FDP EX-CPL User guide

Page 1of 91

Rev. 4.

2

0

INSTALLER MANUAL

EX-CPL

FIRE CONTROL PANEL

EXCELLENT FIRE SYSTEM

FDP International Group S.r.l. -Via Pierobon, 127 - 35010 LIMENA (PD) –ITALY

Tel. +39 049 767249 -fax +39 049 767898

E-mail: info@fdpinternational.com -www.fdpinternational.com -P. IVA 02601740281

Page 2of 91

Rev. 4.

2

0

INDEX

PART 1 DETAILS..........................................................................................................................................................................................6

1.1 GENERAL CHARACTERISTICS...................................................................................................................................................6

1.2 POINT ADDRESSING AND ACQUISITION .................................................................................................................................8

PART 2 CONTROL PANEL INSTALLATION..........................................................................................................................................9

2.1 SAFETY REQUIREMENTS ............................................................................................................................................................9

2.2 CONNECTING THE CONTROL PANEL TO THE MAIN POWER LINE 230VCA......................................................................9

2.3 FUSES...............................................................................................................................................................................................9

2.4 FIXING THE CONTAINER...........................................................................................................................................................10

2.4.1 Cable arrangement...............................................................................................................................................................10

2.4.2 Observation ..........................................................................................................................................................................10

2.4.3 Assembly...............................................................................................................................................................................11

2.5 CONNECTION...............................................................................................................................................................................11

2.5.1 The circuits of the detection..................................................................................................................................................12

2.5.2 Fire alarm siren output.........................................................................................................................................................13

2.5.3 Output for alarm siren fault..................................................................................................................................................14

2.5.4 Outputs of auxiliary relays no supervised.............................................................................................................................15

2.5.5 Open Collector outputs.........................................................................................................................................................15

2.5.6 Auxiliary output 24 Vdc........................................................................................................................................................15

2.5.7 Serial ports ...........................................................................................................................................................................15

2.5.8 Connection to the power supply............................................................................................................................................16

2.5.9 Battery connections ..............................................................................................................................................................16

2.6 LOOP SECTION.............................................................................................................................................................................16

2.7 LOCATION OF GROUND SHUNT IN THE CONTROL PANEL.................................................................................................16

2.8 MAINTENANCE ...........................................................................................................................................................................17

2.8.1 Daily control.........................................................................................................................................................................17

2.8.2 Weekly control......................................................................................................................................................................17

2.8.3 Four-monthly control............................................................................................................................................................17

2.8.4 Yearly control.......................................................................................................................................................................17

2.8.5 Cleaning the Smoke Sensor...................................................................................................................................................17

PART 3 PRELIMINARY REMARKS FOR A CORRECT INSTALLATION ......................................................................................18

3.1 LINE CABLE TEST PROCEDURE BEFORE LOOP CONNECTION..........................................................................................18

3.1.1 Line continuity......................................................................................................................................................................18

3.1.2 Shielded................................................................................................................................................................................18

3.1.3 Isolation between positive and negative of loop ...................................................................................................................18

3.1.4 Isolation between SHI / –LOOP and SHI / +LOOP.............................................................................................................18

3.1.5 Check of SHI short circuits at power supply line..................................................................................................................19

PART 4 ABOUT PROGRAMMING ..........................................................................................................................................................20

4.1 CONTROLS AND INFORMATION..............................................................................................................................................20

4.1.1 Control panel controls..........................................................................................................................................................20

4.1.2 Led indicators of the control panel.......................................................................................................................................21

4.2 HOW TO SELECT AN ITEM FROM THE MENU OF THE CONTROL PANEL.........................................................................22

4.3 PASSWORD MANAGEMENT......................................................................................................................................................23

4.4 ACCESS LEVELS..........................................................................................................................................................................23

4.4.1 Levels for users and installers..............................................................................................................................................23

4.5 OUT OF SERVICE, FAULT, ALARM MESSAGES .....................................................................................................................24

4.5.1 General.................................................................................................................................................................................24

4.5.2 Silence ..................................................................................................................................................................................24

4.5.3 View Messages......................................................................................................................................................................24

4.5.4 Visualizing the event.............................................................................................................................................................26

4.5.5 Active outputs .......................................................................................................................................................................27

4.5.6 Alarm Reset ..........................................................................................................................................................................27

4.6 VISUALIZATION OF EVENTS....................................................................................................................................................27

4.6.1 Main menu............................................................................................................................................................................27

4.6.2 Event menu ...........................................................................................................................................................................27

PART 5 FIRST CONFIGURATION OF CONTROL PANEL.................................................................................................................28

PART 6 LOOP PROGRAMMING .............................................................................................................................................................31

6.1 LOOP STARTING..........................................................................................................................................................................31

6.1.1 Main menu............................................................................................................................................................................31

6.1.2 Loop menu............................................................................................................................................................................31

6.1.3 Loop start/restore (loop selection)........................................................................................................................................31

6.1.4 Loop start/restore procedure................................................................................................................................................32

6.1.5 Information...........................................................................................................................................................................32

Page 3of 91

Rev. 4.

2

0

6.1.6 Confirmation.........................................................................................................................................................................32

6.2 LOOP OUT OF SERVICE..............................................................................................................................................................32

6.2.1 Loop start/restore procedure................................................................................................................................................32

PART 7 POINT PROGRAMMING............................................................................................................................................................33

7.1 POINT INSERTION.......................................................................................................................................................................33

7.1.1 Procedure for the acquisition of a point...............................................................................................................................33

7.1.2 Main menu............................................................................................................................................................................34

7.1.3 Point menu............................................................................................................................................................................34

7.1.4 Address assignation..............................................................................................................................................................34

7.1.5 Type of point acquisition ......................................................................................................................................................34

7.1.6 Loop selection.......................................................................................................................................................................35

7.1.7 Point address selection.........................................................................................................................................................35

7.1.8 Detectors check values .........................................................................................................................................................35

7.1.9 Points Acquisition Modes: installer, activation and pre-set address....................................................................................35

7.1.10 Points Acquisition in mode: serial number...........................................................................................................................36

7.2 POINT INFORMATION ................................................................................................................................................................37

7.2.1 Main menu............................................................................................................................................................................37

7.2.2 Point menu............................................................................................................................................................................37

7.2.3 Loop selection.......................................................................................................................................................................37

7.2.4 Point address selection.........................................................................................................................................................38

7.2.5 Point setting..........................................................................................................................................................................38

7.3 POINTS REMOVAL ......................................................................................................................................................................40

7.3.1 Main menu............................................................................................................................................................................40

7.3.2 Point menu............................................................................................................................................................................40

7.3.3 Points removal (options).......................................................................................................................................................41

7.3.4 Loop selection.......................................................................................................................................................................41

7.3.5 Point address selection.........................................................................................................................................................41

7.3.6 Zone address selection..........................................................................................................................................................41

PART 8 ZONE PROGRAMMING .............................................................................................................................................................42

8.1 DETAILS........................................................................................................................................................................................42

8.2 ZONE CREATION.........................................................................................................................................................................42

8.3 ZONE SETTING.............................................................................................................................................................................42

8.3.1 Main menu............................................................................................................................................................................42

8.3.2 Zone menu ............................................................................................................................................................................42

8.3.3 Loop selection.......................................................................................................................................................................43

8.3.4 Zone address selection..........................................................................................................................................................43

8.3.5 Zone setting ..........................................................................................................................................................................43

PART 9 OUTPUTS PROGRAMMING......................................................................................................................................................45

