FASTRON. VC-210 User manual

MANAGER Copy

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 1

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

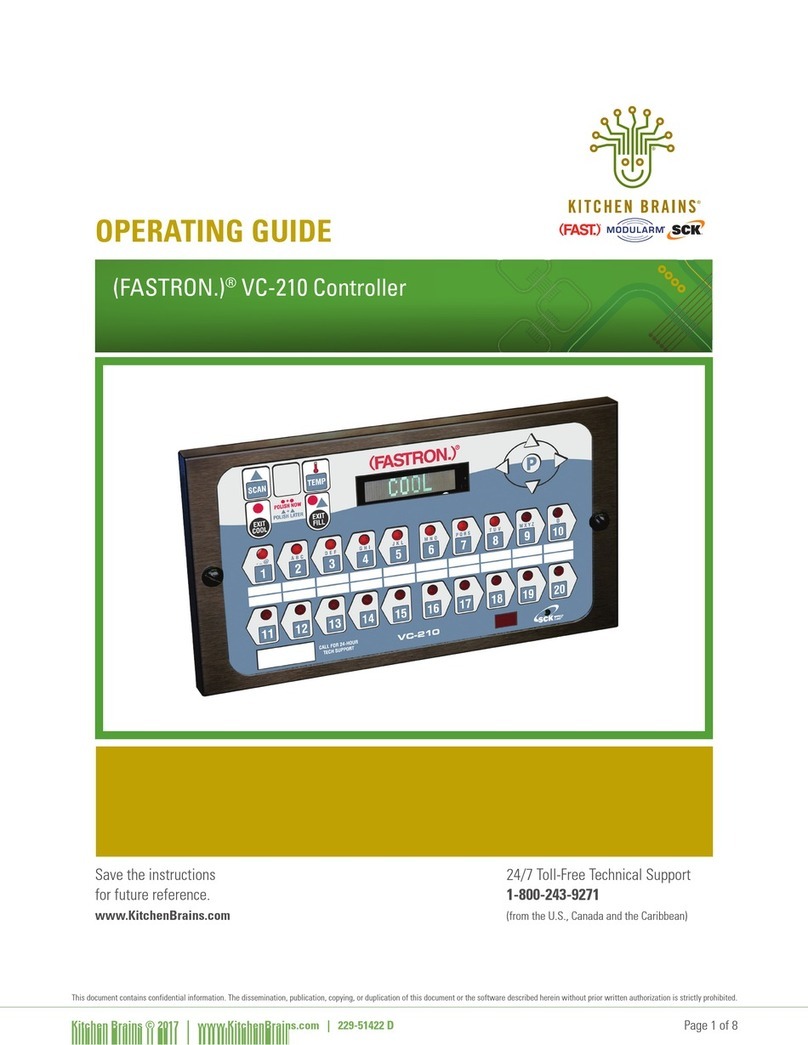

Process Controller – (FASTRON.)®VC-210

The (FASTRON.) VC-210 process controller is used to

control many different appliances.

Each controller can time up to 20 products, store

messages, alarm names, cooking and filtering

parameters, and has shortening management

capabilities.

(FASTRON.) VC-210 Controller

FAST is not liable for any use of product not in accordance with FAST’s installation

and operating instructions.

Before using this equipment or for any questions on the operation of the appliance,

consult and follow all instructions and safety warnings found in the appliance

operators’ manual supplied from the manufacturer of the appliance.

English & Spanish Versions

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 2

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

Installing the (FASTRON.) VC-210 Controller

REMOVE EXISTING (FASTRON.)

1

Unplug fryer

2

Remove the two (2) screws from the bezel securing the (FASTRON.) controller in the header cavity. Remove

the bezel.

3

Remove the controller by disconnecting the 9-pin and 2-pin connectors. (Several pressure and split vat fryers

will have additional connectors that will have to be removed.)

INSTALL THE NEW (FASTRON.)

1

Remove the two (2) 5/32” screws from the NEW controller.

2

Plug the 9- and 2-pin connectors into the corresponding connectors in the fryer. (Several pressure and split vat

fryers will have additional connectors that will have to be connected.)

NOTE: The 3-pin connector coming from the controller has no corresponding connector. It is for future use.

3

Insert the controller back into the fryer header cavity. Re-attach the bezel (frame) to the controller.

