Far Tools TDM 400B User manual

114135-D-20120201 ©FAR GROUP EUROPE

www.fartools.com

FR

EN

Metal lathe( Original version translation )

Tour à métaux ( Version originale )

Professional Machine

TDM 400B

114135-Manual-D-EN.indd 1 21/03/12 10:44:10

©FAR GROUP EUROPE

Huile / Oil : SAE 30-50

Après 20 jours d’utilisation / After 20 days of using.

Ajout d’huile tous les six mois ( après nettoyage ) / Re-adding every 6 months ( must be

cleaned first )

L’adjonction d’huile ne doit pas dépasser les 2/3 de la jauge / The oil adding level

souldn’t be higher than 2/3 of the oil gauge.

TRANSPORTATION AND STORAGE

Always show care when transporting or lifting the machine. Always leave this work

to qualified personnel. When loading / unloading the machine, be sure to not trap

anyone with the machine. Never pass under the machine while it is being lifted by a

crane or hoist.

Protect from damp and impacts.

The machine must be stored at temperatures of between 5°C and 45°C

LUBRIFICATION / LUBRIFICATION

18

1403

17

16

15

114135-Manual-D-EN.indd 2 21/03/12 10:44:12

©FAR GROUP EUROPE

PREPARING THE INSTALLATION LOCATION

SLINGING DEGREASING

The bench where the unit is to be installed must measure at least: L 1000 mm, W 600 mm,

H 550 mm and must be able to bear 150 Kg. For safety reasons, the bench must be placed

against a wall while still leaving access to the rear of the machine. Four holes must be

drilled in the bench (see diagram).

