1

Before using the motor

■Introduction

Only qualied personnel should work with the product. Use the product

correctly after thoroughly reading the section “Safety precautions”.

Should you require the inspection or repair of internal parts, contact the

Oriental Motor oce where you purchased the product.

The product described in this manual has been designed and manufactured

for use in general industrial machinery, and must not be used for any other

purpose. Oriental Motor Co., Ltd. is not responsible for any damage caused

through failure to observe this warning.

■Standard and CE marking

Motors are recognized by UL and certied by VDE or DEMKO.

Recognized name and certied name are motor model name.

Voluntary display of the CE mark conforming to the Low Voltage Directives.

zStandards

UL 1004-1, UL 1004-2, UL 1004-3

CSA C22.2 No.100, CSA C22.2 No.77, EN 60950-1 or EN 62368-1

Standards File No.

UL File No. E64199 (6 W type), E64197 (60 to 90 W type), VDE, DEMKO

zApplications for standard

EN 60034-1, EN 60034-5, EN 60664-1, EN 60950-1 or EN 62368-1

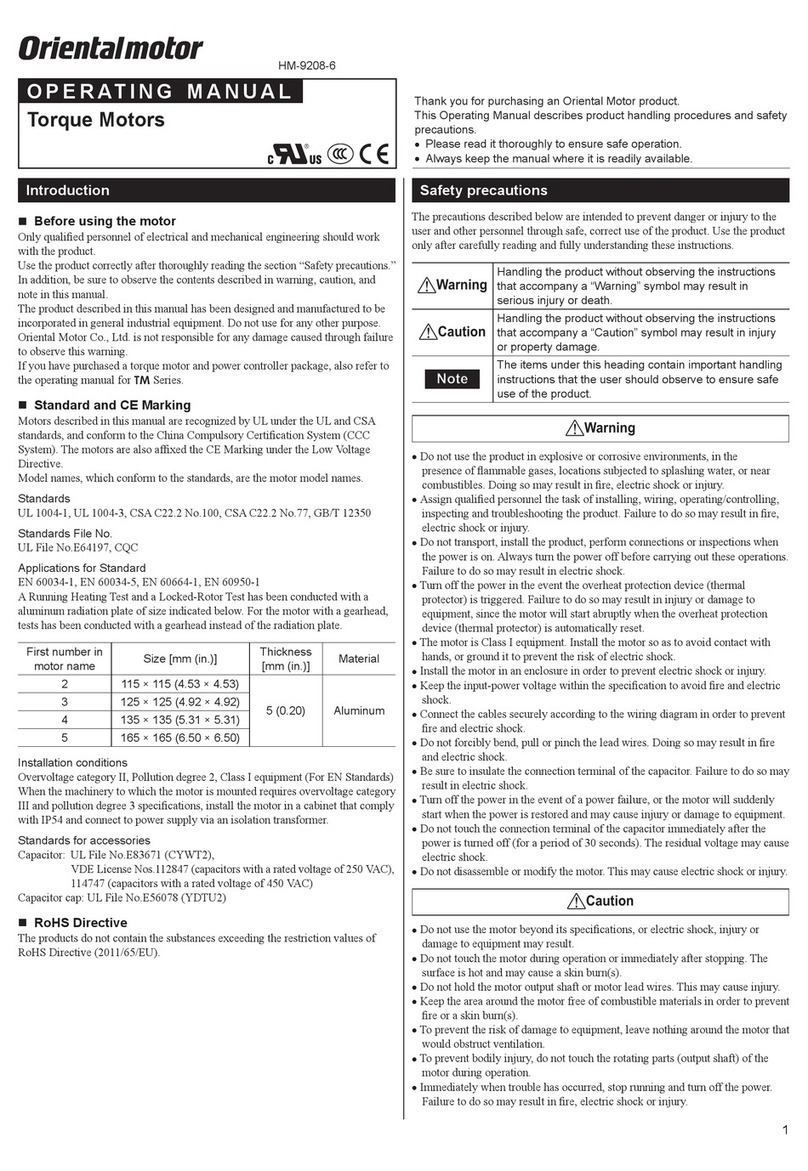

Temperature rise tests required by the standards are conducted for the round

shaft type motors are conducted in a state of attaching a heat radiation plate.

The size, thickness and material of the heat radiation plates are as follows.

First number in

motor name Size [mm (in.)] Thickness

[mm (in.)] Material

2 115 × 115 (4.53 × 4.53) 5 (0.20) Aluminium

5 200 × 200 (7.87 × 7.87)

zInstallation conditions

Overvoltage categoryⅡ, Pollution degree 2, ClassⅠequipment (For EN standards)

When the machinery to which the motor is mounted requires overvoltage

categoryⅢand pollution degree 3 specications, install the motor in a cabinet

that comply with IP54 and connect to power supply via an isolation transformer.

zStandards for accessories

Capacitor : UL File No. E83671 (CYWT2),

VDE Licence No.112847 (for only capacitor rated voltage 250VAC types,

capacitor model ending in FAUL2),

VDE License No. 114747 (for capacitor rated voltage 450 VAC types)

Capacitor cap : UL File No. E56078 (YDTU2)

Safety precautions

The precautions described below are intended to prevent danger or injury to

the user and other personnel through safe, correct use of the product. Use the

product only after carefully reading and fully understanding these instructions.

