6

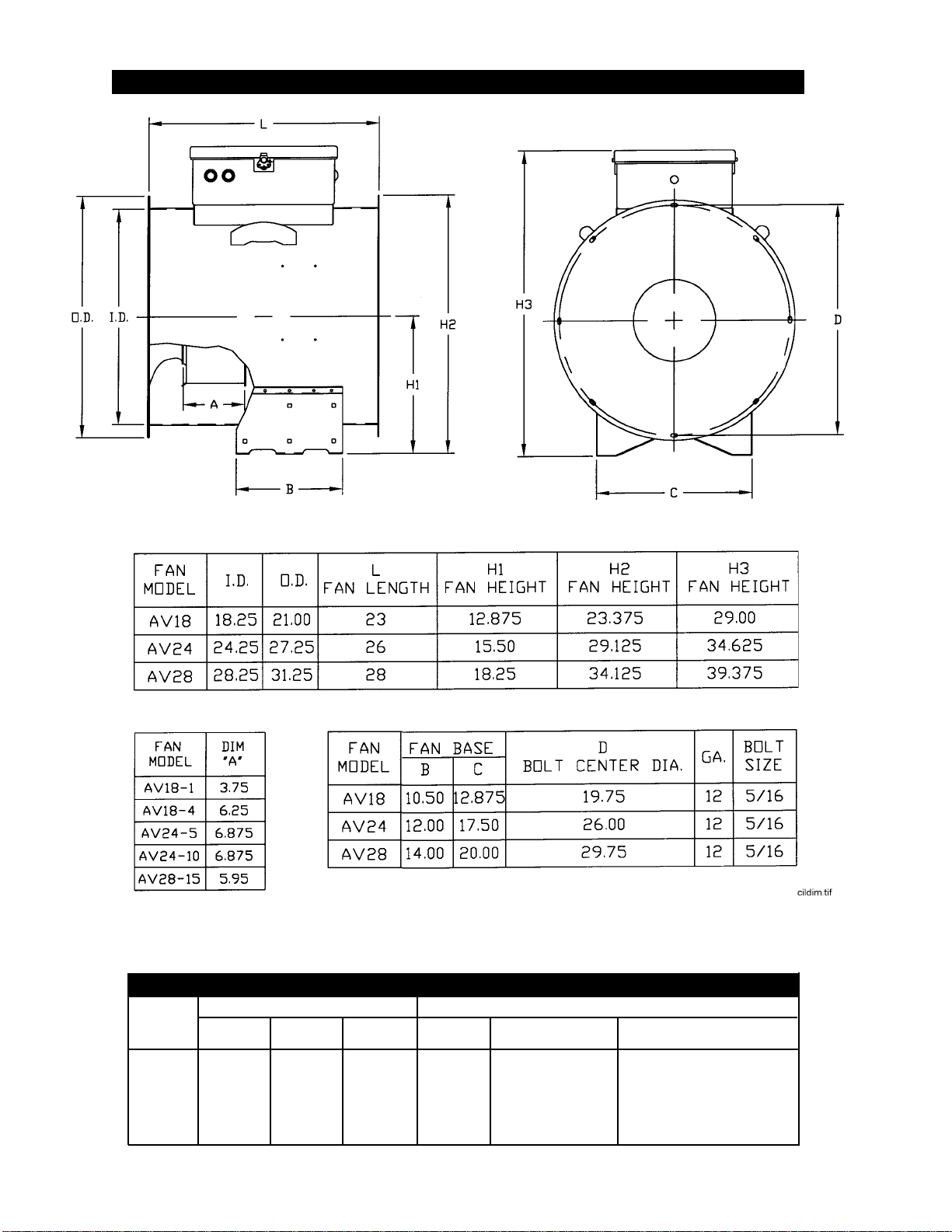

FAN WHEEL REMOVAL & INSTALLATION

The fan wheel is secured to the motor shaft by the use

of a taper-lock bushing, motor shaft key, and cap-

screws. The size, quantity, and torque of capscrews

required will depend on the model of the fan.

CAUTION: Although the taper-lock method of

retaining the wheel onto the motor shaft is very

simple and obvious, it is essential that the follow-

ing points be read carefully and fully understood, as

improper installation can result in serious or fatal injury

caused by a loose, fast flying wheel.