9.1 DETAILS........................................................................................................................................................................................45

9.1.1 Main menu............................................................................................................................................................................45

9.1.2 Output menu .........................................................................................................................................................................45

9.1.3 Output selection....................................................................................................................................................................45

9.1.4 Output setting .......................................................................................................................................................................46

9.2 CONTROL PANEL OUTPUT........................................................................................................................................................48

9.2.1 Output description................................................................................................................................................................48

9.2.2 24Vdc output.........................................................................................................................................................................48

9.2.3 Siren output ..........................................................................................................................................................................48

9.2.4 Fault output..........................................................................................................................................................................49

9.2.5 Relay outputs........................................................................................................................................................................49

9.2.6 Open collector outputs..........................................................................................................................................................49

9.3 LOOP OUTPUT..............................................................................................................................................................................50

9.3.1 Relay output..........................................................................................................................................................................50

9.3.2 Open collector output...........................................................................................................................................................50

9.4 LOGICS OF ACTIVATION ...........................................................................................................................................................50

9.4.1 Logic states...........................................................................................................................................................................51

9.4.2 Logic of activation................................................................................................................................................................51

PART 10 SETTING MENU.........................................................................................................................................................................53

10.1 DETAILS...................................................................................................................................................................................53

10.2 SUPERVISED /UNSUPERVISED...........................................................................................................................................53

10.3 EVACUATION .........................................................................................................................................................................54

10.4 FIRE RESTORATION ..............................................................................................................................................................54

10.5 DATE /TIME ............................................................................................................................................................................55

10.6 PROMPT...................................................................................................................................................................................55

10.7 PASSWORD..............................................................................................................................................................................56

10.7.1 Retrieval of Forgotten Password..........................................................................................................................................56

10.8 LOOP ACTIVATION................................................................................................................................................................57

10.9 RESTORING DEFAULT SETTINGS.......................................................................................................................................57

Page 4of 91

Rev. 4.

2

0

PART 11 DIAGNOSTICS MENU...............................................................................................................................................................58

11.1 DETAILS...................................................................................................................................................................................58

11.2 SOFTWARE VERSION............................................................................................................................................................58

11.3 SMOKE DETECTORS VERIFICATION .................................................................................................................................58

11.4 LAMP TEST..............................................................................................................................................................................59

11.5 AUTORESET............................................................................................................................................................................59

11.6 CHRONOLOGICAL RESET ....................................................................................................................................................60

PART 12 CONNECTION MENU ...............................................................................................................................................................61

12.1 DETAILS...................................................................................................................................................................................61

12.2 EXTERNAL PS2 KEYPAD ......................................................................................................................................................61

12.3 AUXILIARY POWER SOURCE..............................................................................................................................................62

12.4 SERIAL OUTPUTS (RS232-RS485-LAN) ...............................................................................................................................62

12.4.1 Local net setting....................................................................................................................................................................62

12.4.2 RS232 connection.................................................................................................................................................................62

12.4.3 RS485 connection.................................................................................................................................................................63

12.4.4 LAN connection ....................................................................................................................................................................63

PART 13 EVACUATION.............................................................................................................................................................................65

13.1 DETAILS...................................................................................................................................................................................65

13.2 EVACUATION MENU.............................................................................................................................................................66

13.3 EVACUATION START............................................................................................................................................................66

13.4 “EVACUATION” AND “EXTINGUISH” OUTPUTS..............................................................................................................67

PART 14 REPEATER PANEL....................................................................................................................................................................68

14.1 DETAILS...................................................................................................................................................................................68

14.2 RS232 CONNECTION..............................................................................................................................................................68

PART 15 POINTS DESCRIPTION AND UTILIZATION.......................................................................................................................69

15.1 DETECTORS ............................................................................................................................................................................69

15.1.1 Detector addressing..............................................................................................................................................................69

15.1.2 Manual zero setting of the address.......................................................................................................................................69

15.1.3 Smoke detector......................................................................................................................................................................70

15.1.4 Heat detector........................................................................................................................................................................71

15.1.5 Multicriterion detector..........................................................................................................................................................72

15.1.6 Electrical schemes................................................................................................................................................................73

15.2 RESETTABLE BUTTON..........................................................................................................................................................73

15.2.1 Input and output description.................................................................................................................................................73

15.2.2 Button addressing.................................................................................................................................................................73

15.2.3 Manual zero setting of the address.......................................................................................................................................73

15.2.4 Point setting..........................................................................................................................................................................73

15.2.5 Electrical scheme..................................................................................................................................................................74

15.3 INPUT/OUTPUT MODULE.....................................................................................................................................................74

15.3.1 Input and output description.................................................................................................................................................75

15.3.2 Module addressing ...............................................................................................................................................................75

15.3.3 Manual zero setting of the address.......................................................................................................................................75

15.3.4 Point setting..........................................................................................................................................................................75

15.3.5 Electrical schemes................................................................................................................................................................76

15.3.6 Connection Lay-Out of smoke and gas linear Detectors ......................................................................................................76

15.3.7 Programmed I/O Module for bathroom alarm .....................................................................................................................77

PART 16 GENERIC ELECTRICAL SCHEMES......................................................................................................................................78

16.1 CONNECTION BEETWEN CONTROL PANELS AND PC (RS485)......................................................................................79

16.2 CONTROL PANEL CONNECTION ON LAN .........................................................................................................................79

16.3 SIREN AND MAGNET CONNECTION WITH CONTROL PANEL ......................................................................................80

16.4 SOME CONNECTION POINTS...............................................................................................................................................81

PART 17 QUICK PROGRAMMING PROCEDURES.............................................................................................................................82

17.1 DETAILS...................................................................................................................................................................................82

17.2 FIRS CONTROL PANEL TURN ON........................................................................................................................................82

17.3 INSTALLATION LOOP ...........................................................................................................................................................82

17.4 POINT ACTIVATION ..............................................................................................................................................................83

17.5 INPUTPROGRAMMING.........................................................................................................................................................84

17.6 OUTPUT PROGRAMMING.....................................................................................................................................................84

17.7 SETTING AN OUTPUT DELAY..............................................................................................................................................84

17.8 RESET MODE OF FIRE ALARM..............................................................................................................................................85

17.9 RESET OF CONTROL PANEL FOR THE DEFAULT SET UP....................................................................................................86

PART 18 HOW TO SOLVE THE PROBLEMS........................................................................................................................................88

PART 19 TECHNICAL CHARACTERISTICS........................................................................................................................................90

Page 5of 91

Rev. 4.

2

0

Page 6of 91

Rev. 4.

2

0

1.1 GENERAL CHARACTERISTICS

The fire-prevention control panel was designed in observance to the rules EN54-2 and EN54-4, and it has the

following characteristics:

•The available versions of the control panel are at 1 –2 –4 loops.

•It is possible to address on a single loop up to 127 points (detectors, buttons, Input/output modules and

isolators), distributed like as follows:

1. Up to 120 points among detectors, buttons and Input/output modules;

2. Up to 7 isolator modules of line, which will take the addresses from 121 to 127 and they are

compulsory to conform with the regulations at least with every 32 detectors systems, buttons and

Input/output modules;

3. Un-addressed infinite detectors that will refer to point “0”.

•The installation of a control panel at 2 loops allows to install a total of 254 points with the possibility to

address up to 120 points among detectors, buttons and Input/output modules on each single loop.

•The addressing for the assignment to the detectors, buttons and Input/output modules is free (see

example in PART 5).

