Faulhaber MCDC2805 series User manual

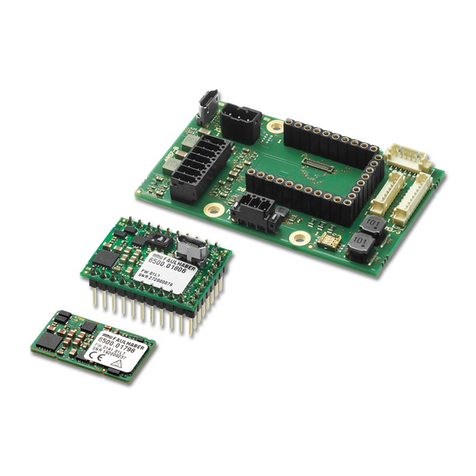

Serie MCDC2805

Motion Controller with

Sine Wave Commutation for EC-Motors

Series MCBL2805

Instruction Manual

1

Table of Contents

2

General Information 4

Data Sheet 6

Cables and Connections 7

First Steps 8

Analog Velocity Control 9

Simple Possibilities to Set Command Velocity with a Potentiometer 10

RS-232 Port and the ASCII Commands 11

Default Configuration of the RS-232 Port 11

The ASCII Commands 11

Saving Configurations 12

Changing the Baud Rate 12

Setting the Node Address 13

Choosing the Motor Type 13

Optional Motor Types and Parameters 14

Configuring the Velocity Control 15

Sources for Velocity 15

Fine Tuning the Digital Filter 19

Position Control 20

Standard Positioning Sequences 21

Combined Motion Profiles 21

Setting the Digital Filter 21

Evaluating the Homing Points and Limit Switch 22

Direct Programming with the HA, HL, and HN Commands 23

Programmable Homing Sequence 24

Hard Blocking Function 25

Hall Indexing Sequence 25

3

Additional Modes 26

Stepper Motor Mode 26

Gearing Mode 28

Position Control with a Voltage at the Analog Input 29

Using an External Encoder to Measure Actual Position 30

Voltage Regulator Mode 32

Handling Errors and the Error Output 33

Show Deviation from Command Speed as Error 33

Delayed Activation of the Error Display 33

The Error Output as a Digital Output 34

Pulse Output 35

Saving and Running Programs 36

Controlling a Program Sequence 37

More About Commands and Functions 38

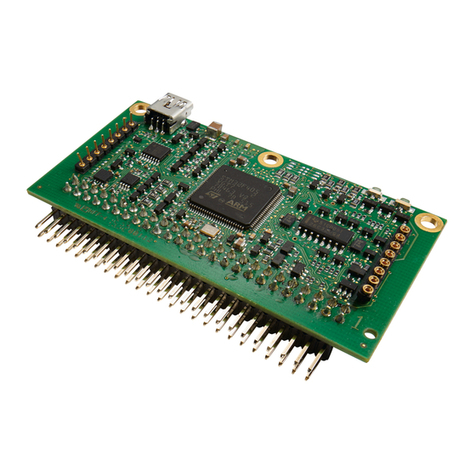

Technical Information 40

Commutation with a Sine Wave 40

Current Controller and Current Limiting 40

Overtemperature Protection 41

Undervoltage Supervision 41

Overvoltage Protection 41

Appendix 42

Electromagnetic Compatability (EMC) 42

The RS-232 Multiplexer Board 43

The ASCII Command Set 44

Example Configurations and Programs 52

Factory Configuration 57

General Information

4

The MCBL2805 was designed for Faulhaber

brushless motors with linear hall sensors. This

means that, even without an external encoder,

low speed and positioning with a resolution up

to 1/1000th of a revolution are possible. The

motion controller is based on a powerful 16-bit

microcontroller with excellent filtering quality.

This intelligent motion controller performs the

following tasks:

■Velocity Control: High performance speed

synchronization and the lowest possible

torque variance even in the most demanding

of applications. A PI-Controller makes sure

that the command velocity is accurately

achieved.

■

Velocity Profiles: Ramping, triangle, trapezoidal

and more complicated combined velocity

profiles are available to the user.

