FASTLITE MOZZA User manual

Contents

1 Introduction 3

2 Mozza Theory 5

2.1 Acousto-optic Tunable Filter (AOTF) ........................ 5

2.2 Mozza principle .................................... 5

2.3 Lock-in detection ................................... 6

3 Discovering your Mozza 8

3.1 Packing list ...................................... 8

3.2 Mozza Serial Number ................................. 8

3.3 Mozza Test sheet ................................... 8

4 Software installation and starting 9

4.1 Mozza application software .............................. 9

4.2 Connections and starting ............................... 9

5 Software guide 11

5.1 Menu area ....................................... 12

5.1.1 File menu ................................... 12

5.1.2 Device menu .................................. 12

5.1.3 Operations menu ............................... 13

5.1.4 View menu .................................. 14

5.1.5 Help menu ................................... 15

5.2 Status bar ....................................... 15

5.3 Basic Settings ..................................... 15

5.4 Advanced Settings .................................. 16

5.5 Panel .......................................... 17

6 Alignment 18

6.1 Basic alignment .................................... 18

6.2 Advanced alignment ................................. 19

7 Troubleshooting 21

7.1 Software starting problems .............................. 21

7.2 No light on the MCT photodiodes .......................... 21

2

CHAPTER 1

Introduction

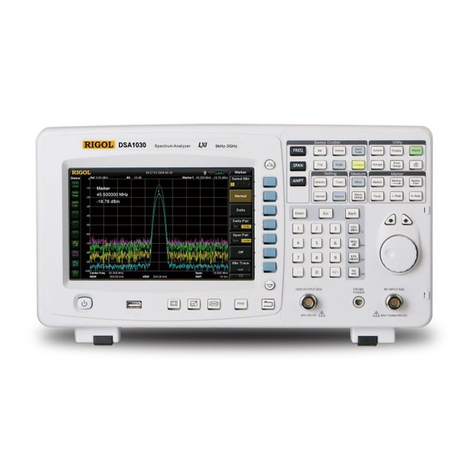

The MOZZA is a multi-octave spectrum analyzer designed to measure accurately the spectrum

of infrared radiations in the range 1-4.7 µm. It is based on an acousto-optic tunable filter

(AOTF) and is specifically well adapted to pulsed sources such as femtosecond amplifiers, OPO

or OPA with repetition rate up to 640 kHz, however, it can also be used with high repetition

rate and continuous sources.

