Oil Burner Installation and

Operation Instructions

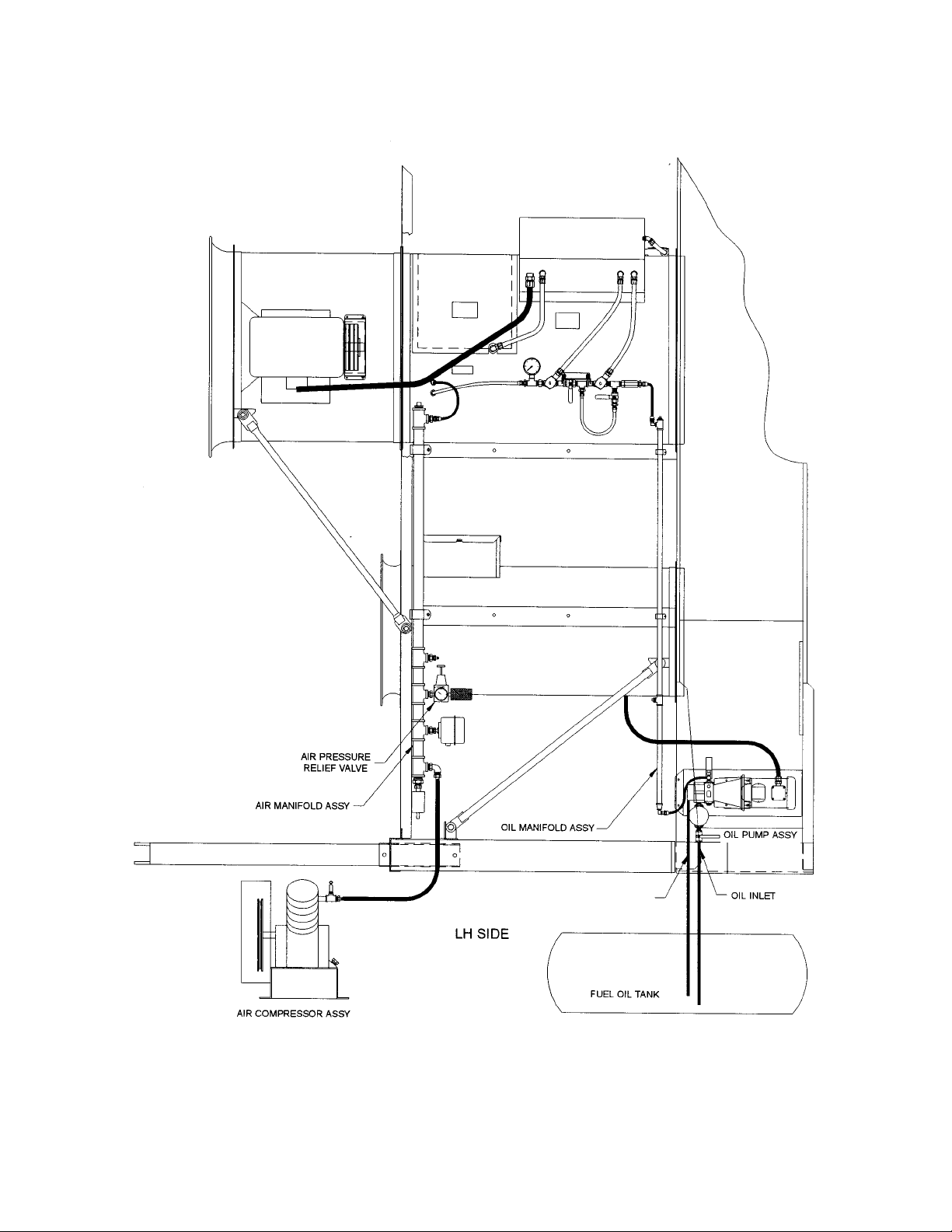

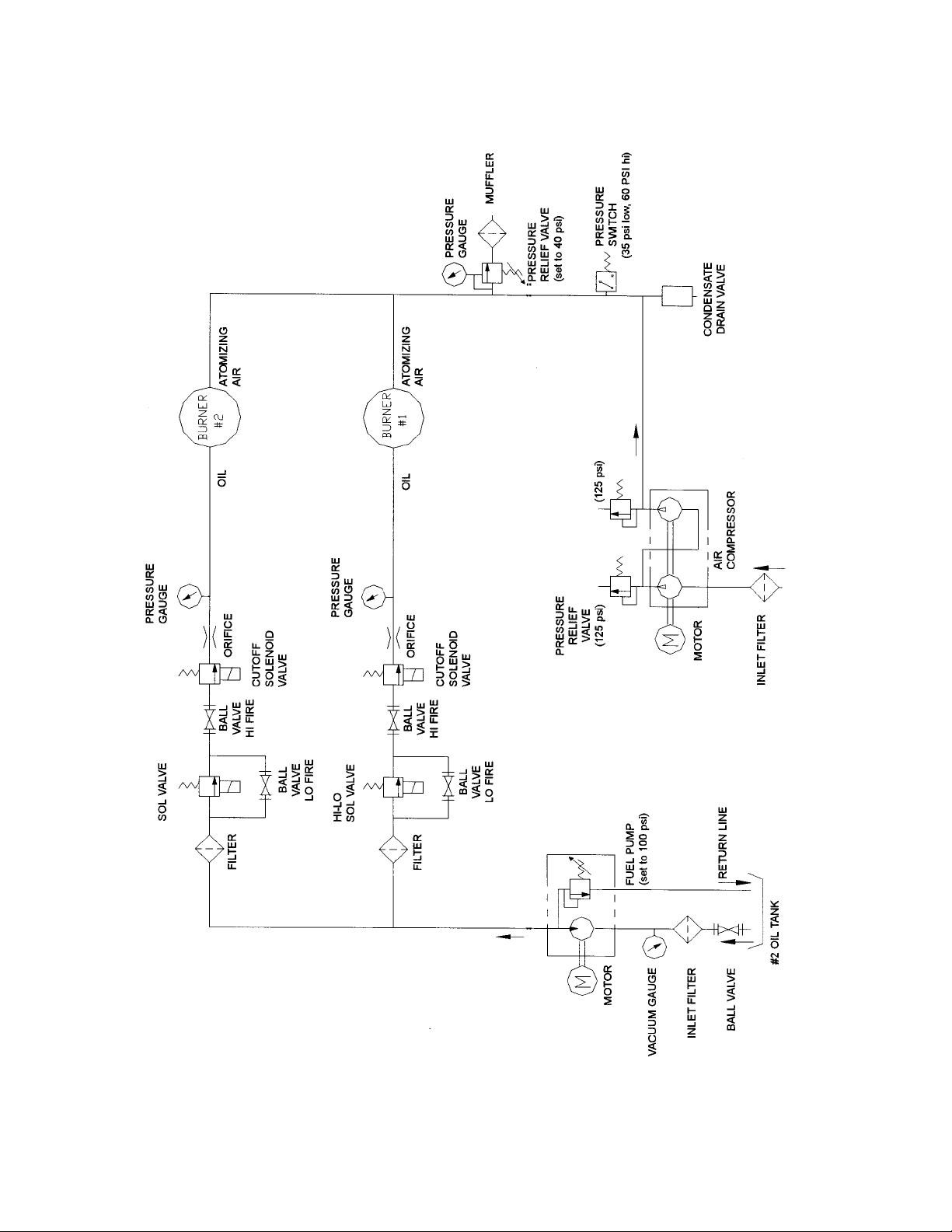

Compressor Assembly

• Locate the compressor in a clean

operating area away from the dryer. Locate

inside a shelter when possible.

• Fill compressor with oil supplied before

starting. See operators manual for compres-

sor.

• Do NOT install a shutoff valve on the com-

pressor inlet, outlet or line to the manifold.

• Check for correct rotation of compressor on

startup.

