Fastway e2 HITCH TRUNNION User manual

Your model # can be found on the stickers on

either spring bar. Make a note of it here for

future reference.

owner’s manual

Read the entire manual

before starting installation.

Dealer: Please give this

manual to the end user

after hitch installation.

Hitch ball not included except model 92-00-1065.

fastwaytrailer.com A Product of Progress Mfg. Inc.

Fastway e2 Hitch - Faster, Easier.

™

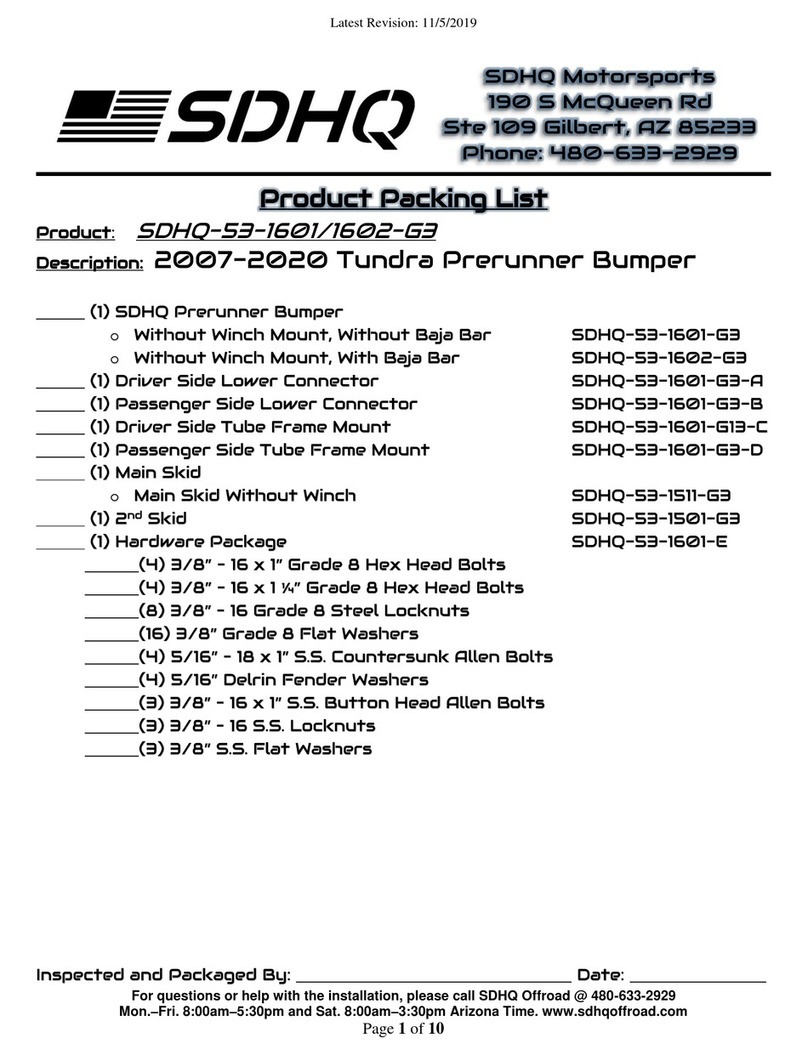

Model Max Tongue

Weight (lb)

Max Trailer

Weight (lb)

92-00-0600 600 6,000

92-00-0800 800 8,000

92-00-1000 1,000 10,000

92-00-1200 1,200 12,000

2fastwaytrailer.com

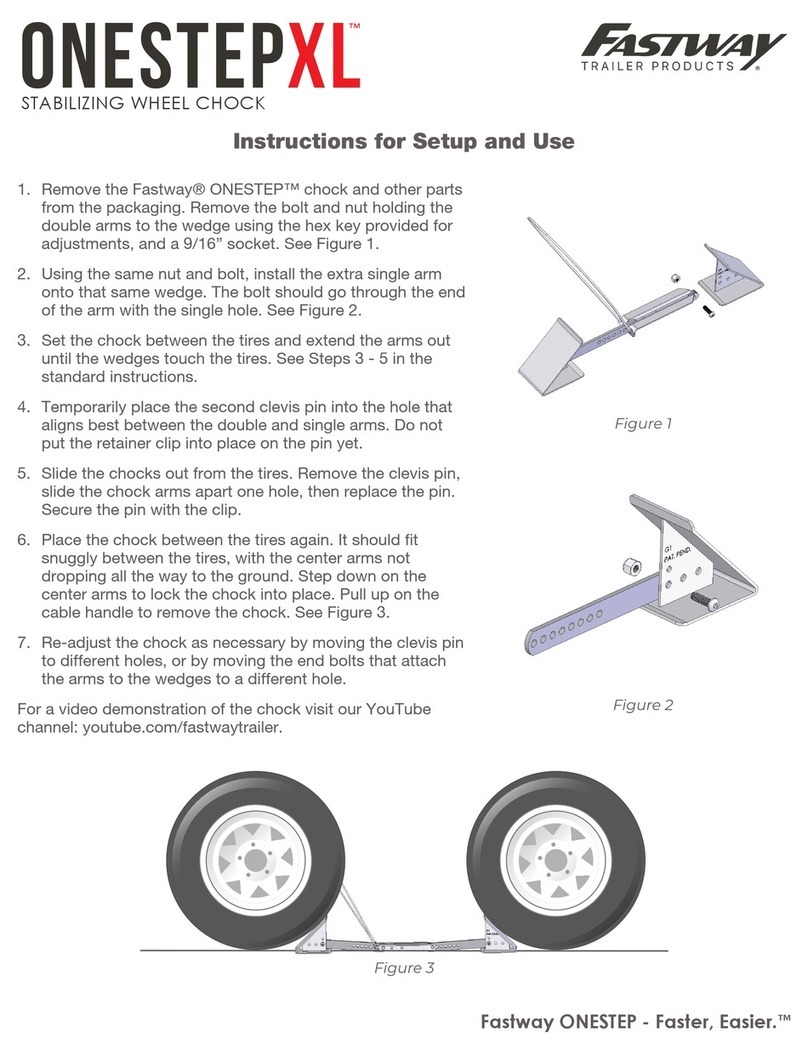

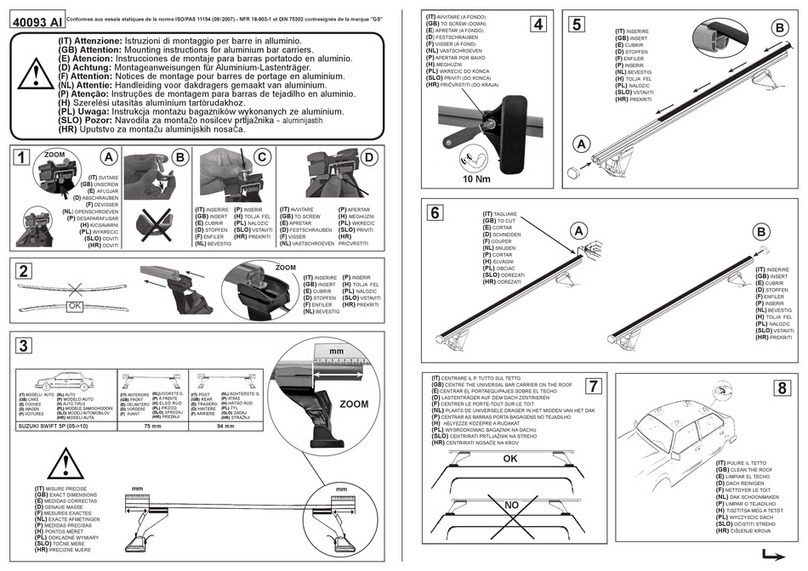

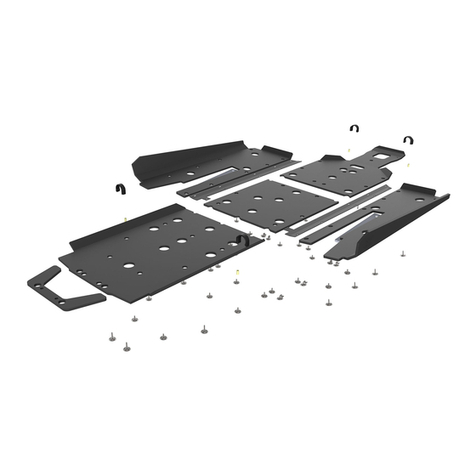

Parts Breakdown

27

26

25

24

23

22

21 20

19 17

18 16 15

14

13

12 11

10

8

9

7

6

5

4

3

2

1

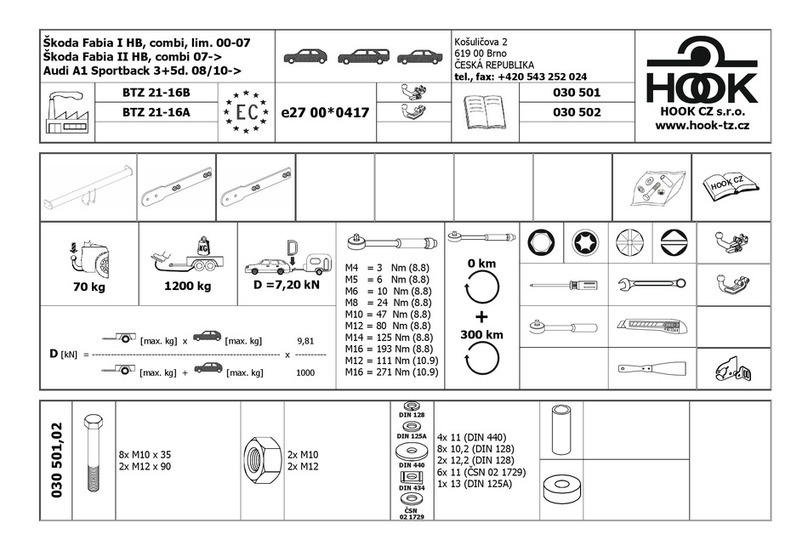

Item # Part Number Part Description Qty.

