14.2.3 Special tramline rhythms ................................................................................................................. 48

THE MOST FREQUENTLY USED TRAMLINE SETTINGS............................................................................................51

RAIL LINE VALVES .......................................................................................................................................52

AIR PRESSURE REDUCING VALVE OF THE TRAMLINES ..........................................................................................53

TRAMLINE MARKERS ...................................................................................................................................54

15 FARMET DISPENSER................................................................................................................................. 55

DISPENSER FUNCTION TEST...........................................................................................................................56

ROUGH SEEDS............................................................................................................................................56

ROLLER REPLACEMENT ................................................................................................................................57

ROLLERS FOR FINE SEEDS..............................................................................................................................58

16 SOWING TEST.......................................................................................................................................... 59

HOSE DISTRIBUTION TYPE.............................................................................................................................59

SOWING TEST ............................................................................................................................................60

SOWING TABLES FOR FARMET DISPENSER......................................................................................................62

17 SETTINGS OF SEED SECTION .................................................................................................................... 64

SOWING DEPTH SETTING..............................................................................................................................64

17.1.1 Recommended depth....................................................................................................................... 65

SOWING SECTION PRESSURE SETTING .............................................................................................................66

17.2.1 Increase the pressure....................................................................................................................... 67

17.2.2 Lowering the pressure ..................................................................................................................... 67

SEED COULTERS .........................................................................................................................................68

17.3.1 Disc and pressure wheel trowels...................................................................................................... 69

17.3.2 Pressure wheel................................................................................................................................. 70

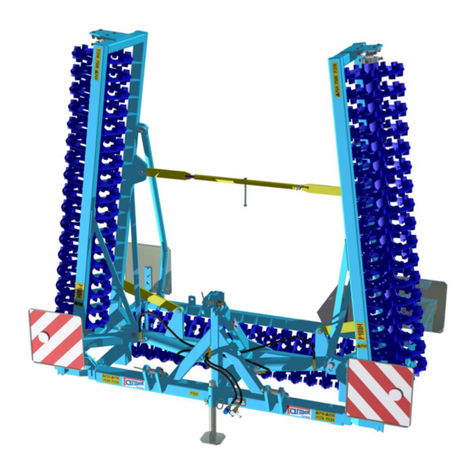

17.3.3 Harrows ........................................................................................................................................... 71

18 ADJUSTIN THE DOSE DURING WORK ....................................................................................................... 72

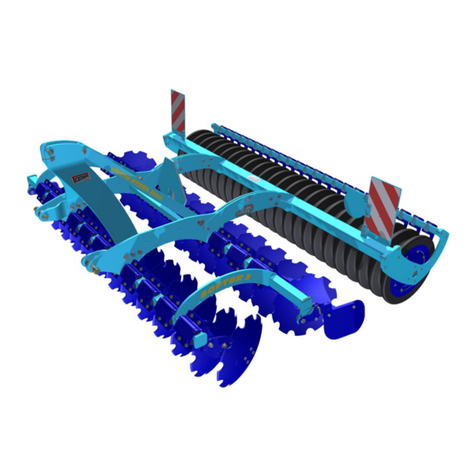

19 EMPTYING THE HOPPER USING ELECTRONICS ......................................................................................... 73

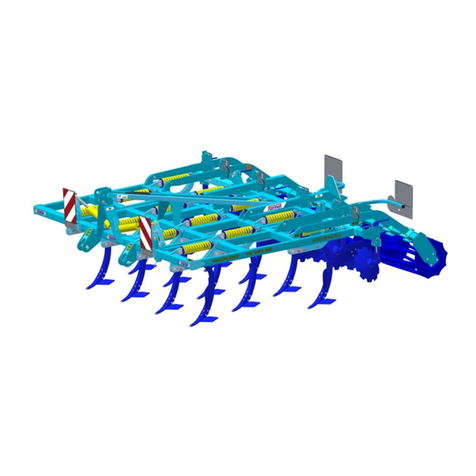

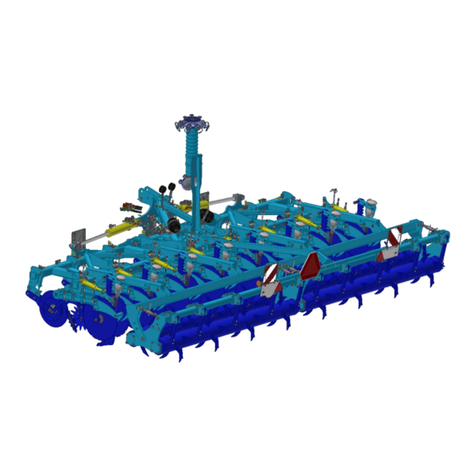

20 WORKING POSITION SOURCE.................................................................................................................. 74

