WARRANTY AND SERVICE CONDITIONS

This certificate is issued by Falco Domestic Appliances, supplier and importer of ALL Unbranded Falco Extractor fan models. Hereinafter referred to as ‘The

Company’, to the original purchaser only, of the product/appliances described on the certificate and shall constitute the only warranty given in respect of this

product/appliance.

The Company warrants to the original purchaser that for the period of TWO YEAR on Barbeque (Braai) extractor model: HES702(48) from date of purchase the

extractor should be free from defect under normal domestic use, both in workmanship and material.

Important Notice:

The HES702(48) barbeque (braai extractor) was designed for the use above inside GAS braai facilities. Please ensure the HES702(48) unit is installed

vented outwards. The HES702 is designed without chimneys and comes standard with a ducting hose and clamp. Due to the amount of airborne

grease and smoke that animates from a barbeque your charcoal filters should be replaced every 3 months with regular use.

Venting Outward and Ducting:

Please ensure your ducting hose (if venting outwards) does not exceed more than 3 meters. An additional in-line extraction motor must be

fitted in-line with the ducting on all ducting exceeding 3 meters. To avoid losing your extraction rate it is very important to keep the length

of your ducting to a distance less than 3 meter. The longer you’re ducting the less extraction your extractor will have unless you fit an

additional in-line motor to support in the extraction of the air. Failure to comply with this shall void the purchasers warranty until such time

they correct the installation.

If not, the warranty is subject to the following conditions:

1. Repair or replacement of any part of this product/appliance, found by The Company to be defective, shall be at the cost of The Company. The

Company reserves the right to affect such service through any Service Division authorised by The Company to carry out service on The Company’s

products/appliances. The cost of the service shall be borne by The Company in full, providing that the product/appliance is located no further than

50km from an authorised service agent.

Where the product/appliance is located beyond the 50km radius, the purchaser shall be liable for the standard travelling charges, as determined by

The Company or alternatively, The Company reserves the right to ask the purchaser to deliver any faulty product/appliance to the dealer from which it

was bought or nearest service agent, for repairs. After the said repair has been completed, the original purchaser is again responsible for the

collection and transportation of said product/appliance.

