7

TRANSPORTING DRYER

An optional Transport Kit is available for transporting the

unit by truck or tractor. Make certain to observe the fol-

lowing safety precautions:

1. Recommended towing hitch height: 16 to 17 inches.

2. Hitch pin to be not less than 3/4 inch in dia. and secure-

ly fastened so it will not come out in travel.

3. Use a safety chain.

4. Dryer must be towed empty and in accordance with

applicable state or provincial regulations.

5. Recommended tire pressure 55-60 psi (cold).

6. Maximum towing speed: 45 mph

7. After first 50 miles and every 200 miles thereafter:

a. Check temperature of transport wheels' hubs and

spindles immediately after stopping. Temperature

should not exceed 150°F. May be hot to touch, but not

melting lubricant.

b. Check wheel lug bolts; they are factory torqued at

115 to 120 ft lbs. Retighten, if required, to approxi-

mately 90 ft/lbs.

INSTALLATION

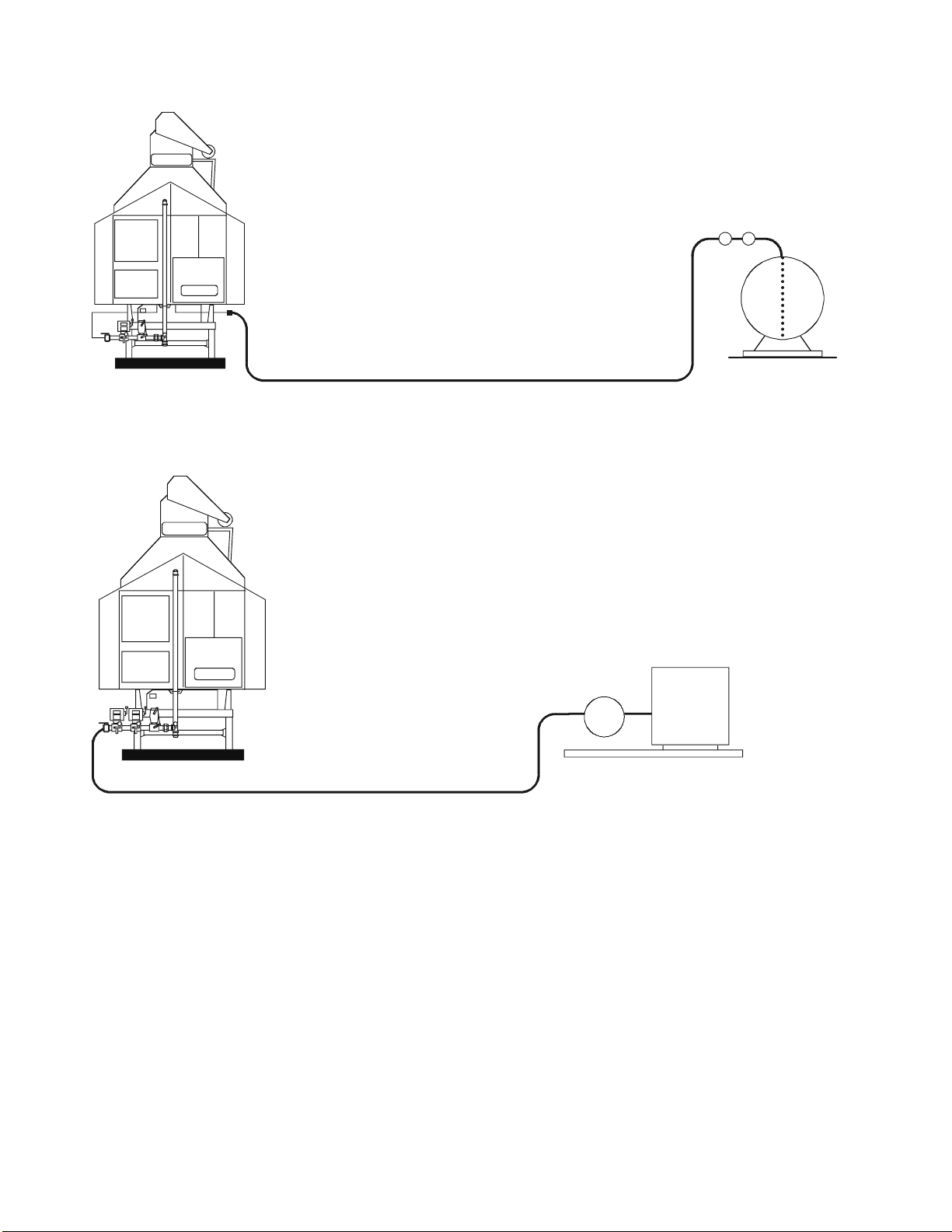

SYSTEM LAYOUT

Consider the grain handling system and location of

storage bins and existing conveyors when selecting

dryer site, to facilitate wet grain supply and dry grain

discharge to conveyors. Other considerations are pre-

vailing wind direction, fuel and power supply locations,

noise, and convenience of control location.

SITE SELECTION

The dryer should not be operated inside a building or in

any area not permitted by electrical code, fuel installa-

tion regulations, or insurance requirements. Do not

operate in an area where combustible material can be

drawn into the fans. Maintain a minimum distance of

three feet to other structures. Refer to dryer specifica-

tions and dimensions in Section 1.

FOUNDATION

The dryer should be placed on an 8" reinforced con-

crete slab located in a well-drained area. The slab

should be large enough to provide working area around

the dryer, with a surface elevation consistent with other

parts of the grain handling and storage systems. See

dryer specifications and dimensions in Section 1 for

suggested foundation size.

The dryer is supplied with a standard leg set to support