1 92-04-9208 L-pin clip 2

2 93-04-9285 1/2” nylock nut 4

3 92-03-9205 L-pin 2

4 93-02-5150 L-bracket 2

593-02-9270 1/2” x 4” bolt - grade 5 4

6 93-02-5350 Studded outside link plate 2

7 93-02-5200 Inside link plate 2

8 92-04-9290 1/2” lock washer 4

9 92-04-9228 1/2” nut 4

10 92-00-6000 Snap-up lever 1

11*†

92-02-0699 6,000 lb spring bar (single)

2*

92-02-0899 8,000 lb spring bar (single)

92-02-1099 10,000 lb spring bar (single)

92-02-1299 12,000 lb spring bar (single)

12 BD094-WS Bar sticker 2

13†92-04-9615 10mm hex bolt 2

14 BD092-WH Trunnion head attn. sticker 1

15†

92-02-0644 6K trunnion knuckle

2

92-02-0844 8K trunnion knuckle

92-02-1044 10K trunnion knuckle

92-02-1244 12K trunnion knuckle

Item # Part Number Part Description Qty.

16†92-04-9620 10mm lock washer 2

17†92-04-9216 10mm nylock nut 2

18 92-03-9700 5/8” angle set bolt 1

19 92-04-9635 3/4-10 x 5” grade 5 bolt 2

20 92-04-9645 3/4” conical toothed washer 4

21 92-04-9625 Hitch pin 1

22 92-04-9630 Hitch pin clip 1

23 92-02-4100 7” Rise x 1” drop adj. shank 1

24 92-04-9650 Spacer rivet 1

25 92-04-9655 Spacer washers 7

26 92-04-9640 3/4” nylock nut 2

27** 94-02-1055 e2 trunnion hitch head 1

NS ‡-- Hitch ball

NS BD094 e2 round bar owner’s manual 1

* Hitch contains two (2) matched spring bars. See

stickers for model # and capacity.

** Hitch contains one (1) head rated as indicated on box.

† Comes preassembled as one unit

‡ Hitch ball NOT included except model 92-00-1065.

NS Not Shown

4fastwaytrailer.com

Table of Contents

Page

Parts Breakdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . 5

Important Hitch Information . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Important Setup Information . . . . . . . . . . . . . . . . . . . . . . . . . 7

Step 1: Ready the Tow Vehicle and Trailer . . . . . . . . . . . . . . . . . . 8

Step 2: Install the Hitch Ball. . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 3: Attach Hitch Head to Shank . . . . . . . . . . . . . . . . . . . . . 9

Step 4: Sway Control Bracket Assembly . . . . . . . . . . . . . . . . . . . 11

Step 5: Spring Bar Installation . . . . . . . . . . . . . . . . . . . . . . . . .14

Step 6: Weight Distribution Setup . . . . . . . . . . . . . . . . . . . . . . 15

Step 7: Weight Distribution Adjustment . . . . . . . . . . . . . . . . . . 17

Step 8: Trailer Pitch Adjustment . . . . . . . . . . . . . . . . . . . . . . . 20

Step 9: Final Tightening . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Step 10: Regular Maintenance . . . . . . . . . . . . . . . . . . . . . . . . .21

Step 11: Hitching Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Step 12: Unhitching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Appendix A: Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . 25

Customer Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Appendix B: Weight Distribution Adjustments . . . . . . . . . . . . . 27

Appendix C: Installing With Auto-Level/Air Bags . . . . . . . . . . . . 28

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Service Tech Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Tools Needed For Hitch Installation

(1) 1-1/8” socket or wrench (shank bolts)

(1) 1-1/16” socket or wrench (shank nuts)

(1) Torque wrench capable of 250ft-lb of torque (shank bolts)

(2) 3/4” sockets or wrenches (link plates and L-brackets)

(1) 15/16” socket or wrench (angle set bolt)

Measuring tape

Pencil

Recommended Tools For Installing The Hitch Ball

(1) 1-7/8” socket

(1) Socket extension

(1) Torque wrench capable of reaching torque recommended by hitch

ball manufacturer, approximately 420 ft-lb

5

A Product of Progress Mfg. Inc.

Important Safety Information

Failure to follow all safety warnings may result in severe injury or death.

Read, understand, and follow all safety warnings, setup, use, and

maintenance instructions of your trailer, tow vehicle, and hitching

equipment before installing your hitch or towing your trailer.

Never cut, weld, grind, bend, or modify hitch components in any way.

It is the driver’s responsibility to adjust equipment and driving habits to

match towing conditions. The driver is responsible for their own safety and

the safety of passengers.

Never exceed the specified weight ratings for the trailer, tow vehicle, hitch,

hitch ball, or any other towing equipment.

No hitch setup guarantees that trailer sway will be altogether avoided.

Always load trailer correctly. Follow trailer and tow vehicle manufacturer’s

recommendations for placement and quantity of cargo.

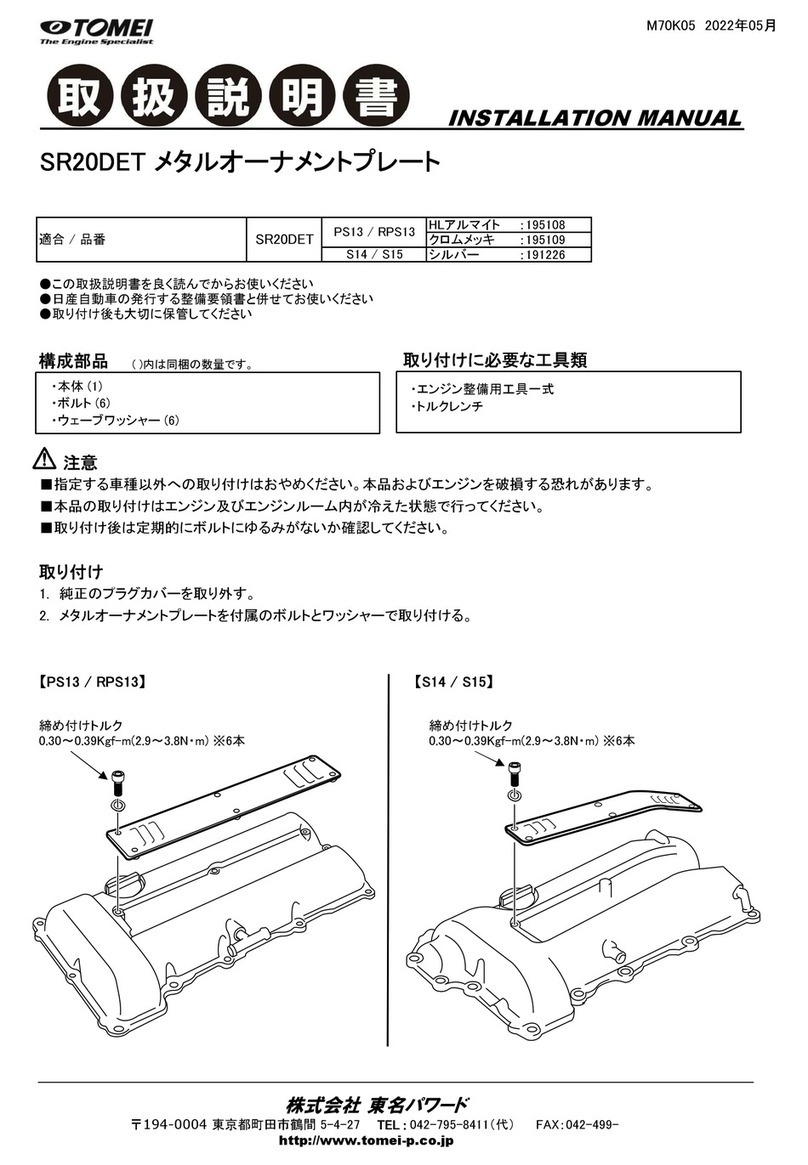

Warning Stickers

Bar Sticker

(not actual size)

Head Sticker

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

WARNING

WARNING

Improper setup can cause severe injury or death.

• Read and follow owner’s manual at all times.

• Check for proper setup before towing.

E2TR_0719

1,000 lb maximum tongue weight

10,000 lb maximum trailer weight

For a copy of the instructions visit

fastwaytrailer.com

The e2

™

hitch is a product of Progress Mfg. Inc.