4

Secure the controller and bezel to the fryer header with the two (2) 5/32” hex screws provided.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 3

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

Parts Description – (FASTRON.)

VC-210 Controller

Part

Function

1. SCAN key

•Used for recipe review during idle.

•Used to review time remaining during multiple cooks (press &

hold)

2. EXIT FILL key

•Depressing this key for three seconds will force a filter that will

reset all internal filter counters.

3. VFD (Vacuum Fluorescent Display)

•Bright blue for easy viewing. Displays programming and cook

cycle information.

4. Programming Buttons

•Used to access programming mode and change parameters.

5. Changeable Menu Strip

•

Menu items are printed directly on easy-to-change menu strip.

6. SCK® Link LED

•

LED will light when communications is enabled.

7. IR Port (Infrared) – Optional

•Used to download programming from wireless device.

8. Product Buttons

•Used to activate cook cycles and for certain programming

functions.

9. Tech Support/Serial # Window •

Easy access to FAST tech support center.

10. Indicator Lights

•

Light up when product key is activated.

11. EXIT COOL key

•Used to exit setback (COOL) mode. Also used to cancel hold

alarms, as well as scroll through active holds when held down.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 4

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

Glossary of Terms and Features

Daylight Savings Time:Some countries have a one-hour change to their clocks in the Spring and Fall to allow

for more daylight hours. Spring / Fall programming as described in this manual allows the operator to quickly

and easily change the time by one hour without accessing the other polish programmable parameters.

Instant On: When turned "On" this feature automatically causes the electric element or gas burner to turn "On"

for a pre-determined time (0-60 seconds) when a cook cycle is started. This helps prevent excessive temperature

drop when product is introduced to the fryer, thereby ensuring product quality.

Polish:The circulation of the shortening through the filter for a period of time, as opposed to filtering which

passes the shortening through the filter only once.

Polish Later:The polish later command is active at all times UNLESS the delay time is programmed to ZERO.

The polish later command is used if a fryer has entered the polish command, yet it is needed to produce product

at that time. The delay time programmed will start counting, and at the end of the delay time the operator will be

forced to polish the shortening. The delay can only be activated once.

Polish Now:The “polish now” command is active at all times once the event times are activated. If a Polish

Now is entered and completed within 3 hours of a scheduled event polish time, the event polish time will be

canceled. This allows an operator to polish a fryer and get credit for the polish before the actual polish command

sounds. This is useful in a store with many fryers where the operator wants to "get ahead" of the polish work if

they have time available.

Polish Scheme:There are 4 events. An event is a polish sequence. (See pages 17 & 18)

Stagger Times:(This is for the 2nd event only) Some operators prefer all the fryers to enter polish at the same

time. In this case, all fryers start beeping at the same time and the need to polish is obvious. The delay command

can then be used to delay those fryers that are needed for cooking. Other operators prefer a staggering of the

Polish activation time (less noise in the kitchen, and can polish in a sequence). Staggered time programming as

described in this manual allows the operator to quickly and easily customize their preference without accessing

the other polish programmable parameters. Staggers are available in 15-minute increments from the set polish

time up 45 minutes.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 5

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

Using the (FASTRON.) VC-210 Controller:

Operational Test Procedure

1

Plug fryer into electrical source

2

NOTE: This scrolling can be bypassed by pressing SCAN.

The controller will scroll through the following:

a. Appliance Type

b. Software #

c. Download #

d. Current Date

e. Time of Day

f. SCK Address

g. “COOL”

3

Turn the fryer power switch on.

4

Press the EXIT COOL key once.

5

Press any illuminated product key.

6

The cook cycle will count down in the display.

NOTE: A cook cycle can be canceled by pressing and holding the active product key for 3 seconds. Pressing

the product key for less than 3 seconds will not cancel the cook cycle.