•The line isolators are addressed through automatic procedure directly by the control panel, assigning in

progression the addresses from 121 to 127.

The power supply and the communication to the device occurs through only two cables. A twisted and shielded

cable must be used in each loop.

Connectible detectors:

Smoke detector: EX-SOD, EX-SD

Heat detector: EX-TD

Multi-criteria detector: EX-MD

Connectable modules:

Manual button: EX-P5, EX-MP

Input / Output module: EX-MEIO

Isolator module: EX-MEIS (discontinued)

Passive isolator module: EX-ISO

Cables used for connections:

Shielded and twisted cable 0,5 mm2CABR205

Shielded and twisted cable 1 mm2CABR21

Shielded and twisted cable 1,5 mm2CABR215

ØThe detectors use a system of digital communication, a low frequency of communication and revelation

elements of errors that become highly free of interferences. The protocol has a special system of

communication (polling system) which allows a quick answer in case of alarm (127 points scanner in less than

half a second) and allows the control of the status, the analogic value and the working parameters of

detectors.

ØLoop can be subdivided into 63 zones per loop; each of them can contain one or more devices. A numerical

address must be assigned to each element of the loop. The address programming in the points occurs

through the control of the panel itself.

ØThe control panel has a retro-illuminated alphanumeric display at liquid crystals 8x21, characters for the

signal display and the programming of control panel. Faults and alarms are displayed through suitable

luminous leds. It is possible to display the analogic level of each detector, the detector type and the belonging

zone. The historical memory can total up to 1000 single or combined events carrying date and hour.

PART 1

DETAILS

Page 7of 91

Rev. 4.

2

0

ØThe control panel has:

1. 2 supervised outputs, one of which is preset for the siren;

2. 2 no supervised outputs at programmable clean relay NO/NC;

3. 4 open collector outputs programmable for typology of alarm and zone.

ØThe control panel is preset for three opto-isolated serial ports, RS-232 and RS-485.

1. COM1

•Module RS 232: Mini-net, LAN TCP/IP.

•Module RS 485: LAN 485.

2. COM2

•Module RS 232 (default): PC, LAN TCP/IP

•PS2: keyboard PS2.

3. COM3

•Module RS 232: Report of detector check.

ØThe control panel is preset for a further output PS2 to which it is possible to connect a keyboard for a quicker

programming of points and zones.

ØAll the programming of the control panel can be made through the panel of the control panel itself, using the

keys that have alphanumeric function.

The possible connections through the three gates described previously are given below.

Rs232 SERVICE PC

Ps2 keyboard

RS232 PC

Detectors status info

LAN TCP-IP

max 64 C.P.

SLAVE

CONTROL

SLAVE

CONTROL

MASTER PC

LAN

1

RS485 Slave control panels net

connected to Master PC,

(Max 64 control panels).

MOXA

MODUL

MOXA

MODUL

MOXA

MODUL

CONTROL PANEL

2

3

Page 8of 91

Rev. 4.

2

0

1.2 POINT ADDRESSING AND ACQUISITION

The necessity of being able more and more to facilitate the phase of starter of the system from part of the

installer, has made way of having to develop more ways of installation of the points in the loop. The installer turns

out therefore not obliged from procedures rigid and standards, being able to choose at second of the situations

the way simpler than installation.

The acquisition of a point from the control panel, can be executed with four different procedures of acquisition

addressing:

1. Acquisition for installation (valid only detectors);

2. Acquisition for activation;

3. Acquisition for serial number (only if the serial number label is present in the point);

4. Acquisition for preset address.

For a suitable selection of the acquisition procedure, refer to the “PRELIMINARY REMARKS FOR A CORRECT

INSTALLATION”.

Remember that:

The acquisition of points through the installation is preferred when it is necessary to insert further un-addressed

detectors on the loop, but on already installed base, along and already active loop and that presents already

addressed points (example: isolators modules – buttons).

The acquisition of points through starting provides for the activation of already installed points along the loop. Such

points must have address 0.

The acquisition of points through serial number provides for the acquisition of a point through the research of the

series number of the same point.

The acquisition of points through the preset address provides for the acquisition of further already installed points on

the loop and addressed previously. The user must not have points with address 0 on the loop.

For more information see chapters: 7.1 and 0.

Page 9of 91

Rev. 4.

2

0

2.1 SAFETY REQUIREMENTS

The installation of the product must be performed by authorized technicians who scrupulously follow all safety

norms and procedures –law provision N° 46/90 (Legislative March 5 1990, n° 46). Only such appointed personnel

is authorized to open the Control Panel; inside there may be parts run through voltage electricity.

The product, is Class I conforming to the EN 60950-1 Normative, must be connected to the mains power line and

maintain the grounding connection and power surge protection (PE) as described on chapter 2.2.

Where to install the product.

The product should be installed in a dry area which is not subject to weather agents. Make sure that sufficient

space is left around the control panel box so that some ventilation is guaranteed. Do Not install the product on top

of or nearby a heat source or dusty areas or wherever there could be corrosive environments.

Excessive operating temperature may lead to malfunction and subsequently influence the overall performance

and duration of the product itself.

In presence of Humidity such as occasional drops of water caused by condensation may damage the product. In

the event of condensation, it is advisable to wait until the area is dried. If the product has been stored in a cold

environment for a long time, it is advisable to wait a couple of hours before the actual power up to the mains

electrical line.

IMPORTANT: only authorized personnel can open the product. Do Not try to open it without proper authorization

or else the warrantee will be Void. Remember to disconnect the mains power line and internal batteries before

proceeding to the regular maintenance every time.

2.2 CONNECTING THE CONTROL PANEL TO THE MAIN POWER LINE

230VCA

It is expected that the electrical wiring edifice/building in which the Control Panel resides is adequately furnished

with a mango-thermic switch as protection for overloads / power surges on line and short circuits.

An adequate omni-polarity switch should be in the power line frame and a accessible connector space fitting of at

least 3mm. apart. It is contemplated to adopt a uni-polarity sectioner device for the conductor phaser so that one

may identify the neutral.

The connector leads for the main power frame and internal cabling must be safely fastened by proper fastening or

fixing materials.

Shut-off main power before substituting the battery or performing other “open box” interventions on the product.

Introduce the mains power line of 230Vca in the panel container through the top right-hand corner by keeping it

distant from any internal wiring, micro-chip or main board circuitry.

Feed the power to the Control Panel adopting the proper mango-thermic power switch. The main line conductor

cable must be of at least 1,5mm² thick with a power work load which can sustain 250Vca.

NOTE: the output relays must be connected only to the circuits type SELV (not harmful power tension) in ref. to

the EN 60950-1:2001 Normative.

2.3 FUSES

On the electronic circuit board there are 5 fuses inserted on as many fittings placed vertically and they have their

feature functions described: type (F= fast, T= delayed) and nominal current.

To better learn all their general characteristics and which fuse is for which function; make reference to the

technical table reported on PART 19. Please comply to what is indicated and to not change or switch the for any

given reason or else you may alter the functioning and may cause serious faults to the Control Panel.

PART 2

CONTROL PANEL INSTALLATION

Page 10 of 91

Rev. 4.

