1. Thank you. Thank you for purchasing the

PanaFlow HT ultrasonic owmeter. Before removing

the PanaFlow HT system from the crate, please inspect

the owmeter. Each instrument manufactured by GE

Measurement & Control is warranted to be free from

defects in material and workmanship. Before discarding

any of the packing materials, account for all components

and documentation listed on the packing slip.

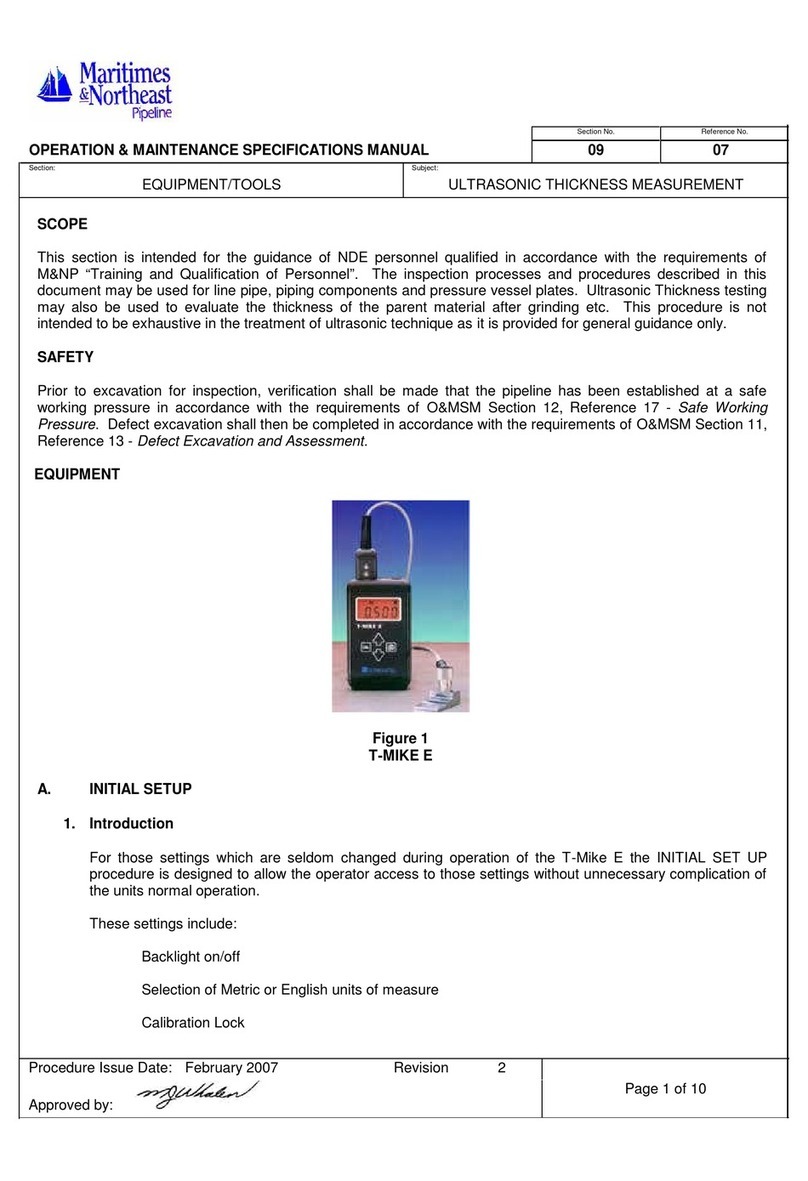

2. Meter Installation. The ideal site is a straight section

of process pipe that meets the following criteria:

• Pipe section is horizontal and above ground.

• Pipe section can accommodate the overall length of the

owcell.

• There is sufcient clearance for the transducers on

the sides of the meter (at the 3 o’clock and 9 o’clock

positions).

• There are at least 10 pipe diameters of straight,

undisturbed ow upstream and 5 pipe diameters

of straight, undisturbed ow downstream from the

transducers.(See User’s Manual.)

• For remote-mounted electronics, the electronics

console should be located within 100 feet (30

meters) from the meter body. (See User’s Manual.)

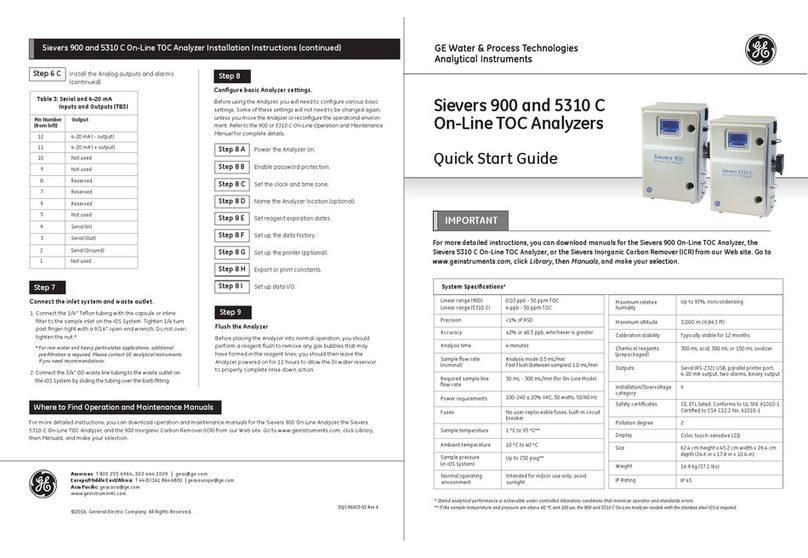

5. Communication and Power Wiring. The picture below

shows the communication and power wiring to XMT900

electronics. Make all communication wiring before wiring

the power terminals.

Once all wiring is complete, apply the power.

6. Programming & Testing.

The keypad and magnetic wand enable

programming of the instrument through the glass

faceplate without removing the cover. Thus, all

programming procedures may be performed while

the unit is installed in a hazardous area. See the

User’s Manual for instructions on programming.

PIN Label

Description

1

A-

Analog Output A:4-20mA/HART Output(SIL) Negative

2

A+

Analog Output A:4-20mA/HART Output(SIL) Positive

3

B-

Analog Output B:4-20mA Negative

4

B+

Analog Output B:4-20mA Positive

5

C-

Digital Output C Negative

6

C+

Digital Output C Positive

7

D-

Digital Output D Negative

8

D+

Digital Output D Positive

Terminal Block - Power Connection(AC)

PIN Label

1

L2/N

Neutral Connection

2

L1

Live Power Connection

Terminal Block -Modbus/Calibration Connections

PIN Label

Description

1

MOD-

Modbus/Service Port Negative

2

MOD+

Modbus/Service Port Positive

3

CAL-

Calibration Port Negative

4

CAL+

Calibration Port Positive

WARNING! The PanaFlow HT ow transmitter can measure the ow rate of many uids, some

potentially hazardous. Be sure to follow local safety codes and regulations for installing electrical

equipment and working with hazardous uids or ow conditions.