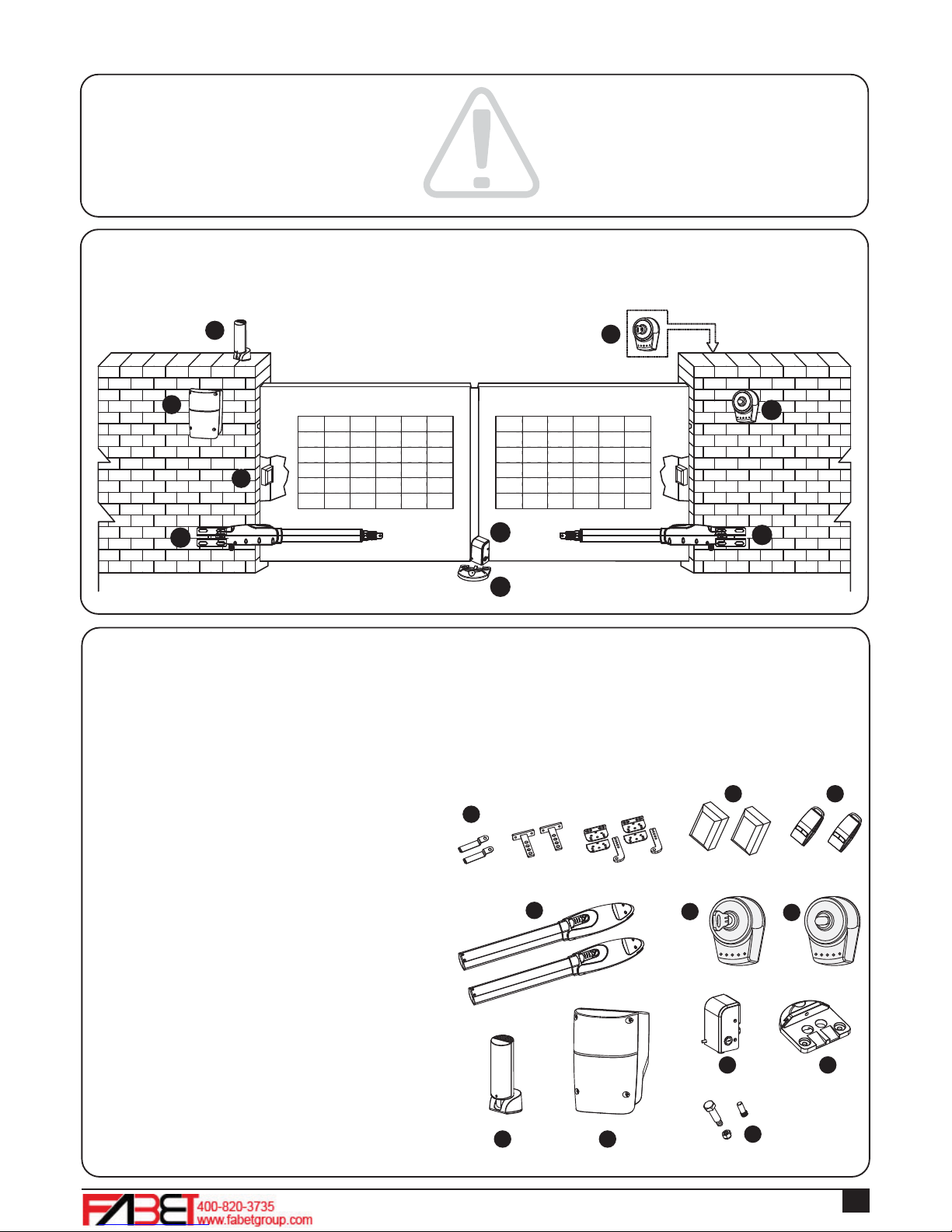

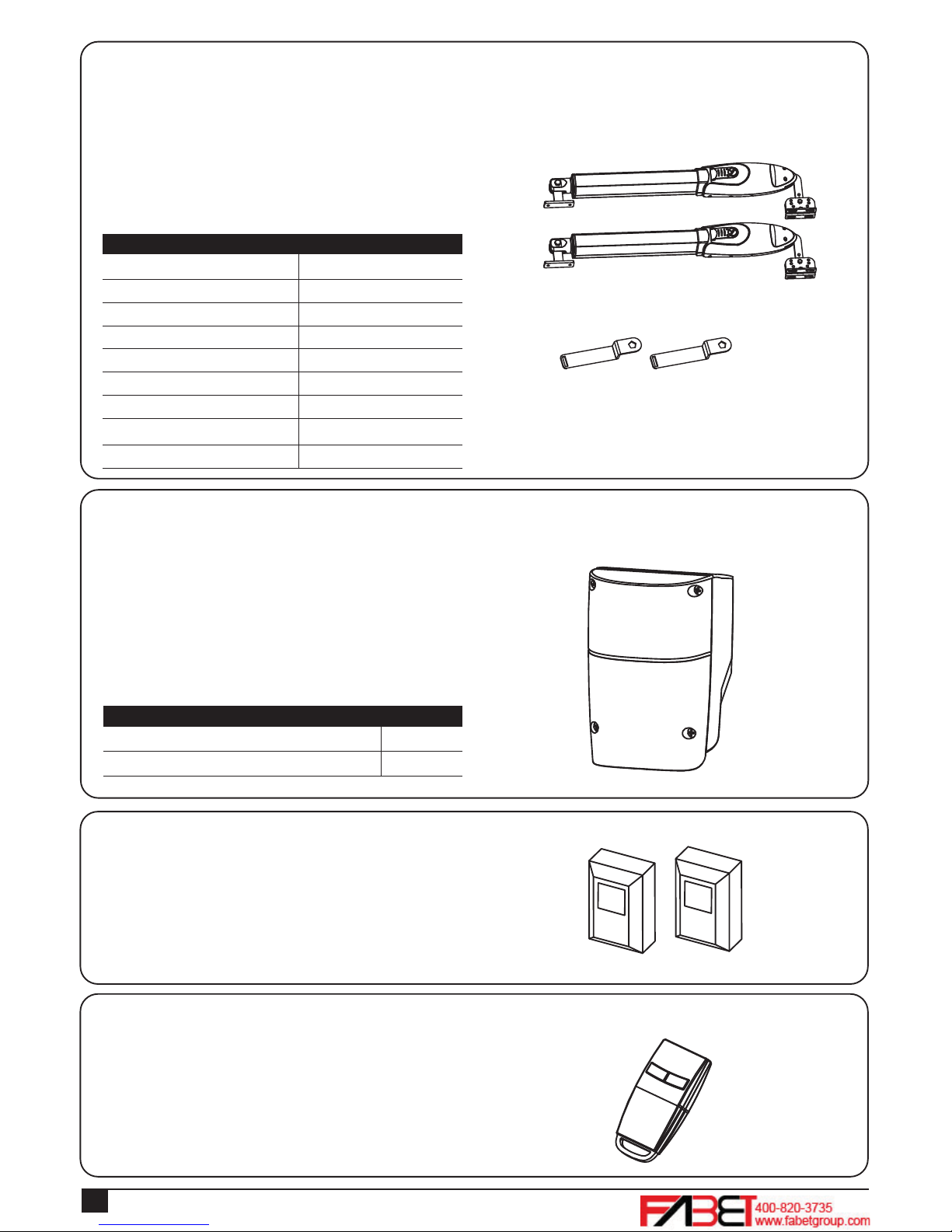

INSTRUCTIONS F330

2

1) Warnings

Please read this instruction manual carefully before the

installation of gate-automated system.

This manual is exclusively for qualified installation

personnel. Is not responsible for improper installation and

failure to comply with local electrical and building

regulations.

Keep all the components of F330 system and this manual

for further consultation.

In this manual, please pay extra attention to the contents

marked by the symbol:

Be aware of the hazards that may exist in the procedures

of installation and operation of the gate-automated

system. Besides, the installation must be carried out in

conformity with local standards and regulations.

If the system is correctly installed and used following all

the standards and regulations, it will ensure a high degree

of safety.