2

0

- B1+ - B2+

- AUX +

FAULT - + (30Vdc)

N L

Battery fuse AUX power supply fuse

AC-DC ADAPTOR

230Vac 30Vdc

Trimmer Vac fuse

Siren out2 fuse 24Vdc out1 fuse

Fault out3 fuse

+

-

+

-

12V 7,2Ah

12V 18Ah 12V 7,2Ah

12V 18Ah

FAULT + - (30Vdc)

-

1

B

+

1

B

S

H

I

-

1

A

+

1

A

-

2

B

+

2

B

S

H

I

-

2

A

+

2

A

-24

+24

SHI

+ S

- S

- +

FAULT

SHI

OC 1

OC 2

OC 3

OC 4

RL2

RL1

PS2

N L

LINE 230Vac

F1 F2 F3

F4 F5

F6

F1: F315mAL 250V

F2: F315mAL 250V

F3: F315mAL 250V

F4: F1,6AL 250V

F5: F1,6AL 250V

F6: T400mAL 250V

FUSES LIST

2.4 FIXING THE CONTAINER

The control panel weighs about 10Kg without batteries inside (one battery weighs about maximum 6.5Kg). The

control panel must be fixed on a vertical wall or adapted and on equivalent support; it does not have to only come

supported without an adequate fixation. For the fixation to the wall, to use first the central holes, then the two

holes low. In order to improve the traction on the implantation support, it is possible to use the two holes in the up

too, for a total of five points of implantation. For the implantation, to use of the lives of 6mm of greater diameter.

For the fixing, use at least 3 screws of 6mm of diameter or more and with an adequate dowel. In case reinforce

the surface if necessary.

WARNING: the procedures described in this manual must be only made accessible to qualified personnel.

2.4.1 Cable arrangement

Payattention to the disposition 230Vac net cables and loops cables.

Watching frontally box the metallic opened, three rectangular openings on the bottom and three holes sluices pre-

cut on the top part, can be viewed.

Use the holes in the following way:

•rectangular hole or circular hole in top at left:

to use for the cables connected to the clips at left (outputs) and at the centrum (data transfer);

•circular hole in top at centrum:

to use for the cables connected to the clips at the centrum (data transfer);

•rectangular hole or circular hole in top at right:

to use for the cables connected to the clips at right (loop);

•rectangular hole in bottom at centrum:

to use for the cables connected to the clips in bottom (auxiliar output at 24Vdc) and that of the transformer

(230Vca);

It is advisable to arrange the cable in tidy mode, so as to diminish the eventual and remote interferences between

they and the control panel.

In particular it is advisable to avoid to make to pass under the card electronic cables of loop and power supply.

This operation, yet, is not necessary, in how much it control panel and the protocol of the data has been plans in

such mode to be immune at the disturbs and similar interferences.

2.4.2 Observation

In the connection between the control panel and the magneto-thermic power switch, it is reccomended to lock the

three-polar cable or the single power supply conductors in way that during the wiring there aren’t any mechanical

movements which may effect or weaken the connection itself.

The purpose of this pre-caution is to maintain in any case a electrical security condition.

Page 11 of 91

Rev. 4.

2

0

For the connection to the power supply clips, the electrical conductors must be terminated between terminal clips,

at scope to have in any case a electrical security condition.

2.4.3 Assembly

After having mounted the panel in the most appropriate place, verify proper cabling to adopt and where to run it:

•the rectangle holes on the case back;

•the round holes are normally closed on the top part of the metal case.

In the case the round pre-fitted holes aren’t utilized; please leave them closed so to prevent any metallic or other

pieces to fall into the metal case so that you may prevent damages to the electronic card inside.

In case you change the cable access to the metal case; make sure that the holes are closed off so to prevent any

possibility of damages to the electronic card.

As for the actual mounting; proceed in the following manner making sure that there is no mains power line or any

current connected:

1. open the front cover by unscrewing the four screws on every corner 4x16;

2. only if you plan to pass the cables through the top holes; then you punch the pre-cut holes to access the

cabinet;

3. fix the metallic case by the three fixing/access points (first the middle one, then the two on the lower part);

one may also use the other two fixing holes on the top part in order to ensure a stronger fixing to the

surface;

4. introduce the cables into the metallic case in a most orderly fashion so that they are well sorted and

separated (follow the instruction reported on the previous page) so they do not run under the electronic

card.

5. proceed in inserting all the electrical connections as described on this manual;

6. close the front cover by re-screwing all the screws provided.

In the case the electronic card should be completely removed and /or re-inserted into the metallic case; pay extra

attention to the ground wire with cable endings "ring type" secured by soldered steel nuts to host the metal screws

4x20 directly on the metallic case.

When the electronic card is re-inserted, re-apply the ground cabling as they were originally: if not executed in this

way the electric safety conditions may be jeopardized.

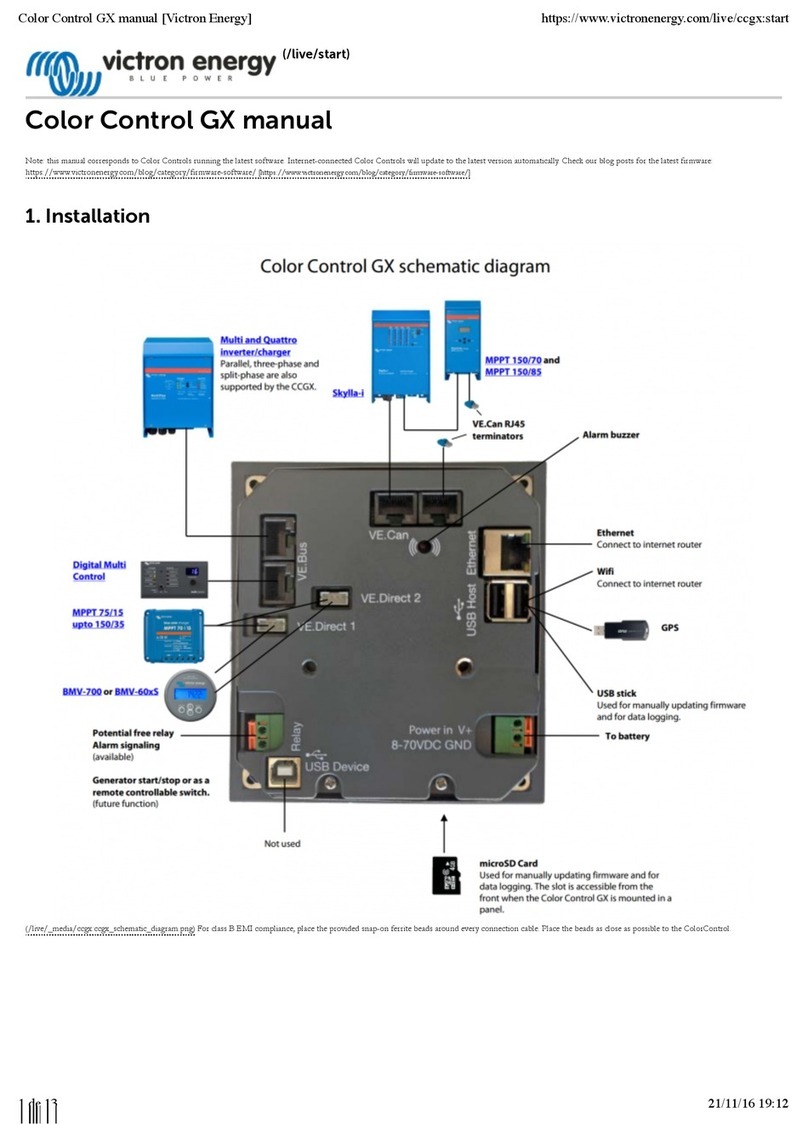

2.5 CONNECTION

The motherboard of the control panel in picture 2. The positions of the clips and fuses are pointed out. Besides

the connector PS2 for the keyboard and the grey button of resetting to push at the first starting of the control

panel are pointed out.