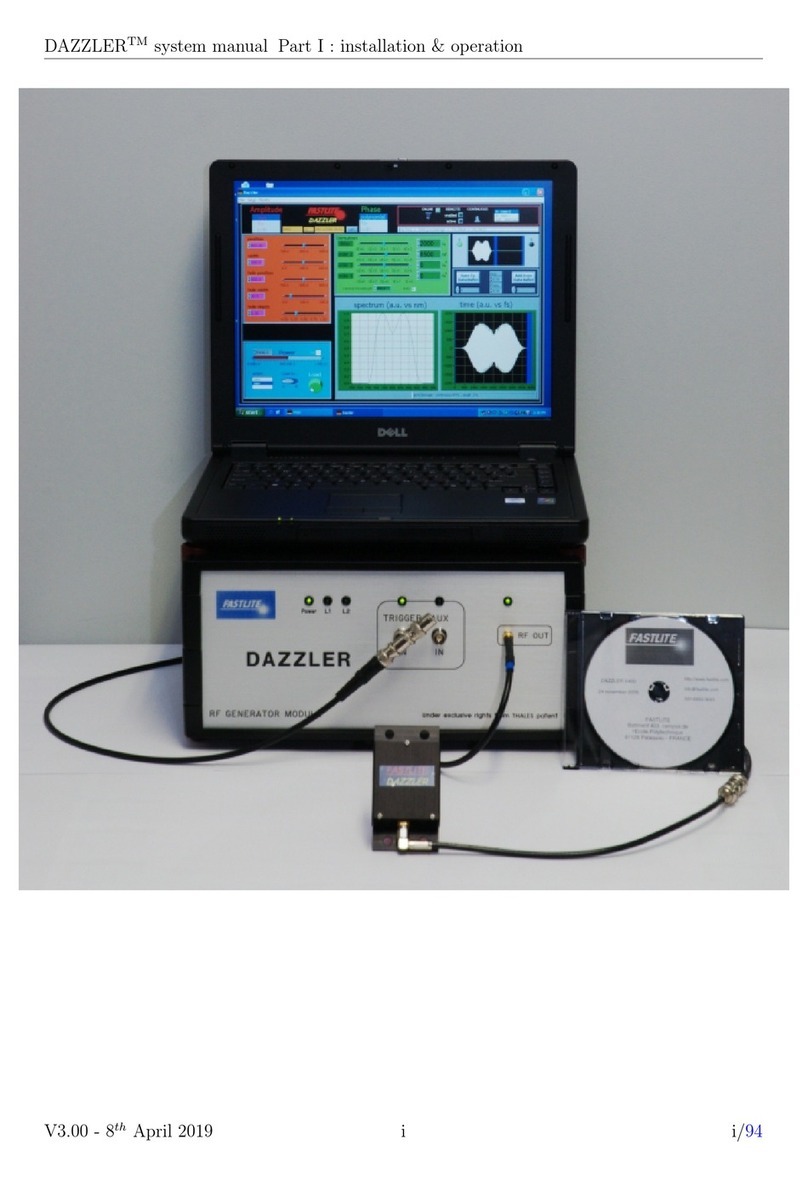

Figure 1.1: Mozza general picture

The MOZZA is a standalone instrument with its hardware, implementing the optical setup

3

Mozza manual Chapter 1 : Introduction

that allows for the high resolution of the AOTF and the MCT photodiodes with its analog-to-

digital converters (ADCs) that record the signal of the diffracted beam and the reference beam

for energy fluctuation compensation, and its software, which reconstructs the spectrum as the

measurement is running.

The MOZZA is an infrared spectral characterization tool. Such a function, despite all efforts

we put into designing this device as user-friendly as possible, cannot be carried out without an

intelligent operator, understanding at least the basic principles and limitations of the technique.

We hope the reading of this document will give you the necessary insights and allow you to

take full advantage of the MOZZA astonishing capabilities.

Note: The user must not move the optics, crystal or photodiodes inside

the MOZZA module. MOZZA has been factory-aligned in order to get

the best resolution and signal. All optical alignment must be done out-

side of the MOZZA module, optimizing the coupling into the MOZZA

Spectrum Analyzer by moving mirrors or lens. Moving optics inside the

MOZZA module results in misaligned spectrometer, resulting in incorrect

wavenumber calibration and/or loss of resolution.

FASTLITE - Mozza manual V1.2 4/21

CHAPTER 2

Mozza Theory

2.1 Acousto-optic Tunable Filter (AOTF)

An Acousto-optic Tunable Filter (AOTF) is a electronically tunable bandpass filter; this tech-

nique uses the acousto-optic interaction inside an anisotropic medium to select a line from a

broadband laser source.

The Mozza spectrometer uses a solid-state TeO2crystal as the acousto-optic tunable filter

to select a narrow band of the incident pulse. The center of the narrow band depends on

the acoustic frequency; therefore, by scanning the acoustic frequency, the diffracted beam is

recorded for each acoustic frequency and the optical spectrum is eventually reconstructed by

mapping the acoustic frequencies to the optical frequencies. The acousto-optic interaction is

sensitive to the polarization of the incident beam and in the Mozza spectrometer, the source

must be S-polarized.

Using Acousto-Optic Tunable Filter provides many advantages over other scanning tech-

niques. Using a solid-state crystal and selecting the wavelength electronically, no moving part

is used in this setup; as a consequence, it is reliable, fast and stable and appears as a very

valuable tool, especially when a pulsed laser is the source to analyze.