THREADED BUSHING HOLES: The threaded holes

within the bushing are provided for disassembly pur-

poses only. Do not attempt to use these holes for

reassembly, as they will not allow the parts to become

locked onto the shaft, thereby causing an extremely

hazardous operating condition.

CLEARANCE HOLES: When reassembling parts, the

capscrews must be installed through the UNTAPPED

CLEARANCE HOLES to cause the wheel to be pulled

forward onto the tapered bushing, thus locking the

parts securely onto the motor shaft. Refer to text for

assembly details.

REMOVAL

1. LOCK-OUT THE MAIN POWER SUPPLY and remove

the fan guard and inlet cone.

2. Remove the three capscrews from the clearance holes

in taper-lock bushing. Inspect for thread damage and

set aside for later reinstallation (do not use these bolts

for step 3, bushing removal).

3. Install two Grade 5 (or better) capscrews into the

THREADED HOLES in the bushing and turn them in by

hand until they bottom against the front surface of the

wheel. These capscrews should not be used for

reassembly, as some thread distortion could occur dur-

ing the removal operation. Grade 5 screws are marked

with three 120° spokes on the head and are more

durable than low strength unmarked bolts.

NOTE: DO NOT ATTEMPT TO USE LOW STRENGTH

(UNMARKED) BOLTS TO REMOVE THE BUSHING,

AS THE BOLTS MAY BREAK OFF.

4. Block wheel to prevent it from turning, and GRADUAL-

LY TURN IN THE CAPSCREWS (up to 1/4 turn at

time), until the wheel breaks loose from the bushing

and motor shaft. Carefully remove bushing and wheel.

With the wheel free from the bushing, a wheel puller

can be used to pull the bushing off of motor shaft, if

required. Reattach bushing onto wheel to prevent the

loss of parts and also to maintain the original alignment

of bushing to wheel. Inspect wheel and bushing at this

time, looking for any cracks, thread or bolt damage,

warpage, etc. Consult your dealer or the factory for

any questions concerning damage.

INSTALLATION

1. Carefully clean motor shaft, key, bushing and bore of

wheel. MAKE SURE MAIN POWER IS LOCKED OUT,

and that shaft and key are completely free of rust and

burrs. Do NOT lubricate the bushing or capscrews.

CHECK AND MAKE SURE ALL MOTOR MOUNT

BOLTS ARE PROPERLY TIGHTENED.

Before installing the wheel, check the following: (1) All

foreign material should be removed from the wheel. (2)

Carefully inspect the wheel weldment and hub casting

for damage, cracks, or other defects. Contact the fac-

tory if there is any question regarding the structural

integrity of the wheel.

2. Slide wheel over motor shaft and locate it against the

motor.

3. Align the keyway in the bushing with the key and SLIDE

bushing onto motor shaft. Do not attempt to drive the

bushing onto the shaft, as it may damage the motor

bearings.

4. Rotate the bushing and wheel so their key slots are in

line and loosely attach the wheel to the bushing.

MAKE SURE THE CAPSCREWS ARE INSERTED

INTO THE UNTHREADED CLEARANCE HOLES IN

THE BUSHING. Refer to previous CAUTION note.

Locate the bushing so it is approximately flush with the

end of motor shaft.

Make certain that the proper capscrews are used for

reassembly and no damage has occurred to these

screws during disassembly! Use only the special type

bolts supplied with the original wheel.

5. Install inlet cone, checking clearance between fan

wheel and inlet cone. Shift the location of inlet cone as

required to center it in relation to the fan wheel, provid-

ing equal clearance completely around the fan wheel.

Tighten inlet cone bolts.

6. Slide the wheel forward onto the taper-lock bushing

and turn the capscrews in by hand as far as possible.

NOTE: The bushing must be located far enough for-

ward so the distance from the inside of the backplate of

the wheel weldment to the closest edge of the inlet

cone is equal to the dimension shown as ‘A’ in the Fan

Dimension Chart. Add approximately 1/8” to this

dimension to allow the wheel to be pulled toward the

inlet during tightening.