The left clips concern the control panel outputs (see charter PART 9 page 45), and exactly:

Ø(out5) Clips RL1 (SEL4): relay 1 is a clean relay no supervised that can be programmed NO/NC;

Ø(out4) Clips RL2 (SEL3): relay 1 is a clean relay no supervised that can be programmed NO/NC;

Ø(out9) Clips OC4: open collector No 4 programmable for typology of alarm and zone;

Ø(out8) Clips OC3: open collector No 3 programmable for typology of alarm and zone;

Ø(out7) Clips OC2: open collector No 2 programmable for typology of alarm and zone;

Ø(out6) Clips OC1: open collector No 1 programmable for typology of alarm and zone;

Ø(out3) Clips FAULT (SEL1,2): supervised output of fault;

Ø(out2) Clips –S +S: supervised siren;

Ø(out1) Clips +24 –24: auxiliary power supply 24Vdc.

WARNING: after the cable connection of the power supply to the GND-N-L clips of AC-DC Adaptor, it is important

to immobilize the three electrical cables with a plastic strip. It is necessary to prevent that electrical cables are free

to move.

WARNING: the power supply cable must have the ground electrical cable (GND) more long respect the line (L)

and neuter (N) cables.

Page 12 of 91

Rev. 4.

2

0

-AUX +

FAULT - + (30Vdc)

N L

Battery fuse

AUX power supply fuse

Ps2 keyboard

LOOP

Optional serial gates

Control panel outputs

Resetting fault system

AC-DC ADAPTOR

230Vac 30Vdc

Trimmer Vac fuse

Siren out2 fuse 24Vdc out1 fuseFault out3 fuse

COM1 COM2 COM3

+

-

+

-

12V 7.2Ah

12V 18Ah 12V 7.2Ah

12V 18Ah

FAULT + - (30Vdc)

-

1

B

+

1

B

S

H

I

-

1

A

+

1

A

-

2

B

+

2

B

S

H

I

-

2

A

+

2

A

-24

+24

SHI

+ S

- S

- +

FAULT

SHI

OC 1

OC 2

OC 3

OC 4

RL2

RL1

PS2

- B1+ - B2+

Fig.2 -Description of motherboard of the control panel.

2.5.1 The circuits of the detection

The control panel supports exclusively detectors and modules that use a communication system of digital data.

A part from a few models, which need auxiliary power supply 24Vdc, the elements are supplied and communicate

with the control panel through two cables connected to an input module. The detection circuit must be kept the

farthest possible from the other installations and the cables passage, to reduce the risk of external interfaces.

Don’t forget, use shielded and twisted cable, to reduce the interferences. The section will depend on the length of

loop.

WARNING

Installations with cable length superior to 2Km are not advised, because the capacity and the induction of cable

can start to interfere with data communication from this length onward.

LENGTH (m) SIZE (mm2)CAPACITY (pF/m)

Length up to 500 m min0,5 max. 150

Length up to 1000 m min1,0 max. 120

Length up to 2000 mmin1,5 max. 100

N.B.: test lines as provided in “LINE CABLE TEST PROCEDURE BEFORE LOOP CONNECTION” before

connecting loop to the control panel.

The system is preset for the installation up to four circuits of detection (1, 2, 3 and 4 loops) with a maximum

capacity of 508 points (detectors, buttons, Input/output modules or isolator) with the possibility to install up to 120

points (exclude isolator) in a single loop.

As reported in the instructions of the single products, the detectors, buttons and Input/output modules must be

addressed.

The descriptions of the different procedures of programming –addressing (single point; self-increment; through

series number) will be dealt with in PART 4 of this manual.

Page 13 of 91

Rev. 4.

2

0

MUDULO

EX-MEI/O

MUDULO

EX-MEI/O

SHORT CIRCUIT

ISOLATOR

MODULE

ISOLATOR

MODULE

MUDULO

EX-MEI/O

MUDULO

EX-MEI/O

ISOLATOR

MODULE

ISOLATOR

MODULE

INTERRUPTED

LINE

The installation of a detection circuit is made connecting all the control devices so that one closet ring is obtained.

As regards the conformity of the system to the rules UNI 9795 and EN 54-2, it is necessary to insert at least a

module isolator every 32 detectors or buttons. One can install up to a maximum of seven modules isolators for

each loop.

The connection uses the clips A-/ A+ for the installation output and B-/ B+ for the return of the same one.

The cable shielding (shielded) is connected only the part of starting to the clip SHI. The shielded of arrival

must not be connected.

•Start from +1A and arrive at +1B, start from –1A and arrive at –1B.

•Connect the cable shielding (SHI) of the starting part to the clip SHI. The arrival shielded must not be

connected.

•If a loop is not used it is necessary to short circuit it with the jumper (-A with –B and +A with +B).

In case a short circuit on the line is produced, the part of circuit interested by the fault and included between the

two modules isolator will be disconnected, with the consequent loss of communication of a maximum of 32

elements (maximum number of elements that the rule UNI 9795 allows to lose in case of line short circuit). In case

of single interruption of loop, the control panel will be able to communicate from the two sides (output and return)

without losing the communication with the other installed elements.

Both the short circuit and the line interruption produce a fault restorable only to executed repair.

2.5.2 Fire alarm siren output

The clips of siren output are identified with the initials S+ and S-.

Each output is supervised for different faults of short circuit or open circuit. It is necessary to connect a 5.6 K• -

1/4 watt resistance of end of line on the last siren of the line. In order to ensure a most accurate supervision, the

siren must be connected to a dedicated line with a terminal resistance. One should not make several lines which

carry also as many terminal resistances, this could result in an incorrect functioning.

In the picture below an example of connection of two sirens.

As regards the maximum supplied current from each output, see page 90.

It is always advised to use fireproof shielded and twisted cable.

SIREN

5.6 Kohm 1/4W

5.6 Kohm 1/4W

-

2

4

+

2

4

S

H

I

+

S

-

S

- +

FAULT

SHI

OC 1

O

C

2

O

C

3

O

C

4

RL2

RL1

Page 14 of 91

Rev. 4.

2

0

2.5.3 Output for alarm siren fault

The fault output connector terminals are identified and marked as FAULT.

The output is normally supervised, but it is possible to change the type of set-up by acting on the software

configuration (see chapter 9.2.4) e hardware (by the Jumpers “SEL1”). In the case of selection of output

supervised, an end of line resistor of 5.6KΩ-1/4Watt needs to connect on the last siren of the line.

For the maximum power allowed on every output, see pg. 90 of this chapter.

It is advisable to always use a fire-resistant, double twisted and protected cable for the installation.

Depending on how the “CONFIG.” parameters are set-up (see chapter 9.2.4), it is necessary to modify, while the

control Panel is off, and the relative Jumpers to “SEL1”:

SUPERVISED OUTPUT

SIREN

5.6 Kohm, 1/4W

5.6 Kohm, 1/4W

-

2

4

+

2

4

S

H

I

+

S

-

S

- +

FAULT

SHI

OC 1

O

C

2

O

C

3

O

C

4

RL2

RL1

SEL4

SEL3

SEL1

SEL2

Only in this case the output is protected by a fuse (see chapter 2.5).