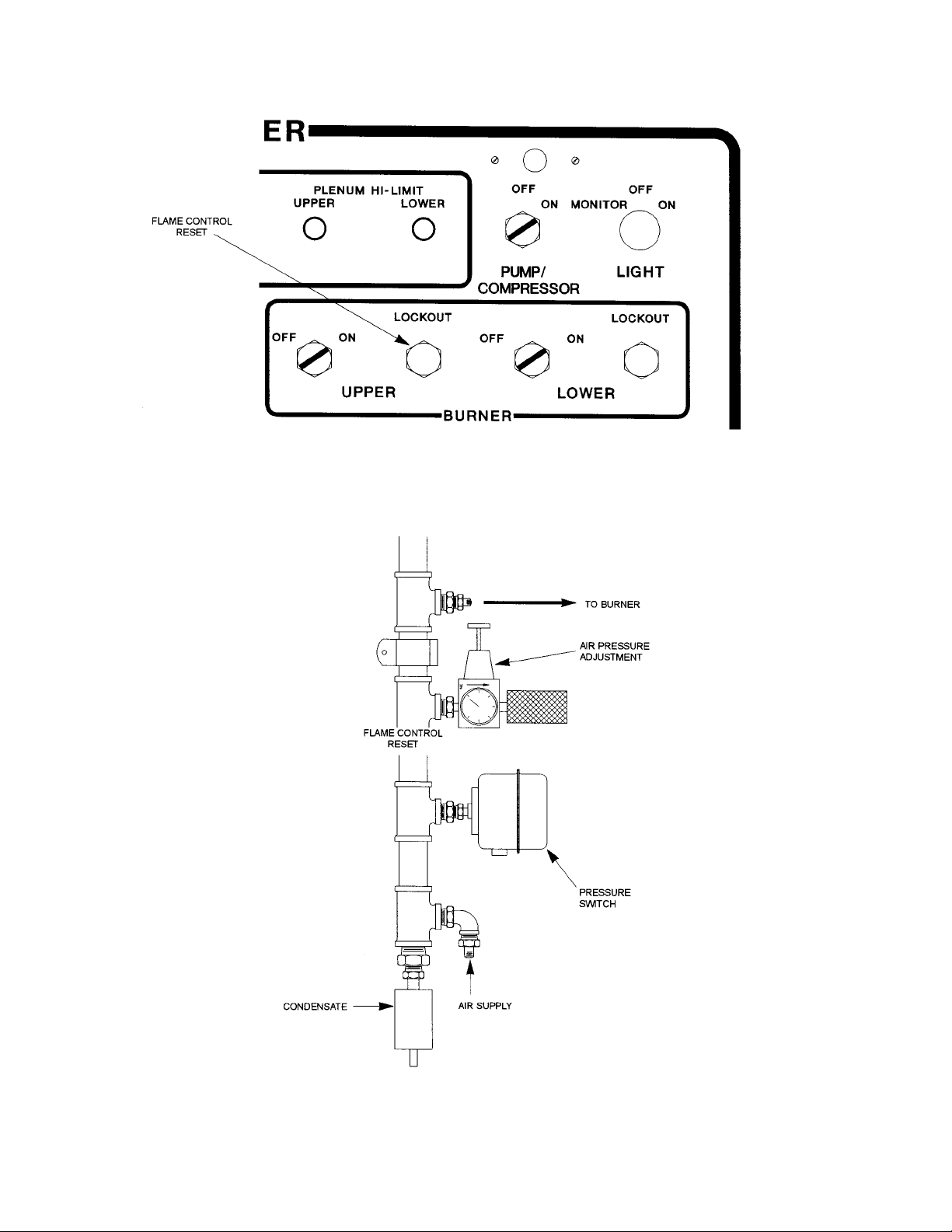

Air Manifold Assembly

• Mount manifold assy to dryer per attached

drawings. Mount manifold with condensate

drain pointing down.

• Connect manifold outlet to burner with

1/2 inch hose supplied.

• Connect manifold to compressor using a

1/2 inch hose. 50 feet have been supplied

• Do NOT install a shutoff valve on the com-

pressor inlet or outlet or lines to the tank.