Before slinging the machine,

take care to remove the wooden

spacers located on either side of

the base. See below for the most

suitable locations for placing the

sling under the machine

Degreasing is carried out using a

cloth dampened with white spi-

rit. Beware of the vapours that

can be toxic and be sure to pro-

perly ventilate the room

20 mm

690 (790) +/- 0,4 mm

750 (850) mm

210 mm

150 +/-0,2 mm

114135-Manual-D-EN.indd 3 21/03/12 10:44:13

©FAR GROUP EUROPE

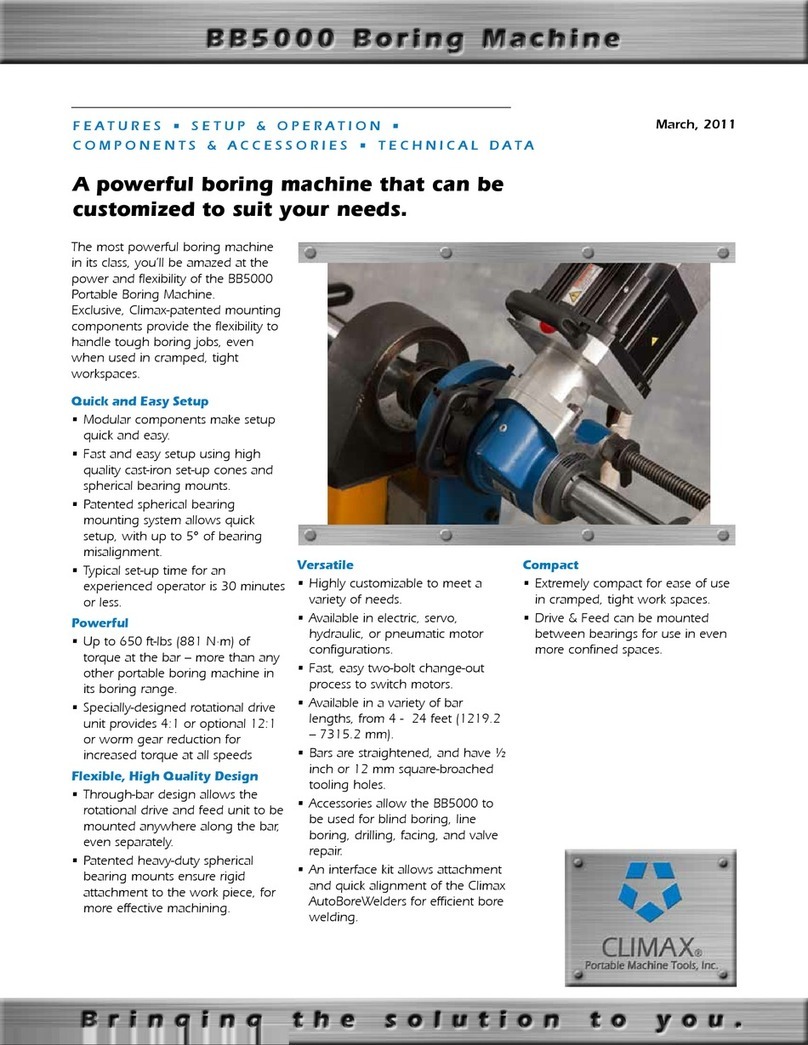

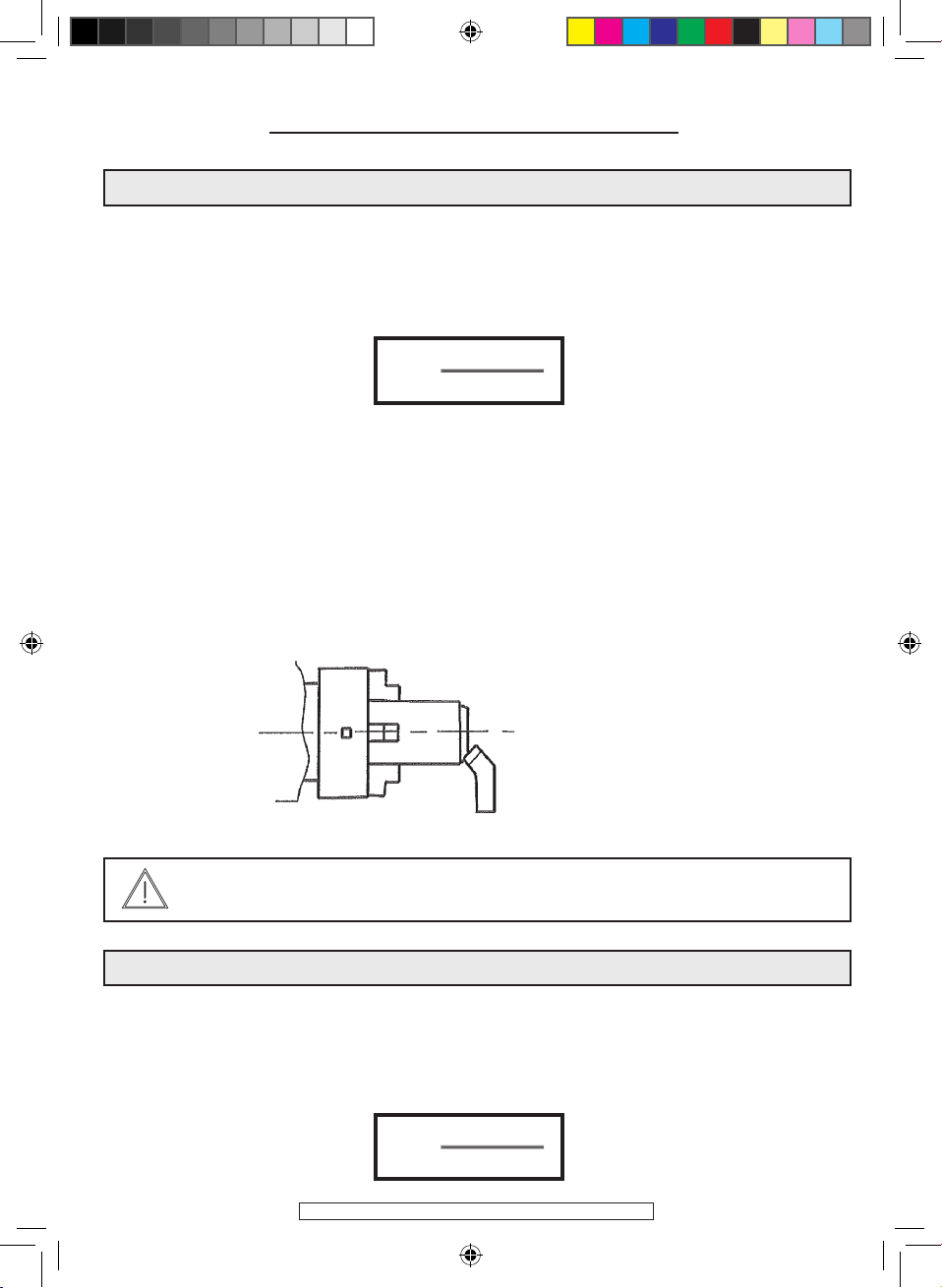

BALL VALVE OILER

with white spirit. Beware of the vapours that can be toxic and be sure to properly venti-

late the room. 13/ BALL VALVE OILER 14/ Using a stiff tip oil can, regularly oil those points

fitted with a ball valve oiler

LUBRICATING UNPROTECTED AREAS

Using an oiled brush, coat areas like the drive screw, the sliders, the cast iron bench...

BEFORE USE

Always let the lathe run under no load for 5 to 10 minutes so that the gearbox gears

can become lubricated

MAINTENANCE

During use, the lathe must receive regular maintenance to avoid impacting its produc-

tivity or its service life. After the first 20 days in service, drain the gearbox oil (using a

syringe not supplied). The oil is filled using the filter cap located on the top of the mo-

tor. The visual level indicator is located under the chuck (it must always be kept on the

halfway mark). Subsequently, oil changes should be made approximately every three

months (depending on frequency of use). Before starting a working session, lubricate

the machine in line with its lubrication requirements. WARNING: The oil level in the

chuck gear box must be checked regularly.

SPECIFIC SAFETY RULES

1- Always remove the chuck key from the chuck,

2- Never wear loose fitting clothing,

3- Always wear protective eye goggles,

4- Before replacing working tools or changing the speed or advance settings, always stop

the motor, disconnected the power connector and wait until the chuck has come to a

complete stop,

5- Attaching the part: Carefully attach the part before starting the lathe,

6- Stopping the lathe: Stop the lathe before taking any measurements on the part.

7- Braking: Braking the part or the chuck is dangerous

8- Eliminating chips: Never eliminate chips with your hands, always use a hook to do so.

114135-Manual-D-EN.indd 4 21/03/12 10:44:13

©FAR GROUP EUROPE

SLAVED SAFETY CASING

114135-Manual-D-EN.indd 5 21/03/12 10:44:23

©FAR GROUP EUROPE

QUICK SPINDLE LOWERING USING THE ARMS: DRILLING

SLOW SPINDLE LOWERING USING THE KNOB: GRINDING

BELT TENSION

114135-Manual-D-EN.indd 6 21/03/12 10:44:33

©FAR GROUP EUROPE

RAISING/LOWERING AND AIMING THE DRILLING HEAD

114135-Manual-D-EN.indd 7 21/03/12 10:44:39

©FAR GROUP EUROPE

MAIN CHARACTERISTICS

- Milling:

Max. machining diameter: 400 mm

Distance between tips: 400 mm

Max. longitudinal apron travel: 410 mm

Max. transverse carriage travel: 80 mm

Tool turret of size 20 x 20 max.

No. 3 jaw taper tailstock

Seven rotation speeds from 160 to 1360 rpm

Metric thread leadscrew (19 metric increments from 0.2 to 3 mm )

- Drilling/milling:

Max. drilling diameter: 16 mm

Max. milling diameter: 12 mm

No. 3 jaw taper mandrel

14 speeds (117 to 1300 rpm),

Working table: 150 x 200 mm

CAPACITY DIAGRAM

114135-Manual-D-EN.indd 8 21/03/12 10:44:46

©FAR GROUP EUROPE

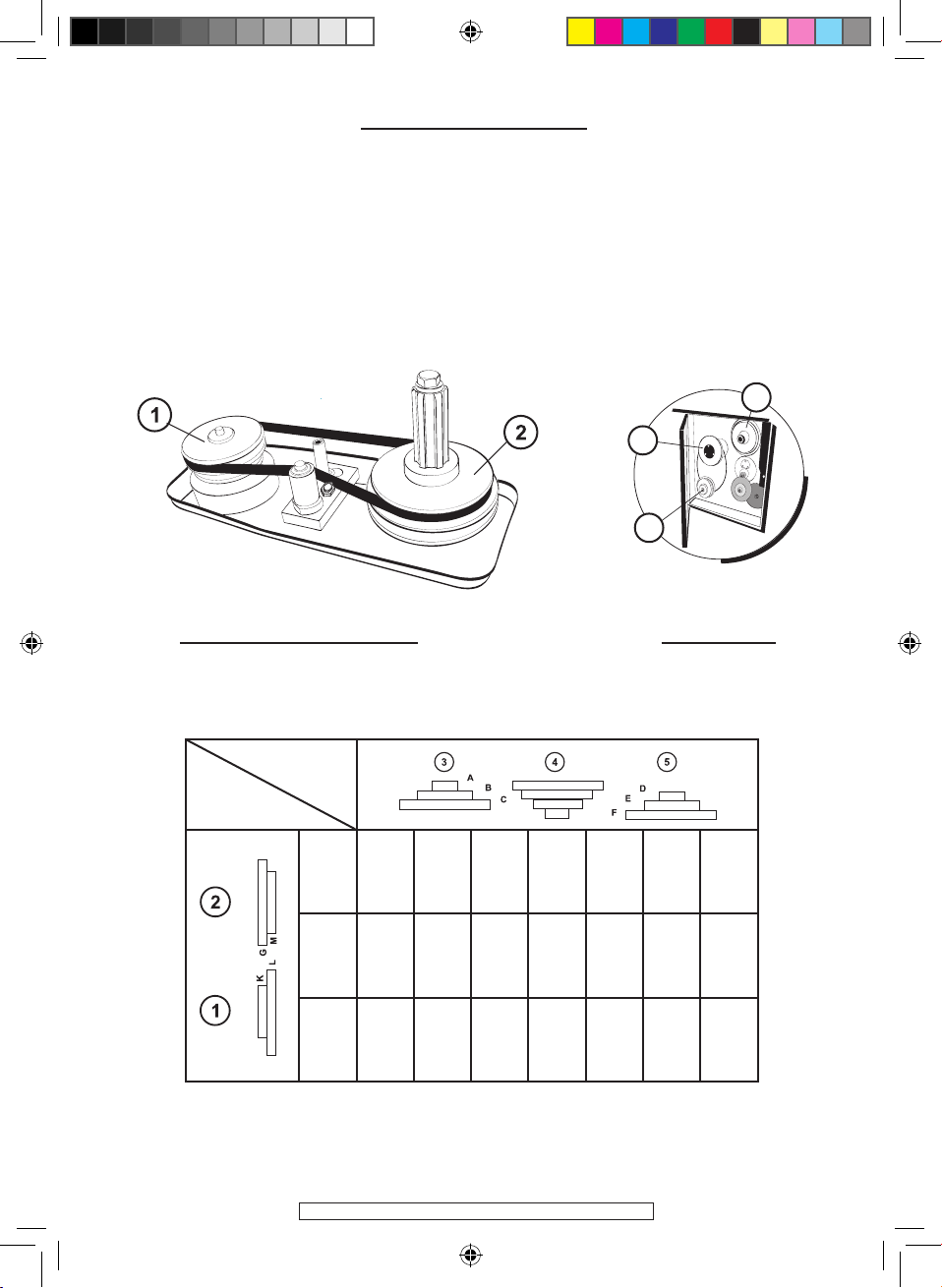

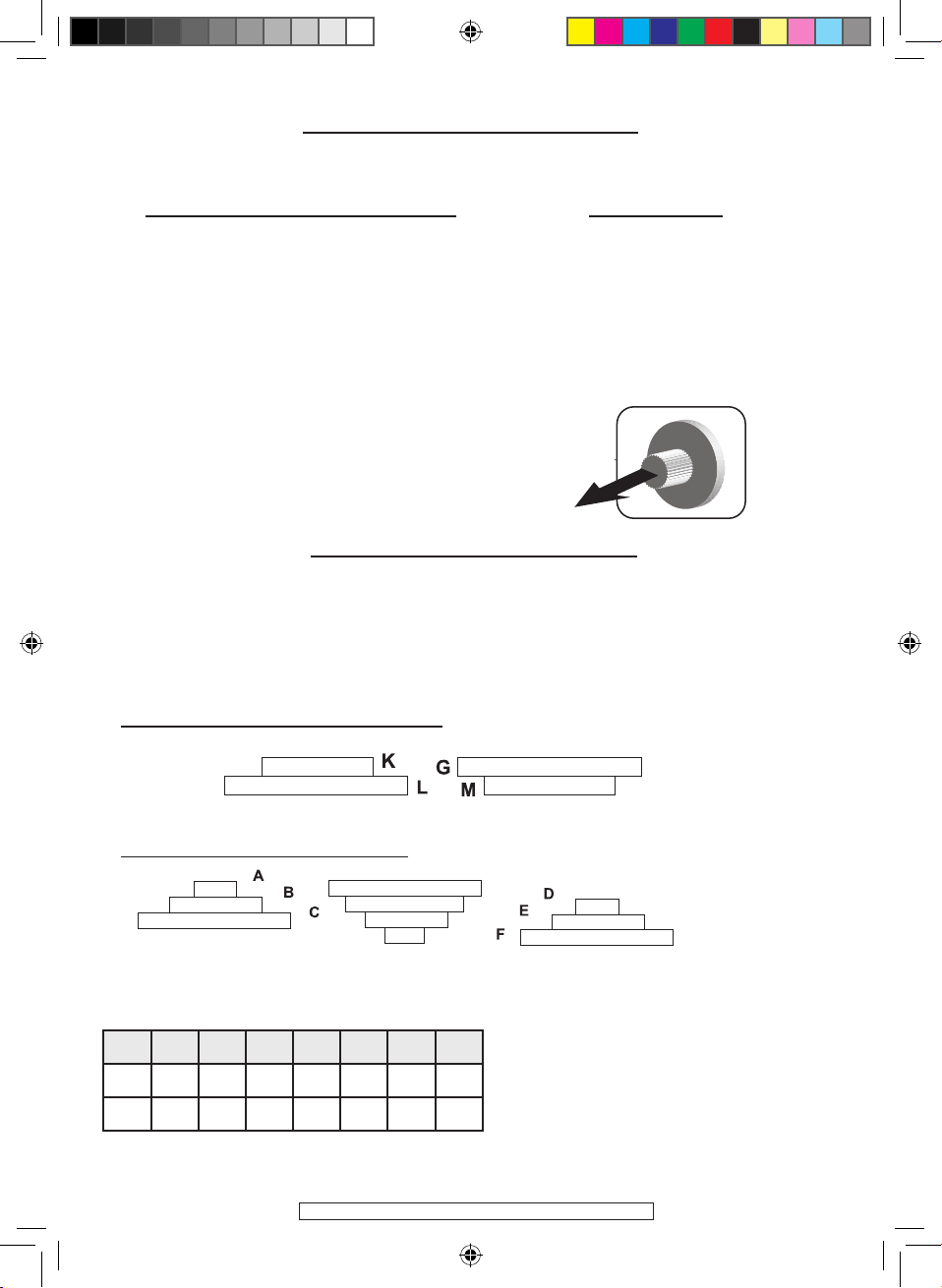

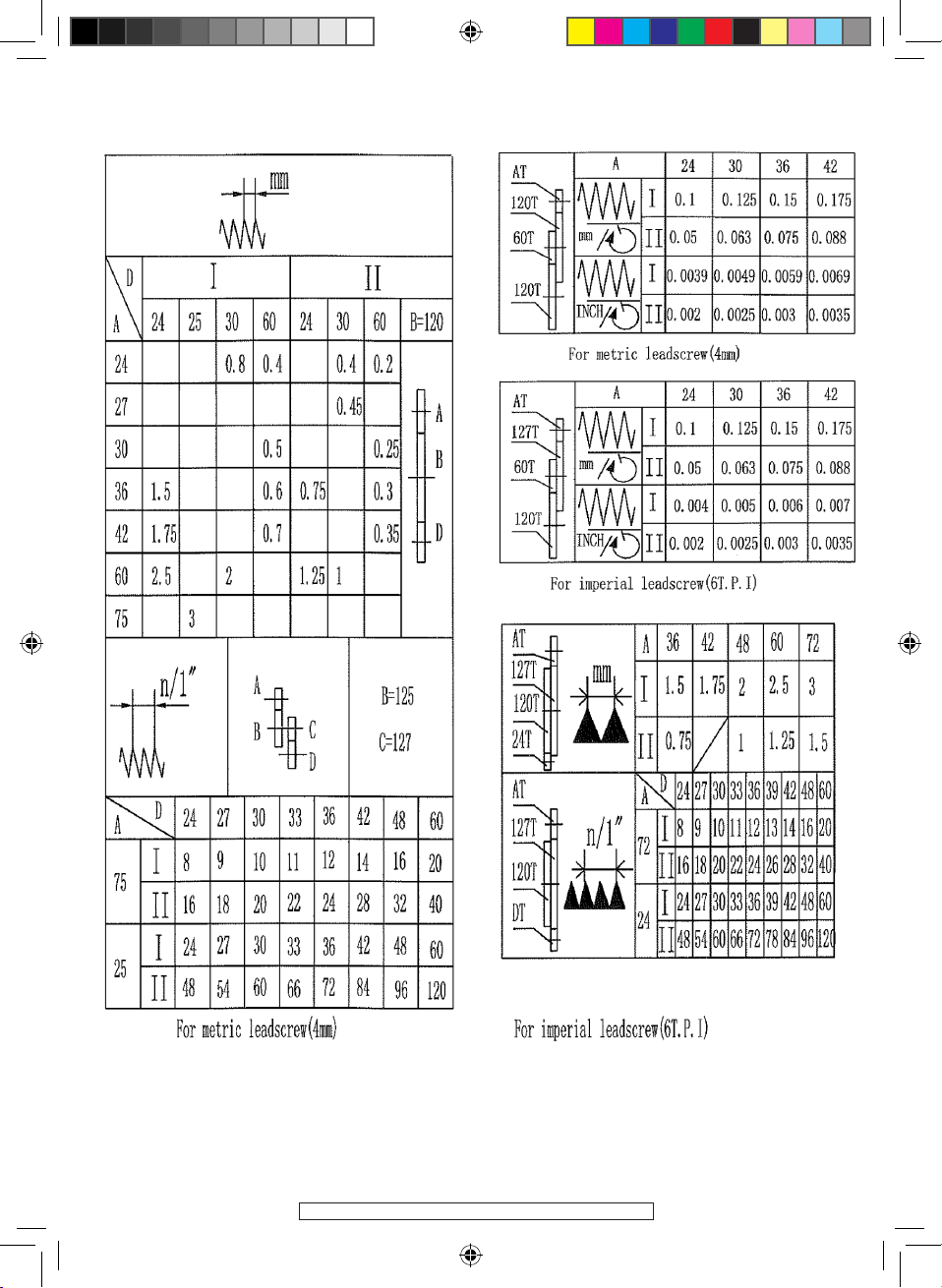

TRANSMISSION SYSTEM

Spindle speed settings: (in rpm)

The spindle speed is set to match the diameter of the part and the material to be ma-

chined, The setting is made after calculating the number of rpm and after determining