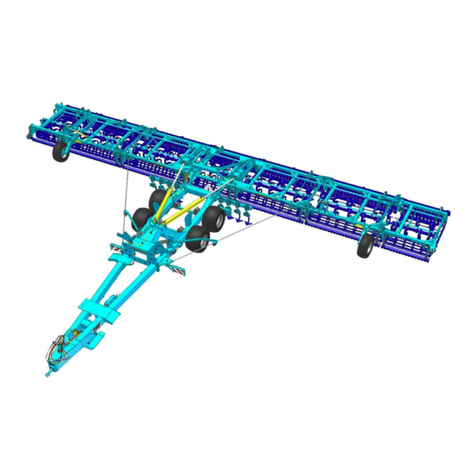

21 SOURCE SPEED MACHINERY .................................................................................................................... 75

22 MACHINE GEOMETRY.............................................................................................................................. 76

23 MACHINE LIGHTING ................................................................................................................................ 77

24 CONTROLLING SECTIONS MANUALLY (SECTION CONTROL) ..................................................................... 78

25 ADJUSTING THE HARROW BEHIND THE ROLLER ...................................................................................... 79

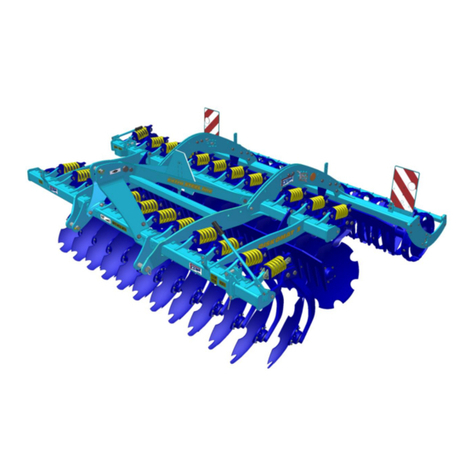

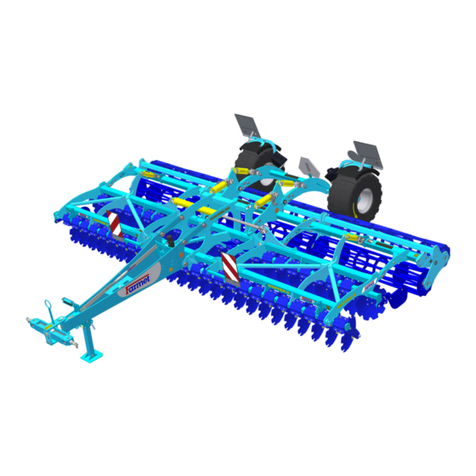

26 ADJUSTING THE DEPTH OF THE FRONT PREPARATION SECTION.............................................................. 80

SIDE DEFLECTORS OF THE FRONT PREPARATION SECTION.....................................................................................81

TRACTOR TRACK CULTIVATORS ......................................................................................................................81

FLEXIBOARD ..............................................................................................................................................82

27 SOWING SECTION SHIFT .......................................................................................................................... 83

28 HANGING THE MACHINE ON A CRANE..................................................................................................... 85

29 ERROR MESSAGES ................................................................................................................................... 86

ISO MESSAGES ..........................................................................................................................................86

REGULATIONS ALARMS ................................................................................................................................88

MACHINE-SPECIFIC ALARMS .........................................................................................................................90

30 MACHINE MAINTENANCE AND REPAIRS.................................................................................................. 94

MAINTENANCE PLAN...................................................................................................................................95

30.1.1 Lubricant nadling ............................................................................................................................. 98

30.1.2 Tire pressure .................................................................................................................................... 99

30.1.3 Recommended tightening torques .................................................................................................. 99