Meets V5 and SAE standards.

92-00-1000

Fastway e2 - Faster, Easier™

Fastway e2 - Faster, Easier™

92-00-1000

92-00-1000

6fastwaytrailer.com

Towing with a tongue weight more than 15% or less than 10% of gross trailer

weight greatly increases the likelihood for loss of vehicle control.

Always use a hitch ball with a rating that equals or exceeds the trailer Gross

Vehicle Weight (GVW). Always use a hitch ball size that correctly matches

your trailer coupler size and make sure it is coupled securely before towing.

Measuring weight distribution setup well does not ensure safe towing. The

operator is responsible for making necessary adjustments to the hitch to

optimize weight distribution and sway control. Each trip is different, and the

weight distribution setup and towing performance should be evaluated by

the operator and adjusted when necessary.

Never tow with your hitch adjusted incorrectly.

Check all hardware before each trip. Do not tow your trailer until all bolts

and nuts have been checked for wear and fatigue, are properly tightened,

and all pins and clips are securely in place.

Do not tow with your hitch engaged on rough roads, through profound

ditches, dips, or swales, or while launching a boat if you need more rear

wheel traction. Excessive strain on the spring bars and hitch head may cause

hitch fatigue or failure.

If your dealer installed your hitch, verify that it is still adjusted correctly

after loading your trailer and tow vehicle for your trip.

Replace worn, faded, or unreadable warning stickers on the hitch.

Do not transfer hitch to a different tow vehicle or trailer without adjusting

the hitch for proper setup and weight distribution.

Do not loosen or remove any part of the hitch while the hitch is under load.

Use the tongue jack to take the tension off the weight distribution bars

before removing the L-pins.

Always secure the tow vehicle and trailer with the parking brake and wheel

chocks before setting up or adjusting the hitch.

Disengage weight distribution before towing or backing the trailer where

there is a significant transition in grade which puts excessive strain on the

hitch, e.g. backing from a flat street to a steep uphill driveway.

ATTENTION

ATTENTION

ATENCIÓN

ATENCIÓN

CAUTION

CAUTION

7

A Product of Progress Mfg. Inc.

Important Hitch Information

Weight Distribution

Weight distribution is the ability of a hitch to transfer load from the rear axle of

the tow vehicle to the front axle of the tow vehicle and to the trailer axles. Without

weight distribution the tow vehicle teeter-totters on the rear axle of the tow vehicle,

and unloads the front axle. Proper weight distribution transfers weight back to the

front axle, forcing it back to the ground.

Proper weight distribution also adds performance to the built-in sway control feature

of your e2 hitch. As the trailer’s tongue weight gets distributed, it helps generate the

friction needed to defend against trailer sway.

Sway Control

Sway control is a built-in, patent pending feature of your e2 hitch. Unlike old chain

style weight distribution hitches, which do not provide sway control, you do not need

to purchase, install, store, or hook up any additional hardware to get sway control.

You can back up without disengaging the hitch. Once the spring bars are tensioned,

the sway control is in force.

Built-in sway control on the e2 hitch works through the connection between your

weight distribution bars and L-brackets. The force required by the hitch to distribute

weight rests on the L-brackets through the spring bars. The e2 hitch takes advantage

of the steel-on-steel friction generated at these points to defend against trailer sway.

This added friction makes it difficult for the trailer to sway side-to-side while it’s

being towed, as sometimes happens when you encounter a gust of wind or pass a

semi-truck. When set up correctly and properly adjusted for your load, the e2 hitch

will noticeably reduce sway.

Important Setup Information

Every trailer and tow vehicle combination requires a different setup and adjustment

because of factors like trailer weight and length, trailer loading, hitch weight, and

tow vehicle geometry and suspension. It is not likely that a good setup for one vehicle

combination will work well for another. If you change the tow vehicle and/or

trailer, you should change the hitch setup for proper weight distribution and

adjust it when necessary.

You must use your best judgment to determine if changes to the setup are required

to ensure a safe and comfortable towing situation. There is no all-inclusive formula

for setting up or adjusting a hitch that will accommodate each combination of trailer

and tow vehicle possible.

The setup may need to be changed slightly at times to accommodate changes in

8fastwaytrailer.com

Step 2 - Install the Hitch Ball

Never exceed the specified weight ratings for the trailer, tow vehicle, hitch,

hitch ball, or any other towing equipment.

Install a properly-sized hitch ball onto the hitch head. The hitch ball diameter must

match the trailer coupler size.

Select a ball with either a 1” or 1-1/4” diameter threaded shank. If your hitch ball

has a 1” diameter shank you must use an appropriate bushing. Make sure that the

ball has a weight rating equal to or greater than your trailer’s gross vehicle weight

(GVW). Always use a lock washer against the nut, unless otherwise specified by ball

manufacturer. Torque the nut to the ball manufacturer’s specifications.

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

WARNING

WARNING

Step 1 - Ready the Tow Vehicle and Trailer

Check and inflate the tires on both the tow vehicle and trailer to their proper

pressures before setting up the hitch.

Park the trailer and tow vehicle on level ground and in line with each other. Chock

and uncouple the trailer. Pull the tow vehicle forward to allow about five feet of

working area in front of the trailer, and set the parking brake.

Ideally, when installing or adjusting the hitch, the tow vehicle and trailer should be

loaded just as they will be while traveling. This includes full propane and fresh water

tanks, and any other cargo (passengers & gear) the tow vehicle or trailer will carry,

including ATVs for toy haulers. If fully-loaded is not possible, set the hitch up for the

trailer as-is, and make adjustments later if needed.

If your tow vehicle is equipped with an auto-leveling suspension, or suspension air

bags, carefully read and follow the instructions in Appendix C - Installing With

Auto-Level/Air Bags on p. 28 as you set up and use your hitch. Also review your

tow vehicle owner’s manual for specific information about using your auto-leveling

system while towing.

your trailer load, perhaps even during the same trip. For example, a trailer that

starts with full clean water and propane tanks may tow differently when that water

becomes black and grey water, and the propane tanks are empty. Or, a trailer loaded

with gear for a long cross-country trip may tow differently than the same trailer

loaded for a weekend getaway. The driver must be conscious of these changes, and

adjust the hitch accordingly.

9

A Product of Progress Mfg. Inc.