OUTPUT 24V MISSING

SELF-POWERED

SIREN

5.6 Kohm, 1/4W

-

2

4

+

2

4

S

H

I

+

S

-

S

- +

FAULT

SHI

OC 1

O

C

2

O

C

3

O

C

4

RL2

RL1

SEL4

SEL3

SEL1

SEL2

COMMAND: POSITIVE DISCONNECTED

+

-

OUTPUT RELAY NOT SUPERVISED N/O

SIREN

5.6 Kohm, 1/4W

-

2

4

+

2

4

S

H

I

+

S

-

S

- +

FAULT

SHI

OC 1

O

C

2

O

C

3

O

C

4

RL2

RL1

SEL4

SEL3

SEL1

SEL2

+

-

Page 15 of 91

Rev. 4.

2

0

OUTPUT RELAY NOT SUPERVISED N/C

SIREN

5.6 Kohm, 1/4W

-

2

4

+

2

4

S

H

I

+

S

-

S

- +

FAULT

SHI

OC 1

O

C

2

O

C

3

O

C

4

RL2

RL1

SEL4

SEL3

SEL1

SEL2

COMMAND: POSITIVE DISCONNECTED

+

-

2.5.4 Outputs of auxiliary relays no supervised

The control panel circuit includes two outputs of programmable auxiliary relays no supervised, with contact NO or

NC free from 1A, 120Vdc / 24Vdc. For the connection of auto-supplied sirens refer to the product instructions.

It is advisable to always use a fire-resistant, double twisted and protected cable for the installation.

For the output configuration, refer to the chapter titled 9.2.5.

2.5.5 Open Collector outputs

Control panel has 4 programmable Open collector outputs. The load must be connected between the open

Collector output and the clip (+) of the 24Vdc ausiliary output. In this condition, the maximum current available is

of 24-27mA, this value depends on a resistance of 1K• that it comes put in series to the output.

+24

-24

OC1

1Kohm

R

load

2.5.6 Auxiliary output 24 Vdc

The circuit includes an auxiliary output 28.5Vdc (with external power supply) 25Vdc (without external power

supply) 300mA. It is advised not to connect too many devices not to overload this output. Do not exceed the

maximum supplied current of 300mA. In case use a source of auxiliary power supply.

The output is protected by a fuse (refer to the chapter titled 2.5).

2.5.7 Serial ports

ØThe control panel is preset for three opto-isolated serial ports, RS-232 and RS-485.

4. COM1

•Module RS 232: Mini-net, LAN TCP/IP.

•Module RS 485: LAN 485.

5. COM2

•Module RS 232 (default): PC, LAN TCP/IP

•PS2: keyboard PS2.

6. COM3

•Module RS 232: Report of detector check.

Page 16 of 91

Rev. 4.

2

0

2.5.8 Connection to the power supply

Execute the connections with suitable materials and procedures prescribed by the rules in force.

Do not execute the electrical connection unless you have verified the actual power cut-off.

PLEASE NOTE

•At the moment of installation always connect the mains 230Vac first and then the batteries. In this manner

you prevent dangerous shock sparks.

•The power cable for the Control Panel must be connected, for safety reasons and to facilitate

maintenance, to a magneto thermic switch dedicated and with proper electrical specifications. The

electrical connection should be direct without any kind of by-pass plug or prongs.

•The minimum required size of cable for power supply must be of 1,5mm² e 250Vca.

•The ground wire (yellow/green) and properly connected by the ground fastner screw from the power

supply to the other end of the mains power. Furthermore, it must be properly fixed with the screws

provided so to ensure it from mechanical solicitations.

•All cables connected to the Control Panel must be fire proof.

•Since the connection to the mains is not off the ground so it does not require any further fastening or

special support to the Control Panel. Shall the case require, please carefully apply any extra cable

connection between the Control Panel and the magneto thermic switch so that the cables and the end

terminals will not be subject to pulls or jerks in their passage way.

•To apply the connector cable to the power supply. the conductor cable endings should be "pin type", this

to ensure and maintain the safety conditions.

2.5.9 Battery connections

On the control panel electronic circuit board there is a fitting to host the power supply from the two auxiliary

batteries.

In the actual connections, pay careful attention to the polarities and to the color differentiation of the cables and

battery terminals. In case of faulty connection, the circuit breaker fuse which is removable will protect the battery

and circuit board.

2.6 LOOP SECTION

A section is a loop partition between two isolators. A loop carrying no partition has only one isolator, section (A-B).

In this figure there is a example of loop with 5 sections and 4 EX-MEIS isolators. The clips A are the loop start

and B are the loop end. The section partition is not applicable when there’re passive EX-ISO isolator.

2.7 LOCATION OF GROUND SHUNT IN THE CONTROL PANEL

The control panel checks the connection of the installation all the time to point out if some external cables have a

round dispersion. In this case an information in the control panel of ground shunt is given through a yellow led.

The control panel will work properly with a round shunt in the system. However it is suitable to solve the fault as

soon as possible.

Most round shunts are located making resistance measures in the cables before collecting them to the control

panel.

Round shunts can be found in the following external connections:

•Connection of siren circuits.

•Connection of detection loop.

•Auxiliary output of 24 Vdc.

ISOLATOR

121

ISOLATOR

122

ISOLATOR

123

ISOLATOR

124

CONTROL

PANEL

A-121 121-122 122-123

123-124124-B

Page 17 of 91

Rev. 4.

2

0

2.8 MAINTENANCE

The maintenance measures advised in EN 54-14 must be followed.

2.8.1 Daily control

The user will check that:

•The control panel works properly. Otherwise the faults will be reported and registered and the

maintenance staff must be informed.

•It is advisable that all or any faults during testing or noted previously, are solved as soon as possible, for

a correct functioning of the control panel.

2.8.2 Weekly control

•It is advisable to check the status of disconnected and connected batteries.

•A detector or a button will be started up to test the control panel and the connected fittings of alarm. It is

suitable to check a different zone every month.

•Where it is admitted, inform the fire brigade or the control centre.

Any malfunctioning must be noted in the event register. The problems must be solved as soon as possible, in

case contacting the installer.

2.8.3 Four-monthly control

The maintenance staff must carry out the following controls:

•Look over the notes of the event register.

•Examine all the connections of batteries.

•Check the alarm functioning, auxiliary fault of the control device and signaller.

•Visual inspection of the control devices and signaller, a possible rise in humidity or any other type of

decay.

•Check there are not structural changes that can cause the malfunctioning of the detectors, manual

buttons or sirens. In this case carry out a visual inspection, too.

Any problem must be noted in the event register, solving the probable problems as soon as possible.

2.8.4 Yearly control

The maintenance staff must have the duty to perform the following controls:

•Carry out the control procedures advised daily, monthly and four-monthly.

•Test the control panel and check all the detectors work as recommended by the manufacturer (check the

parameters).

•Look over visually all the connections to the devices and relative supports are safe, they are not damaged

and are protected properly.

•Examine and check all the batteries.

Any fault must be noted in the event register, solving the problems as soon as possible.

2.8.5 Cleaning the Smoke Sensor

For proper functioning of the detector, it is necessary to perform a yearly periodic maintenance check of at least 2

interventions.

Detector Test: verify the proper functioning of the detector through a smoke device by paying careful attention in

not getting the internal chamber dirty or damage the sensor itself. An alarm simulation can be performed by

activating the internal Reed by placing a magnet (note: the Reed test does not qualify as a smoke test).

Detector cleaning: the detector must be cleaned by means of compressed air blown through the internal part of

the detector. Unscrew the bottom counter-plate screws to take the internal chamber out from the detector head.