■Positioning Mode: Positioning with high

resolution including limit switches and zero

referencing.

■Additional Modes: For example, Stepper

Motor Mode to synchronize multiple motors.

■Torque Controlling: Achieved through current

regulation.

■Saving and Running Program Sequences: For

stand-alone positioning applications and to

relieve the host PC.

Inputs and Outputs:

■Command Value Input: For inputing command

speed values in digital or analog form. This

input can also interpret a reference mark

signal. Depending on the Mode, a frequency

signal or a incremental encoder can be

connected at this input.

■Fault Output (Open Collector): This output can

also be programmed as a direction of rotation

input, a digital input, or reference mark input.

■Third digital input

■RS-232 Ports: For connecting a host PC and

controlling program sequences.

Setting the Parameters and

Configurations

All filter settings can be set over the RS-232 port

and saved to the onboard memory (EEPROM).

Configuration settings (operating modes,

in/outputs, etc.) can likewise be saved.

Therefore, depending on the operating mode,

the motion controllers can function fully in

stand-alone applications.

Programming

A complete ASCII command set is available for

programming and operating the motion con-

trollers. All that is necessary is a terminal pro-

gram such as the Windows Hyperterminal.

The “FAULHABER Motion Manager” program is

available for users of Windows 95/98/NT. This

program makes configuration and operation

easy and allows the user to perform an online

graphic analysis of the performance of the drive.

5

General Information

Area of Application

Ease of installation, integrated technology,

compatability, size, stand-alone capability and

the numerous connection possibilities allow this

motion controller to perform to the highest

standards in a wide range of applications, for

example in decentralized automated production

systems like handling or tooling machines.

Supply Side:

No. Function

V1 RS-232 TXD

V2 RS-232 RXD

V3 Analog GND

V4 Fault Output

V5 Analog Input

V6 +24V

V7 GND

V8 Input No. 3

SUB-D Connector:

No. Function

2 RS-232 RXD

3 RS-232 TXD

5 GND

Motor Side:

No. Function Color

M1 Phase C yellow

M2 Hall Sensor A green

M3 VCC (+5V) red

M4 Signal GND black

M5 Hall Sensor B blue

M6 Hall Sensor C grey

M7 Phase B orange

M8 Phase A brown

Connections

Options

■FAULHABER offers the optional Multiplexer

Board to operate multiple motion controllers

from one RS-232 port.

■To accomadate our customers specialized

needs we offer factory preconfiguring of

Modes and Parameters to fit the application.

■The “FAULHABER Motion Mananger” is

available for download from the internet at

www.faulhaber.de or upon request.

■The adapters allow for simple attatchment to

mounting railings.

Data Sheet

6

General Specifications

Supply Voltage UB12 ... 28 V DC

PWM Switching Frequency fPWM 31,25 kHz

Efficiency 95 %

Max. Continuous Current Icont 5A

Max. Peak Current Imax 10 A

Current Consumption in the Electronics Iel 0,06 A

Velocity Range 10 ... 15000 rpm

Out put Voltage for External Use VCC 5 V DC

– Max. Load Current ICC 60 mA

Input No. 11) Input Resistance 18 kΩ

Command Analog Velocity Voltage Signal ± 10 V

Slope of the Curve 10002)rpm/V

Command Digital Velocity PWM Signal low 0 ... 0,5 / high 4 ... 30 V

Frequency Range 100 ... 2000 Hz

Pulse Duty Ratio 50% 0 rpm

Pulse Duty Ratio <50% left turning

Pulse Duty Ration >50% right turning

External Encoder / Step Frequency fmax 150 kHz

Fault Output (Input No. 2) Open collector max. UB/ 30 mA

No Error Switched to GND

Programmed as an input low 0...0,5 / high 4...UBV

Input No. 3 Logic Level low 0...0,5 / high 4...30 V

Port RS-232 9600 (1200,2400,4800,19200) Baud

Memory for Programs Serial EEPROM 7936 Bytes

Operating Temperature Range 0 ... +70 °C

Storage Temperature Range –25 ... +85 °C

Weight 110 g

1) Can be set over the RS-232 port. (Factory configuration: Command Analog Velocity)

2) Preset value. Can be changed over the RS-232 port.