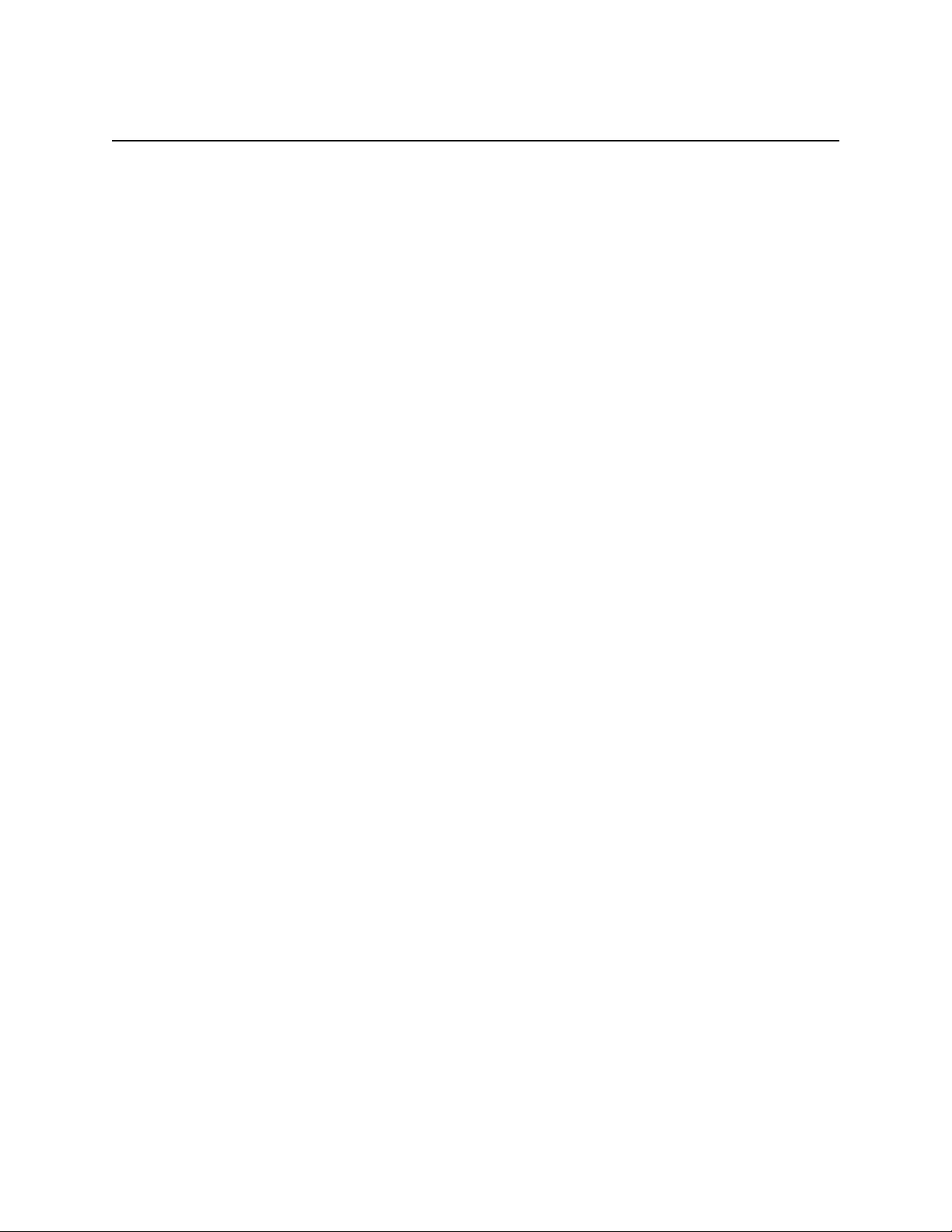

Oil Pump Assembly

• Install the oil pump assy to the LH front

body supports as shown in attached drawing.