If the cycle is canceled during the first 25% of the cook time, the cook cycle simply gets canceled and the

display shows either “COOL” or the actual temperature, depending on the appliance. Canceling the cycle

during the last 75% of the cook time will either put the controller in the filter mode or subtract one from its

cycle count toward filter lockout.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 6

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

Operating the (FASTRON.) VC-210 Controller

RECIPE REVIEW — Quickly see what is programmed for each product key

1. Press the SCAN key.

2. Select any product key previously programmed–LED will be lit above the key.

3. Press the DOWN arrow key to scroll through the list.

4. Press SCAN to exit.

VIEW TEMPERATURE SETTING

1. Press the TEMP key ‘once’ to view Actual temperature, or

2. Press the TEMP key ‘twice’ to view Set temperature.

ACTIVATING THE POLISH FEATURE

1. To Polish ‘NOW’, press and hold the EXIT COOL and EXIT FILL keys at the same time.

2. To Polish ‘LATER’, press and hold the SCAN and EXIT FILL keys at the same time. NOTE: Polish

will only be delayed IF a non-zero polish delay time is set.

DISPLAY TIME OF DAY—2 second display of the current time of day. NOTE: Can only be done if the

controller is at COOL or idle mode.

1. Press and hold the SCAN and EXIT COOL keys at the same time.

DISPLAY APPLIANCE TYPE AND DOWNLOAD INFORMATION—2 second scrolling display of the

Appliance Type, Software #, Download #, Current Date, Time of Day and SCK Address.

1. Press the SCAN and TEMP keys at the same time.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 7

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

Programming the (FASTRON.)

VC-210 Controller

Programming Mode for the Vision Controller is entered by pressing the “P” key for three (3) seconds. Multiple

programming modes are available on the VC-210 as follows:

Passcode

Access Level

System

Recipe

ProdName

Library

Alarm

Library

Clock/Date

SMS Activate

Instant On

SCK Address

6647

Manager

X

X

X

X

X

X

X

NOTES:

•Pressing the “P” key saves the previous parameter.

•If no key is pressed within 2 minutes while in Programming mode, the controller will automatically

return to idle mode.

•All scrolling will loop back through allowed values.

Changing the Menu Strip on a (FASTRON.) VC-210

Process Controller

1

•Turn off the fryer power.

2

•With a flat screwdriver, remove the two screws that secure the bezel of the

VC-210 in place. Remove the bezel.

3

•Remove the existing menu strip(s) by lifting the tab and pulling the menu

strip out from the right side of the controller.

4

•Using the tab as a guide, slide the new menu strip in.

5

•Replace the bezel and screws that secure it to the controller.

6

•Turn on the fryer power.

Replacement Parts List

Part Number

Description

150-10202

1/4-20X3/4" SLOT RD HD BLK O

150-11025

NUT 1/4-20 TINNERMAN SPRING

214-50291

SHEETMETAL BEZEL

214-50660R57

OVERLAY

214-51003-57

MENU STRIP

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 8

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

SYSTEM PROGRAMMING (6647)

KEY PRESS

DISPLAY

ACTION

1

Enter Program mode

OR

•To enter programming mode, press and

hold the "P" key for 3 seconds.

•Scroll Down to Programming.

•Press the “P” key to lock in your entry.

2

Enter pass code

ENTER CODE

****

•Enter pass code 6 6 4 7.

•Press the “P” key when “System” is

displayed.

•Press the “P” key again to enter System

Programming.

3

Confirm or Select

Appliance Type

OR

APPLIANCE TYPE

XXXXXXXX

•Press the LEFT or RIGHT arrow keys

to select from a pre-programmed list of

appliances.

NOTE: Changing appliance type

clears all current recipe

programs.

•Press the “P” key to lock in your entry

3a

OR

Are you sure? Existing

recipes will be cleared!

(NO, YES)

•If the Appliance Type has been

modified, the user will be prompted

with this message. If the user selects

YES then all recipe settings for all

products will be cleared. (0 times, 270

set temps, disabled features). Use the

Left/Right keys to make the selection.

4

Select Language

OR

SELECT LANGUAGE

(English, Other)

•Press the LEFT or RIGHT arrow key to

select language

•Press the “P” key to lock in your entry

NOTE: ‘Other’ is downloadable.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 9

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

5 Set Tone Level

OR

TONE LEVEL

(None, 1, 2, 3, 4, 5)

•Press the LEFT or RIGHT arrow keys

to select a tone level. At each level the

controller will continuously sound the

selected tone.

•Press the “P” key to lock in your entry

6

Set Temperature Mode

OR

TEMPERATURE

F = FAHRENHEIT or

C = CELSIUS

•Press the LEFT or RIGHT arrow keys

to select the method that all

temperatures will be displayed in.

