Ethernet-I/P Fieldbus Expansion Unit

PAGE 8

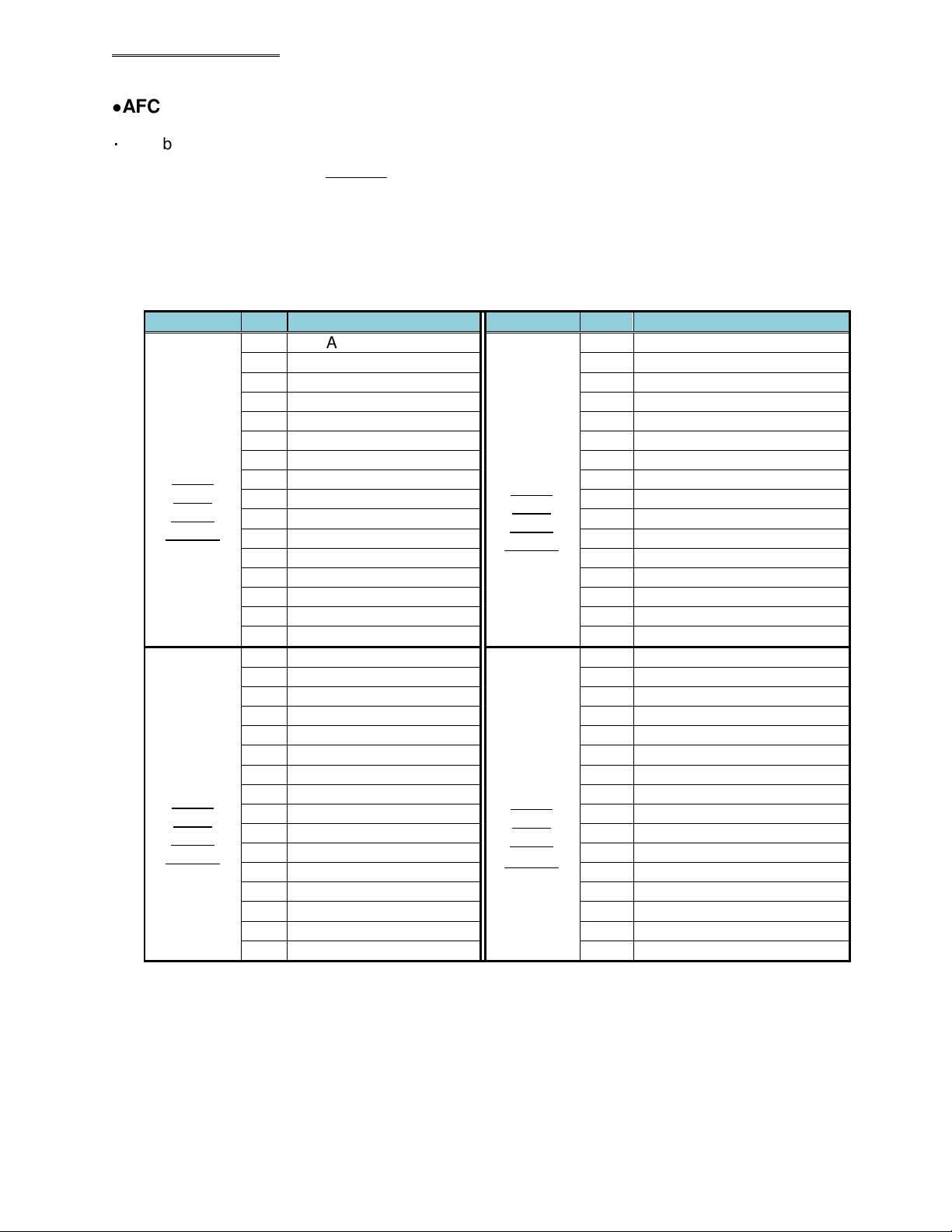

No.05

No.06

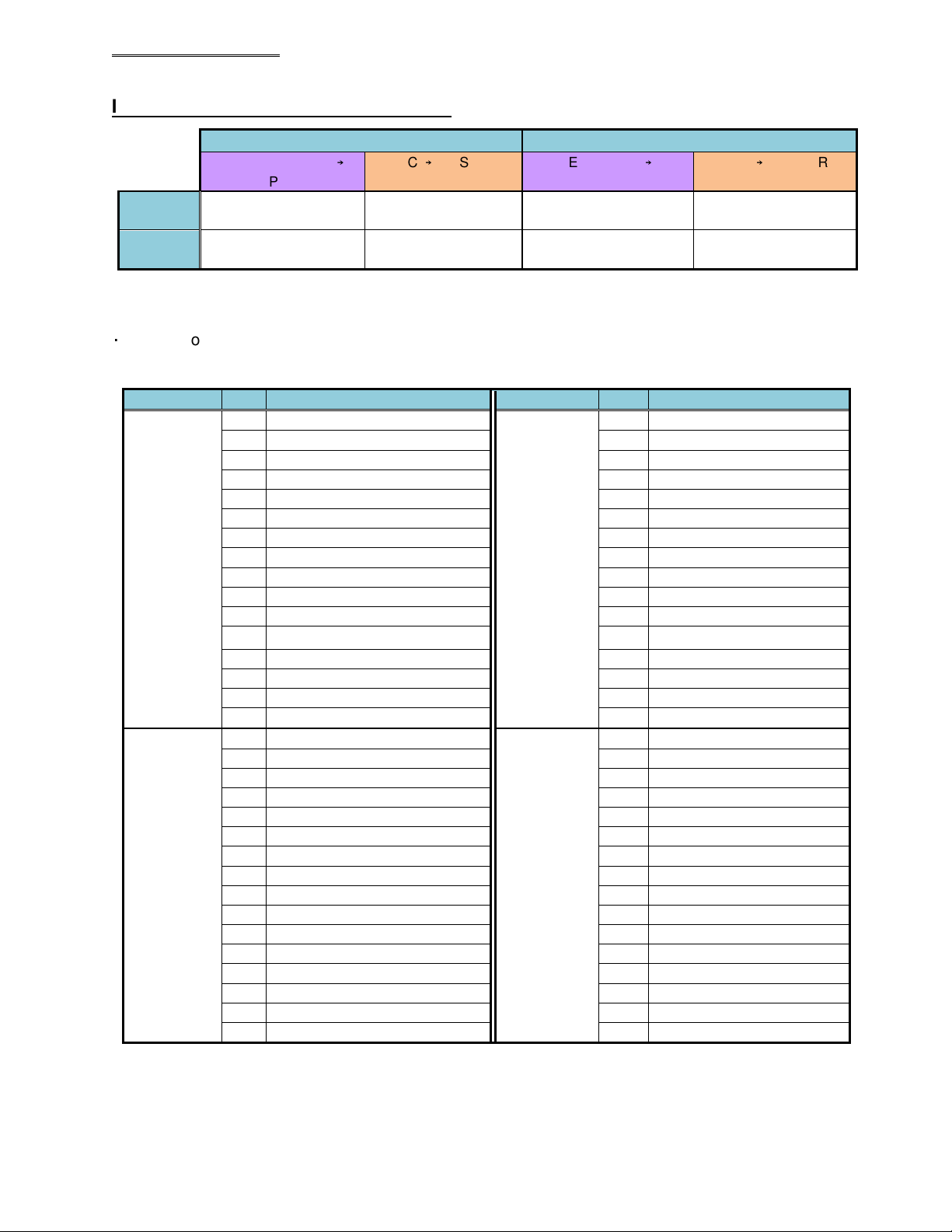

11

BYPASS SPDL No.22 11

* The word No. at the PLC side differs according to the setting of the node address, etc., so please be sure

to confirm before using. Please refer to the AFC3000 Operation Manual, Section 5-3-2 and 5-3-3 for

description of the respective signals.

The allocation of the input signals is fixed (cannot be changed).

The unused area of the inputs is also secured

(and cannot be used by other

devices).