the position of the belts on the pulleys, referring back to the chart provided on the

machine.

DRILLING/MILLING UNIT LATHE UNIT

A-F A-E A-D B-F C-F B-E C-D

K-G 150 290 360 450 575 836 1300

L-M 117 220 276 345 440 640 1000

Drilling /

Milling

3= Motor pulley

4= Intermediate pulley

5= Spindle pulley

Lathe

Speed in rpm

3

5

4

114135-Manual-D-EN.indd 9 21/03/12 10:44:48

©FAR GROUP EUROPE

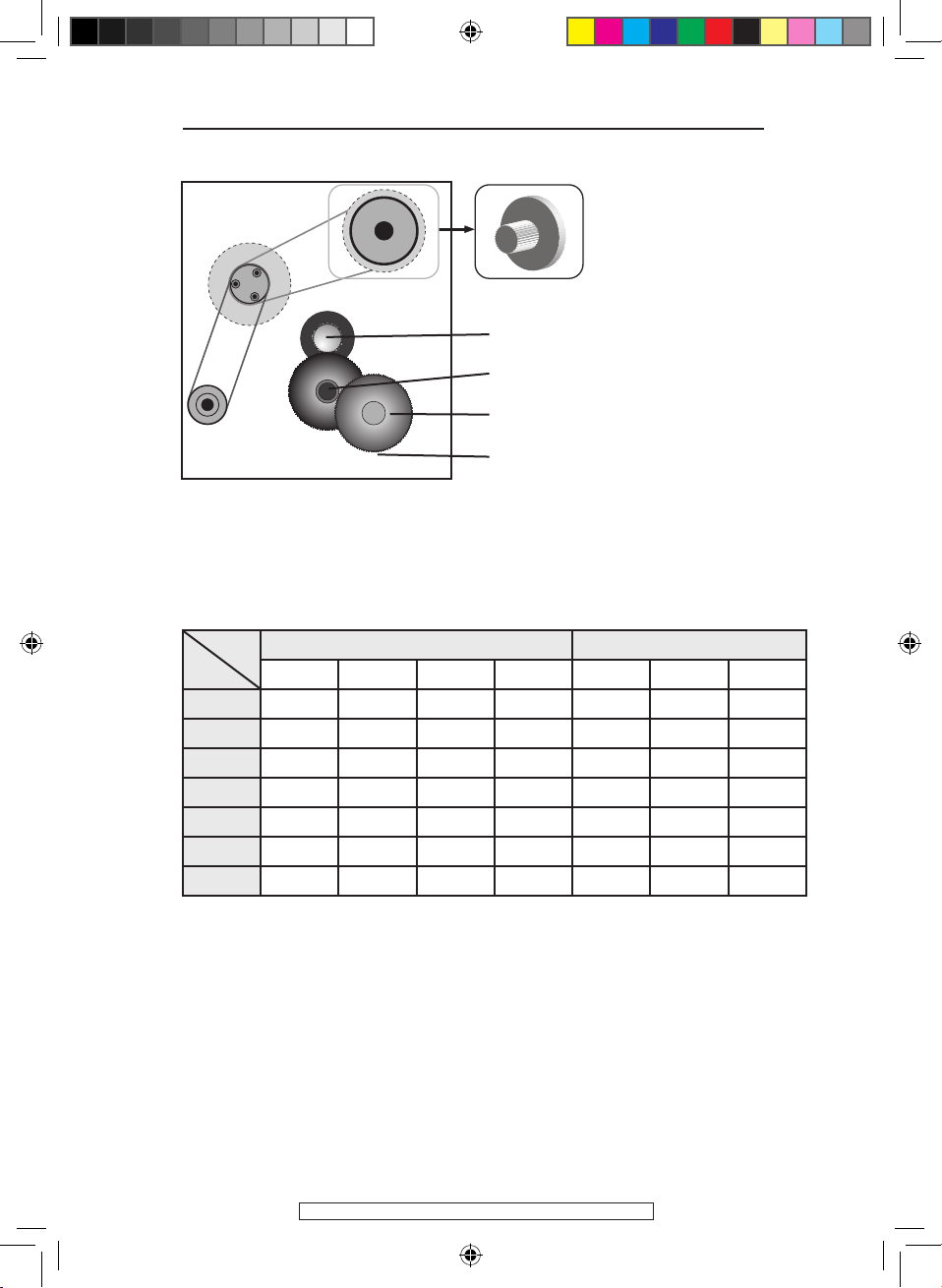

PROCEDURE FOR CHANGING GEARS TO ADJUST THE ADVANCE

The advance is set by changing the gears which are located in the cabinet on the left

hand side of the machine and by making reference to the table.

