FATEK M Series User manual

INDEX

M Series PLC Expansion Module User Manual

INDEX

Chapter 1 List of Expansion Modules......................................................11

Chapter 2 Expansion of M-Series PLC ......................................................1

2-1 I/O Expansion Specifications .................................................................................................2

2-2 Digital I/O Expansion and I/O Channel Numbering.................................................................3

2-3 Analog I/O Expansion and I/O Channel Numbering ...............................................................5

2-4 Expansion Module Configuration Settings..............................................................................8

2-5 Expansion Module Firmware Update ...................................................................................10

Chapter 3 Installation and Wiring...............................................................1

3-1 Environmental Specifications .................................................................................................2

3-2 Installation Precautions..........................................................................................................3

Chapter 4 Power Wiring, Power Consumption Calculation, and Power

Sequence Requirements ................................................................................1

4-1 Specifications and Wiring of AC Power Module......................................................................2

4-2 Maximum Current Consumption of Expansion Module...........................................................5

4-3 Calculation Example of Power Capacity.................................................................................7

4-4 Requirement of Power Sequence in CPU Module & Expansion Module ................................8

Chapter 5 Digital Input Circuit....................................................................1

5-1 Digital Input Circuit Specifications ..........................................................................................2

5-2 24VDC Single-End Input Circuit and Wiring for SINK/SOURCE Input ....................................3

Chapter 6 Digital Output Circuit.................................................................1

6-1 Digital Output Circuit Specifications .......................................................................................2

6-2 Single-End Output Circuit.......................................................................................................3

6-3 Speed up the Single-End Transistor Output Circuit ................................................................6

6-4 Output Device Protection and Noise Suppression in DO Circuit.............................................7

Chapter 7 Left Side Expansion Module Specifications ............................1

7-1 Power Module Specifications .................................................................................................2

Chapter 8 Right Side High Speed Expansion Module Specifications .....1

8-1 High Speed Communication Expansion Module Specifications..............................................2

Chapter 9 Right Side Expansion Module Specifications........................1

9-1 Digital Input Expansion Module Specifications .......................................................................2

9-2 Digital Output Expansion Module Specifications ....................................................................5

9-3 Digital Input /Output Combo Expansion Module Specifications ............................................10

9-4 Analog Input Expansion Module Specifications....................................................................15

9-5 Analog Output Expansion Module Specifications .................................................................21

9-6 Analog Input/Output Combo Expansion Module Specifications............................................27

9-7 Temperature Expansion Module Specifications....................................................................31

9-8 Temperature Combo Expansion Module Specifications........................................................35

9-9 Load Cell Expansion Module Specifications.........................................................................38

Chapter 10 Left Side Expansion Dimensions............................................1

INDEX

M Series PLC Expansion Module User Manual

10-1 Power Module Dimensions ....................................................................................................2

Chapter 11 Right Side High Speed Expansion Dimensions.....................1

11-1 High Speed Communication Expansion Module Dimensions .................................................2

Chapter 12 Right Side Expansion Dimensions .........................................1

12-1 Digital Input Expansion Module Dimensions ..........................................................................2

12-2 Digital Output Expansion Module Dimensions........................................................................3

12-3 Digital Input/Output Combo Expansion Module Dimensions ..................................................5

12-4 Analog Input Expansion Module Dimensions .........................................................................6

12-5 Analog Output Expansion Module Dimensions ......................................................................8

12-6 Analog Input/Output Combo Expansion Module Dimensions ...............................................10

12-7 Temperature Expansion Module Dimensions .......................................................................11

12-8 Temperature Combo Expansion Module Dimensions...........................................................13

12-9 Load Cell Expansion Module Dimensions ............................................................................14

12-10 End Module Cover Dimensions............................................................................................16

Chapter 13 Expansion Module Troubleshooting.......................................1

13-1 Digital Input Expansion Module Troubleshooting....................................................................2

13-2 Digital Output Expansion Module Troubleshooting .................................................................2

13-3 Digital Input/Output Combo Expansion Module Troubleshooting

13-4 Analog Input Expansion Module Troubleshooting ..................................................................2

13-5 Analog Output Expansion Module Troubleshooting................................................................2

13-6 Analog Input/Output Expansion Module Troubleshooting

13-7 Temperature Input Expansion Module Troubleshooting ..........................................................3

13-8 Temperature Combo Expansion Module Troubleshooting

13-9 Load Cell Expansion Module Troubleshooting

Chapter 14 Repairs and Maintenance..........................................................1

14-1 Precautions............................................................................................................................2

14-2 Daily Maintenance .................................................................................................................3

14-3 Regular Maintenance.............................................................................................................4

Chapter 1 List of Expansion Modules

1

M-Series PLC Expansion Module User Manual

Manual for the FATEK M-Series PLC Expansion Module

Preface

This Manual provides important information related to the use of the FATEK M-Series PLC CPU Module.

