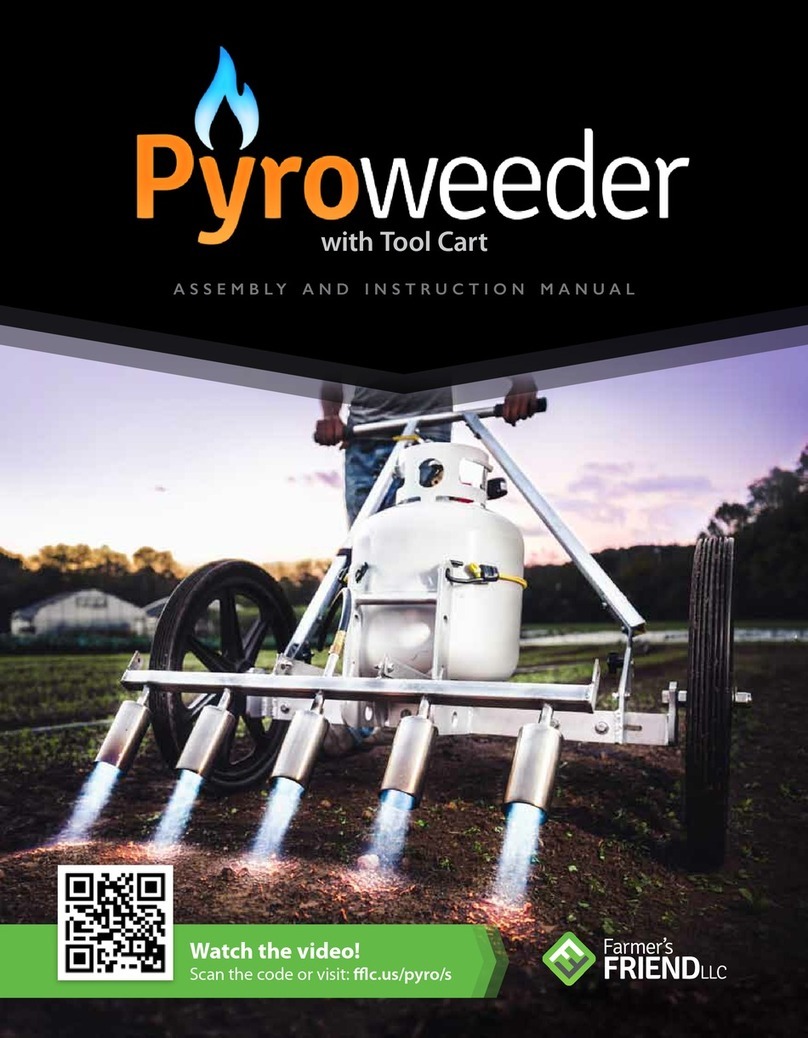

Pyroweeder 30

Tank-mounted Valve

Pyroweeder 30

Handle-mounted Valve

Pyroweeder 48

Tank-mounted Valve

Pyroweeder 48

Handle-mounted Valve

(931) 583-0397 | support@farmersfriendllc.com

FOR YOUR SAFETY

1. Protect your feet—always wear shoes when

operating the Pyroweeder.

2. Take safety precautions around children, pets,

and small animals.

3. Keep hands and feet away from burners while

the machine is operating. Flame may not be

visible in bright sunlight. The burner flames are

most visible when the Pyroweeder is operated

during lower light conditions, such as at dawn or

dusk.

4. Close the propane-tank valve when not in use.

5. Be prepared to promptly ignite the propane

upon opening the control valve for use. Do not

allow prolonged propane flow to un-ignited

burners. If excessive unburned propane flow

occurs, close the control valve and wait for

the propane to dissipate before attempting to

ignite the burners.

6. Keep the propane tank upright while operating

the Pyroweeder. It is recommended that you

use at least two bungee cords to secure the

tank against the tank brace.

Safety

IMPORTANT WARNINGS

1. Read all safety instructions before first use.

2. The Pyroweeder is intended for agricultural

weed management only.

3. Propane is extremely flammable. Before each

use, inspect hoses, valves, and connections for

damage or leaks.

4. Carbon monoxide gas is a poison—it can kill.

Since it is colorless and odorless, it is especially

dangerous. Incomplete propane combustion will

produce carbon monoxide; you can recognize

incomplete combustion by a yellow flame. On

the other hand, complete combustion produces

a blue flame. To operate the Pyroweeder safely,

adjust the pressure and control valve to avoid

a yellow flame—make it blue. Symptoms of

carbon monoxide poisoning include headache,

weakness, dizziness, nausea, vomiting,

confusion, and fatigue. If you have reason to

believe that you or anyone else has carbon

monoxide poisoning, move to fresh air and seek

immediate emergency medical care.

5. Prevent wildfires by complying with local

burn bans.

6. Practice fire safety—do not use on dry

grass, leaves, or brush, or during high fire-risk

conditions.

7. Do not operate in high-wind conditions.

8. Do not operate indoors or in an enclosed space.

9. Do not allow a child to operate the Pyroweeder.

10. Do not operate the Pyroweeder if your

coordination, balance, or judgment are impaired

by any medication, alcohol, or drug.

11. Do not store propane tanks indoors. Store

propane in a cool, well-ventilated outdoor

location.

12. Do not allow the Pyroweeder to tilt back onto

its handle while it is operating.

Rev. 20191205

The Flame Weeder, Refined