2

TABLE OF CONTENTS

SAFETY.................................................................................................................................................5

General power tool safety warnings .................................................................................................5

Jointer safety warnings.....................................................................................................................7

Brief description................................................................................................................................7

Double insulation ..............................................................................................................................7

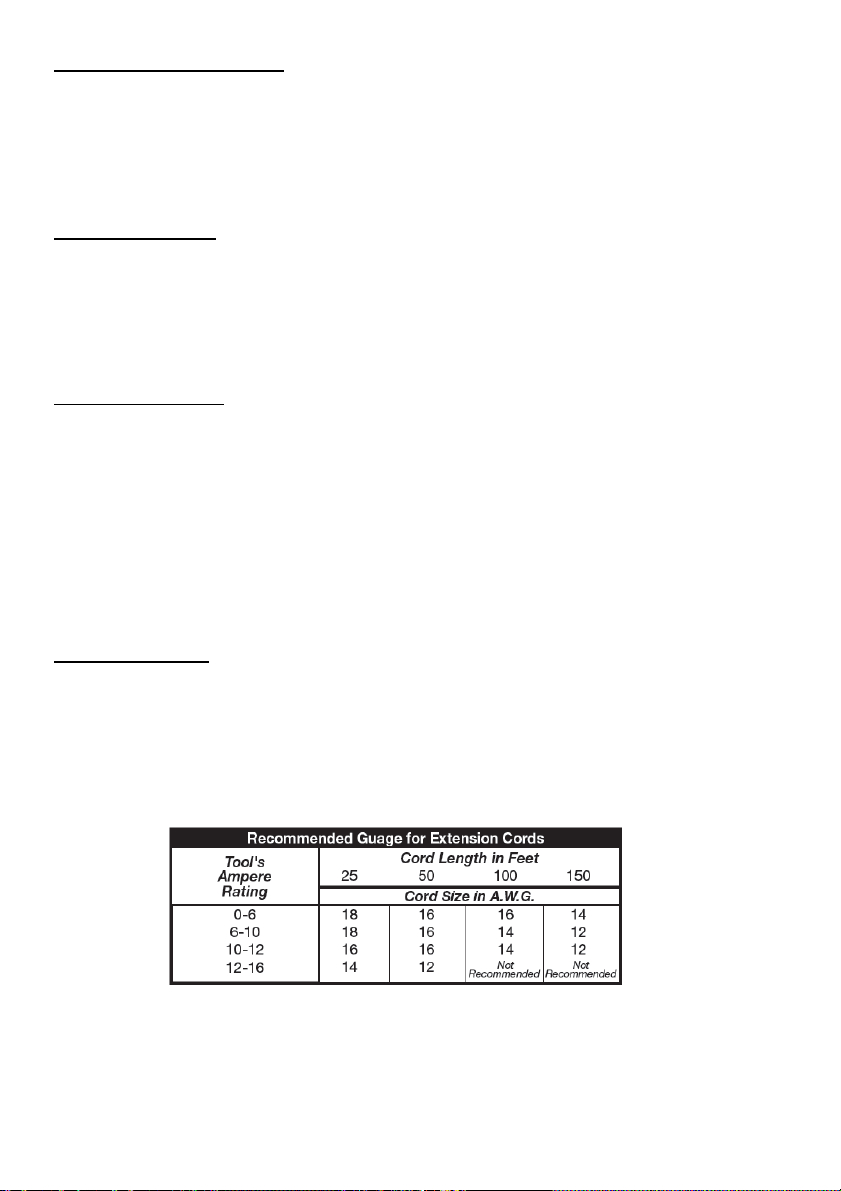

Extension cords ................................................................................................................................7