Before using the product, be sure to read this Manual carefully in order to get familiar with and understand

its content. Should you have any questions or comments, please contact the FATEK distributor for detailed

warranty services and responsibility limit.

Warranty Service

The warranty period provided by FATEK for its product shall last for one year (or other period as

otherwise agreed) starting from the date when the product is sold and it will be offered under the pre-

conditions that there are no defects in product use.

Please contact FATEK or the local distributor in the event failure occurs on any of the FATEK products for

reasons not caused by man-made factors during the aforesaid warranty period. However, the failure due

to any of the following reasons shall not be covered by the warranty services:

1. The malfunction is due to the user’s failure in following the conditions, environment, operations,

installation and correct wiring method specified in this Manual.

2. The malfunction is due to the user’s failure in following the operating method originally designed.

3. The malfunction is not due to the reasons of the product.

4. The malfunction is not caused by the modification and the maintenance executed by FATEK.

5. The malfunction is caused by other types of

force majeure

factors such as natural disasters or man-

made negligence.

In the meantime, the aforesaid warranty services shall be limited to the FATEK product only and the

losses resulting from the product failure will not be covered in the warranty scope.

Limit of responsibilities

Unless it has been confirmed that the product is properly used, stored, installed and serviced and that it

has not been contaminated, abused, misused or improperly modified or repaired as being analyzed by

FATEK; otherwise, FATEK shall not be liable for any product-related particular damage, consequential

damage or derivative damage or even revenue loss or commercial loss that resulted from whatever

means.

Chapter 1 List of Expansion Modules

2

M-Series PLC Expansion Module User Manual

Precautions on using the product

Compliance with the application-related conditions

The user shall evaluate the suitability of FATEK product and shall install the product in the well-designed

equipment or system.

The user needs to check if the system, machinery or device currently used is compatible with the FATEK

product. If the user fails to confirm the compatibility or the suitability, then FATEK shall not be liable for

the suitability of the product.

When required by the customer, FATEK shall provide correlated third party certification to define the

value rating and the application restrictions that will be applicable for the product. However, the

aforesaid certification message shall not be considered as sufficient to determine the suitability of the

FATEK product, the final product, the machine, the system and other applications or relevant

combinations. Described below are certain applications that should be cautiously treated by the user. In

spite of this, the content described below shall neither be considered as having included all of the

intended product purposes nor suggesting that all of the following purposes shall be entirely suitable

for the product. For example, outdoors use, use in an area subjected to potential chemical

contamination or electrical interference or used under conditions or functions not mentioned in this

Manual or used with the system, machine and equipment that may create risks to life or properties.

Before working with the product, the user will be required to check if the entire system is marked with a

hazard sign and shall select the design that can ensure the safety such as the backup design, etc.

Otherwise, the user shall not be allowed to use the product in the application that will present personnel

and the property safety concerns. In no event shall FATEK be liable for the specifications, statutory

regulations or restrictions that will be used by the customer in the product combination or the product

operations.

When using the CPU Module, FATEK shall not be liable for the programs edited by the user or the

resulting consequences.

Chapter 1 List of Expansion Modules

3

M-Series PLC Expansion Module User Manual

Disclaimers

Dimensions and weight

The dimensions and the weight specified in the manual are nominal values only. Even if provided with

the tolerance, they cannot be used in the manufacturing purposes.

Performance data

The data specified in this Manual mean that the performance data obtained under FATEK’s test

conditions are provided for the user to confirm its compliance only. Therefore, the user is also required

to consider the actual application conditions. Therefore, actual performance shall be defined according

to the content of the guarantee and the limit of responsibilities established by FATEK.

Errors and negligence

The content of this Manual is provided through careful checking process and is considered as correct.

However, FATEK shall not be liable for the errors or the negligence that may be found in the text, printing

content and proofreading.