Gear A: 16 mm open end wrench

Gear B: 5 mm Allen wrench

Gear D: 16 mm open end wrench

Gear D adjustment screw: 5 mm Allen

wrench

Choose the advance or increment to be performed, refer back to the table below for the

choice of gears to use. I and II correspond to the No. 3 lever position.

Slacken and remove the nuts from gears A and D using a 16 mm wrench,

Slacken the 6 mm hollow head bolt on gear B using a 5 Allen wrench.

Slacken the 6 mm hollow head bolt used to adjust gear D using a 5 mm Allen wrench.

Remove gears A and D (taking care to not lose the key!),

Take the gears that match the advance or increment to be performed.

Reassembly: Refit gear A and tighten down the 16 mm nut, Adjust gear B in relation to

gear A and tighten down the 6 mm Allen head bolt, Lastly, refit gear D onto gear B by

sliding the support and locking down the 6 mm Allen head bolt

WARNING: Before performing any gear replacement operation, ensure that the power

cable is disconnected.

Transmission box

Unit: mm

I II

24 25 30 60 24 30 60

24 0,8 0,4 0,4 0,2

27 0,45

30 0,5 0,25

36 1,5 0,6 0,75 0,3

42 1,75 0,7 0,35

60 2,5 2 1,25 1

75 3

AD

114135-Manual-D-EN.indd 10 21/03/12 10:44:52

©FAR GROUP EUROPE

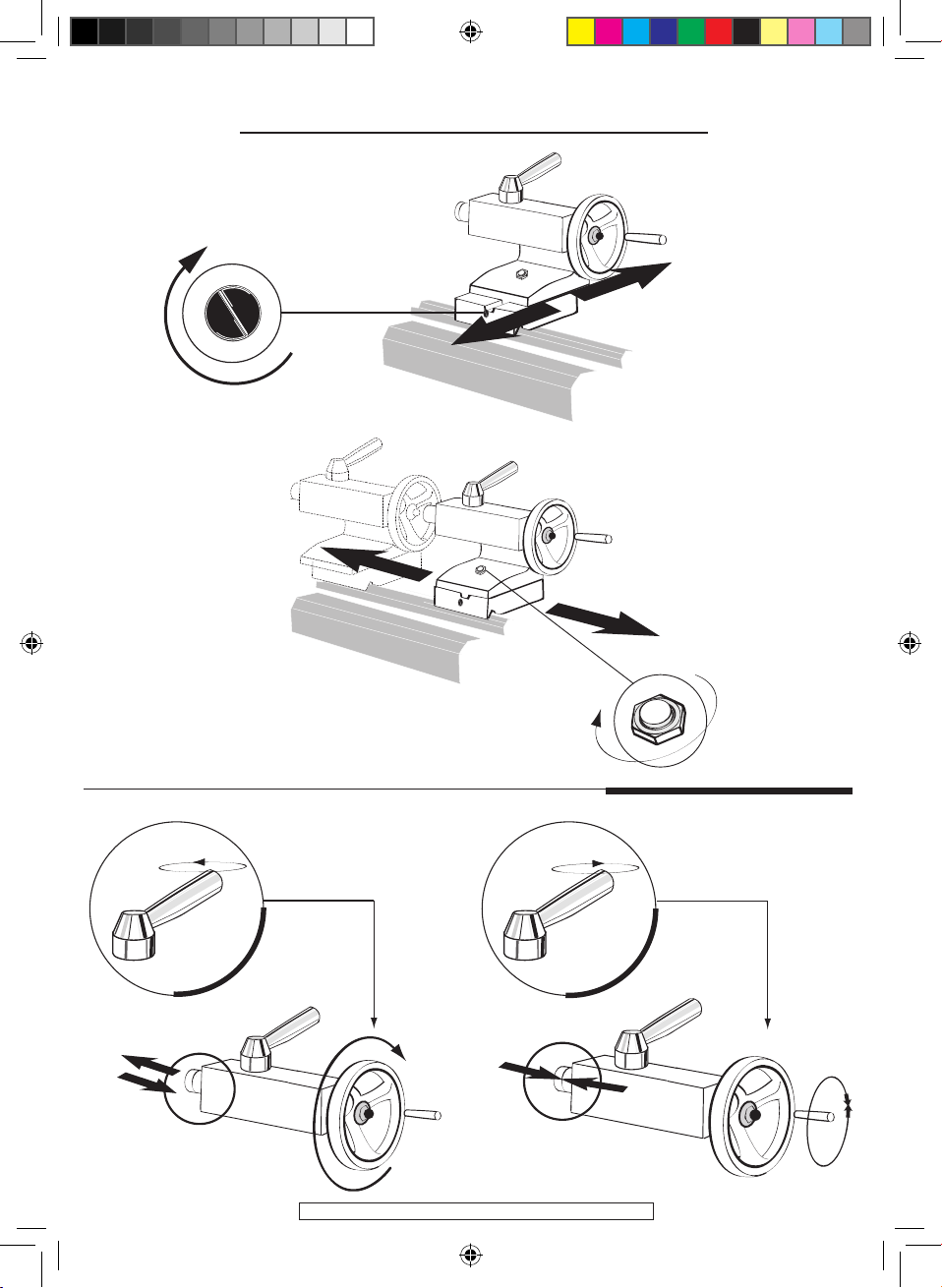

MOVING AND ADJUSTING THE TAILSTOCK CENTRE

114135-Manual-D-EN.indd 11 21/03/12 10:44:53

©FAR GROUP EUROPE

USING THE MILLING DRILLING HEAD

SETTING MILLING SPINDLE SPEEDS

DRILLING-MILLING HEAD PULLEYS

PULLEYS IN THE REAR CASING

When using the drilling/milling head and for improved ease of working, it is preferable

to remove the mandrel from the lathe.

There are 14 speed adjustment possibilities ranging from 117 to 1300 rpm. The spindle

speed is set depending on the diameter of the cutter or drill used and the material to

be machined or drilled. This is set after calculating the rpm and the position of the belts

on the pulleys..

RAISING / LOWERING THE HEAD HEAD CLUTCH

Slacken the 6 mm hollow head

bolt using an 8 mm Allen wrench.

Turn the chromed ring using the

levers

- Clockwise to lower,

- Counter clockwise to raise, As

the head position is set, align

the drilling chuck axis with the

lathe spindle axis (to better use

the drilling head), Lock the head

using the hex head bolt.

To engage the drilling/milling

head:

Open the transmission system

door then push the knobbed

ring all the way in, which auto-

matically releases the lathe spin-

dle and engages the milling head

spindle

To change the drilling head belt posi-

tion:

Remove the casing,

Slacken the belt tensioner,

Change the position of the belts then

retighten the tensioner while applying

pressure to the belt.

Refit the casing.