Clean the chamber, reassemble by making sure that the bottom counter-plate properly matches the fitting (the

part where the Reed is placed corresponding to the n°4 of the bottom plate). Close the detector by replacing the

screws without screwing too tightly.

Page 18 of 91

Rev. 4.

2

0

3.1 LINE CABLE TEST PROCEDURE BEFORE LOOP CONNECTION

For connection use twisted and shielded cable with electro conductive cable characteristics as reported on table:

LENGTH (m) SIZE (mm2)CAPACITY (pF/m)

Length up to 500 m min0,5 max. 150

Length up to 1000 m min1,0 max. 120

Length up to 2000 mmin1,5 max. 100

Check if line isolators are present: they must have been installed with zero address. In this case, at unsupplied

line, the contact of isolator will be off to allow the test of negative-positive electro conductive cables and shielded

at both ends of the loop.

TESTS TO EXECUTE FOR A CORRECT OPERATION OF CONTROL PANEL:

3.1.1 Line continuity

Check the resistance of line electro conductive cables (-1B and -1A, ...) with tester at 200 •.

A resistance for line electro conductive cables superior to 40 •is too high!!

Possible causes can be:

-the line is too long;

-free clips;

-false contacts;

-cable of insufficient section;

-partly cut off or damaged cable.

The cables must usually present a resistance between 20 and 25 •. Besides the resistance of the negative cable

and the positive one must result similar.

3.1.2 Shielded

It must present treble the resistance of line cables at most.

Warning: if shielded cable presents a resistance superior to treble line cables, it is necessary to check the path of

shielded itself.

The shielded must be shielded in the connection to the points (buttons, I/O modules, ...), to avoid the

short circuits with electronic parts..

3.1.3 Isolation between positive and negative of loop

A value superior to 20K•with 127 installed points or gradually increasing values of resistance with installed fewer

points can be found with tester at 200K•or higher range.

3.1.4 Isolation between SHI / –LOOP and SHI / +LOOP

Infinite Ohm value must be found for the isolation-make sure you are not powered up.

If the infinite value is not found, please check the positive and negative wiring for short circuit which may be found

throughout the loop circuit.

NOTE: the clip SHI gets inserted only in the shielded side (that is shielded of start). In the module isolator,

connect the shielded cable wire between the common terminal and the Common wire terminal.

PART 3

PRELIMINARY REMARKS FOR A CORRECT INSTALLATION

Page 19 of 91

Rev. 4.

2

0

3.1.5 Check of SHI short circuits at power supply line

Connect the positive clip +24; to the loop

Set the tester at 50Vdc and measure the voltage between shielded and the negative (of the battery or the clip –

24): THERE MUST NOT BE VOLTAGE!!!

A possible reading of voltage may occur in the case of short circuit in one ore more detectors or between the

shielded clip means that a short circuit, inside a few detectors, between shielded clip and the clip R and the

terminal R and common terminal (common clip of base nr. 2 or nr. 3).

FURTHER CHECK FOR SHORT CIRCUITS ON THE LOOP LINE AND POWERED UP SYSTEM:

Connect the negative cable of the loop to the clip –24; all leds must flash.

Connect a 1KΩ-5Watt resistance between +loop and +24.

The un-flashing leds suggest a problem on the detector.

IF THE LEDS ARE STILL NOT FLASHING; CHECK FOR SHORT CIRCUITS ALONG THE LINE.

Warning: the presence of isolators along the line cuts off the check verification, so to have final proof for the

proper functioning, one may “Jeri Wire” the relay by bridging it to the jumper terminal.

Page 20 of 91

Rev. 4.

2

0

PART 4

ABOUT PROGRAMMING

4.1 CONTROLS AND INFORMATION

The EN-54 norms supplies two level of access for the control panel user. The access levels of the user are

defined as shown previously:

Level 1

All the information reads operative, the control panel controls are disabled.

The access to the superior level is obtained typing in a numerical code through the numerical keyboard.

Level 2

All the information and controls of the control panel are operative. In this level the system configuration cannot be

modified. However it is possible to activate or disable zones or sensors to modify time and date. The access to

level 3 is obtained typing in a numerical code through the keyboard. After a previously programmed time has

passed, the system will go back to level 1 automatically.

4.1.1 Control panel controls

Main control keys:

Silence Silence the internal buzzer.

Reset Delete all the alarm conditions and rearm the control panel.

Menu Access to auxiliary menu.

Besides there are other keys to enter the different functions.

1,2,3,4,5,6,7,8,9,0 Insertion of the numbers from 0 to 9 and the letters from a to z.

Arrow up Advance up wards of the selection.

Arrow down Advance down wards of the selection.

Left arrow Advance left wards of the selection.

Right arrow Advance rightwards of the selection.

Menu Main menu input.

Sel. Select.

Pre. Preceding.

Sub. Subsequent.

Mod. Modify.

Ok To confirm modification.

Scheme of the associations between numerical and alphanumeric push-buttons:

MODALITY

KEY “123” “abc” “ABC”