Change of specifications

The product specifications and accessories may be subject to change along with the technical

improvement or other reasons. In the event that the published specifications or performance need to

be changed or where significant structural change is required, FATEK will change the model number of

the product accordingly. If certain specifications of the product have changed, then FATEK will not give

the notice under the following situation: when it is required to use a special model number or create

particular specifications in order to support the customer’s application according to the instructions

given by the customer. To confirm actual specifications of the product to be purchased, please contact

the local FATEK distributor.

Chapter 1 List of Expansion Modules

4

M-Series PLC Expansion Module User Manual

Precautions for safety

Signs and meaning of safety precautions

The following signs will be used in this Manual in order to provide precautions that will be required for

using the M-Series PLC safely. These precautions are extremely important for using the product safely.

Please read the safety precautions carefully in order to get familiar with and understand the content and

the meaning of the aforesaid instructions.

Warning

Means a potentially dangerous situation that will result in death or serious

injury if not avoided. In the meantime, it may also lead to serious property

losses.

Caution

Means a potentially dangerous situation that may result in minor or

medium level injury or property losses if not avoided.

Means operations that must not be executed.

Means operations that must be executed.

Means general precautions.

Means the precautions relating to hot surfaces.

Means the precautions related to the wiring, grounding and electrocution of the electrical

system.

Chapter 1 List of Expansion Modules

5

M-Series PLC Expansion Module User Manual

Warning

Do not attempt to dismantle any module or touch the internal side of the module when

it is under energized status or it may lead to electrocution injury.

Do not attempt to touch any terminal or terminal board when the module is under

energized status, or it may lead to electrocution injury.

To ensure the system safety in order to avoid abnormal actions that may be caused by

man-made external factors or false actions resulting from the faulty PLC, it is required to

install the following safety measures in the external circuit (not within the PLC

procedure); otherwise, it may lead to serious accident.

The externally controlled circuit must be provided with emergency stop switch,

interlocking circuit, limit switch and similar safety measures. The PLC will stop outputting

the signals when encountering major failure alarm during the operations. However, the

errors in the I/O controller and the I/O register as well as other undetectable errors will

still trigger unexpected actions. To deal with the aforesaid errors, you are required to

install external safety measures to protect the system safety. If the output relay is

jammed, burnt or if the output transistor is damaged, then the PLC may still maintain its

output at the ON or OFF status.

To solve the aforesaid issues, it is required to install external safety measures to protect

the system safety. By installing the corresponding safety measures in the system and the

equipment, it allows you to maintain the safety of the entire system in spite of the fact

that communication errors or false actions have occurred during the operating process.

The user must take corresponding failure preventive measures in order to ensure safety

when the signal line is damaged or when the power is instantly disconnected or when

the signal is wrong, missing or abnormal as may be caused by other reasons. If failing to

taking the appropriate measures, it may lead to improper operations that may result in

serious accidents.

Chapter 1 List of Expansion Modules

6

M-Series PLC Expansion Module User Manual

Precautions

Do not touch the power module when the PLC is under energized status or when the

power source is disconnected. At this time, the power module might still present

extremely high temperature that can cause a scorching injury.

When connecting with the terminal board of the power module, the cable should be

secured with the appropriately sized Ferrule. If the cable is loose, it may lead to

burning or the failure of the power module.

The online editing shall be allowed only after confirming that the extended PLC cycle

duration will not result in any adverse impact or the system may not be able to read

the input signal.

After confirming that the I/O terminal is safe, you may transmit the required

parameters to other terminals such as PLC setting, I/O table and I/O register data,

etc. Otherwise, it may lead to unexpected actions if transmitting or modifying the

aforesaid data before that.

Chapter 1 List of Expansion Modules

7

M-Series PLC Expansion Module User Manual

Precautions for use

When using the M-Series PLC, please observe the precautions provided below.

Using the power

⚫Please use the voltage specified in the Manual. Incorrect voltage will lead to false action or burning

damage to the equipment.

⚫If the number of the module being connected exceeds the current rating of the power module, you

may not be able to start the CPU module or other modules.

⚫Please use the designated power source and then supply the power according to the specified voltage

and frequency rating. Special attention should also be given to the location subjected to unsteady

power supply, as incorrect power supply may result in false action.

⚫Before starting any of the following operations, be sure to disconnect the PLC power; or it may lead

to false action or electrocution injury.