A-F A-E A-D B-F C-F B-E C-D

K-G 150 290 360 450 575 836 1300

L-M 117 220 276 345 440 640 1000

Speed in rpm

Spindle pulleys

MOTOR PULLEYS INTERMEDIATE PULLEYS SPINDLE PULLEYS

114135-Manual-D-EN.indd 12 21/03/12 10:44:54

©FAR GROUP EUROPE

114135-Manual-D-EN.indd 13 21/03/12 10:44:55

©FAR GROUP EUROPE

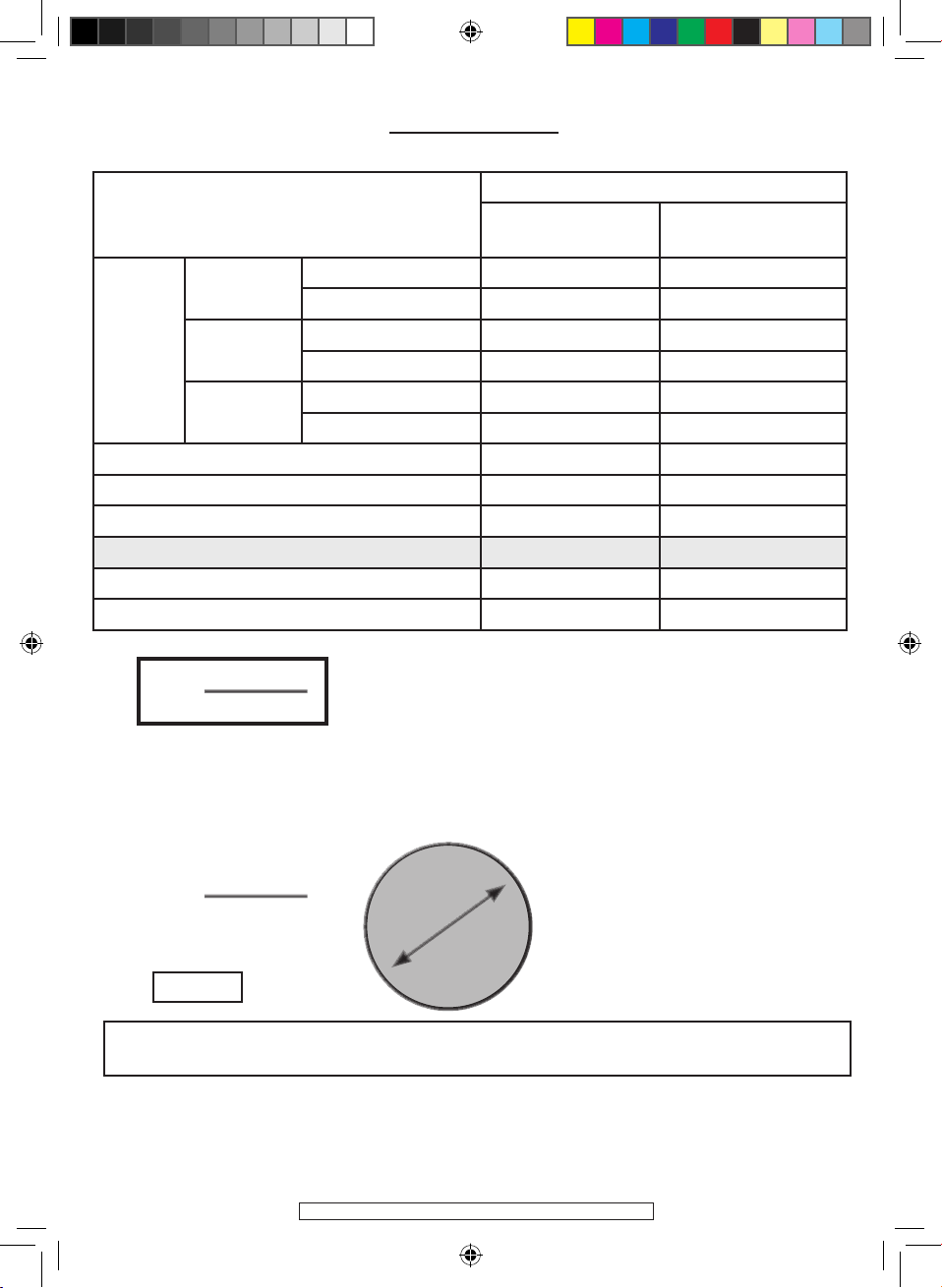

Matière / Material

Outil coupant / Cutting tool

Acier rapide /

Steel

Carbure / Carbide

Acier / Steel

Doux /Soft 30-40 daN/mm230-40 m.min-1 140-300 m.min-1

40-50 daN/mm228-34 m.min-1 130-280 m.min-1

Demi dur /

Half hard

50-60 daN/mm223-30 m.min-1 100-240 m.min-1

60-70 daN/mm220-25 m.min-1 85-200 m.min-1

Dur / Hard 70-80 daN/mm217-22 m.min-1 70-160 m.min-1

80 daN/mm2-> 12-15 m.min-1 60-120 m.min-1

Laiton / Brass 40-65 m.min-1 300-600 m.min-1

Bronze 26-33 m.min-1 270-500 m.min-1

Bronze phosphoreux / phosphorous 18-24 m.min-1 250-400 m.min-1

Aluminium / Aluminum 120-165 m.min-1 800-1300 m.min-1

Cuivre / Copper 90-125 m.min-1 600-900 m.min-1

Fonte / Cast iron 15-25 m.min-1 30-100 m.min-1

N = 1000 x V

π x D

N : Vitesse de rotation ( tr.min-1 ) / Rotation speed ( rpm ).

V : Vitesse de coupe ( m.min-1 ) / Cutting speed ( m.min-1 ).

D : Diametre de la pièce ( mm ) / Workpiece diameter ( mm ).

Expl : Alu ø 40 mm.

N = 1000 x 120

π x 40

N = 955

40 mm

SPEED CHOOSING

Le choix de la profondeur de passe et de la vitesse d’avance doit être basée sur la matière

de la pièce, le type de l’outil et le niveau de l’opérateur.

The choice of cutting depth and feeding speed should be based on the workpiece, the

tool and the operator’s skill level. (114070 / Choosing drive speeds / Gear combinations

for straight turning / thread cutting)

En alésage, la vitesse doit être diminuée de 10 à 20 %

During boring, the speed must be lowered from 10 to 20%

114135-Manual-D-EN.indd 14 21/03/12 10:44:55

©FAR GROUP EUROPE

SHARPENING TOOLS

Note: The grinding head is the ideal tool for this operation. The grinding head may be

fitted with a green grinder (green silicon carbide) specially designed to sharpen carbide

tools

Never heat the carbide and cool it regularly in water

Always pass the carbide plate support part over a fettling grinder.