2.2 Mozza principle

The principle of the Mozza spectrometer is shown in Figure 2.1. The broadband incident beam

is split in two parts:

the first part goes through the acousto-optic crystal and the diffracted narrowband pulse

coming out of the crystal is recorded by a single point detector (MCT), it provides the

spectral density at the given wavelength (related to the current acoustic frequency) in a

5 cm−1spectral bandwidth.

the second part is directed to a second single point detector (MCT). Since the measure-

ment is not single-shot, it can disturbed by the energy fluctuation of the source. To

counterbalance this effect, the second part of the beam records the energy fluctuation of

the source so that the spectrum recorded on the first photodiode can be normalized.

5

Mozza manual Chapter 2 : Mozza Theory

Figure 2.1: Mozza principle

2.3 Lock-in detection

Two beams come out from the acousto-optic crystal: the diffracted beam, which is the narrow-

band part of the incident spectrum, and the transmitted beam which is the beam not affected

by the acousto-optic interaction. Consequently, for broadband sources, the transmitted beam

can be orders of magnitude higher in energy than the diffracted.

To record the spectrum properly, it is required to record on the photodiode after the acousto-

optic crystal only the diffracted beam and no signal corresponding to the transmitted. To do

so, two techniques are used in the Mozza:

first, the transmitted and the diffracted beam are spatially separated (the diffracted

beam is deflected) and then, by using a slit before the diffracted photodiode, most of the

transmitted beam is removed from the detector.

a broadband polarizer is used to select P-polarization, which corresponds to the polariza-

tion of the diffracted beam, the transmitted beam being S-polarized.

However, as mentionned before, the transmitted beam can be orders of magnitude higher

in energy and, for broadband sources, despite these precautions, some part of the transmitted

beam can reach the detector. Furthermore, scattering of the transmitted beam can also be

responsible of misleading results.

To remove all possible contamination in the spectrum caused by scatterring or transmission

of the transmitted beam, a lock-in detection technique is implemented in the Mozza spectrome-

ter. To perform the measurement of the spectrum, the Mozza record the signal on the diffracted

photodiode with and without acoustic wave in the acousto-optic crystal. Substracting the sig-

nal without acoustic wave to the signal with acoustic wave, only the part corresponding to the

FASTLITE - Mozza manual V1.2 6/21

CHAPTER 3

Discovering your Mozza

3.1 Packing list

The Mozza is delivered with the following parts:

one MOZZA optical module including a AOTF crystal and two MCT photodiodes

three pedestal posts

one power supply cable and one USB cable (1.80 m)

one grounding cable

one FLASH Drive including software and manual

one paper version of this user manual, including the test sheet

All items are packed in one single crate. The Mozza crate is re-usable and should be kept

for further servicing.

3.2 Mozza Serial Number

The Serial Number provides essential information about the MOZZA and is indicated on the

MOZZA test sheet, and on a sticker inside and on the box of MOZZA module.

All MOZZA serial numbers have the same structure: MOZZA1-1-5-xxxx where x are num-

bers. The last four numbers indicate the number of the machine.

3.3 Mozza Test sheet

At the end of the paper version of this manual, the test sheet for your MOZZA is provided.

This ensures that your MOZZA’s functionalities have been tested on calibration sources, with

satisfactory results.

8

CHAPTER 4

Software installation and starting

The MOZZA is delivered with a FLASH Drive including all the components of the MOZZA

software to be installed:

4.1 Mozza application software

The application software is located at:

FLASHDRIVE:/setup-mozza-360-r241.exe

Windows 7 and 8 are supported. The software is installed by executing the file, leave all default

options.

This will create the icon:

4.2 Connections and starting

Connect the grounding cable to the grounding terminal and to the optical table or any grounding

point. Plug the power supply cable and the USB cable into the MOZZA module and turn on

Figure 4.1: Mozza installer window

9

Mozza manual Chapter 4 : Software installation and starting

Figure 4.2: Mozza connections and indicators

the MOZZA. To prevent from electro-magnetic perturbations of the USB connection, the short

USB cable, supplied with the Mozza, should be used when possible. If your source is pulsed

(frep ≤640 kHz), then connect a 5V TTL trigger to the MOZZA module.