Ordering Infomation:

The Motion Controllers were developed for and function only with the following motors:

1628T012B K1155 1628T024B K1155

2036U012B K1155 2036U024B K1155

2444S024B K1155 3056K012B K1155

3056K024B K1155 3564K024B K1155

The data sheets for the standard versions of these motors can be found in the catalog or the internet.

The code K1155 means that these motors have been fitted with linear Hall sensors to function with the MCBL2805

Note that the no load speed decreases to 80% of the standard version

Cables and Connections

7

Power Supply Requirements

The power supply should deliver at least 5 A.

It is important to be careful and connect the

controller with the correct polarity. Incorrect

polarity will damage the protection fuse and

it can only be replaced at the factory.

Analog Input (Analog Input,

Analog GND = AGND)

The analog input is a differential input.

The analog-GND should be connected to the

supply-GND. This avoids the effects of the

voltage drop in the supply leads on the given

speed value.

The analog input has, according to

configuration, various applications:

■Velocity control with a voltage over the

analog input (factory-installed setting)

■Velocity control with PWM through the

analog input

■Zero-Referencing (Limit Switch) when used

as a motion controller

■Input for the external encoder in Encoder

Mode (Analog input to ground: Channel A /

Analog-GND to ground: Channel B)

RS-232 Connections

The RS-232 hardware cabling consists of the

TXD, RXD, and Supply-GND connectors.

The built in RS-232 port allows for a direct

connection to the host PC.

Fault Output

The system is outfitted with a fault output

through which system errors are signalled.

Fault Output Characteristics:

■Switch to ground (open collector)

■Output Resistance: switched through (low

level): 47 Ohms, open (high level): 10 kOhms

■In the case of a system error, the switch is

open (the LED is not lit.)

■Output current maximum 30 mA, voltage in

open condition may not exceed supply

voltage

The fault output is activated as a result of the

following situations:

■Dynamic current limiting active

■Low voltage (by voltage under 10 V)

■Overvoltage protection active

(by supply voltage over 32 V)

■Overtemperature protection active

The fault output port can also be configured to

perform other functions:

■Pulse output

■Digital output

■Limit switch input

■Direction of rotation input

Input No. 3

The third input is a digtal input and can be used

to evaluate homing points or as a control input

for program sequences.

First Steps

8

Upon delivery the MCBL2805 is configured for

the motor type 5 (2444S024B K1155).

Important: For successful operation of the

motion controller with the motor of choice

please read the following chapters carefully:

■Choosing the Motor Type (Page 13)

■Fine Tuning the Digital Filter

(Page 19)

■Current Controller and Current Limiting

(Page 40)

When operating the MCBL2805 in one of the

Additional Modes please read the corresponding

chapters carefully. In particular the folllowing:

■Operating Mode: Using an External Encoder

to Measure Actual Position … Interfacing the

external encoder (Command: ENCRES)

■Setting the Fault Output as an Input: Use the

command REFIN or DIRIN and then EEPSAV

before a signal is interfaced with the Fault-

Pin.

If these First Steps are ignored it can lead to

component damage.

Analog Velocity Control

9

PI-Speed

Controller

MOSFET

Power

Amplifier

EC-Motor

Armature

Position

Calculation

Phase A

Phase B

Phase C

Hall Sensor A

Hall Sensor B

Hall Sensor C

Speed

Calculation

It - Current

Limiting

RS

GND

V7

Microcontroller

RS- 3

Communication

and Configurations

Module

+ 4V DC

V6

UB

,7k

LED

V4

Fault

Output

PC TXD

PC RXD

GND

nact

V

V1

RXD

TXD

Iact

RS- 3

Interface

3 Phase

PWM

Sine Wave

Commutator

ϕ(t)

ncom

∆ϕ

Ua

Protection:

Current Limit

Overtemperature

Overvoltage

Undervoltage

5V-Regulator VCC

Signal GND

Evaluation

Input 3

Input 3V8

M8

M7

M1

M

M5

M6

M3

M4

brown

orange

yellow

green

blue

grey

red

black

+5V

Analog

Input

AGND

V5

V3 +

_

±10V

GND

The standard MCBL2805 is

layed out as a Velocity

Controller. The command

velocity is given as a voltage

signal at the analog input.