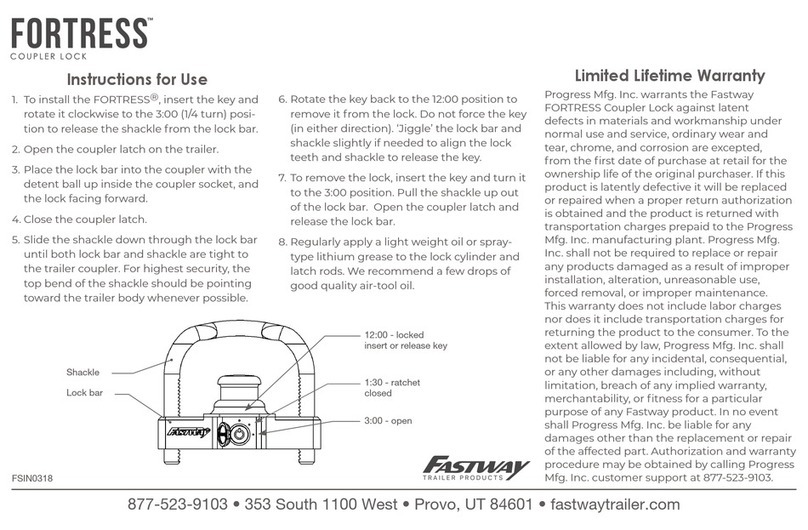

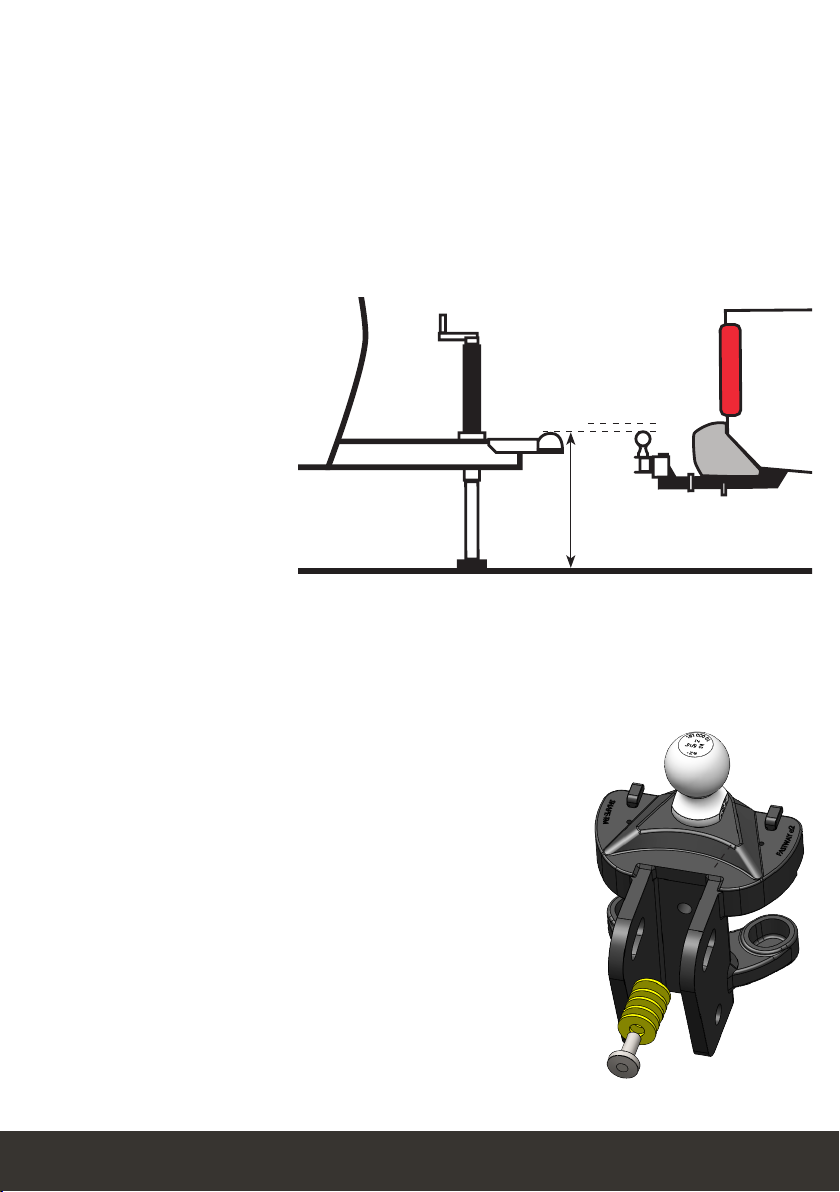

Step 3 - Attach Hitch Head to Shank

Level the Trailer

Measure from the ground at the front and back of the trailer frame, and adjust the

trailer to be parallel to the ground (both front and back measurements should be the

same).

With the trailer parallel

to the ground, measure

to the top of the trailer

coupler. The top of the

hitch ball should be

initially placed between

0” and 1” above this

height. See Figure 1.

Attach Head to Shank

Insert the adjustable

shank into the receiver on

the tow vehicle and secure

it with the hitch pin and

clip.

Insert the spacer rivet

with the spacer washers

into the back of the hitch head to set the angle of the

hitch head. See Figure 2. Start with 6 spacer washers for

most setups. If your actual tongue weight is greater than

90% of the hitch’s max tongue weight rating (e.g. TW >

900 lb on a 1,000 lb hitch), you may want to start with 7

spacer washers, or more as the tongue weight approaches

the maximum hitch rating. Some setups with lighter

tongue weight may only need 5 spacer washers.

Slide the bolt channel around the shank and hold the

hitch head so that the top of the hitch ball is located

between 0” and 1” above the coupler height.

Hitch balls require a 1-7/8” socket and a torque wrench capable of approximately

420ft-lb torque for installation. Your nearest Fastway e2 hitch dealership will have

the tools needed and will usually install the hitch ball for a reasonable fee.

Figure 1 - Set top of hitch ball height between 0”

and 1” above the top of the coupler height, with the

trailer parallel to the ground.

Figure 2

10 fastwaytrailer.com

Insert a 3/4” shank bolt with a conical toothed

washer through the bottom hole in the bolt

channel and corresponding shank hole to hold

the head at the correct height. The teeth of the

washers should be against the bolt channel.

Slide another conical toothed washer, then nut

onto the other side of the bolt, and hand-tighten

them. Then repeat this process for the top shank

bolt. See Figure 4.

Figure 5

Figure 4

Figure 3

In some cases, the shank may need to be turned

upward, or a specialty length shank may be

needed so the ball can be placed at the correct

height. See Figure 3.

Use a wrench to tighten the angle set bolt until

it comes into contact with the shank and lifts the

head to where the spacer rivet also comes into

solid contact with the shank. Tighten the angle

set bolt an additional 1/2 turn. The hitch head

should be angled down slightly. See Figure 5.

The shank bolts will be fully tightened at the

end of the set up and adjustment process.

Extended bumper guards, truck campers, or

rear mounted spare tires can limit your turning

radius, and may lead to a collision between the

tow vehicle and trailer in a tight turn unless a

longer shank is used. If you are not able to turn

tightly with the standard length shank, consult

with your dealer about purchasing a longer

specialty shank.

11

A Product of Progress Mfg. Inc.

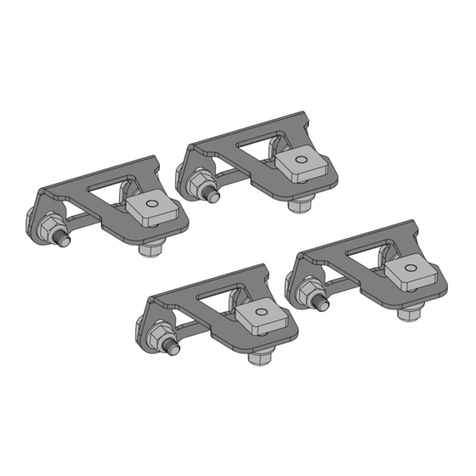

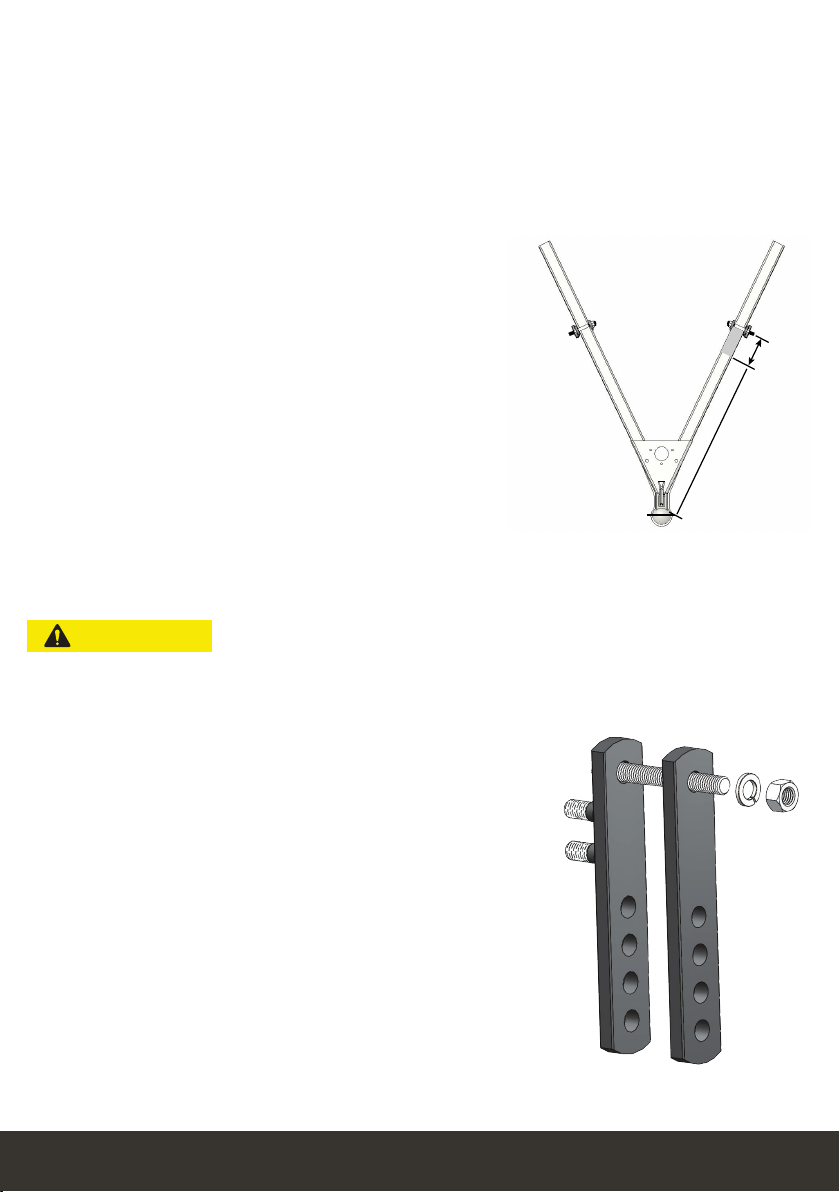

Step 4 - Sway Control Bracket Assembly

Sway Bracket Location

Measure from the center of the coupler along the trailer frame, and place a mark at

30” on both sides. This is the center mark for the sway control bracket assembly.

Make sure there are no gas lines, brake lines, or electrical wires located along the

frame that could be affected by the installation of the link plates. If so, re-route

or avoid the lines so their function will not

be disrupted or damaged by the link plate

installation.

Placing the sway control brackets centered at

30” back puts the least amount of stress on the

trailer and hitch components, and provides the

most comfortable ride. Sway brackets should be

placed at 30” whenever possible.

In some cases where there is an obstruction at

30” that cannot be avoided, like a battery rail

or propane tank support, the brackets may be

moved forward up to a minimum distance of

27” from the center of the coupler. See Figure 6.

