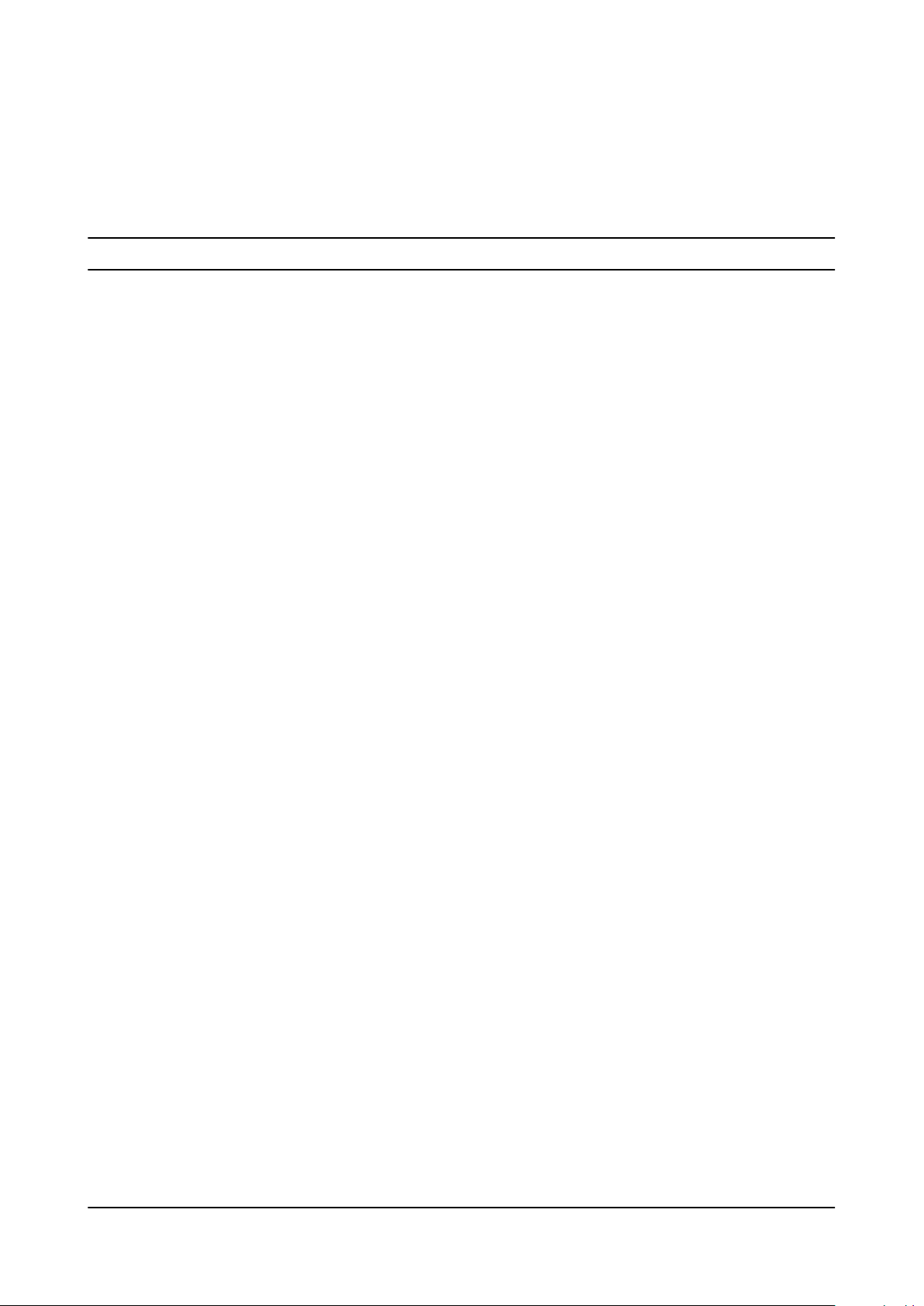

3.9.5 After maintenance work............................................................................................................. 34

3.10 Repair......................................................................................................................................... 35

3.11 Signage...................................................................................................................................... 36

3.12 Safety Components.................................................................................................................. 41

4 Indicators and control elements........................................................................................................ 43

4.1 Machine........................................................................................................................................ 44

4.1.1 Shut-off valve for water spraying system................................................................................... 45

4.1.2 Shut-off valve for compact water spraying system..................................................................... 45

4.1.3 Locking bolt for guide handle..................................................................................................... 45

4.1.4 Lock for transport wheels........................................................................................................... 46

4.2 Engine.......................................................................................................................................... 47

4.2.1 Overview.................................................................................................................................... 47

4.2.2 Engine stop switch..................................................................................................................... 47

4.2.3 Throttle lever.............................................................................................................................. 48

4.2.4 Choke lever................................................................................................................................ 48

4.2.5 Recoil starter.............................................................................................................................. 48

4.2.6 Fuel valve................................................................................................................................... 49

5 Checks prior to start up...................................................................................................................... 51

5.1 Notes on safety........................................................................................................................... 52

5.2 Visual inspections and function tests....................................................................................... 53

5.3 Daily maintenance....................................................................................................................... 54

5.3.1 Checking the fuel level; topping up fuel..................................................................................... 54

5.3.2 Checking the rubber buffers....................................................................................................... 55

5.3.3 Checking the water level, topping up......................................................................................... 56

5.3.4 Check water supply, refill (compact water tank)......................................................................... 56

6 Operation............................................................................................................................................. 59

6.1 Mounting the guide handle........................................................................................................ 60

6.2 Starting the engine...................................................................................................................... 61

6.3 Work mode................................................................................................................................... 65

6.4 Switching the water sprinkling system on/off.......................................................................... 67

6.5 Switching the compact water spraying system on/off............................................................ 68

6.6 Parking the machine in secured condition............................................................................... 69

7 Loading / transporting the machine.................................................................................................. 71

7.1 Loading the machine.................................................................................................................. 72

7.2 Lashing the machine to the transport vehicle.......................................................................... 74

7.3 Transport wheels......................................................................................................................... 75

8 Maintenance........................................................................................................................................ 77

8.1 Preliminary remarks and safety notes...................................................................................... 78

8.2 Fuels and lubricants................................................................................................................... 79

8.2.1 Engine oil................................................................................................................................... 79

8.2.2 Fuel............................................................................................................................................ 79

8.2.3 Oil for exciter shaft housing........................................................................................................ 80

8.3 List of fuels and lubricants........................................................................................................ 81

8.4 Running-in instructions.............................................................................................................. 82

8.4.1 General information.................................................................................................................... 82

Table of contents

DFP6

4