In this operating mode the

RS-232 is not required but can

be used to alter configurations.

More on the topic of “Altering

Configurations” to come.

Diagram 1:

Velocity control with command velocity from the analog input.

Analog Velocity Control

10

Simple Possibilities to Set Command Velocity with a Potentiometer

M

GND

V7

+ 4V DC

V6

UB

,7k

LED

V4

V

V1

RXD

TXD

+

_

Analog

Input

AGND

V5

V3

ncom

10k

10k

M

GND

V7

+ 4V DC

V6

UB

,7k

LED

V4

V

V1

RXD

TXD

+

_

Analog

Input

AGND

V5

V3

ncom

1k

10k

0V

4,7k

4,7k

Diagram 2 shows the simplest possibility, but

note the following:

■The command velocity depends on the supply

voltage.

■The command velocity is not very accurate

due to the changes in voltage at the TXD

connector.

■The RS-232 port cannot be used.

Diagram 3 shows a more precise circuit, but

note the following:

■

The analog GND is separate from the supply

GND.

■The RS-232 is available.

Some Comments about the Input Circuit

The input circuit at the analog input is layed out

as a differential amplifier. If the analog input is

“open” there is already a voltage of 2 V. That

means in this case that the motor would be

turning at a speed of about 2000 rpm. In order

to set 0 rpm the input must be connected over a

low ohm resistor to the analog ground (AGND)

or connected to the AGND-voltage level.

Diagram 2 Diagram 3

11

RS-232 Port and the ASCII Commands

The RS-232 port allows the MCBL2805 to be

connected to a personal computer as well as

various digital controllers, like for example an

SPS or an IPC.

Using the RS-232 Port

■To configure the motor

■Online data analysis

■

Online communications with the motor during

operation

Default Configuration of

the RS-232 Port

■9600 Baud ■8 data bits

■1 stop bit ■No Parity

When working with a terminal program

on a PC one should activate “local echo” and

“carriage return”.

The ASCII Commands

Communication with the PC usually takes place

with a simple ASCII terminal program like the

one provided with the Windows operating

system. Operation becomes more elegant with

the available “Moman” operating program

which provides real time graphics generation

for values like actual speed and position.

Building blocks of the ASCII Commands

1.) Node Address (option...just necessary in a

network)

2.) Command word: a character string, letters

only

3.) Number: in many cases the command word is

followed by a number

4.) The conclusion is always a “carriage return”.

In a terminal program, for example, the enter

or return key.

Example:

V 500 [enter] ... Switch to velocity control

mode and rotate with 500 rpm

GST [enter] ... Get status

LA200 [enter] ... Set absolute position at 200

Spaces (blank characters) are ignored and

capital and lower case letters are allowed.

The answer to the return information command

is always an ASCII Character string.

At the end a “carriage rerturn” [CR] symbol

(Return, decimal code 13) and a LF symbol

(Line Feed, decimal code 10).

Example:

Request the actual postion (POS-Command)

Enter: POS [CR]

Answer: 50000 [CR][LF]

➔

This means that the motor is now at position

50000, which means 50 turns from zero.

RS-232 Port and the ASCII Commands

12

Saving Configurations

Parameters and configurations

can be saved in an on board

EEPROM chip. That means that

saved programs and configura-

tions are not lost in case of a

loss of power. Upon connec-

tion to the supply voltage the

motor runs under the setup

saved in the EEPROM.

To save parameters in the

EEPROM use the ASCII

Command EEPSAV.

Important:

Setup can be lost in the case of a loss of power during

programming.

Comments about the command table:

Commands that are marked in the instruction manual with a *)

will be saved with the EEPSAV command.

Diagram 4: The operation of the EEPROM

Changing the Baud Rate

The baud rate can be set to the

following values: 1200, 2400,

4800, 9600, 19200 Baud.