(1) When installing or dismantling power module, I/O module, CPU module or any other type of

module.

(2) When connecting cables or executing the system wiring.

(3) When connecting or disconnecting the connector.

⚫When using the power module, be sure to observe following precautions.

(1) The voltage applied at the equipment output point or the connected load shall not be higher than

the rated specifications established for the power module.

(2) If it is required to put aside the power module for over 3 months, it shall be stored in a cool and

dry location in order to maintain its function at normal status.

(3) If the power module is improperly installed, it will result in the accumulation of heat as to cause the

aging or the damage of the component within. Therefore, it shall be properly connected and you are

also required to use the standard installation method.

Installation

⚫Do not install the PLC at the location near a high frequency noise interfering source.

⚫Confirm that the terminal board, the connector, the memory card, the peripheral communication wires

and other buckle-mounted devices are latched in position. Improper latching will result in false action.

⚫After connecting to the adjacent module, the buckle at the top or the bottom must be securely locked

(

i.e.,

properly latched). If failing to lock the buckle tightly, the module may not be able to achieve the

intended function.

Chapter 1 List of Expansion Modules

8

M-Series PLC Expansion Module User Manual

Wiring

⚫Please follow the instructions provided in the Manual in order to execute the wiring operations

correctly.

⚫Before connecting the power, please check the setting status of all wires and switches. Incorrect

wiring may result in burning damage to the equipment.

⚫After checking the installation position, you may start installing the terminal board and the

connector.

⚫During the wiring process, the label should be tagged on the module. If you tear off the label,

foreign mattes may get into the module as to cause a false action.

⚫To ensure normal heat dissipating function, please tear off the label after completing the wiring

operations. If retaining the label, it may lead to false action.

⚫Please use an EU-standard terminal to execute the wiring operations. Do not connect the terminal

with bare stranded wires. The aging or the breaking of wires may result in burning damage to the

equipment.

⚫The voltage applied to the input module shall not be higher than the input voltage rating or it may

result in burning damage to the equipment.

⚫The voltage or the load applied to the output module shall not be higher than the maximum

switch capacity. The over-voltage or the overload may result in burning damage of the equipment.

⚫Do not drag or bend the cable excessively. Such action may cause the breaking of the cable.

⚫Do not place any objects on the cable or other type of wires or it may cause the breaking of the

cable.

⚫Please set the grounding wire correctly for the power module and communication port to avoid

communication error and equipment malfunction caused by noise interference.

⚫It is recommended to use M series dedicated AC power modules to supply power to MPLC related

modules.

⚫It is recommended to use twisted-pair shielded cables for communication cables and ground them

properly.

Operating

⚫Before supplying power to the MPLC to start the operations, ensure that the setting of the data

register is correct without any mistakes.

⚫Before executing any of the following tasks, confirm that it will not bring about any adverse

impact on the system; otherwise, it may result in unexpected action.

(1) When changing the operating mode of the PLC (RUN Mode/STOP Mode).

(2) When executing compulsory enable/ compulsory disable for any of the data retained in the

register.

(3) When changing the present value of any bit or setting that has been logged in the register.

⚫Do not attempt to dismantle, repair or modify any module; or it may result in false action, fire or

electrocution.

Chapter 1 List of Expansion Modules

9

M-Series PLC Expansion Module User Manual

⚫It is required to protect the PLC from falling or from excessive vibration or impact.

⚫If the I/O is located at the “ON” position, when switching the “RUN Mode” to the “STOP Mode,”

the system will set the PLC output at the “OFF” position and then all output actions will be

disabled. Please ensure that the external load will not generate hazardous factors during the

aforesaid process.

⚫If the CPU module stops running due to catastrophic error, please set all of the output points on

the output module at the “OFF” position. The output status will be retained after being set as

the holding-type memory configuration parameters.

⚫If the status monitoring pages or the parameters are improperly set, it may result in unexpected

action. Even though the status monitoring pages or the parameters are correct, it is also

required to confirm that the controlled system will not be subject to adverse impact before

starting.

⚫When applying maximum level of voltage or when the power supplied to the operating switch is

interrupted suddenly during the Insulation Strength Test, it may result in the damage of the CPU

module. In this case, please use the variable resistor to increase or reduce the voltage level

gradually.

⚫Before conducting the Withstand Voltage Test or the Insulation Resistance Test, please separate

the wire grounding terminal of the power module from the functional grounding terminal.