27” min / 30” max

Figure 6

Assemble Link Plates

Insert one 1/2” x 4” bolt through the single hole

of the outside link plate so it goes through in the

opposite direction of the L-bracket mounting studs.

Insert the same bolt through the single hole on the

inside link plate. Slide on a split washer, and then

thread on a 1/2” nut a few turns. See Figure 7.

ATTENTION

ATTENTION

ATENCIÓN

ATENCIÓN

CAUTION

CAUTION

Do not use an impact wrench to tighten the link plate or L-bracket bolts.

Figure 7

12 fastwaytrailer.com

Insert the second bolt tight against the frame through the link plates from the

outside in. Slide on a split washer, then thread a 1/2” nut onto the bolt.

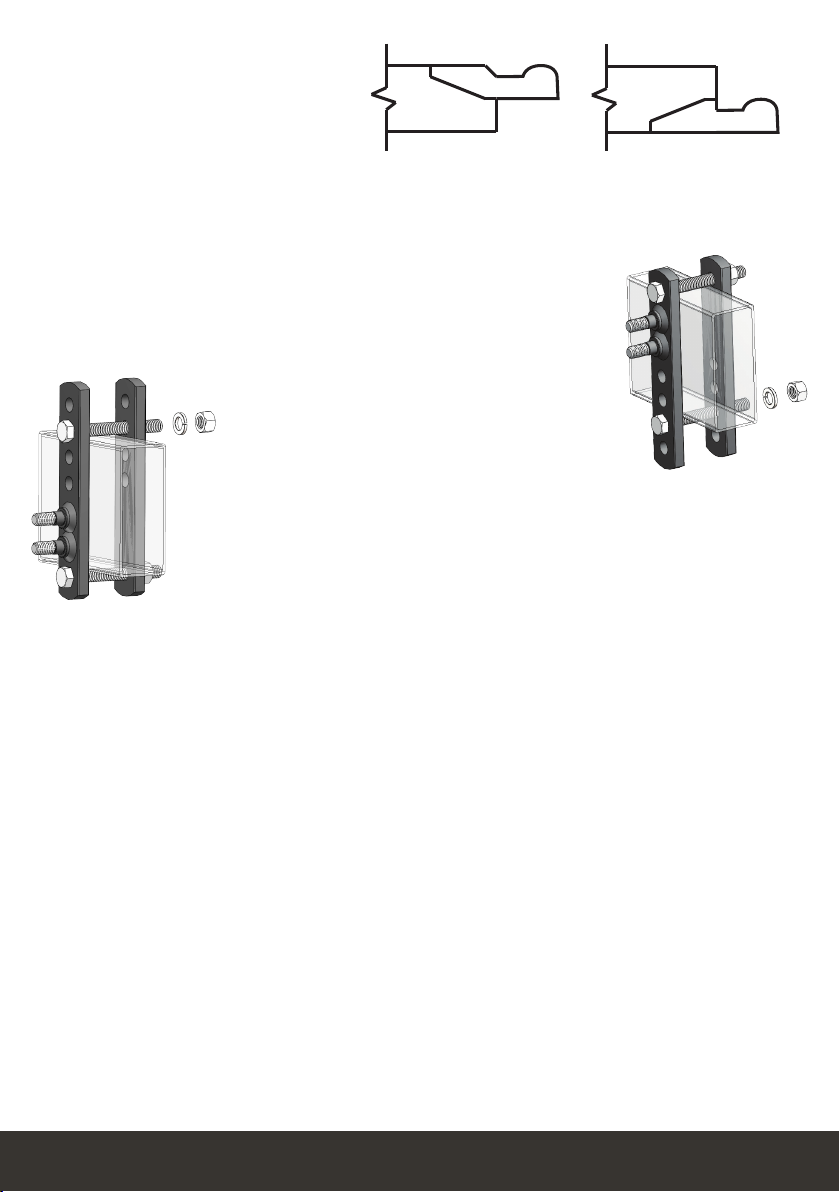

Bottom-mount Couplers

If your trailer has a bottom-mounted

coupler, is a V-nose trailer, or has

some other obstacle that makes installing the link plates in

the upright position difficult, install the link plates upside

down so that the single hole is below the trailer frame, and

the L-bracket studs are toward the bottom of the frame. See

Figure 10.

Top-mount Couplers

Place the link plates so the single hole is above the trailer

frame, and the L-bracket studs are toward the top of the

frame on the outside. See Figure 9.

Identify your coupler style.

See Figure 8.

Figure 10

Figure 9

Top-mount Bottom-mount

Figure 8

13

A Product of Progress Mfg. Inc.

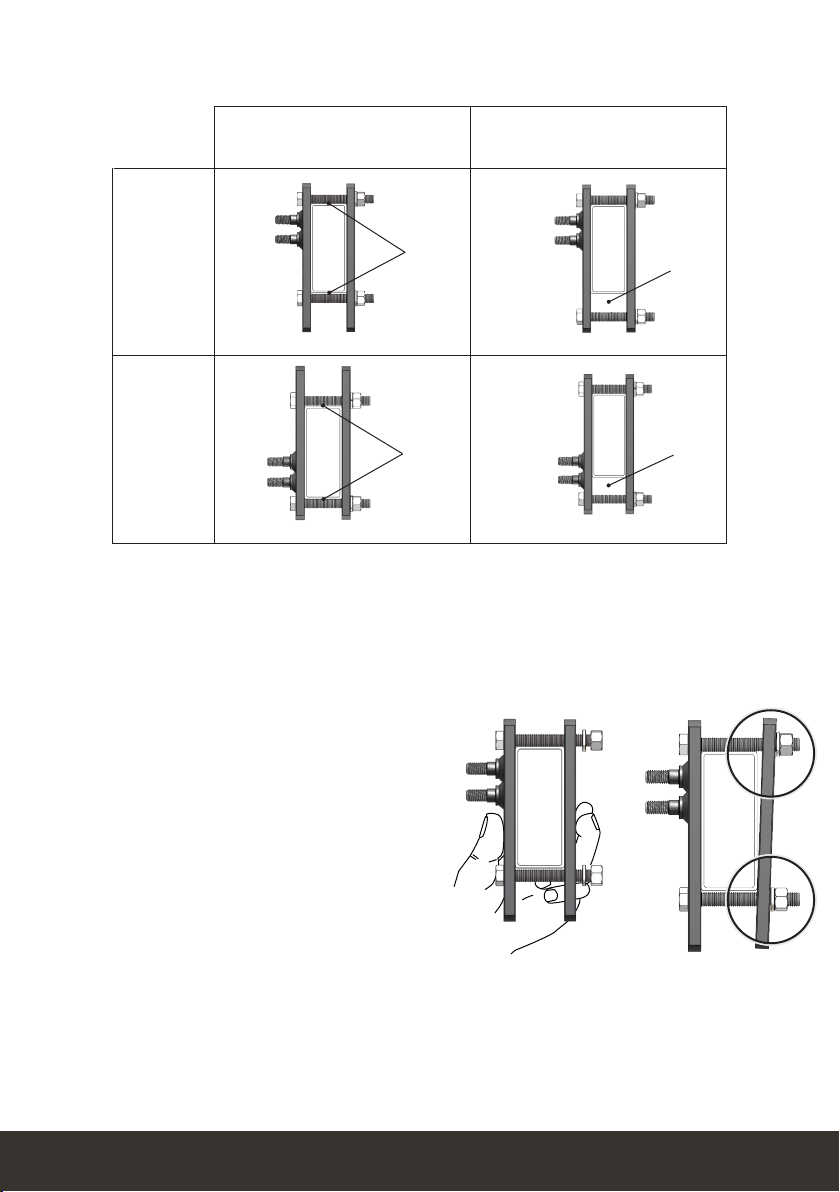

Pinch the link plates tight to the trailer frame so both lay flat against the frame, and

hand-tighten the nuts on the inside. See Figure 12.

Tightening only one nut without first

pinching the link plates to the frame may

cause the inside link plate to bend when

torqued completely. It may also give you

a torque wrench reading that indicates

the link plates are tight, even though they

are not. See Figure 13.

Use wrenches to finish tightening the

link plate bolts until they are snug,

alternating from top to bottom bolt,

1/2 turn at a time. The link plate bolts

should be torqued to 65ft-lb. Figure 12

Correct

Figure 13

Incorrect

Figure 11

Bottom-mount

coupler or

V-nose trailer

Top-mount

coupler

Incorrect - Gap Between

Frame and Bolt

Correct - No Gaps

There should not be a gap between the trailer frame and the link plate bolts above

or below the frame. See Figure 11. Move electrical or propane lines if necessary.

14 fastwaytrailer.com

L-bracket Installation

For the first setup, slide the L-brackets onto the link plate studs with the studs in

the two center holes, with the friction plate facing away from the trailer. They may

need to be adjusted up or down later to get good weight distribution. Thread on the

nylock nuts and tighten them. See Figures 14 and 15.

When the weight distribution setup is complete, L-bracket nuts should be torqued to

75ft-lb.