Turn on the Mozza module. When MOZZA module is turned on, the left led indicator is

always green, the middle one is blinking (green), the rigth led indicator is red and is blinking at

the very beginning: the MCT photodiodes are cooled down with Peltier modules, the red light

indicates that they have not reached correct temperatures; after 30 seconds-1 minutes, the red

light should not be blinking, indicating the correct behavior of the MCT photodiodes.

The device must now be recognized by the computer as MOZZA Spectrum Analyzer. You

can check the good behavior of the device by opening the Device Manager and searching for

MOZZA Spectrum Analyzer.

Double-click on the Mozza icon. The software detects

the Mozza automatically. If no Mozza hardware is de-

tected, the software displays a window with the following

message

You are now ready to use MOZZA software. For a complete description of the MOZZA

software functionalities, please refer to chapter 5.

FASTLITE - Mozza manual V1.2 10/21

CHAPTER 5

Software guide

When starting the MOZZA software, the following window appears. Some parts might be

hidden, depending on the saved configuration of the software.

Figure 5.1: Mozza software main window

Menu area gives access to File,Device,Operations,View and Help settings, as de-

scribed in section 5.1

Basic Settings allows to select the basic parameters of the scan: start and stop points

of the scan, step, units averages and photodiodes gain, as described in sections 5.3.

11

Mozza manual Chapter 5 : Software guide

Advanced Settings give access to specific parameters of the Mozza spectrometer such

as trigger source and its value (trigger freq), offset of the reference photodiode, power and the

possibility to enable or disable normalization process by the energy level of the laser. These

settings will be described in details in section 5.4.

Status bar displays some useful information about the status of the hardware (connected

or not connected), the trigger source and the duration of the scan and the current point in the

scan.

Graph is a selectable display area. The available contents depend on the value of the

”Graph Selection” control. A description of these displays is included in the following.

5.1 Menu area

5.1.1 File menu

Figure 5.2: File menu

Load launches a browser window to select and read the datas saved by Save or Save as ....

Save As... opens a browser window enabling to save the raw data as .npz,.dat or .csv

format.

Save config as ... allows the user to save the current parameters in a file as .yaml format.

Quit Shutdown the Mozza software.

5.1.2 Device menu

Connect allow the software to connect to a detected Mozza hardware.

Disconnect allow the software to disconnect to a detected Mozza hardware.

FASTLITE - Mozza manual V1.2 12/21

Mozza manual Chapter 5 : Software guide

Figure 5.3: Device menu

Info gives some information in order to monitor the hardware (power supplies, tempera-

ture, ...) and check that Mozza is working properly (see Figure 5.4).

Auto-detect : the software detects every Mozza hardware connected to the computer.

Mozza0:xxxx is the list of all Mozza hardware detected by the software.

Figure 5.4: Monitoring window

5.1.3 Operations menu

Figure 5.5: Operations menu

Alignment allows the user to remove all the warnings. The warning are enabled when

the Mozza is supposed to work properly; however, during the alignment procedure, warning can

be annoying (due to low signal level for example). Clicking on ”Alignment” avoid the warning

to be displayed.

FASTLITE - Mozza manual V1.2 13/21

Mozza manual Chapter 5 : Software guide

Trigger setup displays the window ”Trigger Wizzard” which allows the user to choose

the correct value for synchronization of the Mozza spectrometer with the laser.

Figure 5.6: Correct (left) and incorrect (right) Trigger delay parameter

In this window (see Figure 5.6), the graph show the signal on the reference and diffracted

photodiodes. Wavelength allows the user to choose the diffracted wavelength; Trigger delay

controls the synchronisation of the Mozza with the laser. When working with high repetition

rate laser (1kHz ≤frep ≤25kHz), Mozza works in ”Trig on Previous” mode; in this case,

clicking on the ”OPT” button will calculate the correct value for the Trigger delay if trigger

and laser arrive at the same time. Adjustement of the Trigger delay parameter must be done

so that the background can be processed properly by the software (green points on the figure

before the pulse) and the sample points (red points on the figure) are located at the maximum

of the pulse. The red vertical line indicate where the maximum of the pulse must be. Figure

5.1.3) show correct and incorrect value of the Trigger delay parameter; in the second case, the

red points are located at the beginning of the pulse, which means the software does not record

correctly the pulse and the measurement can therefore provide bad results and/or reduced

signal-to-noise ratio.