7. Use an INCH-POUNDS torque wrench and GRADU-

ALLY TIGHTEN the three capscrews (1/4 turn at a

time) until the taper bushing becomes fully seated.

Refer to the following chart for recommended capscrew

tightening torques. DO NOT EXCESSIVELY OVER-

TIGHTEN THE BUSHING.

SERVICE

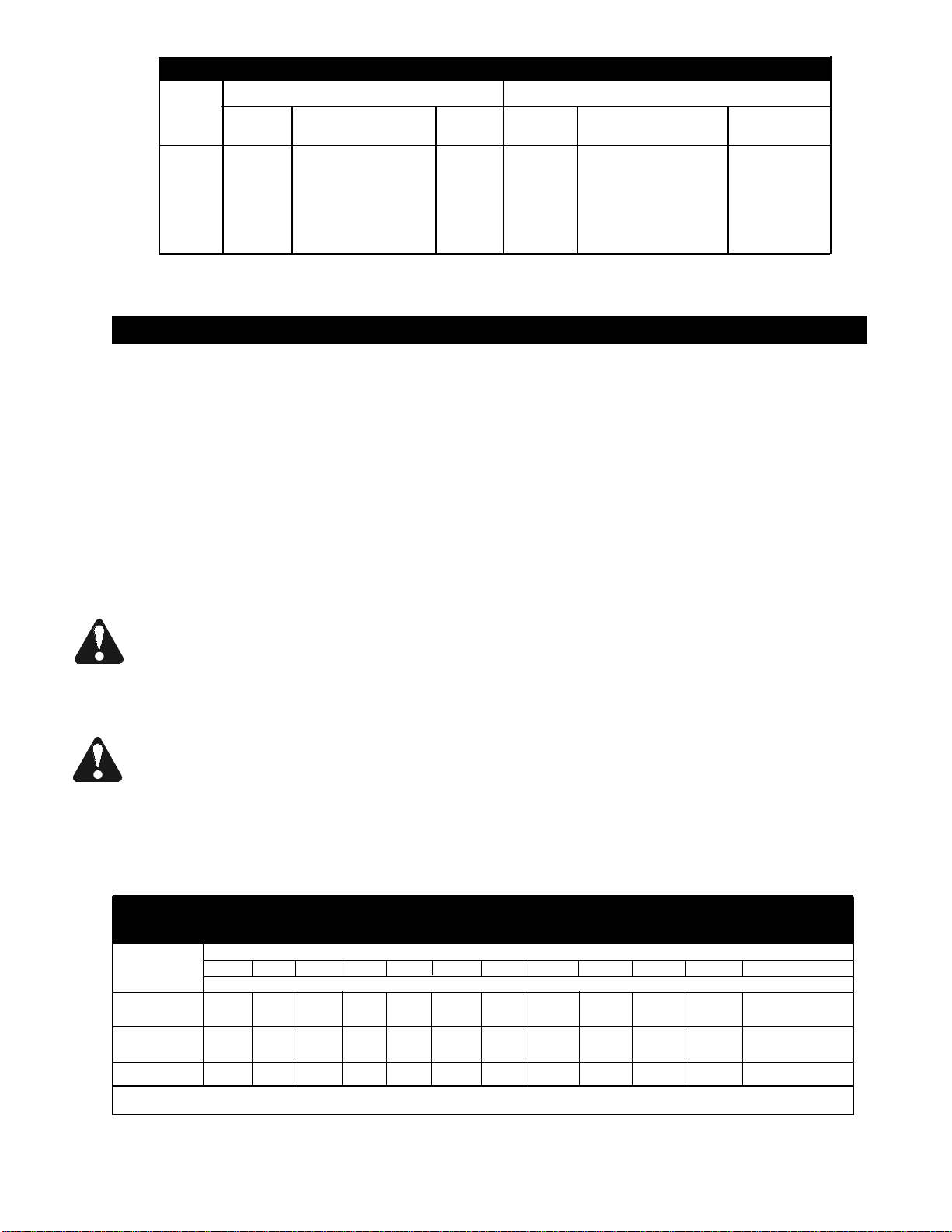

Browning Taper-Lock Bushing Bolt Tightening Torques

Bushing Size Hex Bolt Size Torque (Inch-Lbs.)

P 5/16-18x1-1/4 192