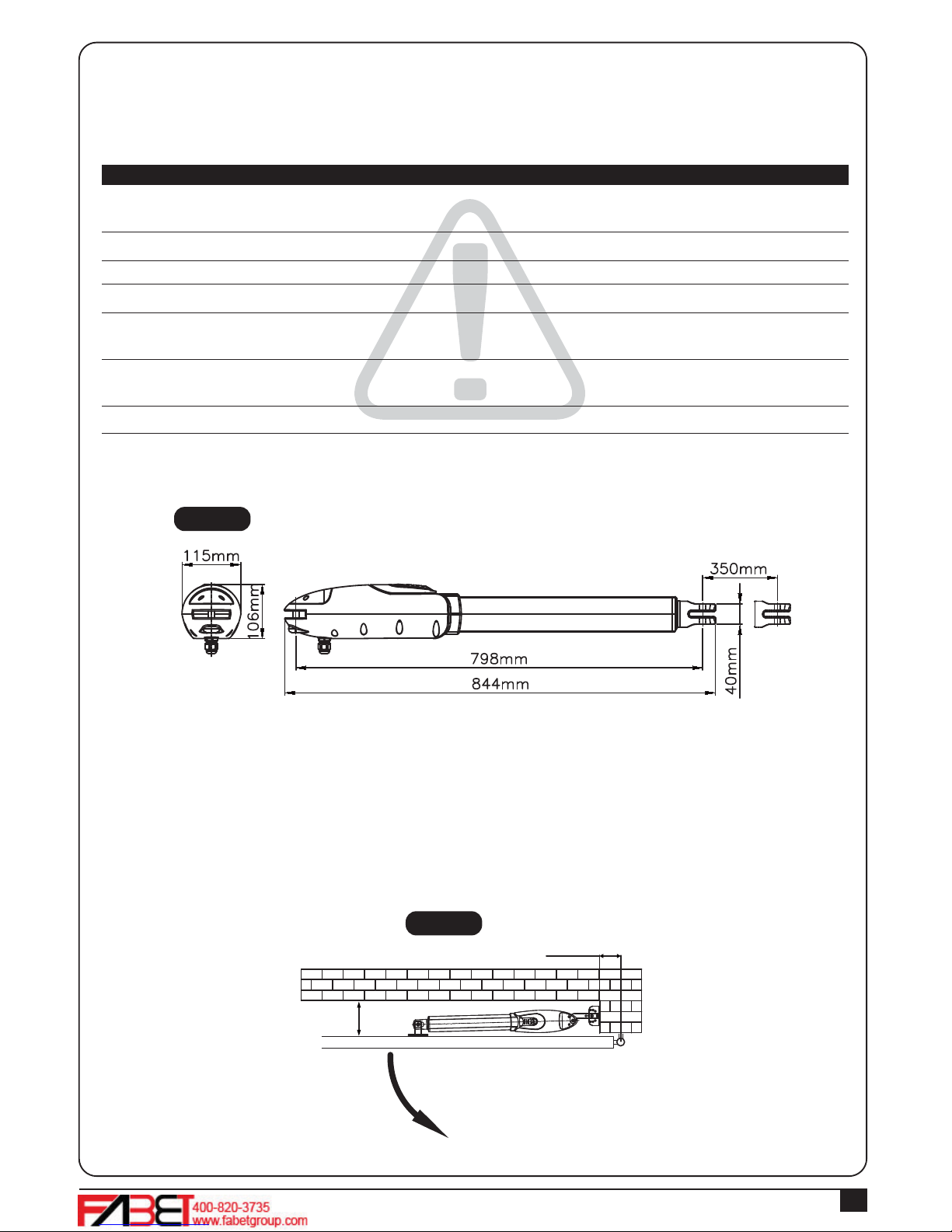

Make sure that the gates works properly before installing

the gate-automated system and confirm the gates are

appropriate for the application.

Do not let children operate or play with the

gate-automated system.

Do not cross the path of the gate-automated system when

operating.

Please keep all the control devices and any other pulse

generator away from children to avoid the gate-automated

system being activated accidentally.

Do not make any modifications to any components except

that it is mentioned in this manual.

Do not try to manually open or close the gates before you

release the gear motor.

If there is a failure that cannot be solved and is not

mentioned in this manual, please contact qualified

installation personnel.

Do not use the gate-automated system before all the

procedures and instructions have been carried out and

thoroughly read.

Test the gate-automated system weekly and have

qualified installation personnel to check and maintain the

system at least every 6-month.

Install warning signs (if necessary) on the both sides of

the gate to warn the people in the area of potential

hazards.