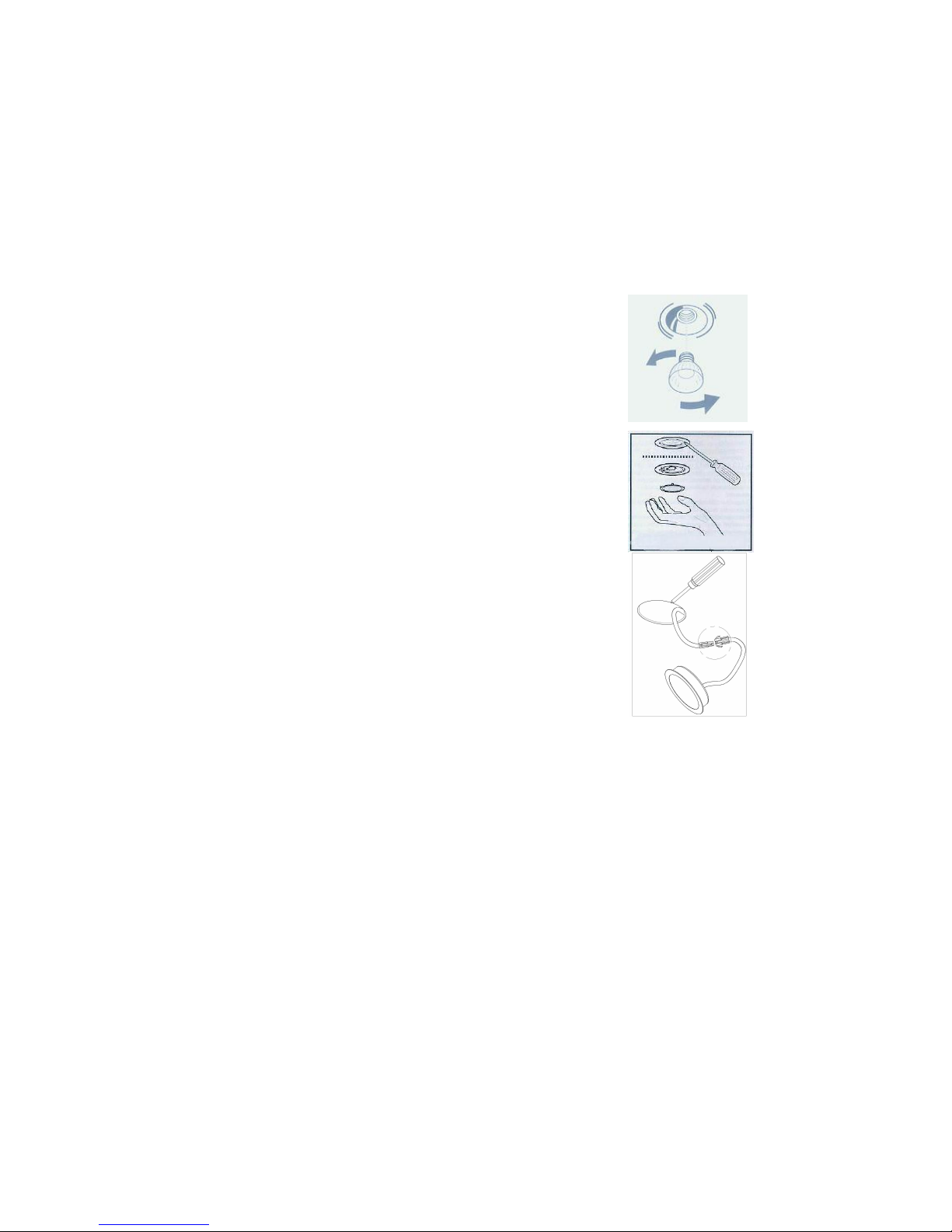

2. All lamps,halogen lamps,infrared lights,globes,Metal filters, charcoal filters and metal drip trays are excluded from these warranties.

Abuse, misuse in conflict with the operating instructions, connection to incorrect voltages (generators, solar panels, wind turbines without the

additional and compulsory addition of pure sine wave invertors), shall release The Company from all its obligations under warranty. It is an express

condition of these warranties that the purchaser takes due care and attention in the use and maintenance of the product/appliance.

3. Any physical damage to the product/appliance that occurred prior to delivery/receipt of the product/appliance will only be included in this warranty

provided that it is reported, together with the proof of purchase within 48 hours thereof. Any part on any of the abovementioned products/appliances

will be excluded from this warranty, should findings indicate that the parts are damaged or malfunctioning because of any form of physical damage.

4. This warranty shall become void and cease to be valid if the product/appliance is dismantled by, or any repairs to the product/appliance are affected

by any person not authorised by The Company, or if replacement parts not approved by The Company are used in any product/appliance, or if the

serial number of the product/appliance is removed.

5. These warranties shall not apply if the product/appliance is purchased or used beyond the borders of the Republic of South Africa (Swaziland,

Lesotho, Namibia, Botswana and Zimbabwe).

6. The Company shall not be responsible for damages resulting from fire, floods, civil disturbances or any Act of God. The Company shall not, in terms

of these warranties be responsible, nor held liable for any consequential loss or damage of any kind caused by or due to the failure or malfunctioning

of the appliance/product.

7. The Company shall not be held responsible for transportation/other costs other than those incurred within the provisions of Point 1 of this Certificate.

8. Where service is requested under warranty and no fault or any defect is found by the Company service agents, all costs incurred will be for the

purchaser’s account.

9. This certificate together with the purchaser’s proof of purchase (Invoice from Dealer) will serve as proof of purchase. For warranty purposes, it will be

essential to produce this Certificate with the Invoice. Failure to do so will render the purchaser liable for service costs.

10. The Company will not exchange any faulty product/appliance still under warranty EXCEPT if the appointed service agent inspects and

confirms with valid proof that the appliance is irreparable.

11. Where the purchaser lives in an outlying area (farms/ remote locations) where appointed Service Agents are scarce or non-existent, The Company

reserves the right to request such a purchaser to transport the unit to and from the nearest appointed Service Agent for repairs.

12. This warranty shall become void and cease to be valid if the product is installed at the incorrect height. Please refer to your manual.

13. This warranty shall become void and cease to be valid if the incorrect size Extractor Fan is installed above any electrical or gas hob. Example of such

an installation is installing a 600mm Extractor above a 900mm gas or electrical hob.

14. This warranty does not cover rodent or insect infestation.

15. Repairs and parts covered by the Company includes: the motors, the main PCB, Display PCB the power and light switches, the capacitor, the motor

fan blade and any transformers.

KEEP THIS WARRANTY AND SERVICE CERTIFICATE AS WELL AS SALES INVOICE AS YOUR PROOF OF PURCHASE FOR ALL WARRANTY

SERVICE CALLS PURPOSES

16. Extractor Fan Warranty calls:

Lategan & Van Biljoens Appliance Spares

636 Frederika Street, Gezina, Pretoria, PO Box 23151, Gezina, 0031, Pretoria

Warranty

Tel

: (012) 330-00287extension 207or 301; Fax: 086-684-2247; email: [email protected]Any service-related queries should be directed directly to the dealer (store) where the purchaser purchased the product. Alternatively, the purchaser can

contact the appointed call centre as per point 16 of this certificate. The appointed call centre, Lategan & Van Biljoens Appliance spares, will allocate the service

call under the warranty procedure to one of their closest service agents in the purchaser’s area. No service call will be considered under the warranties if no

proof of purchase can be presented

Happyor Unhappy lets us know: Christie@falco.co.za Tel: 011 454 6423/4314/6146