USER MANUAL FOR UPSIDE LOAD TOWERS 2

IMPORTANT

Read and understand precisely all points and aspects

of this manual. Irresponsibly lifting loads can cause

lethal accidents. Installation of lifting systems and

proper use are only responsibility of the user.

It is recommended to attach this manual with tower

system used.

If in doubt, consult the technical department of

Fantek Industrial S.L.

CONTENT

RULES AND SAFETY USE ..................................... 3

PARTS IDENTIFICATION...................................... 8

HOW TO USE. STEP BY STEP............................... 9

ACCESSORIES.................................................... 11

.STANDARDS..................................................... 14

LOAD DATA ...................................................... 15

DYNSYS SYSTEM............................................... 16

MAINTENANCE................................................. 17

TRANSPORT...................................................... 18

With forklift..................................................18

With truck or container. .............................. 19

DGUV V17/18 NORM REGULATION................. 20

ESPECIFICACIONES / ESPECIFICATIONS............ 40

DECLARACION DE CONFORMIDAD /

DECLARATION OF COMFORMITY..................... 41

MARCADO DGUV / DGUV MARK ..................... 42

CONTACT

Internet: www.fantek.es

ILLUSTRATION INDEX

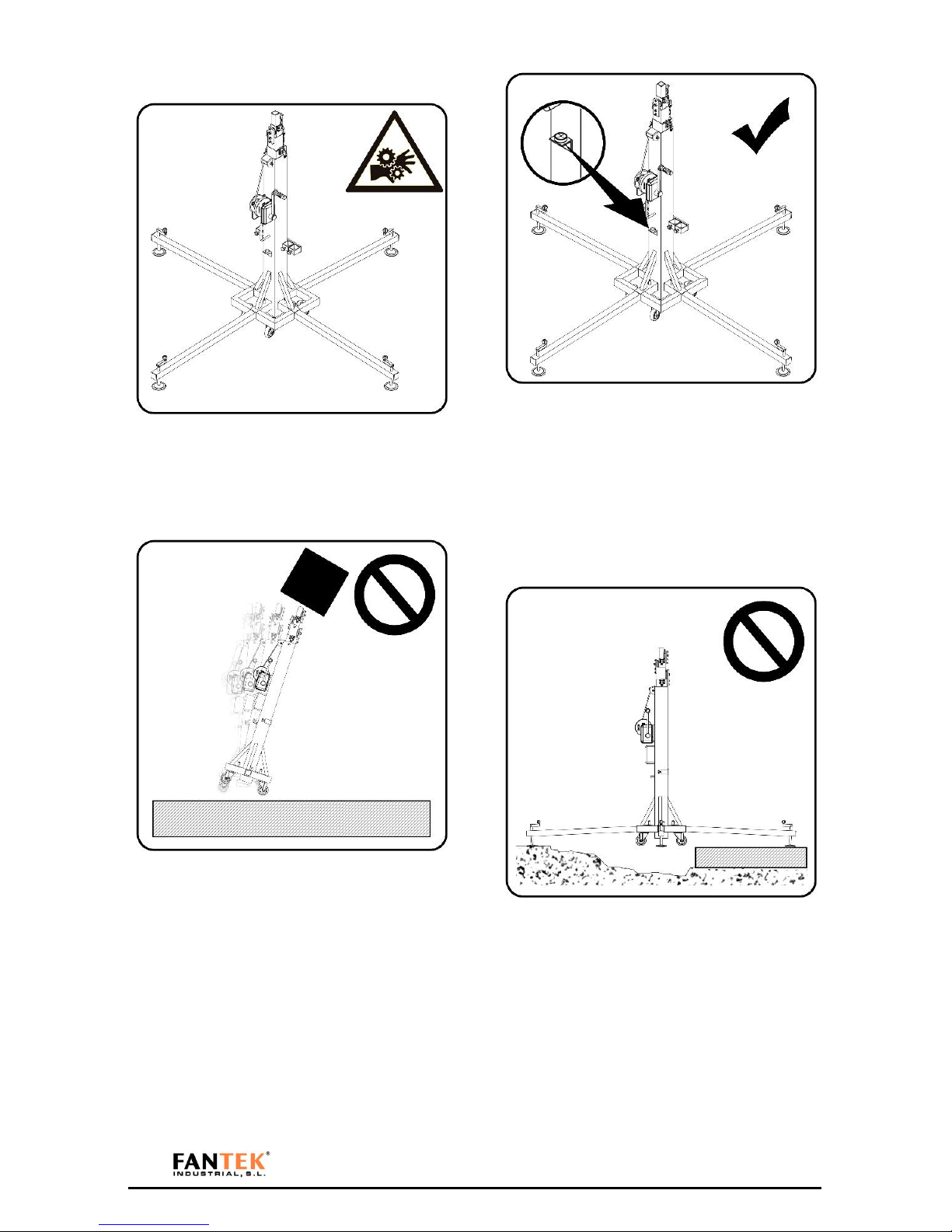

Figure 1.............................................................. 3

Figure 2.............................................................. 3

Figure 3.............................................................. 3

Figure 4.............................................................. 3

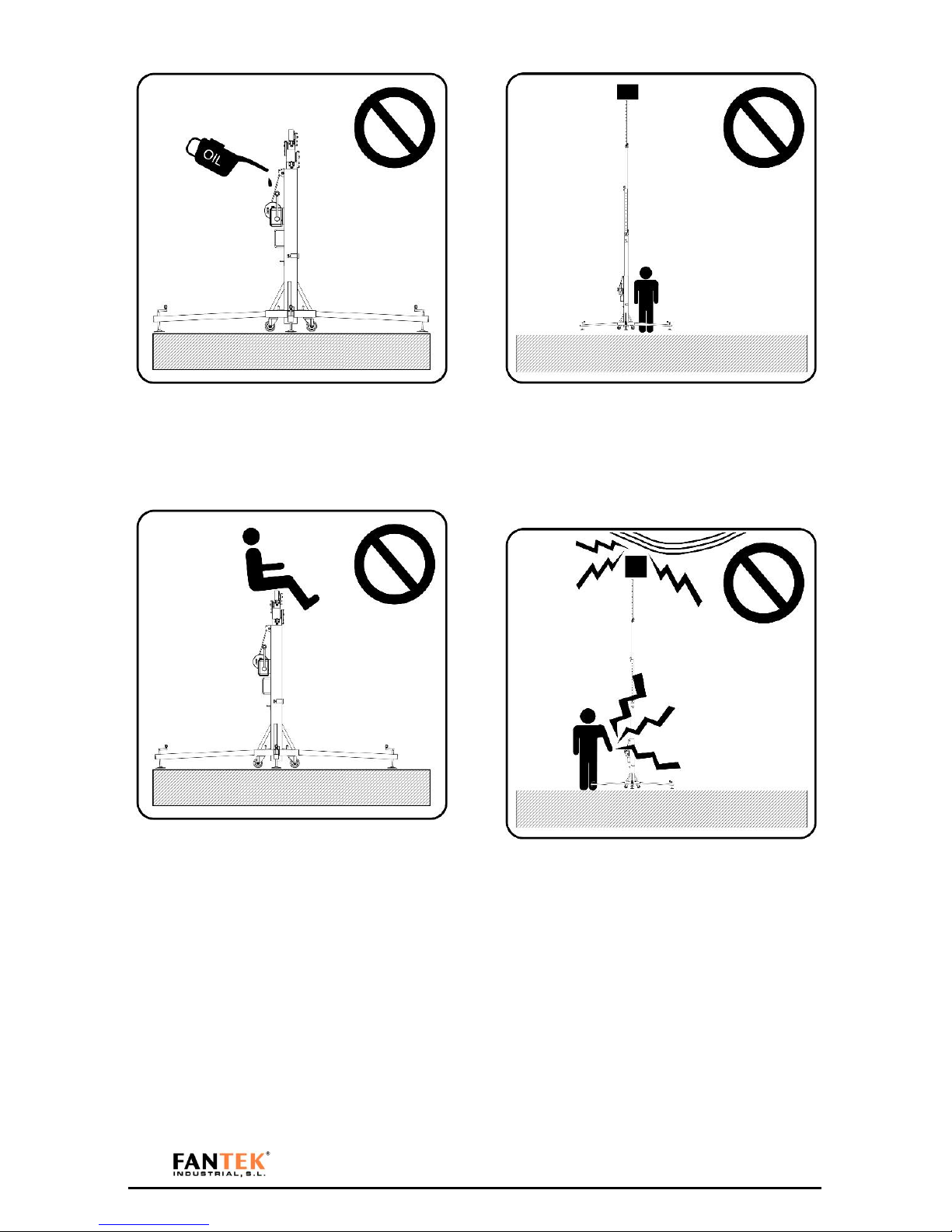

Figure 5.............................................................. 4

Figure 6.............................................................. 4

Figure 7.............................................................. 4