Handling the product without observing the

instructions that accompany a“WARNING” symbol

may result in serious injury or death.

Handling the product without observing the

instructions that accompany a“CAUTION” symbol

may result in injury or property damage.

Note The items under this heading contain important

handling instructions that the user should observe

to ensure safe use of the product.

•Do not use the product in explosive or corrosive environments, in the

presence of ammable gases, locations subjected to splashing water, or near

combustibles. Doing so may result in re, electric shock or injury.

HM-9189-6

OPERATING MANUAL

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety

precautions.

• Please read it thoroughly to ensure safe operation.

• Always keep the manual where it is readily available.

World KSeries Terminal Box Type

Induction Motors and Reversible Motors

•Assign qualied personnel the task of installing, wiring, operating/ controlling,

inspecting and troubleshooting the product. Failure to do so may result in

re, electric shock or injury.

•Do not transport, install the product, perform connections or inspections

when the power is on. Always turn the power o before carrying out these

operations. Failure to do so may result in electric shock.

•Turn o the power in the event the overheat protection device (thermal

protector) is triggered. Failure to do so may result in injury or damage to

equipment, since the motor will start abruptly when the overheat protection

device (thermal protector) is automatically reset.

•The motor is ClassⅠequipment. Install the motor so as to avoid contact with

hands, or ground it to prevent the risk of electric shock. If the motor has a

protective ground terminal, be sure to connect the terminal to the ground.

Dieser Motor ist in Geräten mit Schutzklasse I zu verwenden. Der Motor ist

so einzusetzen, dass er nicht berührt werden kann, bzw. er ist zu erden, um

Stromschläge zu verhindern. Wenn der Motor über eine Schutzerdungsklemme

verfügt, ist die Erdung über diese vorzunehmen.

•Install the motor in an enclosures in order to prevent electric shock or injury.

•Keep the input-power voltage within the specication to avoid re and

electric shock.

•Connect the cables securely according to the wiring diagram in order to

prevent re and electric shock.

•Do not forcibly bend, pull or pinch the lead wires. Doing so may result in re

and electric shock.

•Be sure to insulate the connection terminal of the capacitor. Failure to do so

may result in electric shock.

•Turn o the power in the event of a power failure, or the motor will suddenly

start when the power is restored and may cause injury or damage to equipment.

•Do not touch the connection terminal of the capacitor immediately after the

power is turned o (for a period of 30 seconds). The residual voltage may

cause electric shock.

•Do not disassemble or modify the motor. This may cause electric shock or injury.

•Do not use the motor beyond its specications, or electric shock, injury or

damage to equipment may result.

•Do not touch the motor during operation or immediately after stopping. The

surface is hot and may cause a burn.

•Do not hold the motor output shaft. This may cause injury.

•Keep the area around the motor free of combustible materials in order to

prevent re or a burn.

•To prevent the risk of damage to equipment, leave nothing around the motor

that would obstruct ventilation.

•To prevent bodily injury, do not touch the rotating parts (output shaft, cooling

fan) of the motor during operation.

•When an abnormality is noted, turn o the power immediately, or re, electric

shock or injury may occur.

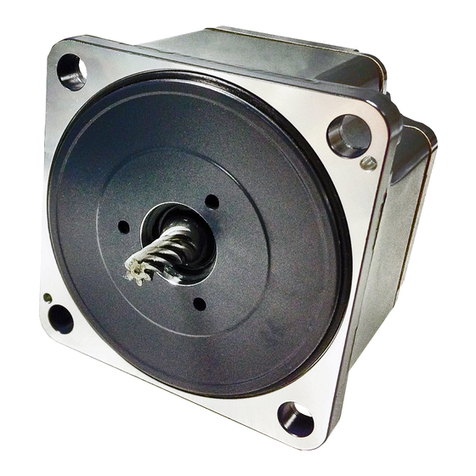

•The motor’s surface temperature may exceed 70 °C, even

under normal operating conditions. If a motor is accessible

during operation, post the warning label shown in the gure

in a conspicuous position to prevent the risk of burns. Warning label

•Dispose the product correctly in accordance with laws and regulations, or

instructions of local governments.

Preparation

■Checking the product

Upon opening the package, verify that the items listed below are included.

Report any missing or damaged items to the branch or sales oce from which

you purchased the product.

•Motor..................................................................1 unit

•Capacitor...........................................................1 piece (only for single-phase motor)

•Capacitor cap...................................................1 piece (only for single-phase motor)

•Operating manual (this manual) ..............1 copy