GSK983Ta-H/ GSK983Ta-V Turning CNC System Connection Manual

Contents

Precautions...................................................................................................................................1

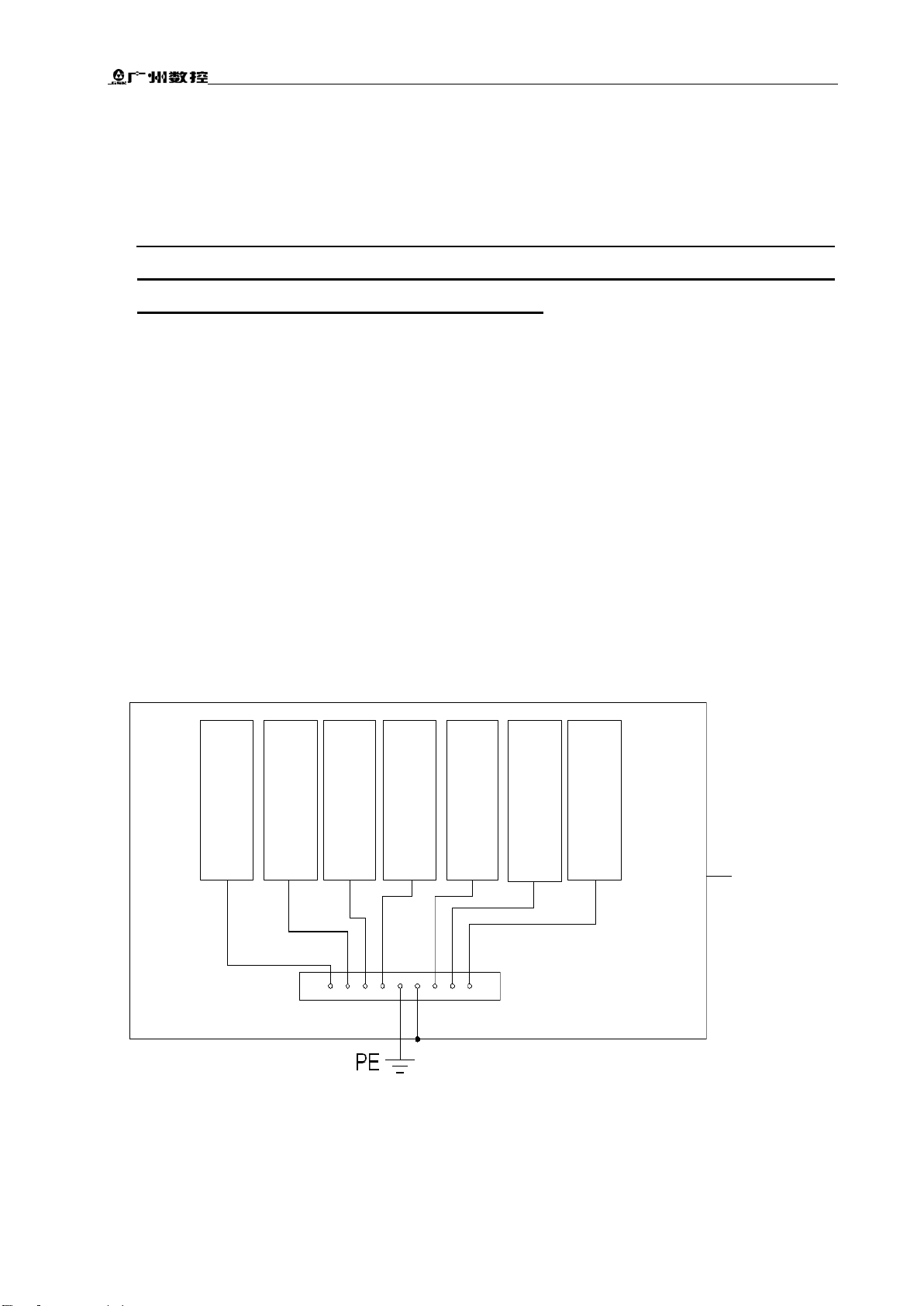

1.NC Unit Interfaces......................................................................................................................3

