9

ENGLISH

Before connecting the hood to the electrical mains power supply, check that:

• voltage supply corresponds with what is reported on the data plate located

inside the hood;

• the electrical system is compliant and can withstand the load (see the techni-

cal specications located inside the hood);

• the power supply plug and cable do not come into contact with tempera-

tures exceeding 158°F (70 °C);

• the power supply system is eectively and properly connected to earth in

compliance with regulations in force;

• the socket used to connect the hood is within reach.

In case of:

• devices tted with cables without a plug: the type of plug to use is a ''stand-

ardised'' one. The wires must be connected as follows: yellow-green for

grounding, blue for neutral and brown for the live. The plug must be con-

nected to an adequate safety socket.

• xed equipment not provided with a power supply cable and plug, or any

other device that ensures disconnection from the electrical mains, with an

opening gap of the contacts that enables total disconnection in overvoltage

category III conditions.

Said disconnection devices must be provided in the mains power supply in

compliance with installation regulations.

The cable must not be cut o by the switch.

The Manufacturer declines all responsibility for failure to comply with the safety

regulations.

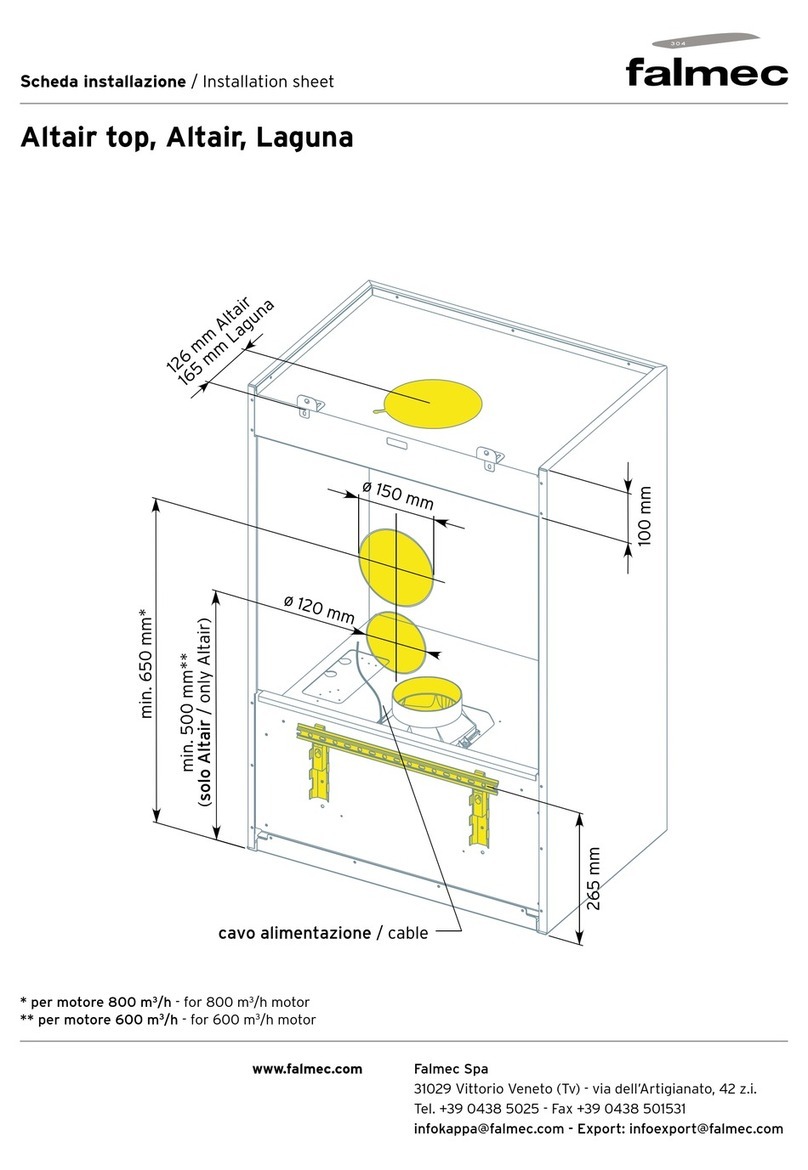

FUMES DISCHARGE

EXTERNAL EXHAUST HOOD SUCTION

In this version the fumes and vapours are discharged outside

through the exhaust pipe.

To this end, the hood outlet tting must be connected via a

pipe, to an external output.

The outlet pipe must have:

• a diameter not less than that of the hood tting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from owing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 500CFM or higher, a check valve is present to

prevent external air owing back.

HOOD WITH INTERNAL RECIRCULATION FILTERING

In this model, the air passes through the charcoal lters to be

puried and recycled in the environment.

Ensure that the active carbon lters are assembled into the

hood, if not, install them as indicated in the assembly instruc-

tions.

In this version the check valve must not be assembled: remove it if it is

on the air outlet tting of the motor.

ASSEMBLY INSTRUCTIONS

Intended only for qualied personnel

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-o

function which will allow the hood to turn o automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

1st speed: maintains the circulation of clean air with low electricity consump-

tion.

2nd speed: normal conditions of use.

3rd speed: presence of strong odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal lters must be cleaned every 30 hours of operation.

The active carbon lters must be replaced every 3-4 months, depending on the

use of the hood.

For further details refer to the “MAINTENANCE” section.

USE OF MECHANICAL PUSH BUTTON CONTROL PANEL

Light on/o

OFF

OFF button

Press this button to switch the motor o

1Button 1: Press this button (button in) to start or set

the motor at minimum speed

2Button 2: Press this button (button in) to start

or set the motor at medium speed

3Button 3: Press this button (button in) to start or

set the motor at maximum speed

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters : frequent clean-

ing of the lters and their supports ensures that no ammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use too much moisture or water around the push button

control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

The glass panels can only be cleaned with specic, non-corrosive or non-abra-

sive detergents using a soft cloth.

The Manufacturer declines all responsibility for failure to comply with these in-

structions.