Command Function Description Example

BAUD *) Select Baud Rate Sets the baud rate BAUD9600

for the RS-232 port

Default Setting: BAUD9600

In order to continue working after the baud rate has been changed

in the motor, the baud rate must also be changed at the PC.

13

RS-232 Port and the ASCII Commands

Setting the Node Address

With the assistance of the

RS-232 Multiplexer Board it

becomes possible to drive

multiple motors from one host.

Use the ASCII addressing

command to address the

individual motors.

Command Function Description Example

NODEADR *) Define Node Defines the node address NODEADR5

Address from 0 to 255

GNODEADR Get Node Calls up node address GNODEADR

Address at the host ➔5

Command Function Description Example

ANSW *) Asynchron Answer ANSW0 ... automatic answering ANSW1

On/Off deactivated

ANSW1 ... automatic answering

active

Command Function Description Example

MOTTYP *) Motor Type Sets the type of motor to MOTTYP4

be used. (see table)

GMOTTYP Get Motor Type Sends the type over the GMOTTYP ➔8

RS-232 port

Default Setting: NODEADR0

Important Note:

Only one motor may be connected at the time of addressing.

Otherwise, multiple motors will receive the same node address.

Careful when hosting multiple motors:

If commands are sent without a node address, all the motors in

the network will receive the command. If one calls up the status

of a motor without entering the node address an error will occur

because all the motors will attempt to answer at the same time.

Turning off the Asynchronus Answer Commands:

In the case of the Asynchronus Answer Commands problems can

occur even if the node address is given because the answer is not

sent directly after the command is given.

Example: NP20000 ... Notify Position (details to come)

The answer “p” will come only after the motor has reached

position 20000. Other nodes (motors) could be answering at the

same time. If this occurs the data (answers) can be lost.

Choosing the Motor Type

The Motion Controller comes standard set to the 2444S024B

K1155 motor. The motor type can be changed with the following

commands.

RS-232 Port and the ASCII Commands

14

Optional Motor Types and Parameters

No. Motor Type P-portion (POR) I-portion (I) Peak Current (mA) Continuous Current (mA)

1 1628T012B K1155 3 6 3000 770

2 1628T024B K1155 4 10 3000 410

3 2036U012B K1155 5 6 3000 980

4 2036U024B K1155 6 5 3000 480

5 2444S024B K1155 4 15 5000 1370

6 3056K012B K1155 6 10 7000 1940

7 3056K024B K1155 12 12 3000 930

8 3564K024B K1155 8 20 8000 2800

These parameters can be individually changed or reset to the default parameters of the individual

motor with the command RN.

Important: By setting the Motor Type other internal parameters will also be changed. Therefore it

is important, when changing motor types on a Motion Controller, to set the type with

the MOTTYP command.

15

Configuring the Velocity Control

Sources for Velocity

Command Function Description Example

SOR *) Source for Sources for the Velocity SOR1

Velocity SOR 0: Command velocity at the

RS-232 port

SOR 1: Command velocity with a

voltage at the analog input

SOR2: Command velocity with a PWM

signal at the analog input

a.) Command Velocity with Voltage at Analog Input

In Analog Velocity Mode other setup values can be changed.

Setting the Maximum Velocity

Command Function Description Example

SP *) Load Loads new maximum velocity. SP4000

Maximum

Arguement in rpm (from 0 to 30000).

Speed Settings apply to all modes.

GSP

Get Maximum

Calls up maximum speed. GSP

Speed ➔2500

Example: SP5000 [return] ➔The maximum velocity is set to

5000 rpm. That means that 10 V at

the Analog Input represents a

command velocity of 5000 rpm

Default Setting: SP10000

Setting the Minimum Velocity

The lowest possible velocity, at minimum analog voltage,

can be set.

Command Function Description Example

MV *) Minimum Sets the minimum speed MV100

Velocity

GMV

Get Minimum

Calls up the minimum speed GMV ➔0

Velocity over the RS-232 port.

Default Setting: MV0

Upon delivery the controller is

set up as a velocity controller.

