– Install the product in a suitable control cabinet. The minimum degree of pro

tection required for the control cabinet is IP54.

– Prior to commissioning, ensure that the resulting movements of the connec

ted actuators cannot endanger anyone.

– During commissioning: systematically check all control functions and the

communication and signal interface between controller and drive regulator.

– Keep the documentation somewhere safe throughout the entire product life

cycle.

In the event of damage caused by unauthorised manipulation or any form of use

other than that intended, the warranty is invalidated, and the manufacturer is not

liable for damages.

In the event of damage caused by using unauthorised software or firmware with

the device, the warranty is invalidated, and the manufacturer is not liable for dam

ages.

Safety instructions for the safety sub-functions

It is only possible to determine whether the product is suitable for specific applic

ations by also assessing further components of the overall system.

Analyse and validate the safety function of the entire system.

Check the safety functions at adequate intervals for proper functioning. It is the

responsibility of the operator to choose the type and frequency of the checks

within the specified time period. The manner in which the test is conducted must

make it possible to verify that the safety device is functioning perfectly in interac

tion with all components. Time period for cyclical test

è 15.1 Technical data, safety engineering.

Prior to initial commissioning, wire the control inputs of the safety subfunction

STO. The safety subfunction STO is always available without the need for any

additional parameterisation.