the dryer body at 24" high. (Optional 36" and 48" high

leg sets are available.) The dryer must be anchored to

the foundation with tie-down cables or by placing

anchor bolts through the leg supports into the founda-

tion. See C-2100B FIELD ASSEMBLY INSTRUC-

TIONS, Bulletin C21BIN-01-2, for leg installation

details.

Before proceeding with the installation, at this point it is

recommended that the dryer assembly be completed

according to C-2100B FIELD ASSEMBLY INSTRUC-

TIONS, Bulletin C21BIN-01-2, which provides essential

instructions for leg assembly, coupling the body and

fan-heater modules, assembling the fan-heater enclo-

sure, and installing fuel plumbing, electrical conduits

and the heat reclaimer option.

FUEL CONNECTION

LIQUID PROPANE (LP) DRYERS WITH INTERNAL

VAPORIZERS

LIQUID DRAW - The dryer is designed to operate on

liquid propane, with liquid draw from the supply tank.

A piping system is provided on the dryer, including

strainer, pressure relief valve, and manual shut-off

valve; a pressure regulator is provided on the fan-

heater unit, between the vaporizer and burner.

AMMONIA TANKS - Do not use propane supply tanks

which have previously contained ammonia or fertilizer

solutions. These substances are extremely corrosive

and damaging to fuel supply and burner parts.

OIL OR WATER IN TANKS - With liquid draw from the

supply tank, any water present in the tank may freeze

in the piping and controls in cold weather. To ensure

that tanks are free of moisture, the usual precaution is

to purge with methanol. Avoid tanks which may con-

tain an accumulation of oil or heavy hydrocarbons from

long use on a vapor withdrawal system.

NATURAL GAS (NG)

GAS VOLUME AND PRESSURE - The dryer is

designed to operate on natural gas having a heat value

of about 1,000 BTU per cubic foot. The dryer is

equipped with a natural gas supply pipe system con-

nected to the heater solenoid valves. A regulated pres-

sure of 8 to 10 PSI must be provided at the connection

to the dryer, with gas available in sufficient volume to

maintain operating pressure.