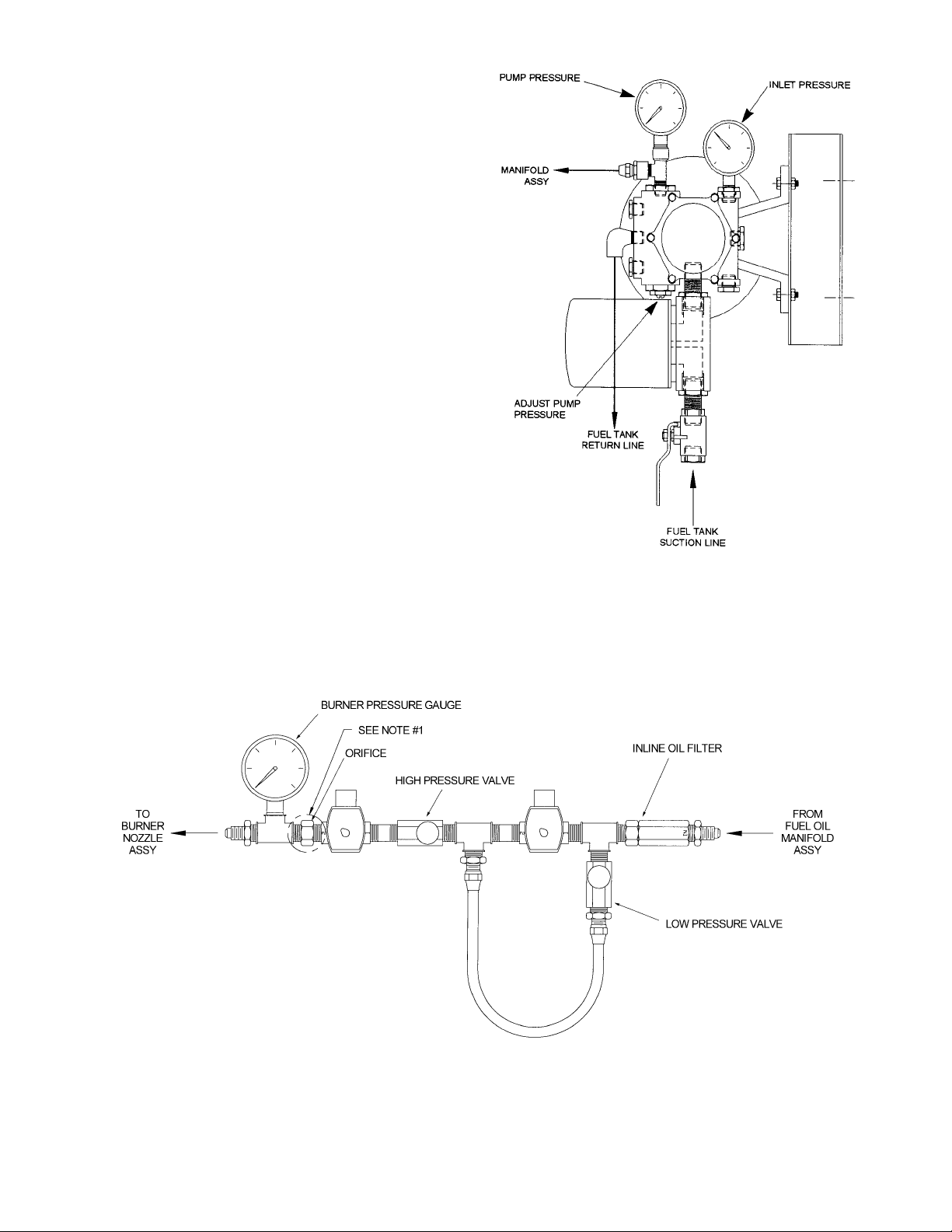

• Connect the pump outlet to the oil manifold.

• Connect the oil manifold to the burner

plumbing assy using 1/4 inch hose supplied.

• Connect a suction line from the tank to the

pump. Line must be adequately sized so that

inlet suction does not exceed 17" hg.

Minimum size is 1/2 inch diameter.

• Connect a return line from the pump to the

tank. Use a minimum of 3/8 inch diameter

line.

• Check for correct rotation on startup. CCW

as view from shaft end of pump or fan end of

motor.