The input signal is a voltage at

the analog input, for example,

a potentiometer. By changing

the configuration of the motor

many other sources for control-

ling the velocity can be chosen.

Configuring the Velocity Control

16

Setting the Minimal Analog Voltage

Command Function Description Example

MAV *) Minimum Sets the minimum analog voltage. MAV500

Analog

Voltage

GMAV Get Minimum Calls up the minimum analog GMAV

Analog Voltage voltage over the RS-232 port. ➔25

Example: MAV100 [return] ➔ 100 mV is the necessary minimum

starting voltage. The motor will

not turn if the voltage ranges from

–99 mV to 99 mV.

Default Setting: MAV25

Advantages: While 0 mV at the analog input is normally very

difficult to achieve, 0 rpm can not be accurately set.

Setting the minimal analog voltage > 0 prevents this

from being a problem. The resulting dead zone is

also useful because the motor will not start up when

small disturbance voltages occur.

nCom

Uin

SP

MV

10V

MAV

-MAV

-MV

Diagram 5: Characteristic curve with a given analog velocity

17

Configuring the Velocity Control

Setting the Direction of Rotation

Command Function Description Example

ADL *) Analog Armature rotates left with positive ADL

Direction voltage at the analog input

Left

ADR *) Analog Armature rotates right with positive ADR

Direction voltage at the analog input

Right

Default Setting: ADR ... Right rotation with positive voltage.

b.) Command Velocity with Pulse Width Modulation (PWM) at

the Analog Input

The factory setting are:

■Pulse Duty Ratio > 50% ➔Rotation Right

■Pulse Duty Ratio = 50% ➔Rotation Stop

■Pulse Duty Ratio < 50% ➔Rotation Left

The commands SP, MV, MAV, ADL, and ADR can also be used in

this mode.

c.) Command Velocity at the RS-232 Port

Command Function Description Example

V *) Select Activates velocity control mode V2000

Velocity and rotates with the given value.

Mode

GV Get Velocity Calls up the command velocity GV ➔500

Directly following the SOR0-Command the motor continues

rotating with the current command velocity.

Special Setting: Constant Velocity

SOR0 [enter] ➔Switches to RS-232 Mode

V500 [enter] ➔Enter desired velocity

EEPSAV [enter] ➔Saves setting to EEPROM

Now the motor will always start with the saved velocity.

Configuring the Velocity Control

18

Setting an Acceleration

Command Function Description Example

AC *) Load Loads a new value for AC100

Command acceleration.

Acceleration Arguement in Rev/s2

GAC Get

Calls up current acceleration value

GAC ➔1000

Acceleration

Default Setting: 30000 Rev/s2

This acceleration value makes soft acceleration and braking in

Velocity Control Mode possible.

Direction of Rotation Input

The Fault Output can be configured to serve as a direction of

rotation switch.

Command Function Description Example

DIRIN *) Direction Sets the fault output to function DIRIN

Input as a direction of rotation input.

(activates the limiter switch function)

Level and Direction:

Low: 0 to 0,5 V ... Rotation Left

High: 4 to Supply Voltage ... Rotation Right

The logic level at the direction of rotation input is dominant to

changes made with the ADR and ADL commands.

When the Fault Output is used as a Direction of Rotation Switch,

it functions with all sources after the setup is initially given over

the RS-232 port.

To take the position limits into account

The position limits (LL-command) will become applicable with the

input of the command APL1. With the input of the APL0 com-

mand position limits will be ignored.

19

Configuring the Velocity Control

Instructions:

1.) Set output configuration

■SOR0 [enter] ➔

Sets Source for Command Velocity: RS-232

■POR 8 [enter] ➔ Proportional Term = 8 (example)

■I20 [enter] ➔ Integral Term = 20 (example)

■V1000 [enter] ➔ Sets Velocity to 1/3 of Maximum Appli-

cation Speed (only an example value)

■ AC10000 [enter] ➔ Sets Acceleration to Maximum Appli-

cation Value (only an example value)

2.) Raise the Proportional Term

POR 13 [enter] ➔ Proportional Term = 13

(Step Width 5, smaller later)

3.) Velocity Jump

V2000 [enter] ➔ Velocity jumps from 1/3 to 2/3 the

Maximum Application Speed

(only an example value)

4.) Velocity Jump

V1000 [enter] ➔ Velocity jumps from 2/3 to 1/3 the

Maximum Application Speed

(only an example value)

5.) Repeat steps 2-4 until the controller becomes unstable. Then

reduce the Proportional Term until the stabilty is achieved.