5.1.4 View menu

Figure 5.7: View menu

Single Plot and Dual Plot allows the user to display a single plot or dual plot. Dual plot

give more information on the current measurement (for example, reference level)

Advanced Settings allows the user to display or hide the Advanced Settings part of the

window.

FASTLITE - Mozza manual V1.2 14/21

Mozza manual Chapter 5 : Software guide

5.1.5 Help menu

Figure 5.8: Help menu

About displays a window with some information on the software.

Figure 5.9: Help window

5.2 Status bar

Status bar gives information to the user: it displays the status of the scan (current point,

remaining number of points in the scan), it indicates if the device is connected or disconnected,

it gives the trigger frequency, the approximate scan duration and the real duration of the last

scan.

Figure 5.10: Status bar

5.3 Basic Settings

start is the starting point of the scan.

stop is the final point of the scan. If stop = start, then the MOZZA works in single frequency

mode: the graph displays N points, with N = averages. It represents the signal sequentially;

this mode is useful for alignment. If stop is not equal to start, MOZZA is doing the scan from

start to stop.

FASTLITE - Mozza manual V1.2 15/21

Mozza manual Chapter 5 : Software guide

Figure 5.11: Basic settings

step is the step of the scan.

units allows the user to choose between different units (cm−1, nm, µm or THz).

averages allows the user to average the measurement in order to increase the signal-to-noise

ratio. In internal trigger mode, the same frequency is repeated N times, which N = averages. In

external trigger mode, Mozza record an entire scan and average the measurement with previous

scans.

Sweep duration gives an indication on how long it will take to do one scan.

PhD signal gain and Reference signal gain allow the user to select the gain of each

photodiodes. When signal is high, it is recommended to use low gain in order to not saturate

the signal.

Start will start the measurement. By clicking again on Start before the end of the scan,

Mozza will finish the current scan and stop (the button will then indicate ”Waiting” instead of

”Start”).

Abort will finish the measurement immediately.

5.4 Advanced Settings

Figure 5.12: Advanced settings

Trigger source allow the user to choose between ”Internal” (with continuous or very high

repetition rate laser, frep ≥640kHz) and ”External”.

ref. offset is used in ”Internal” trigger mode: it defined the signal level on the reference

photodiode when no external light enter the Mozza spectrometer. It is necessary to set this

value when working in internal trigger mode and the normalization process by the reference

is activated. To do so, press the ”Meas” button on the right and block the beam so that the

Mozza can record the value of the reference offset.

acq. time is calculated automatically and is an indicator of the acquisition on the photodiode.

power is a setting which control the power of the acoustic wave. It allows the user to reduce

the signal on the diffracted photodiode in the case power is high. The user can select 2 values:

1 (full power) or 0.3 (reduced power); the ”ATT” button switch between the 2 values.

FASTLITE - Mozza manual V1.2 16/21

Mozza manual Chapter 5 : Software guide

trig. delay is an indicator of the trigger delay; this parameter can be changed with Trigger

setup option (see section 5.1.3).

Trigger freq is an indicator of the trigger frequency when external trigger mode is activated;

in internal trigger mode, the user can select the trigger frequency between 100 Hz and 20 kHz.

1 kHz is a good compromise between speed and signal-to-noise ratio.

divide by ref enable the normalization process by the energy of the pulse recorded by the

reference photodiode.

Lock-in is an indicator of the lock-in mode.

5.5 Panel

The panels show the recorded data. Displayed data depends on the mode (single frequency or

scan) and on the option chosen in graph selection. The left panel displays the current spectrum

(”Spectrum”), the current and average spectrum (”Spectrum/Average”) or the signal on the

diffracted photodiode (”Raw signal”). The right panel can be used to displayed additional

information on the diffracted signal (”Signal FFT”’) or reference signal (”Raw reference”).