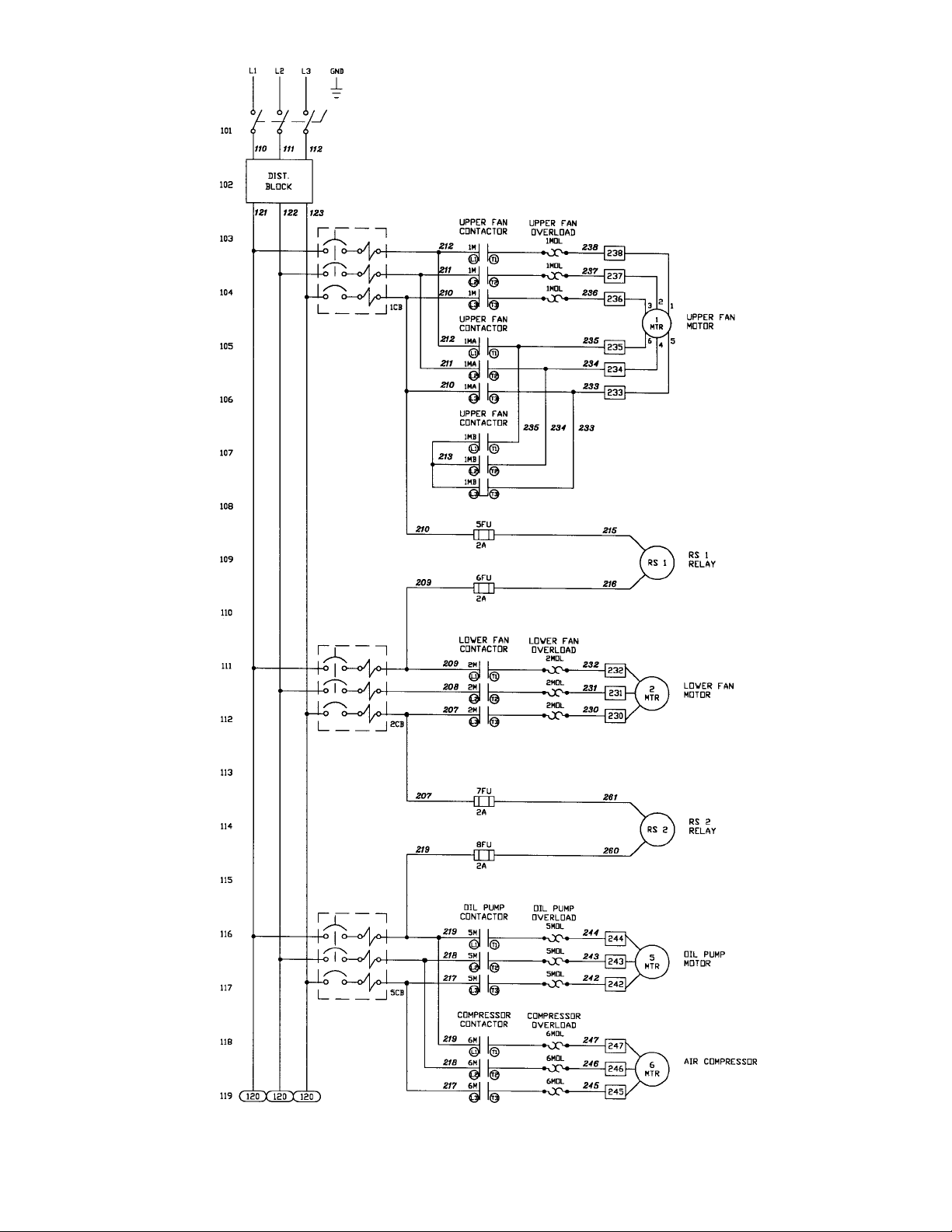

Burner Test Fire

1. Check rotation of compressor by bumping the

pump/compressor switch. Compressor should

rotate CW as viewed from the shaft end of com-

pressor.

2. Check rotation of pump. Pump should run

CCW as view from the shaft end of pump or fan

end of motor.

3. Open the suction and return line valves going

4

to the oil tank. With compressor circuit breaker

off, turn pump switch ON and check for pressure

on outlet gauge. Pressure should read 100 psi.

Adjust pump pressure as required. Check pres-

sure on pump inlet. Inlet pressure should be less

than 17 inches of Hg.

4. Turn on the compressor circuit breaker and

turn pump switch ON. Compressor should begin

building pressure in tank up to 45-50 psi. This

may take 10-15 seconds. Adjust relief valve on

air manifold as required to achieve the 45-50 psi.

Pressure must be in a range between 35 and 60

psi in order to fire the burner.

5. With the high fire valve OFF, turn the burner

switch to the ON position. Following a 30 second

purge period, the burner should attempt to ignite

for 4 seconds and then lockout. The red lockout

light will come on. The dryer will shut down after

a 2-3 minutes unless the flame control is reset or

the burner switch is turned OFF. The dryer shut-

down time can be adjusted by resetting the 3TR

timer located in the ASC box behind the control

front panel.

6. Reset the flame controller by pressing the red

lockout switch. The dryer must be powered, the

pump/compressor switch ON and the burner

switch ON in order to reset the flame control.

When the flame controller is reset (red lockout

light off), it will begin a 30 second purge period

and then try to reignite unless the burner switch is

turned OFF. Turn the burner switch off at this

time.

7. Turn the high fire valve approximately 1/3 on

and the low fire valve approximately 1/3 on. With

pump/compressor and fan motors on, turn the

burner switch to ON. Burner should light immedi-

ately following a 30 second purge period. The

amber light on the burner switch will indicate that

the flame has been proven. Check that the oil

pressure on the burner is in the correct range.

8. Observe fire through the hole in the dryer

access door. Check the quality of the flame

through the normal operating range of pressures

by using the high fire valve to change firing rates.

Typically, no atomizing air adjustment is needed

over the full range of firing rates. The lowest fire