Step 5 - Spring Bar Installation

Apply a thin layer of bearing grease to the top and bottom knuckles of the trunnion

spring bars. The bars will fit either side of the hitch; they are not side-specific. See

Step 10 - Regular Maintenance. Holding the bar perpendicular to the vehicle, place

the bottom knuckle into the bottom socket of the hitch head, then roll the bar until

the top knuckle passes the locking tab and is inserted into the top socket. See Figures

16 and 17. Repeat for the 2nd bar.

Figure 14 - Initial position for top-

mounted coupler.

Figure 15 - Setup for bottom-

mounted coupler.

Figure 17Figure 16

Grease

here

15

A Product of Progress Mfg. Inc.

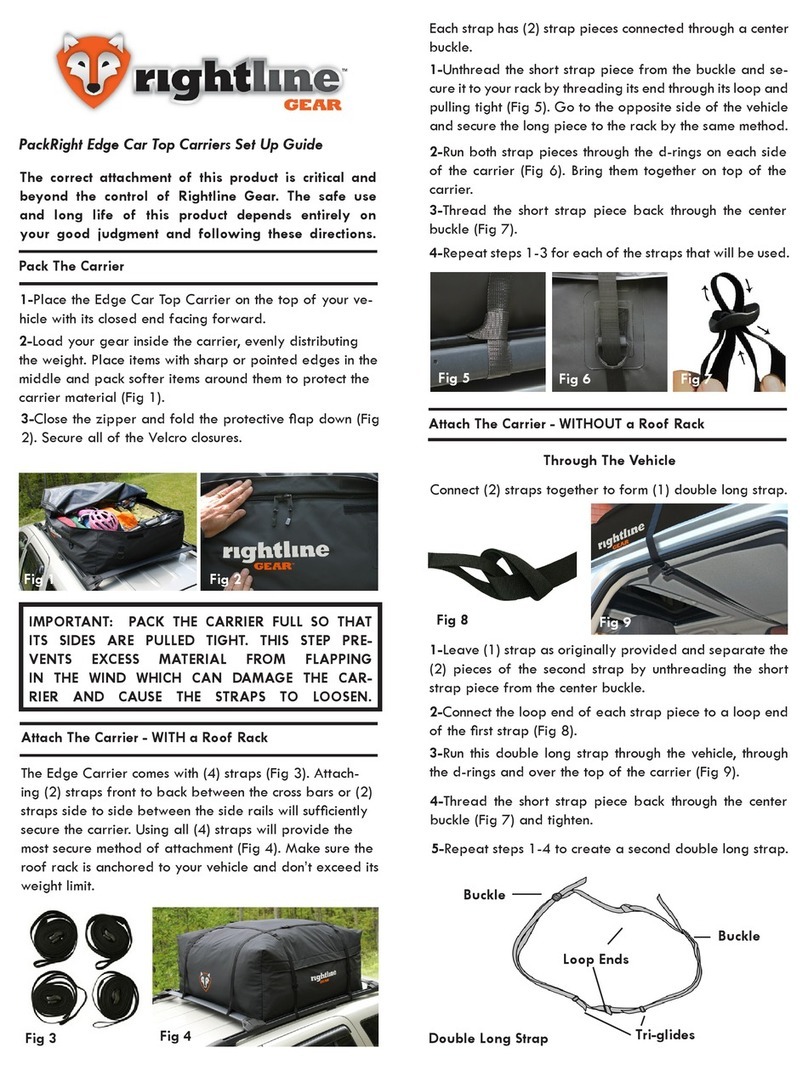

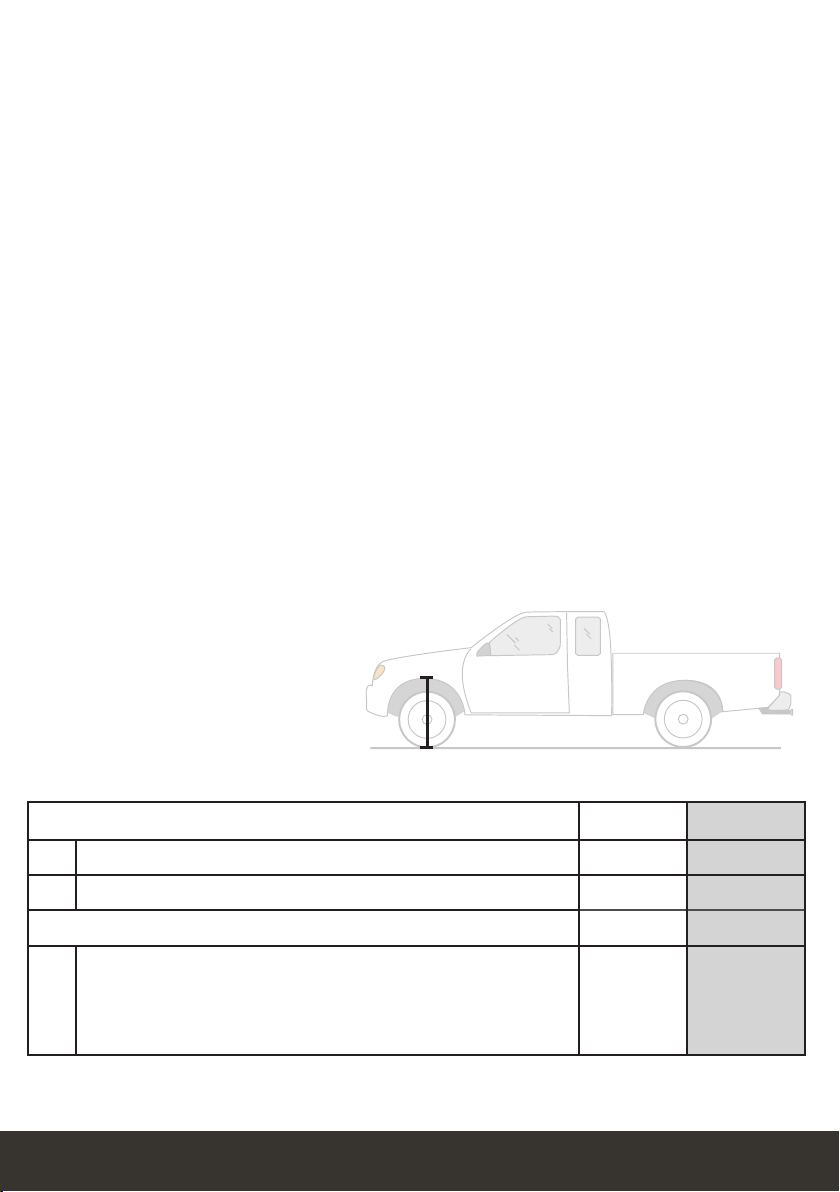

Measure from the ground

to fender through the

center-line of the axle.

RearFront

Figure 18

Weight Distribution Setup Table FRONT Example

ATow vehicle loaded for trip but still uncoupled from trailer 28”

BTrailer coupled but NO weight distribution 30”

Calculate height halfway between A and B (A+B)÷2=

29”

C

Trailer coupled with weight distribution engaged. Should

be at least halfway back to line A. Higher than this

may still be under adjusted. Lower than line A is over

adjusted. See Step 7 - Weight Distribution Adjustments.

28”-29”

Good

__________

29”-30”

Need More

Release the bars by lifting the locking tab and rolling the bar out of the top socket of

the hitch head.

Frequently apply a thin coat of bearing grease to the area of the spring bar knuckles

where they rub inside the hitch head sockets to reduce wear and make insertion

easier. This will also reduce hitch noise.

It is not necessary to apply lubricant to the joint where the spring bars rest on the

L-bracket. This may decrease the amount of sway control provided by the hitch.

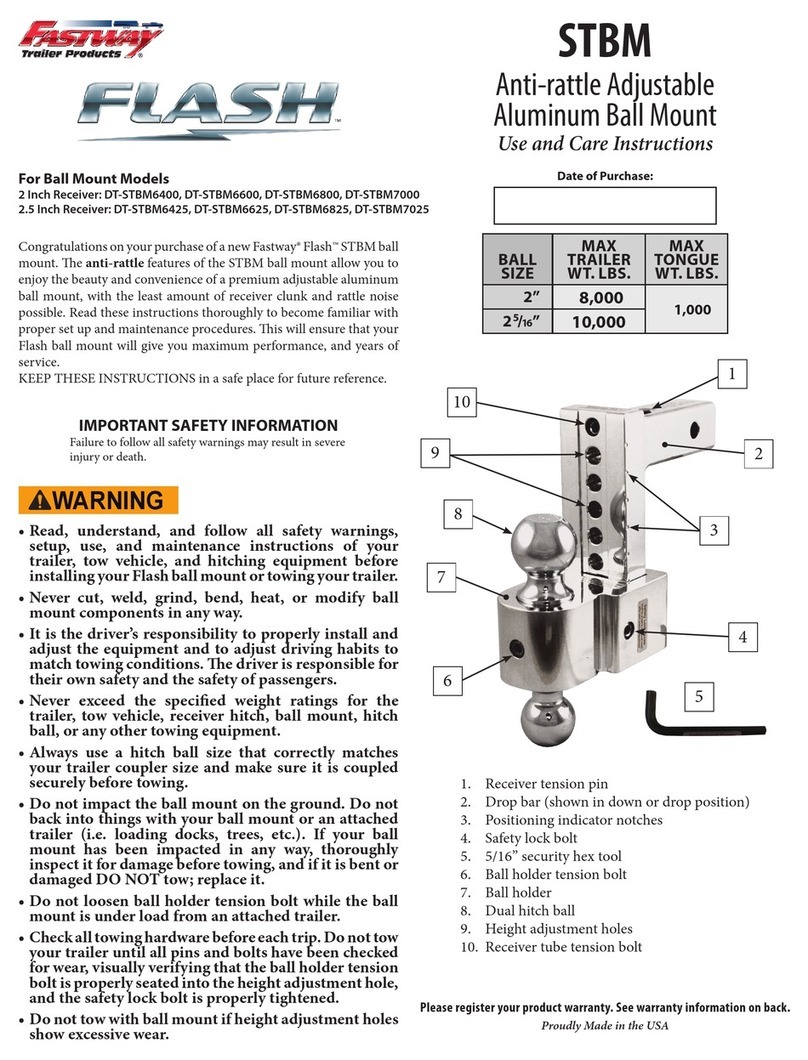

Step 6 - Weight Distribution Setup

Before starting the weight distribution setup, turn off or disable the auto-level