Figure 5.13: Dual plot graphs

Figure 5.14: Toolbar

Additionally, by clicking on the cross on the left of the graph selection, a toolbar appears. With

this toolbar, the user can zoom in and out, change to log scale or linear scale and save data.

FASTLITE - Mozza manual V1.2 17/21

CHAPTER 6

Alignment

The MOZZA is delivered with feet to set the input beam height at 113.1 mm. It is, however,

possible to change the posts for customized height down to 38.1 mm (1.5 ”), and for higher

beam height, 3 M4 holes can be used to put the feet in the MOZZA module.

This chapter gives a step by step alignment procedure of the MOZZA. If it is the first time you

are using the MOZZA, please read first chapter 5for a complete description of the MOZZA

software functionality. A troubleshooting guide is available in chapter 7.

Note: The user must not move the optics, crystal or photodiodes inside

the MOZZA module. MOZZA has been factory-aligned in order to get

the best resolution and signal. All optical alignment must be done out-

side of the MOZZA module, optimizing the coupling into the MOZZA

Spectrum Analyzer by moving mirrors or lens. Moving optics inside the

MOZZA module results in misaligned spectrometer, resulting in incorrect

wavenumber calibration and/or loss of resolution.

The MOZZA requires a linearly vertically polarized beam and a maximum of 10 µJ focused on

the slit (the user can put more power if working with collimated beam).

6.1 Basic alignment

When power of the infrared source is quite high or if the infrared radiation can be visualized

with laser viewing card (λ≤2mm), user can easily align MOZZA spectrometer.

First, verify that polarization is vertical and adjust the beam direction to be horizontal and to

go through the entrance slit.

In the software user interface, select Advanced settings (in the Menu area, ”View/Advanced

Settings”) and choose the correct trigger source (internal or external). If the trigger source is

external, then you must choose the correct trigger delay to synchronize the Mozza with the

laser. If the laser repetition rate is low (frep ≤1kHz), then you must provide a trigger which

arrives at least 40 µs before the pulse. If the laser repetition rate is high (frep ≥1kHz), the

trigger laser must arrive at the same time as the laser pulse.

When working with external trigger, choose ”Trigger setup” in the Menu area to select the

correct values for the timing. Then, use the Trigger Wizzard to set the correct value for trigger

delay (see 5.1.3).

18

Mozza manual Chapter 6 : Alignment

Figure 6.1: MOZZA outside view

Then, move mirrors and/or lens (outside of the Mozza, do not touch optics in the Mozza module)

to maximize the signal on the photodiodes. If the source to be analyzed is a broadband source

(≥500cm−1), then a large signal must be observed on the reference photodiode. If the source

is narrowband (≤500cm−1) and correct wavenumber is selected, then a large signal will be

recorded on the diffracted photodiode.

If no signal can be observed, then go to the Advanced alignment section.

6.2 Advanced alignment

Infrared alignment could be touchy, especially for wavelength above 2 µm since laser viewing

card does not exist or have very poor efficiency.

Alignment can be realized by using a visible laser, for instance 632.8 nm HeNe laser. Define

an optical axis with the visible light by placing 2 iris. Then place the focusing optic, lens

or concave mirror and ensure that the visible light is going in the right direction. For this

purpose, the cover can be opened; the user should provide that the visible light pass through

the entrance slit and the first metallic mask of diameter f = 3 mm.

Note: when opening the MOZZA module, make sure that it is clamped

on the optical table, otherwise, it will tip over.

Note: with very high power laser pulse, the alignment with visible light

might not be necessary since the user can use a collimated beam so that

he probably get some signals on the photodiodes. If this is the first time

you use MOZZA module, follow the indicated procedure.

Then, guide the infrared radiation by aligning with the 2 iris (with a laser viewing card or with

a powermeter). If this is done properly, some light should now enter the spectrometer. Note

that, for lens, due to chromatic aberrations, the lens must be translated a few mm to ensure

the best coupling in the spectrometer.

FASTLITE - Mozza manual V1.2 19/21

Table of contents

Other FASTLITE Measuring Instrument manuals