Metal carbides

WARNING: Always wear protective goggles while sharpening

(Cobalt, tungsten, titanium, boron combinations) These carbides that are obtained with

a special heat treatment called sintering, are used in the form of disks or “inserts”. The

latter are placed onto the tool body and attached by brazing using a special brazing

powder

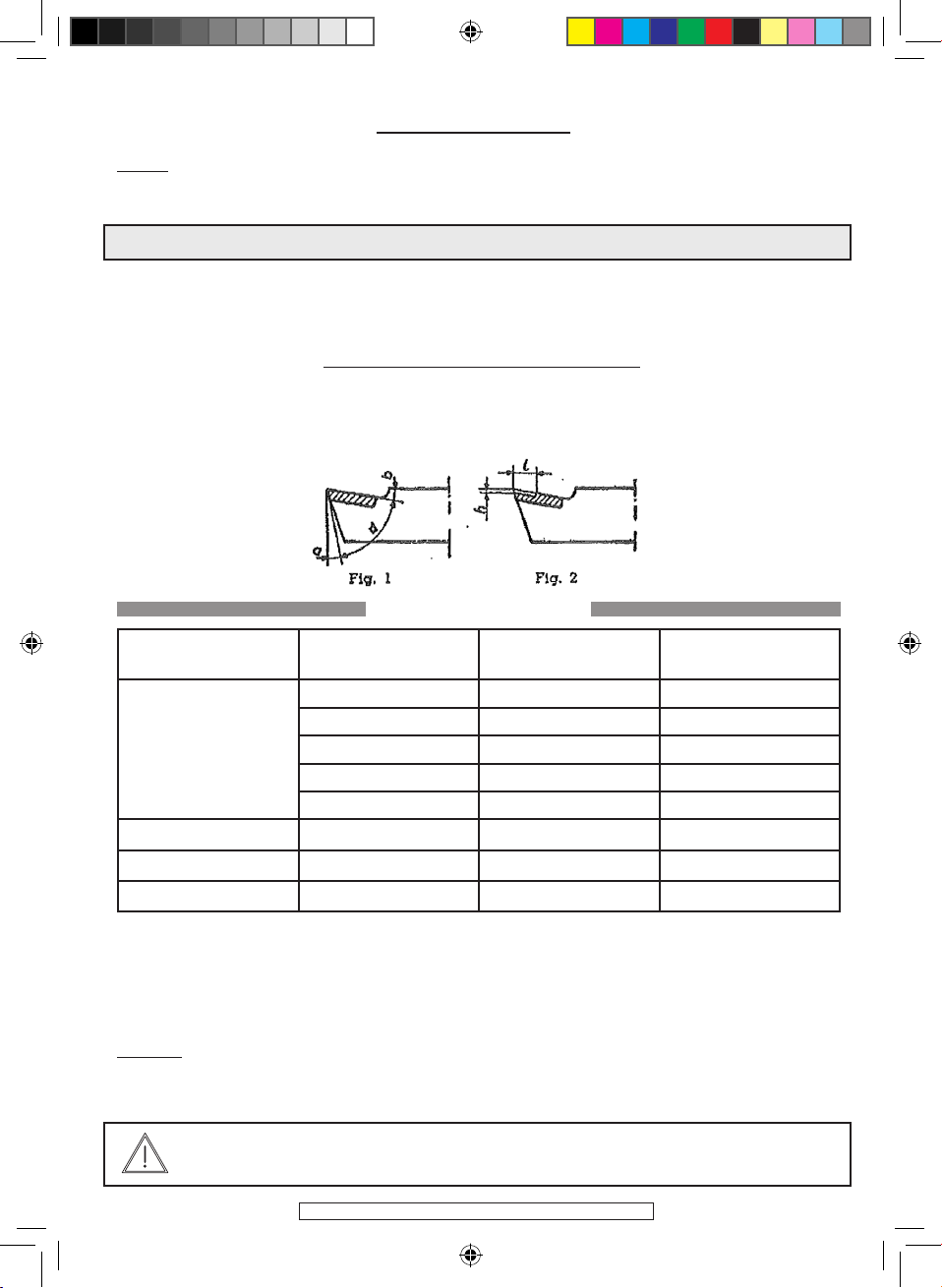

LATHE TOOLS with metal carbide tabs

a, delivery angle.

. Characteristic angles: b, sharpening slope

(a+b+d=90°) d, cutting angle.

Angle values a and b

Metals and alloys to

be machined

/ Resistance R

kg/mm2

Delivery

angle a

Sharpening slope

t

Steel

up to 50 kg 6° 22 to 25°

50 to 60 kg 6° 18 to 20°

60 to 70 kg 6° 15 to 18°

70 to 80 kg 5° 12 to 15°

80 to 95 kg 5° 10 to 12°

Grey cast iron 6° 8 to 10°

Various bronzes 7° 5 to 6°

Aluminium 8° 25 to 30°

Chip breaker (Fig.2): When machining steel grades only, the tool cutting edge receives suitable

sharpening. The length l of the chip breaker varies according to the grade of steel and the pass

load:

For steel up to 50 kg/mm2.............. l= 3.5 mm

For steel of 55 to 75 kg/mm2.............. l= 3.0 mm

For steel of 80 to 95 kg/mm2.............. l= 2.5 mm

Remark. The depth or the height of the chip breaker does not vary, it is 0.5 mm (approximately).

114135-Manual-D-EN.indd 15 21/03/12 10:44:56

©FAR GROUP EUROPE

VARIOUS GRINDING/MILLING OPERATIONS

a/ Comprises removing metal from the part surface,

b/ Clamp the part into the chuck, always use the same jaw tightening square. Never let

the part protrude by more than twice its diameter (spinning in the air),

c/ Position the tool tip so that it is perfectly aligned with the part axis (to do this, use steel

shims that are placed under the tool body)

d/ Start the machine after first setting the speed in rpm.

e/ Angle the tool to the part face, push the tool back, set a cutting depth of 0.5 to 1 mm

max. by turning wheel 17 on the longitudinal carriage, then advance towards the centre

of the part by turning wheel 18 on the transverse carriage at a consistent rate.

f/ Never remove the part if it is to be corrected

g/ Where possible, lubricate using a can containing soluble oil and water and a brush.

a/ This comprises removing material over the diameter of the part,

b/ Use a cutting tool, position the tool tip perfectly in line with the part axis,

c/ Start the machine to allow automatic advance after first setting the speed in rpm

FACING

STRAIGHT TURNING

N = 1000 x V

π x D

N = 1000 x V

π x D

WARNING: Always wear protective goggles and remove the chips using a

hook, never with your hands

A right hand 45° facing tool

114135-Manual-D-EN.indd 16 21/03/12 10:44:56

©FAR GROUP EUROPE

Example:

To advance by 0.2 mm per revolution: Gear A=24, B=120, D=60, lever No. 3 on position II,

d/ Set the tool at a tangent to the part diameter. Reverse the tool to the right to escape

from the part. Set a penetration depth of 0.5 mm.

10 divisions on the Vernier callipers = 1 mm in diameter.

Start the AUTO advance function using lever No. 3 .

e/ Release at the desired moment (desired length). Be careful to allow for inertia.

f/ Reverse the tool away to the right,

g/ Stop the machine and take measurements

This operation is required before boring. It uses a drill bit. There are two kinds of drill

bits as described below. Refer to the table for more detailed explanations

Cylindrical or conical:

Cylindrical: For bits with a diameter of 0.5 to 13 mm that fit into a self tightening chuck

(option 111482).

Conical: For larger diameter bits that fit directly into the cone on the sliding headstock,

a/ Position the conical drill bit into the cone on the sliding headstock, first making sure

that the bit is properly sharpened,

b/ Start the machine after first setting the rpm,

c/ Move the tailstock centre up to the part, and lock (lever 16),

d/ Then move the bit by turning the handle smoothly.