2.2 Intended use

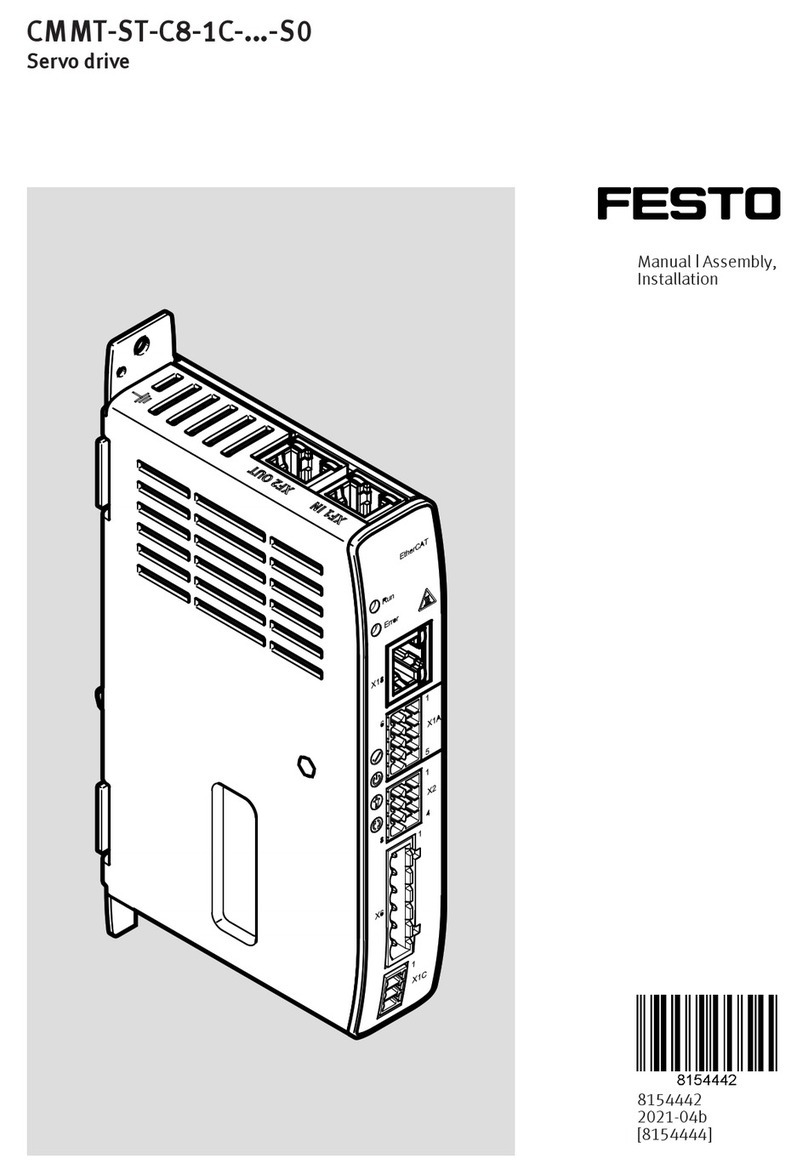

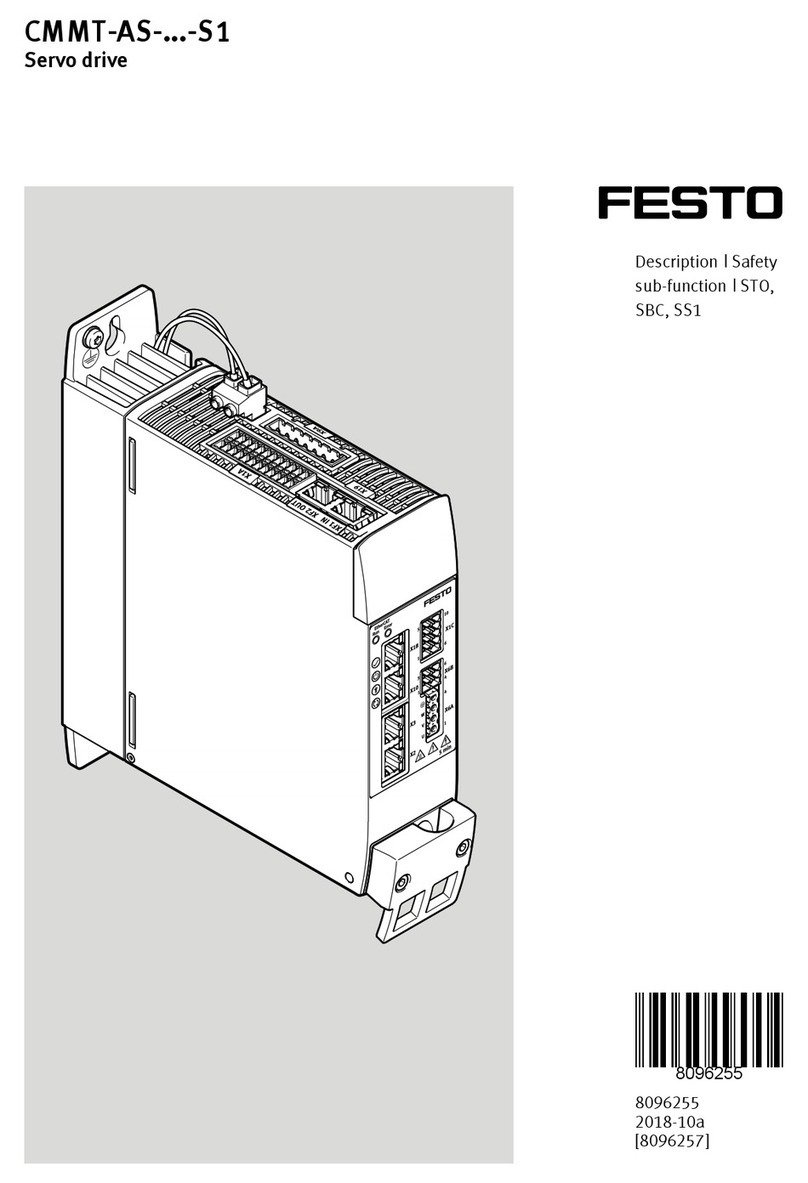

The servo drive CMMTST is intended to supply a stepper motor or an EC motor

with power, as well as to regulate them. The integrated electronics permit regula

tion of torque (current), rotational speed and position.

Use exclusively:

– In perfect technical condition

– In its original condition, without unauthorised modifications

– Within the limits of the product defined by the technical data

è 15 Technical data

– In an industrial environment

The safety function might fail, malfunctions might occur, and the connected actu

ators might move unintentionally if you do not comply with the parameters

required for the ambient and connection conditions.

The CMMTST...S0 supports the following safety subfunctions in accordance

with EN6180052:

– Safe torque off (STO/Safe torque off)

– Safe stop 1 time controlled (SS1t/Safe stop 1 time controlled), can only be

implemented with a suitable safety relay unit and appropriate servo drive cir

cuitry

The safety subfunction STO is intended to switch off the torque of the connected

motor, thereby preventing an unexpected restart of the motor.

The safety subfunction SS1t is intended to perform a rapid stop with subsequent

torque switchoff.

Ensure that wiring is crosscircuit proof in accordance with ENISO138491.

2.2.1 Range of application

Safety subfunctions may only be used for applications for which the stated safety

reference values are sufficient è 15 Technical data.