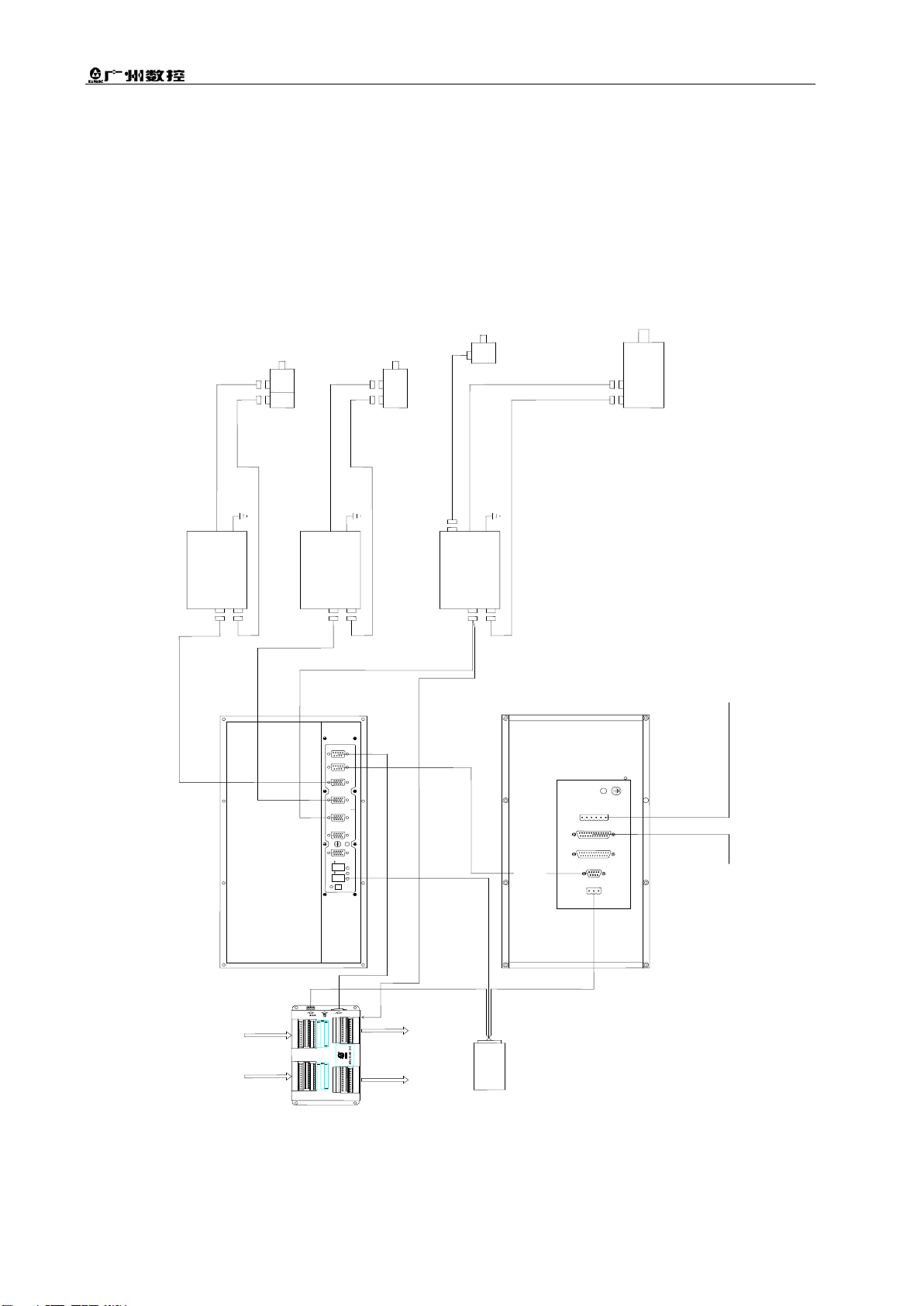

2.Interconnect Block Diagram........................................................................................................4