Figure 8.............................................................. 4

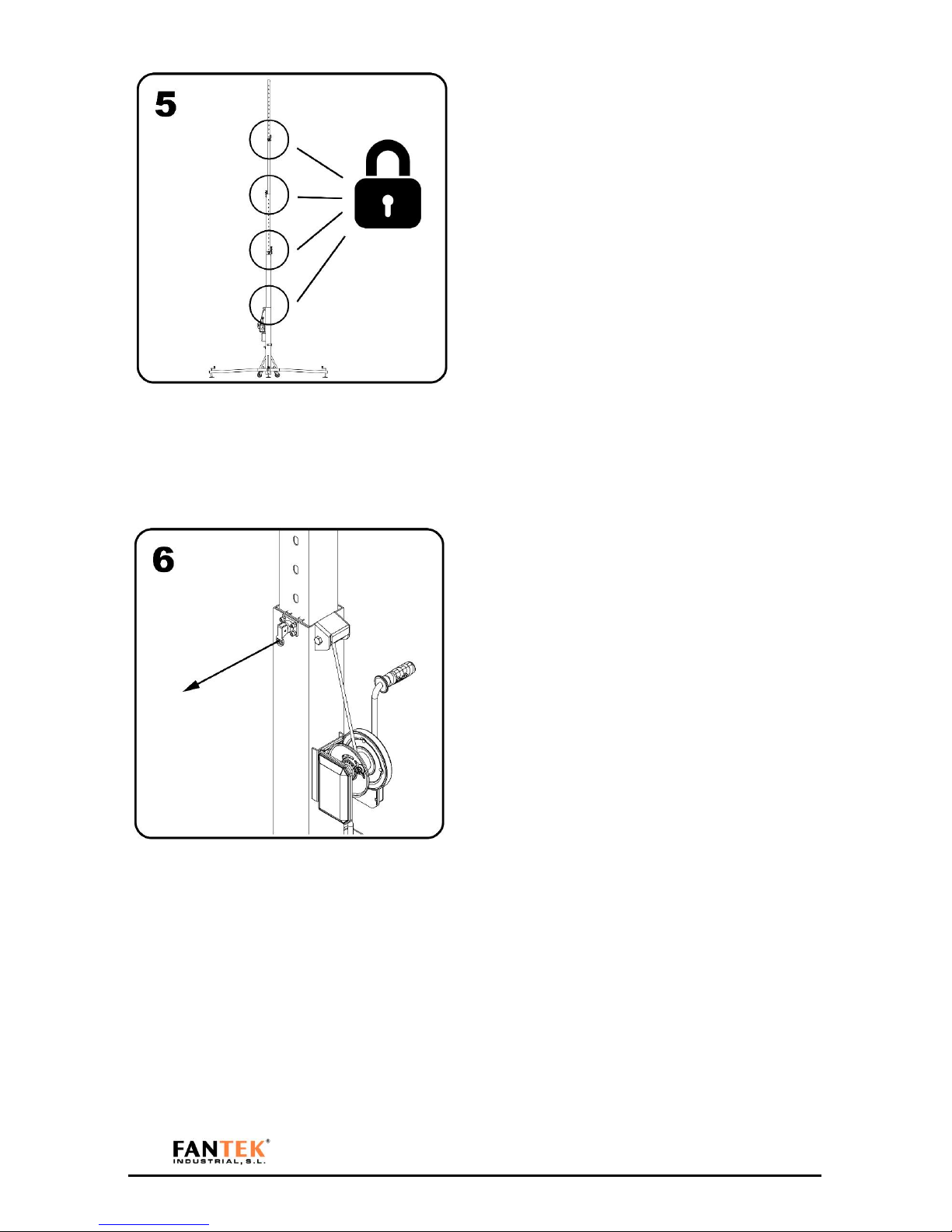

Figure 9.............................................................. 5

Figure 10............................................................ 5

Figure 11............................................................ 5

Figure 12............................................................ 5

Figure 13............................................................ 6

Figure 14............................................................ 6

Figure 15............................................................ 6

Figure 16............................................................ 6

Figure 17............................................................ 7

Figure 18............................................................ 7

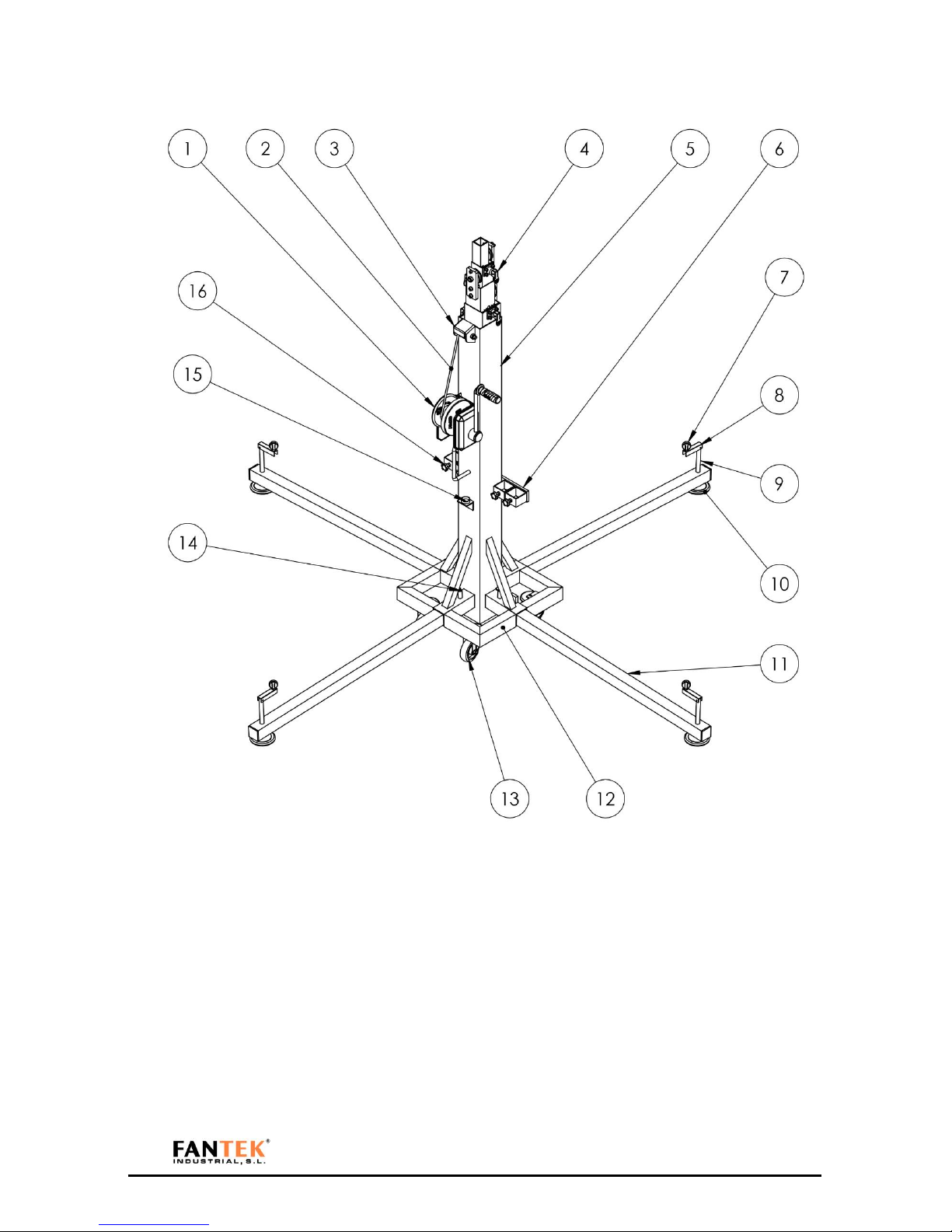

Figure 19............................................................ 8

Figure 20............................................................ 9

Figure 21............................................................ 9

Figure 22............................................................ 9

Figure 23............................................................ 9

Figure 24.......................................................... 10

Figure 25.......................................................... 10

Figure 26.......................................................... 11

Figure 27.......................................................... 12

Figure 28.......................................................... 13

Figure 29.......................................................... 14

Figure 30.......................................................... 15

Figure 31.......................................................... 16

Figure 32.......................................................... 17

Figure 33.......................................................... 18

Figure 34.......................................................... 19