2.2.2 Permissible components

The load and logic power supply must meet the requirements of EN602041 (pro

tective extralow voltage, PELV).

Supported motors:

– Stepper motors

– EC motors

The servo drive supports motors with or without an integrated holding brake

(electrical springoperated brake). The holding brake is actuated automatically by

the controller enable of the servo drive. The actuation concept is based on the

assumption that a drive that is already stationary is being held. The actuation sys

tem is not designed for decelerating a moving drive. If a moving drive is deceler

ated, this can cause excessive wear on the brake.

Motor configuration Behaviour following removal of controller enable

Motor without holding brake The drive can move freely.

Motor with holding brake The holding brake is applied and holds the motor and axis in posi

tion.

Tab. 6 Example: removal of controller enable

The holding brake must be designed for the load torque to be stopped. Detailed

information about brake control èOnline help for the CMMTST plugin.

Supported encoders:

– BiSSC encoders

– Incremental encoders

Additional information èwww.festo.com/catalogue.

2.3 Foreseeable misuse

Foreseeable misuse of the safety sub-function STO

– Use outside the limits of the product defined in the technical data.

– Bypassing of the safety function.

– Crosswiring of the diagnostic feedback signals of more than 10 servo drives.

– Use of the diagnostic contact STA to switch a safety function.

The diagnostic contact STA must not be used to open a secure locking mech

anism directly, forexample.

The diagnostic contact STA is not part of the safety circuit. The diagnostic

contact STA is used to improve diagnostic coverage of the related safety sub

function. The diagnostic contact STA may only be used in combination with

the related safe control signals (AND operation) plus a reliable time monitor

ing function in the safety relay unit for the purpose of switching additional

safetycritical functions.

– Use of the safety subfunction STO without external measures for drive axes

influenced by external torques.

If external torques influence the drive axis, use of the safety subfunction STO

on its own is not suitable for stopping the axis safely. Additional measures

are required to prevent dangerous movements of the drive axis, suchas use

of a mechanical brake.

– Operation of EC motors requiring a safety classification of SIL3, cat.3, Ple

without evaluation of the diagnostic contact STA.

– Operation of the connected motor without the danger zone being restricted or

enclosed by suitable means.

The user must not be able to enter the danger zone without triggering the

safety function.

– The safety subfunction STO does not provide protection against electric

shock, only against dangerous movements.

– The safety subfunction STO cannot prevent nonsafetyrelated subfunctions

from failing, e.g.the braking ramp for the SS1t function or the device's tem

perature monitoring function.

2.4 Training of qualified personnel

The product may be installed and commissioned only by a qualified electrical

engineer who is familiar with:

– The installation, operation and maintenance of electrical control systems

– The applicable regulations for operating safetyrelated systems

Work on safetyrelated systems may only be carried out by qualified personnel

trained in safety engineering.

2.5 Approvals and certifications

The product has the CE marking. For details of directives, see

è 15.2 Technical data, product conformity and approvals.

The productrelated EU directives and standards are listed in the declaration of

conformity èwww.festo.com/sp.

The product is a safety device in accordance with the Machinery Directive. For

details of the safetyoriented standards and test values that the product complies

with and fulfils, see è 15.1 Technical data, safety engineering. Please note that

compliance with the named standards is limited to the CMMTST...S0.

Certain configurations of the product have been certified by Underwriters Laborat

ories Inc. (UL) for the USA and Canada.

These configurations bear the following mark:

Fig. 2

cUL Listed Mark for Canada and the United States.

During installation and operation of this product, comply with all safety require

ments, statutes, codes, rules and standards relevant for the product, such as the

National Electrical Code (USA), Canadian Electrical Code (Canada) and regulations

of the US federal agency OSHA. When selecting the circuit breaker, comply with

the maximum permissible electrical protection for UL.

3 Additional information

– Accessories èwww.festo.com/catalogue.

– Spare parts èwww.festo.com/spareparts.

– All available documents for the product and current versions of the firmware

and commissioning software èwww.festo.com/sp.

4 Service

Contact your regional Festo contact person if you have technical questions

èwww.festo.com.

5 Product overview

5.1 Scope of delivery

Component Number

Servo drive CMMTST... 1

Assortment of plugs NEKMC22 1

Hrail clamp (premounted) 1

Instruction manual CMMTST... 1

Tab. 7 Scope of delivery

Uptodate information on the accessories èwww.festo.com/catalogue.