system. See Appendix C, p. 28.

Good weight distribution is a critical component of the e2 hitch setup to get the best

performance from your hitch. Every tow vehicle and trailer combination will react

differently to weight distribution.

To correctly set up weight distribution you must take three measurements at the

front of your tow vehicle. See Figure 18. First, measure without the trailer coupled.

Next, measure with the trailer coupled, but with no weight distribution. Third,

measure with the trailer coupled and the spring bars in place.

16 fastwaytrailer.com

If you reach the top of the jack before the spring bars will swing into position, you

can use the Snap-up lever to lift the spring bars up and onto the L-brackets. Use the

L-pins to secure the spring bars on the L-brackets. See Figures 20 and 21.

With the spring bars resting on the L-bracket and the trailer and tow vehicle in line

with each other, check

to make sure there is a

minimum of 3” from

the end of the spring

bars to the center of the

L-brackets. See Figure 22.

If necessary, unload the

spring bars, then move

and tighten the sway

control bracket assembly.

Start by measuring the distance from the ground to the wheel well directly above the

front axle with the trailer uncoupled. Measure both driver and passenger sides,

and use the average of these two. Record this on line A of the weight distribution

setup table. A temporary piece of masking tape placed on the fender gives a clean

edge to measure to.

Back the tow vehicle to the trailer and lower the coupler onto the ball. Lock the

coupler and retract the tongue jack until it raises off the ground about 1”, so the full

tongue weight of the trailer is resting on the hitch ball.

Measure the tow vehicle height again exactly above the front axle, to the same point

that you measured to earlier when uncoupled. Record this on line B of the weight

distribution setup table on p. 15.

With the tow vehicle still coupled to the trailer, use the tongue jack to lift both

vehicles until you can swing the spring bars into place over the L-brackets. See

Figure 19. Then, retract the jack.

Figure 20 Figure 21

Figure 19

17

A Product of Progress Mfg. Inc.

Step 7 - Weight Distribution Adjustment

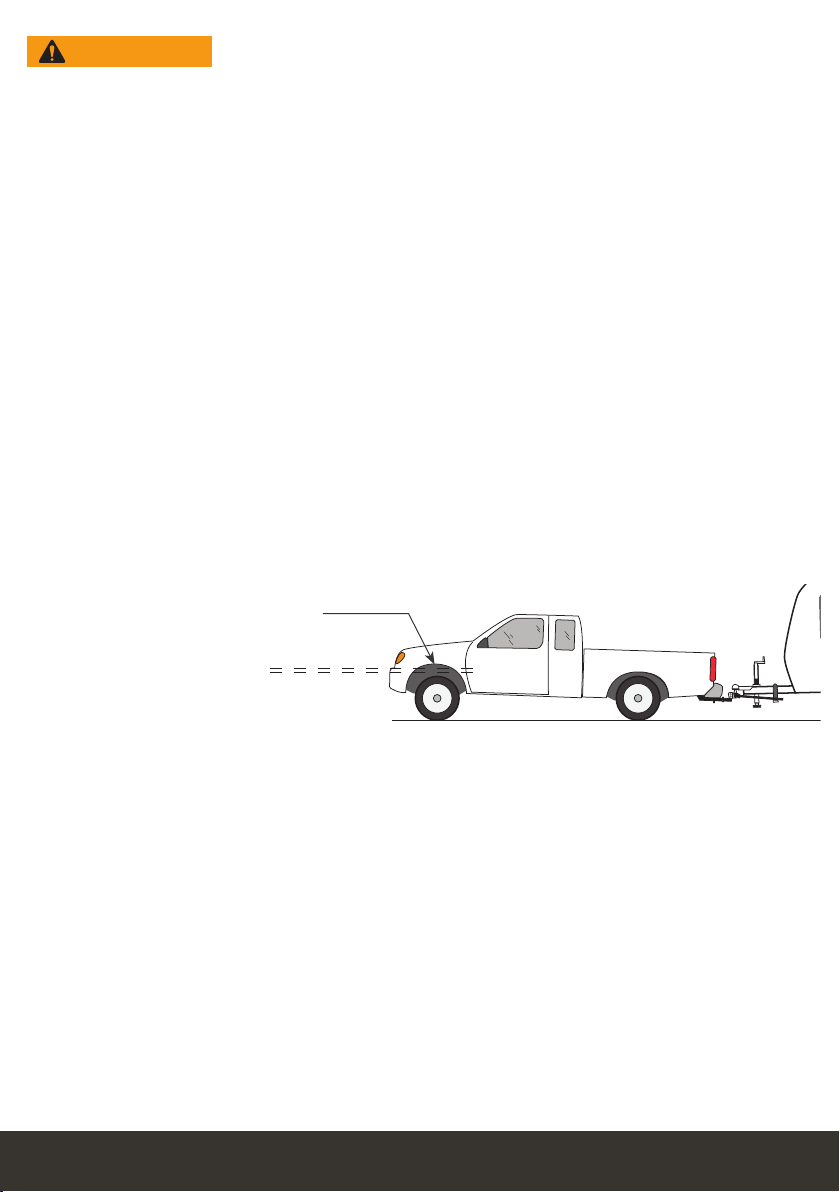

Weight distribution is only one of many things that influences sway. The

operator is responsible for making necessary adjustments to all contributing

factors in order to minimize sway.

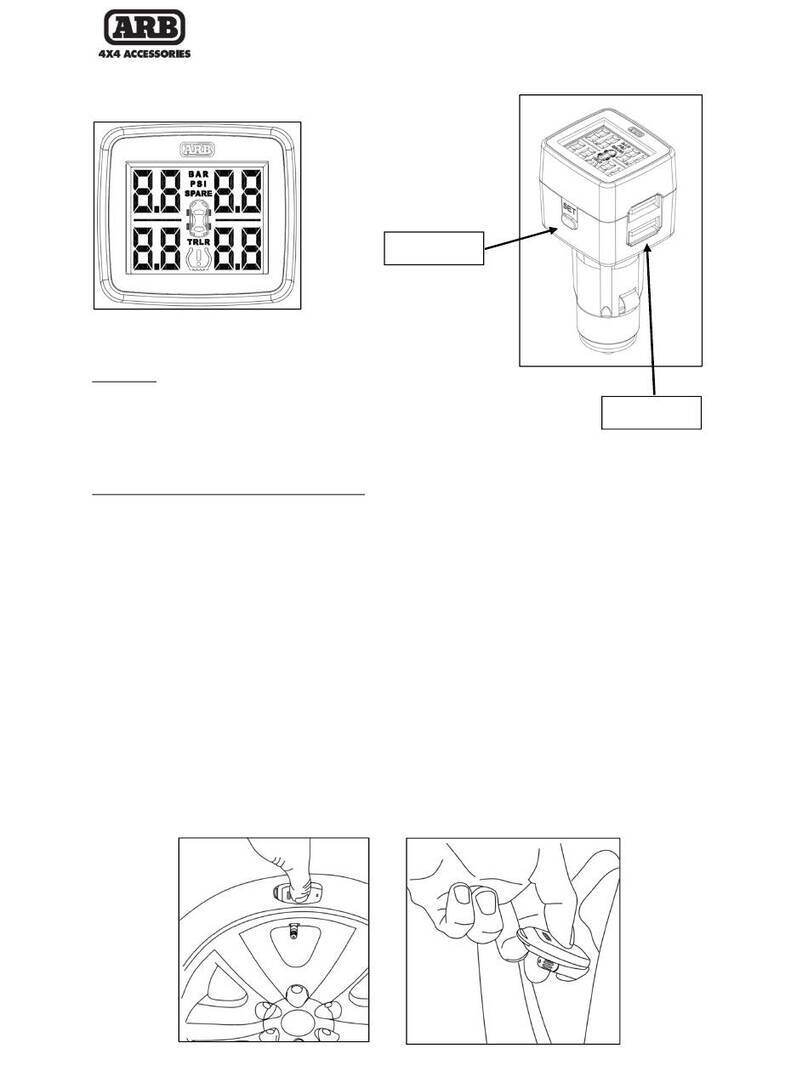

Good adjustment:

You have most likely achieved good weight distribution adjustment if your

measurement on line C of the weight distribution setup table shows that front wheel

well measurement is at least halfway back to the original uncoupled measurement.