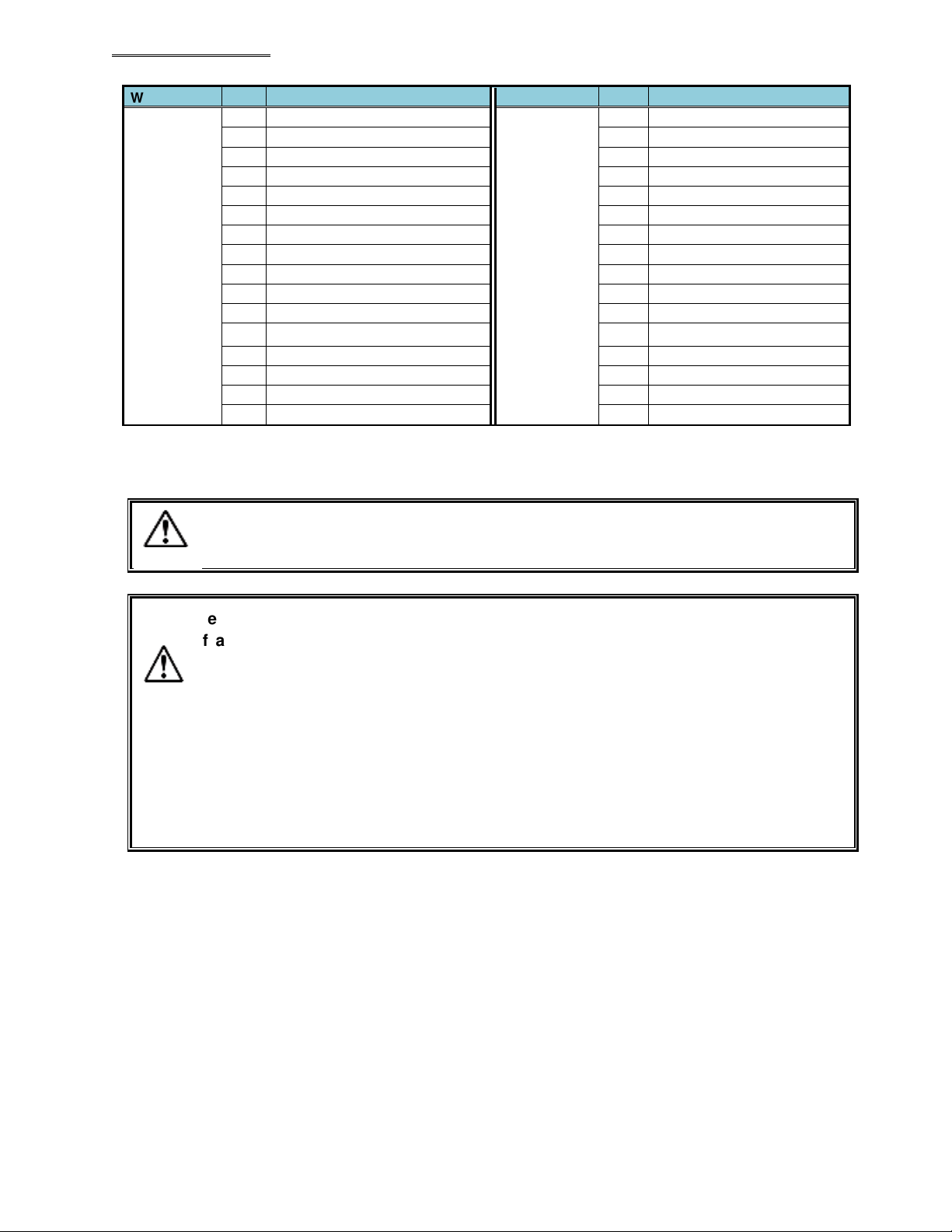

Be careful of the following points when using the BYPASS No. # (1 to 32) signals.

If a certain Unit is to be put in the BYP

ASS mode, set the corresponding signal

among the BYPASS No. # (1 to 32) signals to “ON” with the START signal of the Unit

being in the “OFF” state and the BUSY signal of the MASTER Spindle

communication and I/O (PLC) control being in the “OFF” state.

When fastening is executed with any of the spindle

BYPASS No. # (1 to 32) signals

in the “ON” state, the fastening judgment of th

at Unit will be ignored as if it does not

exist.

Also, when any of the BYPASS No. # (1 to 32) signals is set to “ON” with th

of the MASTER Spindle

being in the “ON” state, the sequence judgment may result

in REJECT.

Caution

Cautio