RESTRICTED USE ONLY Fargo Electronics, Inc.

HDP100 High Definition Card Printer/Encoder User Guide (Rev. Beta) iii

Table of Contents

Section 1: Printer Overview __________________________________________________ 1

How to use the guide___________________________________________________________________1

Safety Messages (review carefully)________________________________________________________2

HDP100 Overview ____________________________________________________________________3

Reviewing the HDP100 Block Diagram__________________________________________________3

Reviewing the HDP100 Sequence of Operations___________________________________________4

Reviewing the HDP100 Boot up Sequence _______________________________________________7

Reviewing the Lamination Module Sequence of Operations __________________________________8

Reviewing the Lamination Module Boot up Sequence _____________________________________10

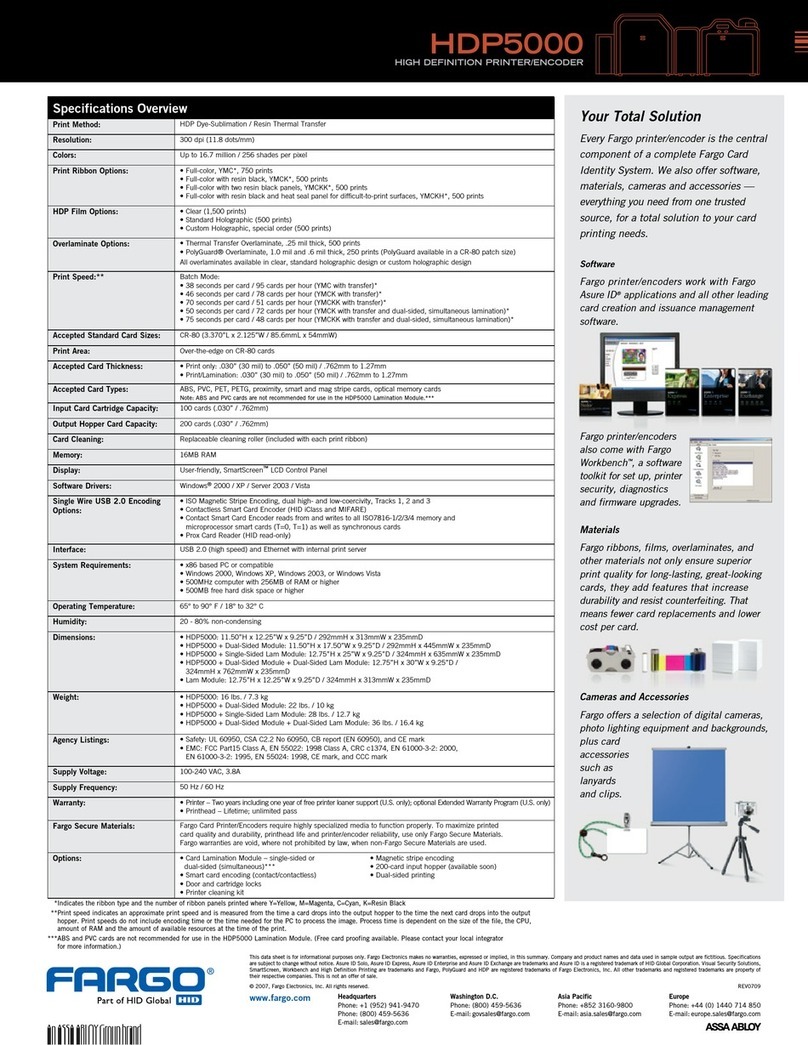

Section 2: Specifications_____________________________________________________ 1

Safety Messages (review carefully)________________________________________________________1

Introduction__________________________________________________________________________2

Reviewing the HDP100 Printer Overview table ______________________________________________2

Reviewing the HDP100 Package _______________________________________________________3

Reviewing the HDP100 (front)_________________________________________________________3

Reviewing the HDP100 Card Printer ____________________________________________________4

Regulatory Compliances, Agency Listings and FCC Rules _____________________________________5

Regulatory Compliances ________________________________________________________________5

Agency Listings_______________________________________________________________________6

FCC Rules ________________________________________________________________________6

Technical Specifications ________________________________________________________________7

Functional Specifications ______________________________________________________________13

Printer Components: Resin Thermal Transfer to USB Interface Port __________________________14

Printer Components: LCD and Softkey Control Pad_______________________________________16

Printer Components: Print Ribbons____________________________________________________21

Printer Components: Blank Cards _____________________________________________________22

Printer Components: Card Input and Output Hoppers______________________________________23

Printer Components: Card Output Hopper and Reject Hopper _______________________________23

Printer Unit: Reviewing the Card Lamination Module _____________________________________24

Printer Components: Transfer Roller___________________________________________________25

Reviewing the Overlaminates ___________________________________________________________26

Reviewing the Thermal Transfer Film and PolyGuard Overlaminates__________________________26

Reviewing the CR-80 Patch Size ______________________________________________________27

Reviewing the Overlaminate Design ___________________________________________________27

Section 3: General Troubleshooting ___________________________________________ 1

LCD Messages _______________________________________________________________________1

Troubleshooting LCD Messages__________________________________________________________2

General Troubleshooting Guide _______________________________________________________14

Magnetic and E-card Troubleshooting Guide_____________________________________________19

Communications Errors________________________________________________________________22

Resolving the Communication Errors___________________________________________________22

Card Feeding Errors __________________________________________________________________24

Resolving an Unable to Feed Card Error ________________________________________________24

Resolving a Card Not Fed Error (Two (2) or more card feed at the same time)___________________27

Resolving a Card Hopper Empty Error__________________________________________________29

Resolving a Card Output Hopper Full __________________________________________________30

Resolving a Card Not Fed Error (Cards will not feed off the Hopper)__________________________31

Resolving a Card Jam Error __________________________________________________________32

Resolving a Card Jam (Encoder) Error__________________________________________________33

Resolving a Card Jam (Flipper) Error___________________________________________________34

Resolving a Card Jam (Laminator) Error ________________________________________________36