See line C on Weight Distribution Setup Table (p. 15) and Figure 23 below.

With the trailer coupled and weight distribution

engaged (spring bars in place and jack retracted),

measure the front wheel well height exactly as done

before for lines A and B. Record this new measurement

on line C of the weight distribution setup table on p. 15.

good

adjustment

needs more

weight distribution

See Weight Distribution

Setup Table on p. 15.

Figure 23

A uncoupled

C halfway back with WD

B coupled - no WD

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

WARNING

WARNING

Figure 22

3”

18 fastwaytrailer.com

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

WARNING

WARNING

If the measurement on line C is still higher than the calculated halfway point, you

need more weight distribution adjustment (see line C on Weight Distribution Setup

Table, Figure 18). With an under-adjusted setup your hitch is not unloading the rear

axle sufficiently, giving back as much steering control as it could, nor is it providing

as much friction as it could to help reduce trailer sway.

To correct under adjustment you must add more weight distribution force to the

hitch by adding spacer washers, or raising the L-brackets.

If this is the initial set up, use the tongue jack to unload the spring bars. Remove

the spring bars from the hitch head. Uncouple the trailer and pull the tow vehicle

forward. Remove the hitch head and add a spacer washer. Repeat step 6 and 7 to

readjust and check weight distribution.

Over or under adjusted weight distribution decreases tow vehicle stability.

Fixing Under or Over Adjustment:

If the hitch is transferring too little or too much weight, you must make adjustments

to the hitch setup. For changes during the initial setup we recommend adding or

removing spacer washers first to try and keep the spring bars parallel with the trailer

frame. This gives you more adjustment options later if needed, and may also reduce

some noise.

Once the maximum (9) or minimum (5) number of spacer washers has been

reached, further adjustments can be made by raising or lowering the L-brackets.

Minor adjustments later for changes in loading can usually be done by moving only

the L-brackets.

The distance from the tow vehicle rear axle to the hitch ball significantly affects

how the tow vehicle reacts to weight distribution adjustments. The same washer or

L-bracket change will have varying results on different vehicles.

Under adjustment occurs when there is not enough weight being transferred to the

front axles of the tow vehicle. See Figure 24.

Figure 24 - Under-adjustment

Good adjustment

(line C target)

Wheel well

measurement too high

19

A Product of Progress Mfg. Inc.

If you have reached the maximum number of spacer washers (9), or if adjusting

temporarily due to a change in vehicle loading, use the tongue jack to unload the

spring bars. Raise the L-brackets one hole. Move the spring bars back over the

L-brackets and retract the tongue jack. Measure the wheel wells and check for

proper weight distribution.

Repeat Steps 6 and 7 until the measurements show that the hitch is distributing

weight well.

Over adjustment occurs when there is too much weight being transferred to the

front axle of the tow vehicle. See Figure 25.

Figure 25 - Over-adjustment

Wheel well measurement

too low

Good adjustment

(line C target)

If Cis lower than A, you need less weight distribution adjustment (see line C on

Weight Distribution Setup Table, Figure 18).

Overadjustment is a very dangerous situation where loss of control and jack-knifing

is possible, especially in wet or slick road conditions and/or with heavy trailers.

To correct over adjustment you must take some of the weight distribution force out

of the hitch by removing spacer washers, or lowering the L-brackets.

If this is the initial set up, use the tongue jack to unload the spring bars. Remove the

spring bars from the hitch head. Uncouple the trailer and pull the vehicle forward.

Remove the hitch head and remove a spacer washer. Repeat Steps 6 and 7 to adjust

and check weight distribution.

If you have reached the minimum number of spacer washers (5), or if adjusting

temporarily due to a change in vehicle loading, use the tongue jack to unload the

spring bars. Lower the L-brackets one hole. Move the spring bars back over the

L-brackets and retract the tongue jack. Measure the wheel wells and check for

proper weight distribution.

Repeat Steps 6 and 7 until the measurements show that the hitch is distributing

weight well.

20 fastwaytrailer.com

Step 9 - Final Tightening

Do not tow your trailer until all bolts and nuts have been checked and

properly tightened, and all pins and clips are securely in place.

Towing with loose bolts for an extended period of time can cause abnormal

stress on the hitch resulting in accident, severe injury, and property damage.

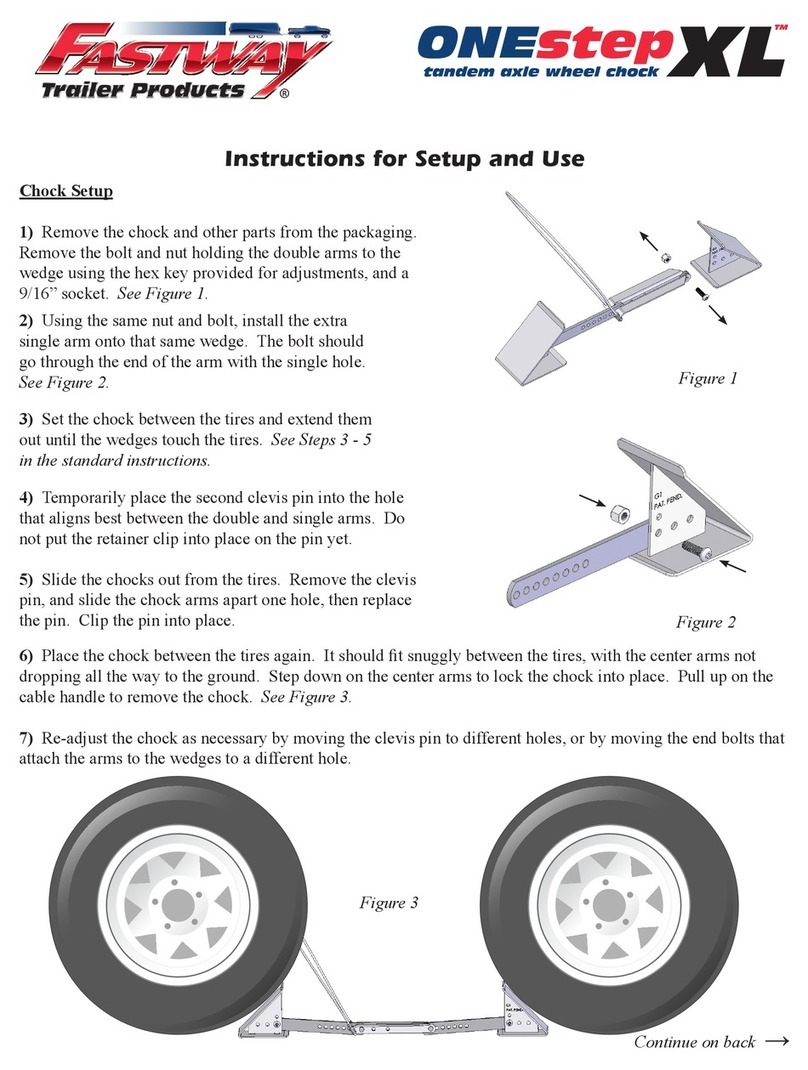

Step 8 - Trailer Pitch Adjustment

After achieving a good weight distribution setup you may need to adjust the pitch

(angle or attitude) of the trailer. Step back and look at the trailer to see if the front

appears to be tipped up or down excessively.

Measure the front and rear of the trailer again at the same points you did when

setting the trailer parallel to the ground in Step 3. Record these measurements on

the Trailer Pitch Adjustment chart. See Figure 26.

Find the difference between the front and rear heights.

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

WARNING

WARNING

Figure 26

Trailer Pitch Adjustment Chart Actual Example

Highest Measurement 20

Lowest Measurement -- 18

Difference between highest and lowest 2

If the difference between the highest and lowest measurement is 1-1/4” or more,

adjust the hitch ball height. If it is less than 1-1/4” different, complete Step9 and tow

a short distance with this setup to see how it handles before making any adjustments.

If the higher measurement is the front of the trailer, move the hitch head down one

hole position on the shank. If the lower measurement is the front of the trailer, move

the hitch head up one hole position on the shank.

Adjustments made to the ball height affect how weight is distributed. Moving it up

slightly reduces the amount of weight distribution you get from a particular setup.

Moving it down slightly increases the weight distribution from that same setup.

After making an adjustment to the ball height, return to Step 6 and 7 to check the

weight distribution measurements again. Adjust the weight distribution if necessary

until it falls within the guidelines. Check the trailer pitch again to see the difference

made by moving the hitch ball height. You may need to try several setups before you

get one that achieves good weight distribution and trailer pitch.

This manual suits for next models

4

Table of contents

Other Fastway Automobile Accessories manuals