•Press the “P” key to lock in your entry

7

Set Profile Timing

OR

PROFILE TIMING

(NO, YES)

•Press the LEFT or RIGHT arrow keys

to activate Profile Timing to monitor

each individual stage of the cook time.

•Press the “P” key to lock in your entry

7a

OR

Are you sure? Existing

recipes will be cleared!

(NO, YES)

•If a profile recipe exists in the current

recipe setting and the user selects NO in

the profile timing field, the user will be

prompted with this message. If the user

selects NO then no change will be

made. If the user selects YES then all

recipe settings for all products will be

cleared. (0 times, 270 set temps,

disabled features). Use the Left/Right

keys to make the selection.

8

Program Setback Time

SETBACK TIME

HH:MM

•Press the numbered product keys to

select the time in HH:MM format for

activating Setback mode.

•Press the “P” key to lock in your entry

9

Program Setback

Temperature

SETBACK TEMP

XXX

•Press the numbered product keys to

select the Setback temperature in the

range of 200 to 375°F.

•Press the “P” key to lock in your entry

10

Program Quantity Prompt

Time

OR

QTY PROMPT TIME

MM:SS

•Use the numeric keys to enter the

quantity prompt time in MM:SS format.

Range is 00:20 to 2:00.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 10

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

11 Program Global Filter

Lockout

GLOBAL FLTR CNT XX

(“0” to “99”)

•Type in the number of cooks allowed on

all keys before forcing Filtering by

pressing the appropriate numbered

product key(s). The range is 0 to 99,

where 0 means No Global Filtering.

•Press the “P” key to lock in your entry

12

Set Repair Function

OR

REPAIR FUNCTION (YES,

NO)

•Press the LEFT or RIGHT arrow keys

to select whether the Repair Function

will be active or not.

•Press the “P” key to lock in your entry

13

Set Repair Fail Time

REPAIR FAIL TIME

MM:SS

This option will only appear if the Repair

Function is enabled.

•Press the numbers to set Repair Fail

time in minutes/seconds. The range is 0

to 59:59 minutes.

•Press the “P” key to lock in your entry

14

Set Daylight Savings Mode

OR

DAYLIGHT SAVINGS

(SPRING, FALL)

•Press the LEFT or RIGHT arrow keys

to select the appropriate Daylight

Savings choice.

•Press the “P” key to lock in your entry

15

Set Stagger Time

OR

SELECT STAGGER

(00 MINUTES,

15 MINUTES,

30 MINUTES,

45 MINUTES,

60 MINUTES)

•

Press the LEFT or RIGHT arrow keys

to select the SMS stagger time.

•Press the “P” key to lock in your entry

16

Set # of RQI Trackers

OR

# RQI TRACKERS

NONE, 1-30

•Press the LEFT or RIGHT arrow keys

to select number of RQI Trackers.

•Press the “P” key to lock in your entry

17

Set SCK Status Sound

OR

SCK STATUS SOUND

YES or NO

•Press the LEFT or RIGHT arrow keys

to change.

•Press the “P” key to lock in your

choice.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 11

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

18

Set Communication Error

Display

OR

COM ERROR DISP

YES or NO

•Press the LEFT or RIGHT arrow keys

to change.

•Press the “P” key to lock in your

choice.

19

Exit Program Mode

OR

EXIT

•Press the UP or DOWN arrow keys to

scroll to “Exit.”

20

•Press the “P” key

to return to idle mode.

PRODUCT OR ALARM NAME LIBRARIES (6647)

KEY PRESS

DISPLAY

ACTION

1

Enter Program mode

OR

•To enter programming mode, press and

hold the "P" key for 3 seconds.

•Scroll Down to Programming.

•Press the “P” key to lock in your entry.

2

Enter Pass Code

SYSTEM

PROGRAMMING

****

•Enter pass code 6 6 4 7.

•Press the “P” key to lock in your entry.

3

OR

PROD NAME LIB

Or

ALARM LIB

•Scroll to “Prod Name Lib” or “Alarm

Lib”

•Press the “P” key to advance.