Otherwise, it may result in burning damage to the equipment.

Chapter 1 List of Expansion Modules

10

M-Series PLC Expansion Module User Manual

Precautions for the application environment

⚫Please follow the instructions described in this Manual for carrying out the installation activities

correctly.

⚫Do not operate the control system in any of the following locations:

(1) The location exposed to direct sunlight.

(2) The location with temperature or humidity exceeding the specified range.

(3) The location vulnerable to dewing effect due to abrupt temperature changes.

(4) The location exposed to corrosive or combustible gases.

(5) The location exposed to dust (especially iron chips) or smoke.

(6) The location exposed to water, oil or chemicals.

(7) The location vulnerable to impact or vibration.

⚫When installing the system in any of the following locations, appropriate and effective

preventive measures should be taken:

(1) The location exposed to electrostatic or other type of noise.

(2) The location exposed to strong electromagnetic field.

(3) The location that may be exposed to radioactive pollution.

(4) The location near the power supply source.

Chapter 1 List of Expansion Modules

11

M-Series PLC Expansion Module User Manual

1

List of Expansion Modules

Chapter 1 List of Expansion Modules

12

M-Series PLC Expansion Module User Manual

List of Expansion Modules

Module Name

Specifications

Left Side Expansion Modules

Power Modules

MPA024-24

Input: 100~240VAC(50/60Hz),output: 24VDC 1A(Shared CPU dedicated power

supply and external Sensor power supply),Max. Power Consumption 24W.

MPA048-24

Input: 100~240VAC(50/60Hz),output: 24VDC 2A(Shared CPU dedicated power

supply and external Sensor power supply),Max. Power Consumption 48W.

Right Side Expansion Modules

High Speed

Communication

Modules

MHCM25

1 port RS232+1 port RS485 communication module.

MHCM55

2 ports RS485 communication module.

DI Modules

M16X

16 points 24VDC digital input

DO Modules

M16Y◇

16 points relay or transistor output

DIO Combo

Modules

M1616XY◇

16 points high-density 24VDC digital input,16 point high-density transistor

output,hybrid 40 pin I/O extension cable.

AI Modules

M04AD

4 channels, 14-bit analog input module (-10V~0V~+10V or -20mA~0mA~+20mA…)

M04ADR

4 channels,18-bit analog input module (-10V~0V~+10V or -20mA~0mA~+20mA…)

AO Modules

M04DA

4 channels,14-bit analog output module (-10V~0V~+10 or 0mA~+20mA…)

M04DAR

4 channels,16-bit analog output module (-10V~0V~+10 or 0mA~+20mA…)

AIO Combo

Modules

M0202AH

4 channels, 14-bit analog input module (-10V~0V~+10V or -20mA~0mA~+20mA…)

4 channels,14-bit analog output module (-10V~0V~+10 or 0mA~+20mA…)

Temperature

measurement

Modules

M04TC

4 channels, TC temperature input module with (K, J, T, E, R, B, N, S, mV),0.1℃

resolution.

M04TCR

4 channels, TC temperature input module with (K, J, T, E, R, B, N, S, mV),0.1℃

resolution.

Temperature

Measurement

Combo

Modules

M0202TH

2 channels, TC temperature input module with (K, J, T, E, R, B, N, S, mV),0.1℃

resolution.

2 channels, RTD temperature input module with(Pt-100, Pt-1000, JPt-100, JPt-

1000),0.1℃resolution.

Load Cell

Module

M02LC

2 channel, load cell measurement module with 24-bit resolution,Conversion

precision ±0.5%(25° C±5° C)

M02LCR

2 channel, load cell measurement module with 24-bit resolution,Conversion

precision ±0.01%(25° C±5° C)

End module

MRE

End module,This must be connected to the rightmost side of the CPU module or

the entire string of modules.

Remote Expansion Modules

Communication

Connector

MC0MN

Remote I/O Coupler (Modbus/ TCP)

Chapter 1 List of Expansion Modules

13

M-Series PLC Expansion Module User Manual

Peripheral and Accessory

High Density

DIO Cable

MFW40I-50

High-density I/O extension cable,40 pin Socket, 28AWG I/O cable,length 50cm

External

terminal

module

MFT40T

40 pin External terminal module

European

terminal Block

MFT18C

18 Pin European terminal Block

MFT06C

6 Pin European terminal Block

MFT04C

4 Pin European terminal Block

1. ◇: R-Relay output (CPU module and combo high-density DIO does not have); T-Transistor SINK(NPN) output; J-Transistor

SOURCE(PNP) output.