6.) Repeat steps 2-5 with the Integral Term.

Fine Tuning the Digital Filter

The digital filter parameters can be adjusted to improve the

dynamic performance. These parameters should be carefully

chosen to fit the application because they have a great influence

on performance.

Command Function Description Example

POR *) Load Loads controller amplification POR20

Proportional (values: 0-255)

Term

I *)

Load Integral

Loads controller integral term I10

Term (values: 0-255)

GPOR

Get

Calls up controller amplification. GPOR ➔8

Proportional

Term

GI Get Integral Calls up the setting for GI ➔20

Term the integral term

Position Control

20

PI-Speed

Controller

MOSFET

Power

Amplifier

EC-Motor

Armature

Position

Calculation

Phase A

Phase B

Phase C

Hall Sensor A

Hall Sensor B

Hall Sensor C

Speed

Calculation

It - Current

Limiting RS

GND

V7

Microcontroller

RS- 3

Communication

and Configurations-

Module

+ 4V DC

V6

UB

,7k

LED

V4

Fault

Output

Analog

Input

AGND

PC TXD

PC RXD

GND

nact

V5

V3

V

V1

RXD

TXD

Iact

Position

Controller

Command

Position

Evaluation

Limit Switch

10k

Example:

Limit Switch

+

_

RS- 3

Interface

3 Phase

PWM

Sine Wave

Commutator

ϕ(t)

ncom

∆ϕ

Ua

Protection:

Current Limit

Overtemperature

Overvoltage

Undervoltage

5V-Regulator VCC

Signal GND

Evaluation

Input 3

Input 3

V8

M8

M7

M1

M

M5

M6

M3

M4

brown

orange

yellow

green

blue

grey

red

black

+5V

Diagram 6: Position control with a reference switch at the analog input

The following Command Sequence is necessary to switch from Speed Control Mode (factory setting)

to Positioning Mode:

SOR0 [enter] ➔Switches to RS-232 Communication in Speed Control Mode

LR0 [enter] ➔Load Relative Position 0

M [enter] ➔Switches to Positioning Mode

Positioning commands:

Command Function Description Example

M *) Initiate Motion Activates positioning mode and starts positioning M

LA Load Absolute Loads the new value for the absolute position. LA100000

Position Arguement: 1000 indicates 1 revolution.

LR Load Relative Position Loads a new relative position LR5000

SP *) Load Maximum Loads a new maximum velocity. SP4000

Speed Arguement: rpm from 0 to 30000

AC *) Load Command Loads a new value for acceleration. AC100

Acceleration Arguement: Rev/s2from 0 to 30000

NP Notify Position A “p” will appear on the screen when the motor has NP10000

rotated beyond a given position. asynch ➔p

NV Notify Velocity A “v” will appear when a given velocity has been NV5000

achieved. asynch ➔v

Table of contents

Other Faulhaber Controllers manuals

Faulhaber

Faulhaber MC 3001 B User manual

Faulhaber

Faulhaber SC 1801 Series User manual

Faulhaber

Faulhaber MC 5004 User manual

Faulhaber

Faulhaber SC 1801 User manual

Faulhaber

Faulhaber MC 5010 Use and care manual

Faulhaber

Faulhaber MCDC 3002/03/06 RS/CF/CO Series User manual

Faulhaber

Faulhaber MCLM 300 RS Series Parts list manual

Faulhaber

Faulhaber Series MCBL 3002/03/06 RS/CF /CO User manual

Faulhaber

Faulhaber MCLM 300x CO Series Parts list manual

Faulhaber

Faulhaber MC 5010 Owner's manual