From this point, you can either MODIFY an Existing Name, or ADD a New Name.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 12

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

4a

MODIFY or ADD an Existing

Product or Alarm Name

OR

Prod Name Lib

xxxxxxx

OR

x

Alarm Name Lib

xxxx

•Start spelling the name

(predictive method) using keys 1-

10, OR

•Use the UP and DOWN arrow

keys to scroll through the library

(traditional method).

4b

•Once name is located, press the

SCAN key to toggle from

predictive text input to traditional

text input.

4c

OR

•Use the LEFT and RIGHT arrow

keys to move the cursor.

•Press “Exit Fill” to toggle between

Upper and Lower case.

•“Exit Cool” can be used to clear

the existing product name.

•Press the “P” key to complete.

4d

OR

SAVE LIBRARY

MODIFY, ADD, CANCEL

•Press the LEFT or RIGHT arrow

keys to select “Modify” or “Add.”

•Press the “P” key.

NOTE: Selecting “Cancel” allows

you to exit without making any

changes.

4e

Exit Program Mode

OR

EXIT

•Press the UP or DOWN arrow

keys to scroll to “Exit.”

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 13

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

CLOCK/DATE PROGRAMMING (6647)

KEY PRESS

DISPLAY

ACTION

1

Enter Program mode

OR

•To enter programming mode, press and

hold the "P" key for 3 seconds.

•Scroll to Programming.

•Press the “P” key.

•The display will prompt user to enter a

pass code.

2

Enter Pass Code

OR

CLOCK/DATE

****

•

Enter pass code 6 6 4 7.

•Press the “P” key to lock in your entry.

•Scroll to Clock/Date

•Press the “P” key to advance.

3

Set Time of Day

OR

TIME OF DAY

HH:MM

CURRENT YEAR

“XXXX”

CURRENT MONTH

“XXXXXXXXX”

CURRENT DATE

“XX”

CURRENT DAY

“XXXXXXXX”

•Use the numbered product keys to set

the time of day. The range is from 00:00

to 23:59.

•Press the “P” key.

•Press the LEFT and RIGHT arrow keys

to set the Year.

•Press the “P” key.

•Press the LEFT and RIGHT arrow keys

to set the current Month.

•Press the “P” key.

•Press the LEFT and RIGHT arrow keys

to set the current Date.

•Press the “P” key.

•Press the LEFT and RIGHT arrow keys

to set the Day.

•Press the “P” key.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 14

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

4

Exit Clock/Date

Programming

OR

•Scroll to Exit.

•Press the “P” key to return to idle mode.

SMS ACTIVATION PROGRAMMING (6647)

KEY PRESS

DISPLAY

ACTION

1

Enter Program mode

OR

SMS ACTIVATE

•To enter programming mode, press and

hold the "P" key for 3 seconds.

•Scroll to “Programming.”

•Press the “P” key.

•The display will prompt user to enter a

pass code.

2

Enter Pass Code

ENTER CODE

****

•Enter pass code 6 6 4 7.

•Press the “P” key to lock in your entry.

•Scroll to “SMS Activate.”

•Press the “P” key.

3

Setting SMS Activation Time

NOTE: Depending on the scheme entered (see below), one of four SMS Activation times will be

selected.

3a

SCHEME 1

OR

Set SMS Timing

For SMS use:

•Event 1 = 7:00 A.M., 30 Min. Duration,

0 Hour Delay

Event 2 = 2:00 P.M., 30 Min. Duration, 3

Hour Delay

OR

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 15

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

3b

SCHEME 2

OR

Set SMS Timing

For SMS use:

•Event 1 = 7:00 A.M., 15 Min. Duration,

0 Hour Delay

•Event 2 = 2:00 P.M., 15 Min. Duration,

3 Hour Delay

OR

3c

SCHEME 3

OR

Set SMS Timing

For SMS use:

•Event 1 = 2:00 P.M., 15 Min. Duration,

3 Hour Delay

•Event 2 = 8:00 P.M., 15 Min. Duration,

3 Hour Delay

OR

3d

SCHEME 4

OR

Set SMS Timing For SMS use:

•Event 1 = 2:00 P.M., 30 Min. Duration,

3 Hour Delay

•Event 2 = 8:00 P.M., 30 Min. Duration,

3 Hour Delay

4

OR

EXIT

•Press the “P” key to advance to next

step.