2. Right side expansion modules are divided into standard type and high-speed type. High-speed type can only accept up to 6 units.

And it must be installed in the first 6 positions on the right side of the CPU module.

Chapter 2 Expansion of M-Series PLC

1

M-Series PLC Expansion Module User Manual

2

Expansion of M-Series PLC

2-1 I/O Expansion Specifications ..................................................................................................................2

2-2 Digital I/O Expansion and I/O Numbering........................................................................................3

2-3 Analog I/O Expansion and I/O Numbering.......................................................................................5

2-4 Expansion Module Configuration Settings.......................................................................................8

2-5 Expansion Module Firmware Update............................................................................................... 10

Chapter 2 Expansion of M-Series PLC

2

M-Series PLC Expansion Module User Manual

The expansion of M-series PLC means when the resources provided by the M-series CPU module are

insufficient or the interface not provided by the CPU module. The number of I/O or interface types can be

expanded by adding expansion modules. The expansion of M series PLC can be divided into two categories:

I/O expansion and communication port expansion.

2-1 I/O Expansion Specifications

The expansion of M Series PLC I/O consists of Digital I/O (DI/O, which status is represented by a single

bit) and the Numeric I/O (NI/O, which status is represented by a 16-bit Word). Either the DI/O or the NI/O

expansion is realized through expansion modules cascaded thru the usage of the “I/O Output Expansion

Connector” located at the right side of M Series PLC or expansion module.

The I/O points of M-Series PLC are limited to 2048 points of DI/O (1024 points each for DI and DO),512

words of NI/O (256 points each for NI and NO). Hardware limitations: ①. A maximum number of 64

modules can be used in the expansion. ②The number of expansion modules that can be connected in

series in each segment of the M-series PLC is limited to 16 units, and expansion modules or branch modules

must be used for extension between each segment.

Caution

1. If the I/O points of the application system exceed one of the limitations (1024 DI,1024 DO,256 NI,

256 NO), while startup the M-Series PLC will treat this as an illegal I/O configuration, which in return

will flag as an error situation by turn on the “ERR” LED. The corresponding error code will also be

indicated in the CPU status register (DR35361).

2. The maximum number of expansion modules of M-Series PLC is 64. Beyond this numbers will be

treated as an invalid I/O configuration and the CPU Module will stop its operation, which in return

will flag as an error situation by turn on the “ERR” LED. The corresponding error code will also be

indicated in the CPU status register (DR35361).

3. The number of expansion modules that can be connected in series in each segment of the M-series

PLC is limited to 16 units, and expansion modules or branch modules must be used for extension

between each segment.

Warning

1. The maximum length of the I/O expansion cable for M-Series PLC is @5 meters. Cables longer than

that will cause incorrect I/O operation because of excess signal delay in hardware or noise pickup,

resulting in damage to equipment or posing hazard to operating personnel. Since this kind of

situation cannot be detected by the CPU Module, users are advised to take extra cautions and

necessary measures.

Chapter 2 Expansion of M-Series PLC

3

M-Series PLC Expansion Module User Manual

2-2 Digital I/O Expansion and I/O Numbering

Digital I/O means I/O with the discrete type status, including digital input (with initial X in DI

numbering) and digital output (with initial with Y in DO numbering). The DI and DO of M Series PLC can

both be expanded up to 1024 points (numbered as X0~X1023 and Y0~Y1023, each with 1024 points).

The status of input contacts (X0~X1023) of PLC come from the input signal connected to the digital

input terminal block on CPU Module or expansion module; while the status appears at digital output

terminal block of CPU Module and expansion module reflects the digital output relay (Y0~Y1023) status

inside PLC.

On M Series CPU Module, at the position right of the external terminal connector, there have labels

indicate the corresponding signal name. They label each terminal with numbers representing the

corresponding digital input contact Xn and digital output relay Yn. In the example of the CPU module in

ME3C6-1616T, The labels of the digital input contacts on the left side of the external terminal connector

are X0~15, S/S and the labels of the digital input contacts on the right side of the external terminal

connector are Y0~Y15, COM. Users only need to locate the printed label for each terminal to find out its

I/O number. The LED status display region also indicates the ON/OFF status for all DI(X0~X15) and

DO(Y0~Y15) on the main unit. Users can easily find each terminal with its I/O number and LED status

indication.