1 1 a b c A B C

2 2 d e f D E F

3 3 g h i G H I

4 4 j k l J K L

5 5 m n oM N O

6 6 p q r P Q R

7 7 s t u S T U

8 8 v w x V W X

9 9 y z space Y Z SPACE

0 0 space . space SPACE . SPACE

This manual suits for next models

1

Table of contents

Other FDP Control Panel manuals

Popular Control Panel manuals by other brands

B&R

B&R 4PP065.0571-B00 Technical documentation

Beckhoff

Beckhoff CPX29 0000 Series Installation and operating instructions

Renkforce

Renkforce 1713218 operating instructions

Freedom Scientific

Freedom Scientific TOPAZ PHD Reference card

ZKTeco

ZKTeco InBio Pro Series installation guide

Truma

Truma CP plus VarioHeat operating instructions

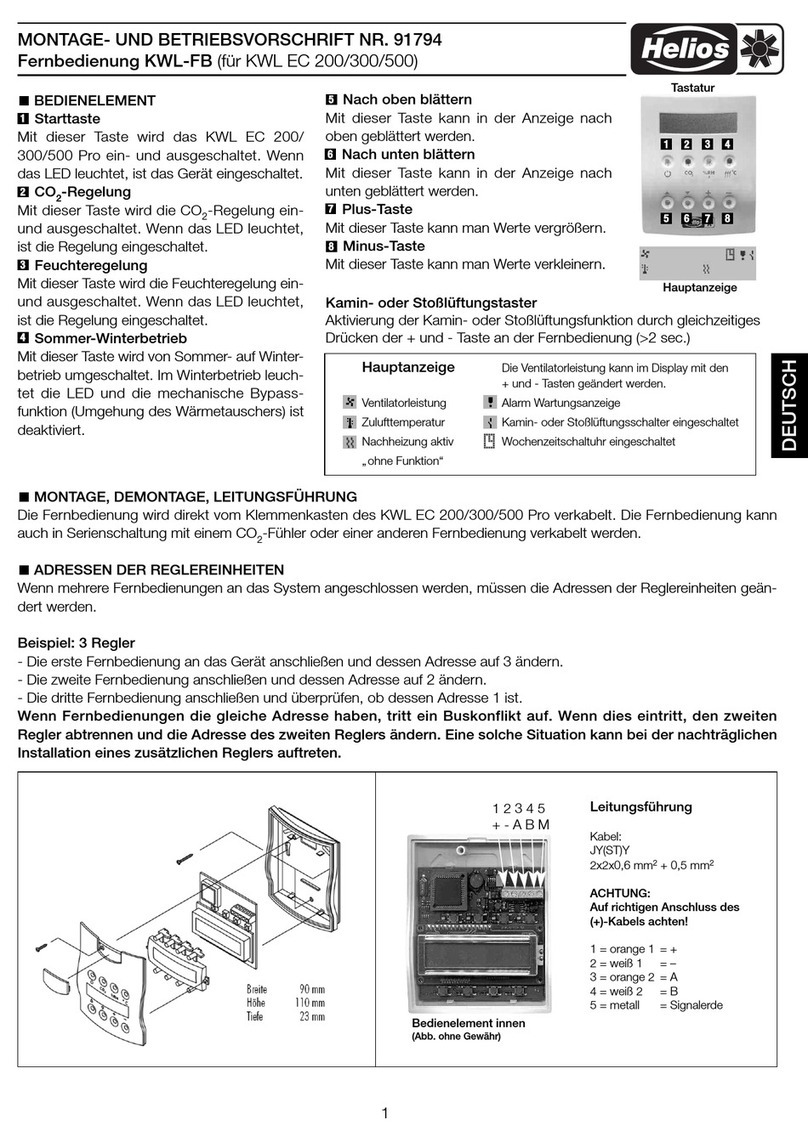

Helios

Helios KWL-FB Installation and operating instructions

Danfoss

Danfoss OPTYMA Control AK-RC 101 Operation and maintenance guide

CombiSteel

CombiSteel VBL-5 manual

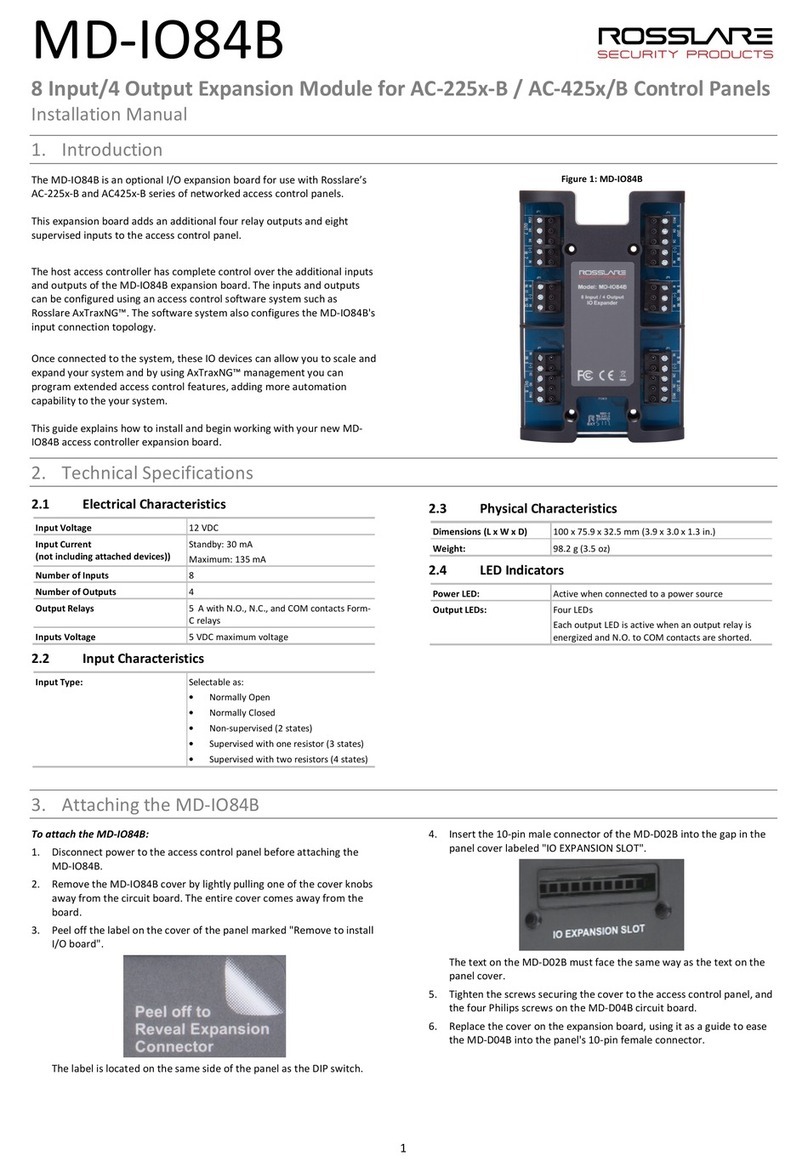

Rosslare

Rosslare MD-IO84B installation manual

AKO

AKO PROPlus 3PH Series quick guide

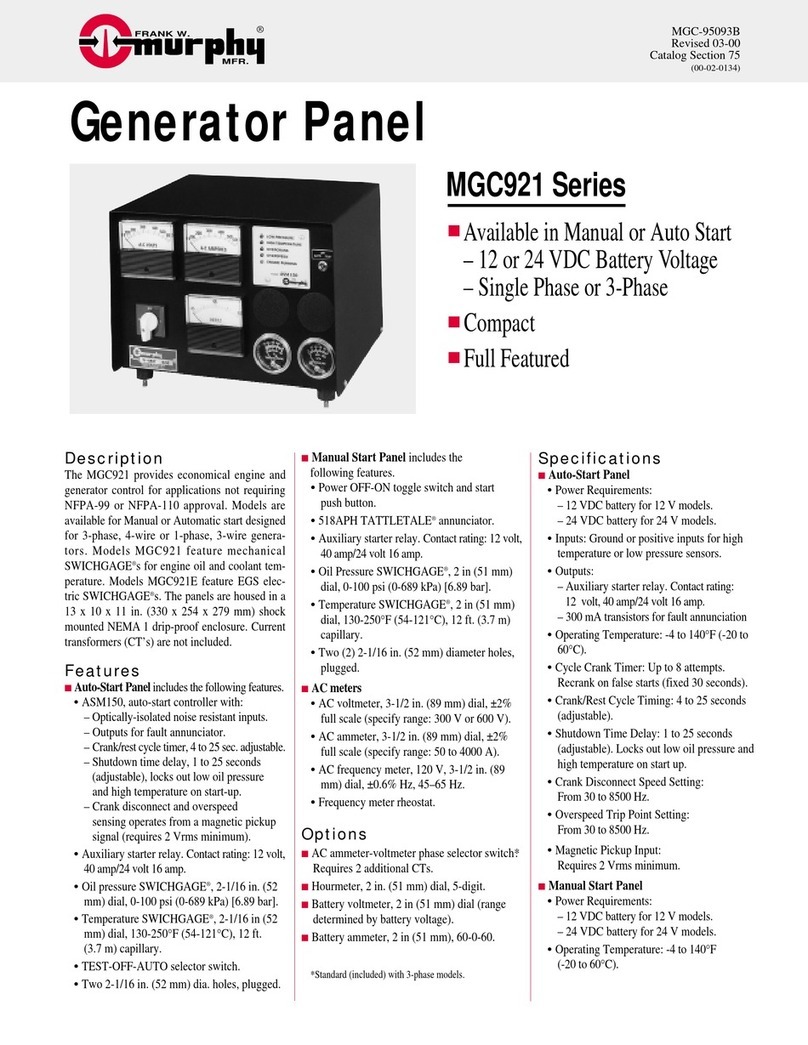

Murphy

Murphy Generator Panel MGC921 Series Specifications