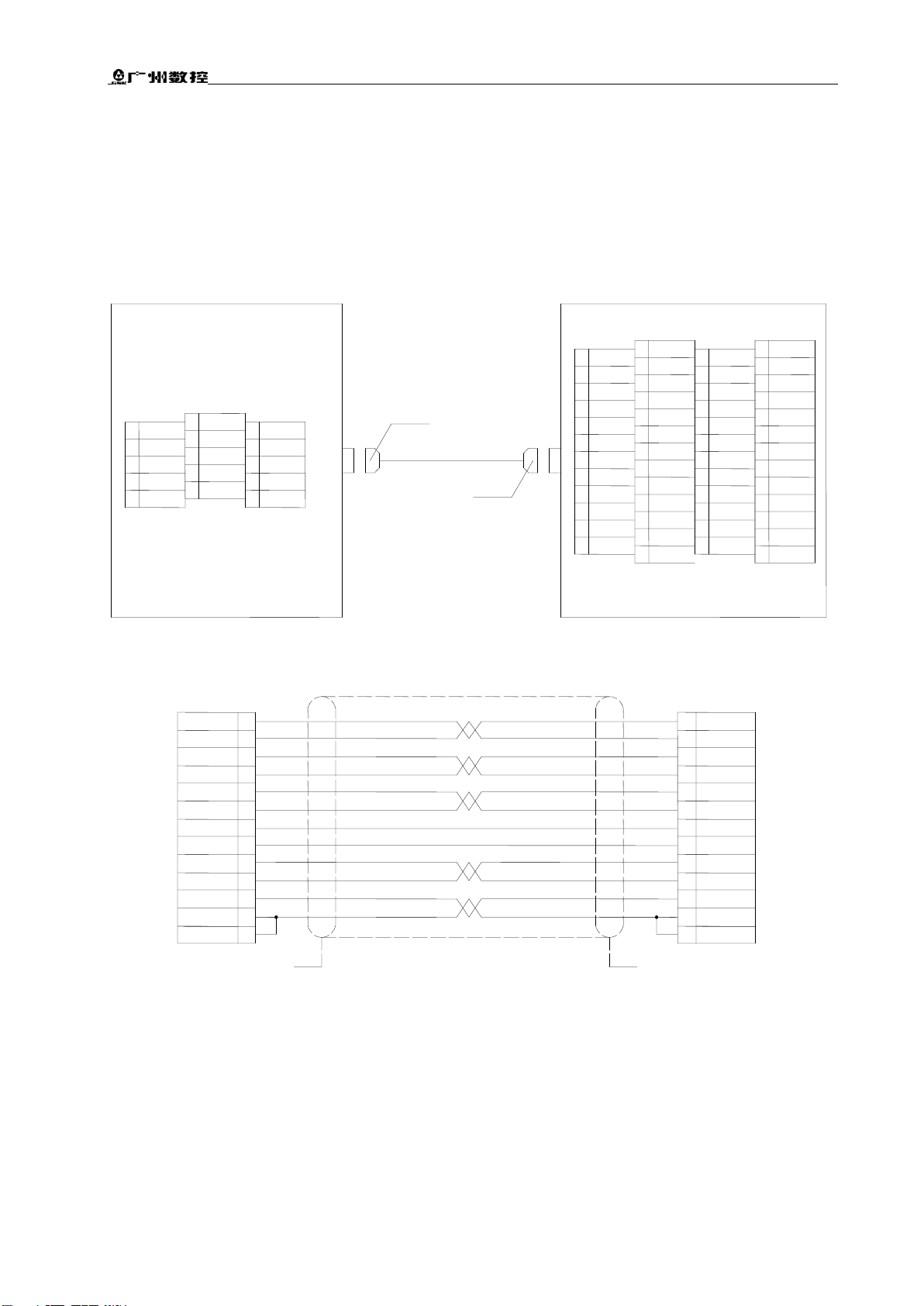

3.Connection between NC Unit and GS2000T-CA1 Drive Unit.....................................................5

(without brake) ...............................................................................................................................5