•From SMS Activate, scroll to Exit and

press the “P” key.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 16

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

SET INSTANT ON (6647)

KEY PRESS

DISPLAY

ACTION

1

Enter Program mode

OR

•To enter programming mode, press and

hold the "P" key for 3 seconds.

•Scroll to “Programming.”

•Press the “P” key.

•The display will prompt user to enter a

pass code.

2

Enter Pass Code

ENTER CODE

****

•Enter pass code 6 6 4 7.

•Press the “P” key to lock in your entry.

•Scroll to “Instant On.”

•Press the “P” key.

3

SELECT PRODUCT TO

PROGRAM

•Select a Product Key

4

INSTANT ON

:XX

•Use Product Keys to enter 0-60.

5

SELECT PRODUCT TO

PROGRAM

•To program additional products, select

another product key.

6

Exit Instant On

Programming

OR

•Scroll to Exit.

•Press the “P” key to return to idle mode.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 17

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

SCK®ADDRESS (6647)

KEY PRESS

DISPLAY

ACTION

1

Enter Program Mode

OR

•To enter programming mode, press and

hold the "P" key for 3 seconds.

•Scroll to Programming.

•Press the “P” key.

•The display will prompt user to enter a

pass code.

2

Enter Pass Code

OR

ENTER CODE

****

•Enter pass code 6 6 4 7.

•Press the “P” key to lock in your entry.

•Scroll to SCK Address.

•Press “P” to advance.

3

Set SCK Address

OR

SCK ADDRESS

XX

•Press the LEFT or RIGHT arrow keys

to scroll through the SCK address to be

used for this controller. The range is

from 1 to 31, or “Auto Assign.”

•Press the “P” key to lock in your

selection.

4

Set SCK Node

NETWORK NODES

XX XX XX XX XX

•The display will scroll in marquee-style

all SCK Nodes currently in the system.

Scrolling will constantly be updated.

•Press the “P” key to advance.

5

Exit SCK Programming

OR

EXIT

•Scroll to Exit.

•Press the “P” key to return to idle.

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 18

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

This page left intentionally blank.

NOTES:

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 19

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

This page left intentionally blank.

NOTES:

Process Controllers

FAST Lit. Part No. 229-51311 Rev. E (MANAGER) 24SEP2010 Page 20

2005-2010 Food Automation – Service Techniques, Inc. All Rights Reserved

This document contains confidential information. The dissemination, publication,

copying, or duplication of this document without prior written authorization is

strictly prohibited.

Food Automation -

Service Techniques, Inc.

905 Honeyspot Road

Stratford, CT 06615-7147 USA

Phone: +1-203-377-4414

Sales: 1-800-FASTRON

Fax: +1-203-377-8187

International Callers: +1-203-378-6860

Toll-free technical support 24/7 from the U.S.,

Canada, and Caribbean: 1-800-243-9271

International offices are located in:

China: +86 13916854613

Singapore: +65 98315927

United Kingdom: +44 0 1268 544000

www.fastinc.com

PATENTS

The products manufactured by FAST are protected under

one or more of the following U.S. Patents:

5,331,575 5,539,671 5,711,606 5,723,846

5,726,424 5,875,430 6,142,666 6,339,930

6,401,467 6,505,546 6,581,391 7,015,433

7,650,833

Plus foreign patents and patents pending.

Plus licensed patent 5,973,297

Specifications subject to change without notice.

This document contains confidential information. The

dissemination, publication, copying, or duplication of this

document without prior written authorization is strictly

prohibited.

SCK Link is a registered trademark of Technology

Licensing Corporation and use is subject to the

appropriate license agreement.

Other manuals for VC-210

2

Table of contents

Languages:

Other FASTRON. Controllers manuals

FASTRON.

FASTRON. VC-210 User manual

FASTRON.

FASTRON. VISION VC-220 User manual

FASTRON.

FASTRON. VC-210 User manual

FASTRON.

FASTRON. MERIDIAN Series User manual

FASTRON.

FASTRON. Meridian MEC-110 User manual

FASTRON.

FASTRON. VISION Series Operating instructions

FASTRON.

FASTRON. S-S Series Use and care manual

FASTRON.

FASTRON. F330 Series Manual

FASTRON.

FASTRON. Meridian MEC-110 User manual

FASTRON.

FASTRON. FTM1 Series User manual