15

7

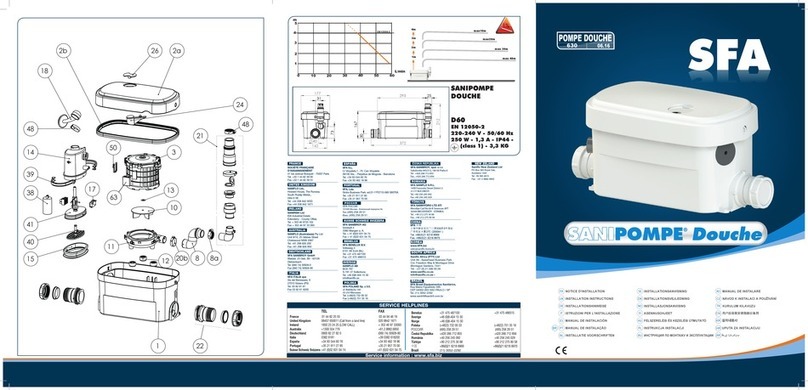

Warranty for Submersible Pumps, Fast Flow Pumps warrants to the original purchaser only that this prod-

uct is free from defects in material and workmanship, and agrees to repair or replace, at Fast Flow’s option,

any submersible pump part found to be defective within 12 months from the date of purchase. This warran-

ty is not transferable. This warranty does not cover damages resulting from shipping damage, improper in-

stallation, lack of service, incorrect power, or severe service applications such as pumping abrasives,

rocks, corrosives, or fluids in excess of 160°F. Warranty coverage is normally not available for wear parts

such as: Pump Volutes, Impellers, drive shaft, and hydraulic motor seals. Any modification or alteration of

this equipment will void the warranty. Any claim for warranty damage must include photos of the defective

part or parts, the serial number from the equipment, and a detailed description of the defect and possible

causes. All warranty claims should be emailed to www.fastflowpump.com or mailed to our Moss Point MS

address.

Submersible Pumps judged by Fast Flow Pumps to have been defective in workmanship or materials when

shipped from the factory and within the warranty period will be either repaired or replaced at option free of

charge excluding motor freight both ways, within the continental United States.

Fast Flow LLC Limited Warranty for Hydraulic Power Units. Fast Flow Pump warrants to the original pur-

chaser that this product is free from defects in material and workmanship, and agrees to repair or replace,

at our option, any part found to be defective within 12 months or 500 hours of use (whichever comes first)

from the date of purchase. This warranty is not transferable. This warranty does not cover damages result-

ing from normal wear, abuse, careless handling, lack of service / proper preventatives mainentance, im-

proper fueling, improper application, and improper operation. Warranty coverage is not normally applied for

items such as: Tires, belts, hoses, (fuel, oil, hydraulic oil) filters, batteries, and paint.

Fast Flow LLC does not warranty engines – warranty claims for engines must be handled through the en-

gine distributor. Any modification or alteration of this equipment will void the warranty. Any claim for war-

ranty damage must be accompanied by digital photos of the defective part or parts, the serial number from

the equipment, and a detailed description of the defect and possible causes.

All warranty claims should contact Fast Flow Pumps at 9700 Hwy 63, Moss Point, MS 39562. Power Units

judged by Fast Flow Pumps to have been defective in workmanship or materials when shipped from the

factory and within the warranty period, will be either repaired or replaced at the discretion of Fast Flow

Pumps free of charge excluding motor freight both ways.

Fast Flow Pumps shall not be liable for any damages, including consequential damages arising out of any

breach of warranty and whether or not arising out of or based on Fast Flow’s negligence, whether actual or

implied, and for damages to any property or person arising out of the purchase or the use, operation or

maintenance of the equipment. Fast Flow shall not be responsible for repairs or alterations made by oth-

ers. No person is authorized to make any representations or warranties on behalf of Fast Flow Pumps and

no other person is authorized to alter or extend any of the conditions contained in this warranty