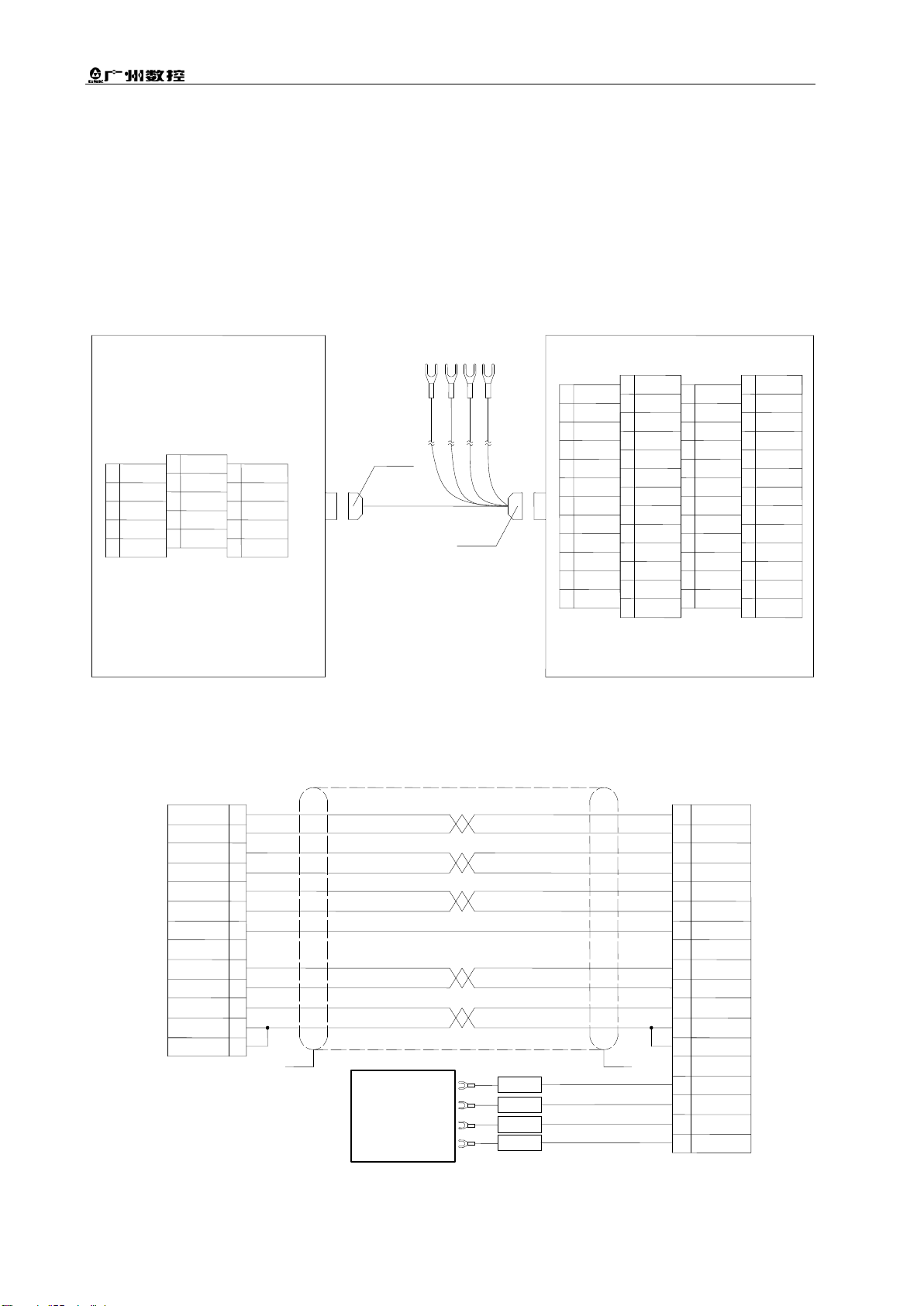

4. Connection between NC Unit and GS2000T-CA1 Drive Unit....................................................6

(with brake)..................................................................................................................................6

5. Full closed-loop connection with Grating Ruler.........................................................................7

6. Connection between NC Unit and DAP03 Spindle Servo Drive Unit........................................8

7. Connection between NC Unit and GS3000Y-NP2 Spindle Servo Drive Unit............................9

8. Connection between NC Unit and Spindle Inverter.................................................................10

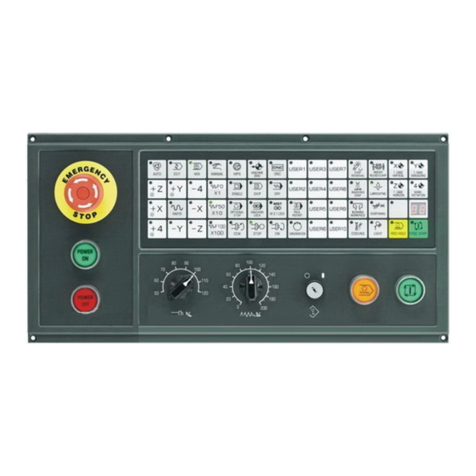

9. Machine Tool Operation Panel................................................................................................11

10. Connection between NC Unit and Operation Panel..............................................................12

11. Connection between external MPG and Operation Panel.....................................................13

12. Connection between NC Unit and PC ...................................................................................14

13. Connection Method for Brake and System Power-on Control ..............................................15

14. Connection between NC Unit and I/O Unit............................................................................16

15. General of External I/O Unit (X1) Interfaces..........................................................................17

16. Connectivity Diagrams for I/O Unit (X1) Input/Output Signals ..............................................18

17. I/O Points Definition (X1) .......................................................................................................19

Appendix 1 Installation Dimension Drawings............................................................................23

Appendix 2 Connection between NC Unit and DA98D Drive Unit(obsolete product)..........28

GSK983Ta-H/ GSK983Ta- V Turning CNC System Connection Manual....................................30

Version Upgrading Records.........................................................................................................30