WARNING: Avoid hitting the tool in the jaws. If the part is too long, then

you will need to fit the centred tailstock fitted with a spinning tip. Always

wear protective goggles.

Always remove the chips using a hook, never with your hands

WARNING: We recommend lubricating the part using a can containing so-

luble oil and water and a brush. For very long drilling lengths, we recom-

mend removing flashing from time to time. Before starting any drilling,

mark the centre point using a centring drill mounted in the self tightening

chuck

DRILLING

Cutter tool

114135-Manual-D-EN.indd 17 21/03/12 10:44:57

©FAR GROUP EUROPE

BORING

a/ Comprising removing matter from a hole to enlarge it so as to achieve a good surface

condition,

b/ Use a boring tool with a 45° angle to bore a through hole or make a chamfer or use a

boring-dressing tool when boring a non-though hole, bring the tool to the same height

(again using shims) as the part axis or slightly higher,

c/ Start the machine in automatic advance mode, after first setting the rpm and the

advance

Example:

Advance by 0.25 mm per revolution: Gear A=30, B=120, D=60, Lever 3 on position II,

d/ Set the tool at a tangent to the part face by turning wheel 17. Make a mark on the

Vernier callipers, then bring to a tangent inside the hole in the part by turning wheel 14.

PAY ATTENTION to the anti-clockwise direction, make a mark on the Vernier callipers.

e/ Disengage the tool from the part using wheel 17. Take a cutting depth of 1 mm per

pass off the diameter (10 divisions of the Vernier calliper for wheel 14), then regularly

advance using wheel 17 or in automatic mode by actuating lever 2. When the bore is a

through one (to bore a 10 mm depth), then have the wheel 17 Vernier callipers perform

ten turns from the point where you made a mark.

f/ Disengage the tool then take a measuremen

N = 1000 x V

π x D

WARNING: Always wear protective goggles and remove the chips using a

hook, never with your hand

Rotation speeds & advances

Helicoidal drills

angles of the edges

Steel Steel Steel

Cast iron

Metal to work

Normal cut Normal cut

Insufficient cut

Excessive cut

Boring tool angled 45 ° Boring tool - dressing tool

RPM

Advance

mm/r

Drill diameter

Advance

mm/r

Advance

mm/r

Advance

mm/r

RPM

RPM

RPM

114135-Manual-D-EN.indd 18 21/03/12 10:44:58

©FAR GROUP EUROPE

CUTTING

OUTER AND INNER THREAD CUTTING

a/ Comprises cutting a part that has already been drilled and

bored to obtain a spacer or washer,

b/ Use a cutting tool. Bring the tool tip to the same height as

the axis (again using shims) or a little below the part centre,

c/ Start the machine after first setting the rpm,

d/ Offset your tool to the left (wheel 17) using a straight edge to check the distance

between the part face and the right hand side of your tool. Stop as soon as you obtain

the desired distance and add 1 mm to it to correct the face surface.

e/ Manually and regularly advance the tool using wheel 14. We recommend lubricating

(with soluble oil and water) using a brush. As soon as the tool drills through into the

bore, reverse and disengage to the right

Designation: Threads are designated by the M symbol, followed by their diameter and

pitch in mm, separated by a multiplication sign. Example: M 30 x 3.5, i.e. M 30 for a 30

diameter thread with a 3.5 mm thread pitch. Standard threads are:

/ Outer thread: The tool profile sharpening angle for cutting a metric thread is 60°, The

tool profile sharpening angle for cutting a Whitworth thread (English pitch) is 55°,

CUTTING A TRIANGULAR THREAD

Tool penetration

- Normal penetration (see Fig. below).

The tools are aimed and their profiles sharpened to 60°

or 55° using angle centre gages.

Tool height position. Absolutely aligned with the tip

axes (part axis).

nominal Diameter M Typical pitch P (mm)

M 3 0,6

M 4 0,7

M 5 0,8

M 6 1

M 8 1,25

M 10 1,50

M 12 1,75

M 14 2

M 16 2

M 18 2,5

M 20 2,5

M 22 2,5

M 24 3

M 27 3

M 30 3,5

N = 1000 x V

π x D

Outer

threading

tool

Outer threa-

ding tool

Cutting tool

114135-Manual-D-EN.indd 19 21/03/12 10:44:59

©FAR GROUP EUROPE

The tool is aligned with the part using a centre gage. This centre gage is useful when

checking tool sharpening.

1/ Once the tool is correctly sharpened and aligned, set the rpm, a setting that will be far

slower than the theoretical rpm rate, (approx. 50% less).

Example: For an M 20 x 2.5, semi-hard steel=30

setting that will be far slower than the theoretical rpm rate, (approx. 50% less).

Example: For an M 20 x 2.5, semi-hard steel=30 132/ To cut a thread, a speed of 220 rpm

will be used

2/ Then the pitch will be set by changing the gears. For a 2.5 mm pitch, the choice will be

A=60 teeth, B=120 teeth and D=24 teeth and lever 3 will be set to I,

3/ Before starting machining, calculate the tool penetration depth using the following

formula:

Example:

For a 2.5 mm pitch: 0.61 x 2.5 = 1.525 mm in radius

4/ Pull the part far enough out of the chuck when cutting a thread so that no collision

occurs between the thread cutting tools and the chuck jaws (as the chuck does not have

a brake). The technique used to stop thread cutting is first of all to shutdown the motor

and then to quickly withdraw the tool.

5/ Start up. Place the tool at a tangent to the part. The part has a nominal diameter of

20. For an M 20 x 2.5 mm thread, make a pencil mark on the Vernier callipers. Disengage

the tool to the right on removing it from the part.

Take a 0.5 mm cutting depth (for the first pass only), i.e. 10 divisions on the Vernier cal-

lipers. Stop the machine.

Engage lever 2 (leadscrew clutch),

Lubricate the part with cutting oil.

Start up and place one hand on wheel 14 to disengage the tool when it reaches the de-

sired thread length, then place the other hand on the motor stop button.

Reverse the machine to return the tool to its starting position, and start another 0.25

pass (5 divisions on the Vernier calliper in addition to the 10 divisions already taken du-

ring the first pass)

- Repeat the operation six times to achieve the theoretical 1.525 cutting depth.

- After the final pass, perform one more blank pass to correct tool part flex,

- Back off the tailstock centre and try the thread with a 20 mm 2.5 pitch nut.

Pdp = 0,61 x P

N = 1000 x 30 = 477 tr/ min

π x 20

WARNING: Do not disengage lever 2 for the tool may no longer fit into

the same pitch during the next pass.

114135-Manual-D-EN.indd 20 21/03/12 10:44:59

Table of contents

Other Far Tools Lathe manuals

Popular Lathe manuals by other brands

Grizzly

Grizzly G1495 parts list

Jet

Jet E-1440VS Operating instructions and parts manual

Gude

Gude GDM 1000 Translation of original operating instructions

Central Machinery

Central Machinery 65044 Set up and operating instructions

Delta

Delta 46-756 instruction manual

Southbend

Southbend SB1015F insert Manual insert