CPU Module Digital I/O Number

Chapter 2 Expansion of M-Series PLC

4

M-Series PLC Expansion Module User Manual

While the various expansion modules other than the CPU module have the same printed labels on the

input/output terminals as the CPU module do, these labels are only relative I/O numbers, different from

the absolute I/O numbers on CPU module. The number of a terminal only represents its order on the

expansion module. For example, the first contact is 1, the second is 2, etc. All numbers on the expansion

module begin with 1. The actual number of digital input contact or the output replay, however, is

determined by summing the numbers on all previous expansion modules and the CPU module. See the

following figure and its calculation.

Expansion Module Digital I/O Number

As shown in the above figure,10 output points on the 2nd expansion module M16X. Because the top X

numbers of the previous two units are 15 and 16, respectively, the number of input contact X41 on second

expansion unit should be:

X( 15+16+10 ) = X41

This manual suits for next models

10

Table of contents

Other FATEK Controllers manuals

Popular Controllers manuals by other brands

GameSir

GameSir G3s Enhanced Edition user manual

Azbil

Azbil SLPC1F user manual

SMC Networks

SMC Networks VCHR30 Series Installation and maintenance manual

We Care Solar

We Care Solar Suitcase installation guide

Streck

Streck CD-Chex CD34 Instructions for use

ATI Technologies

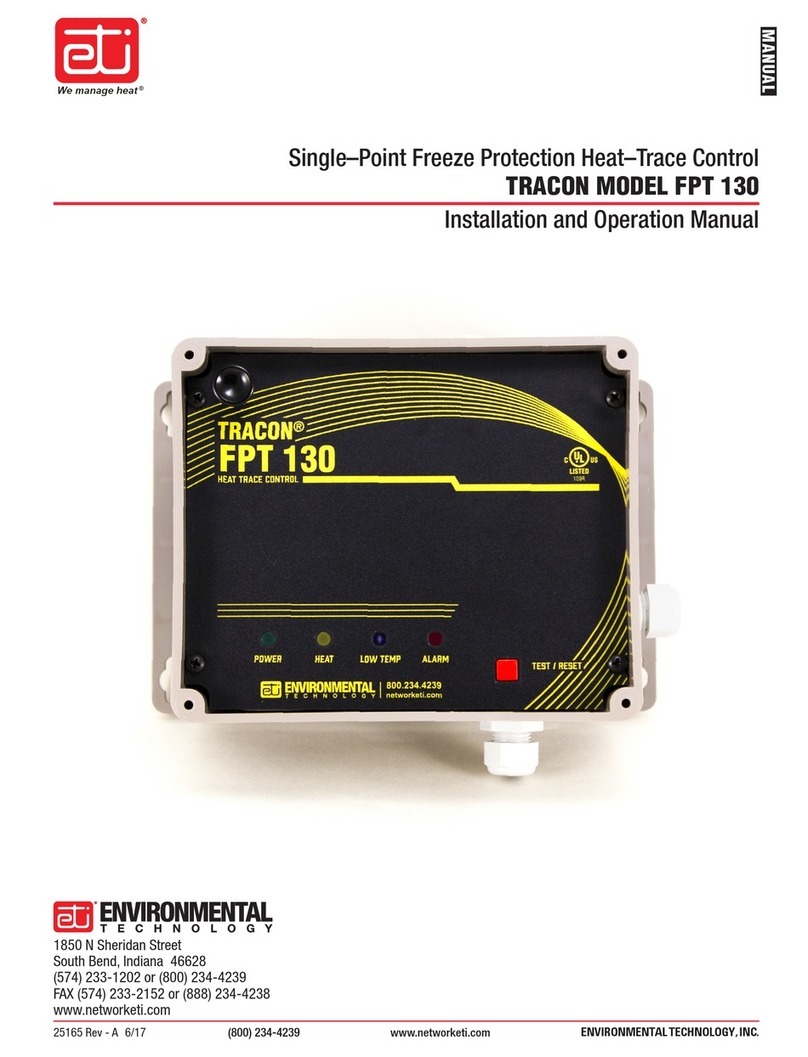

ATI Technologies TRACON FPT 130 Installation and operation manual