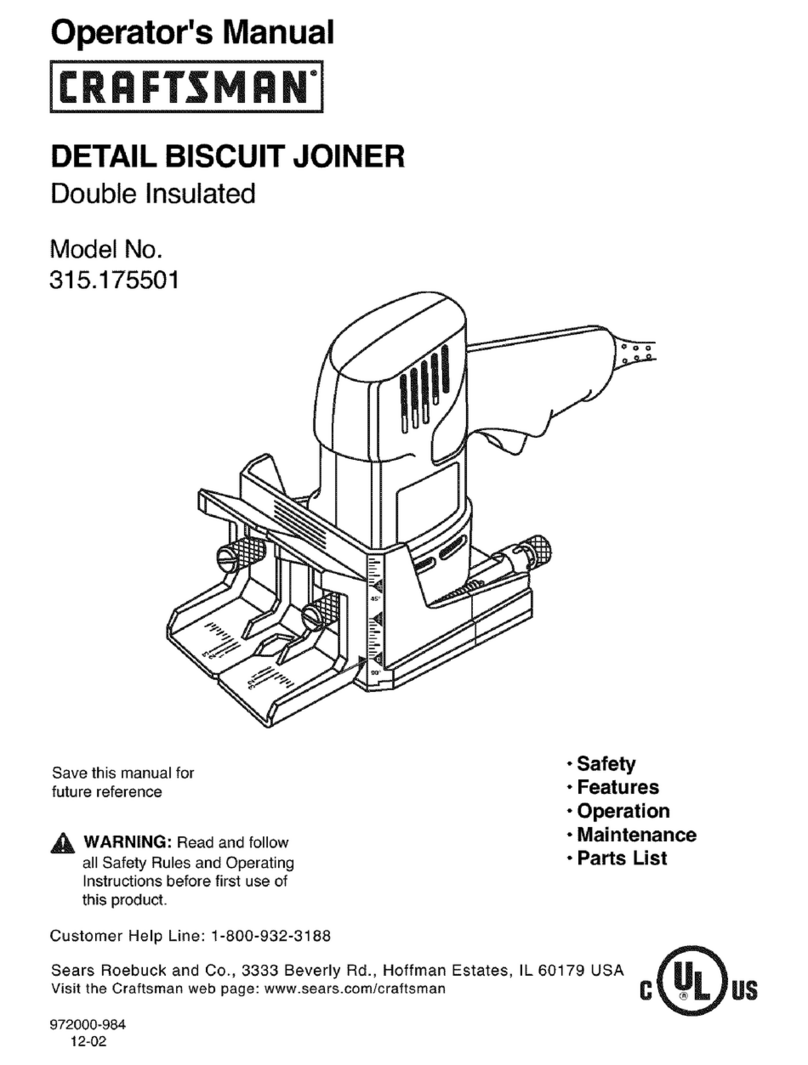

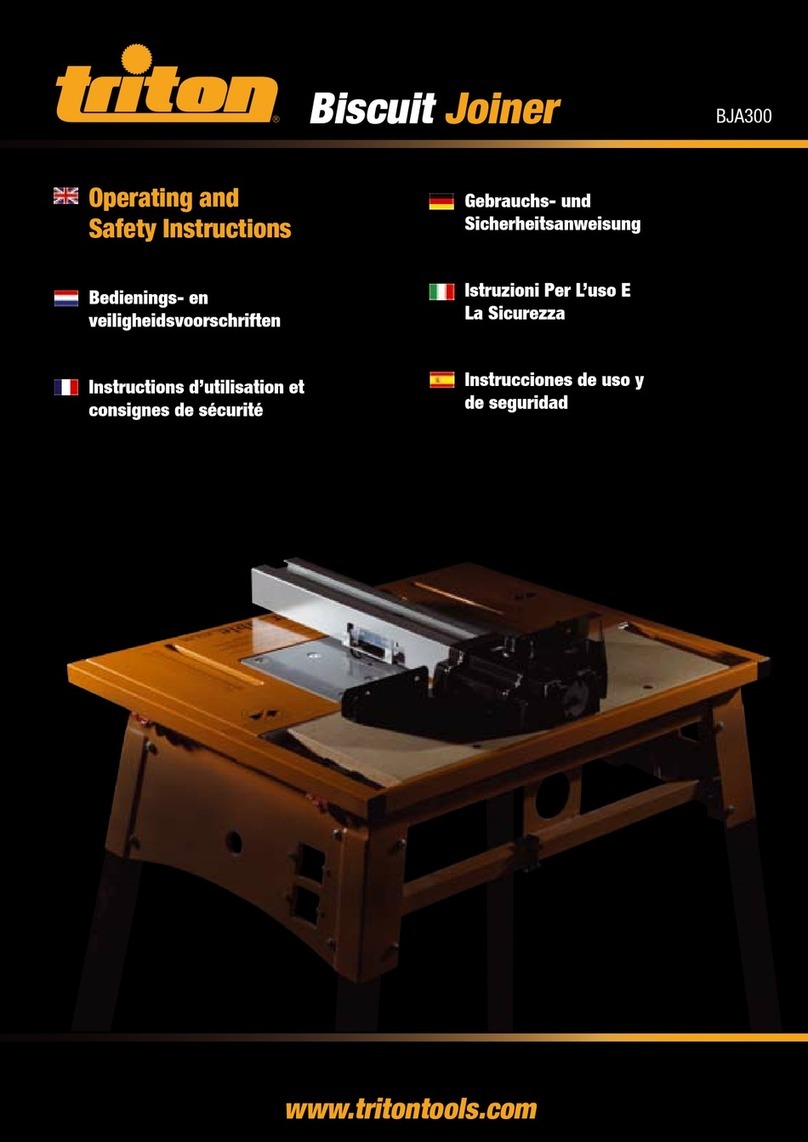

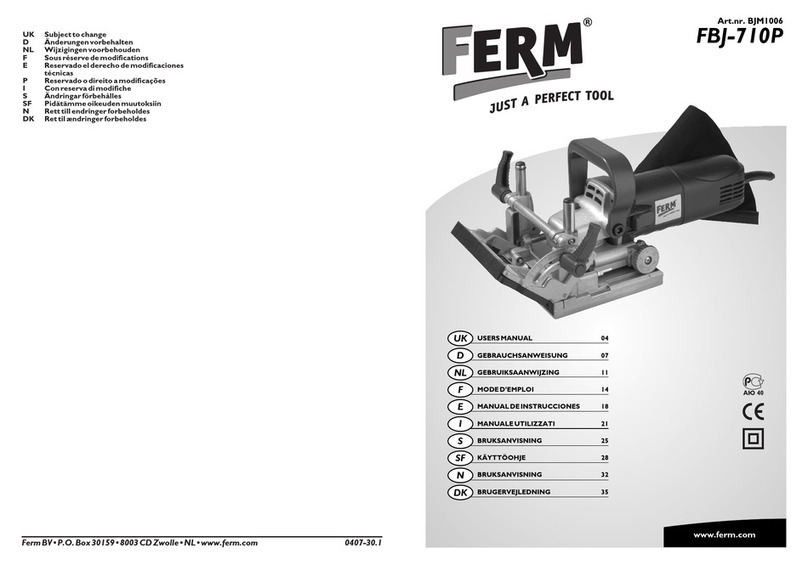

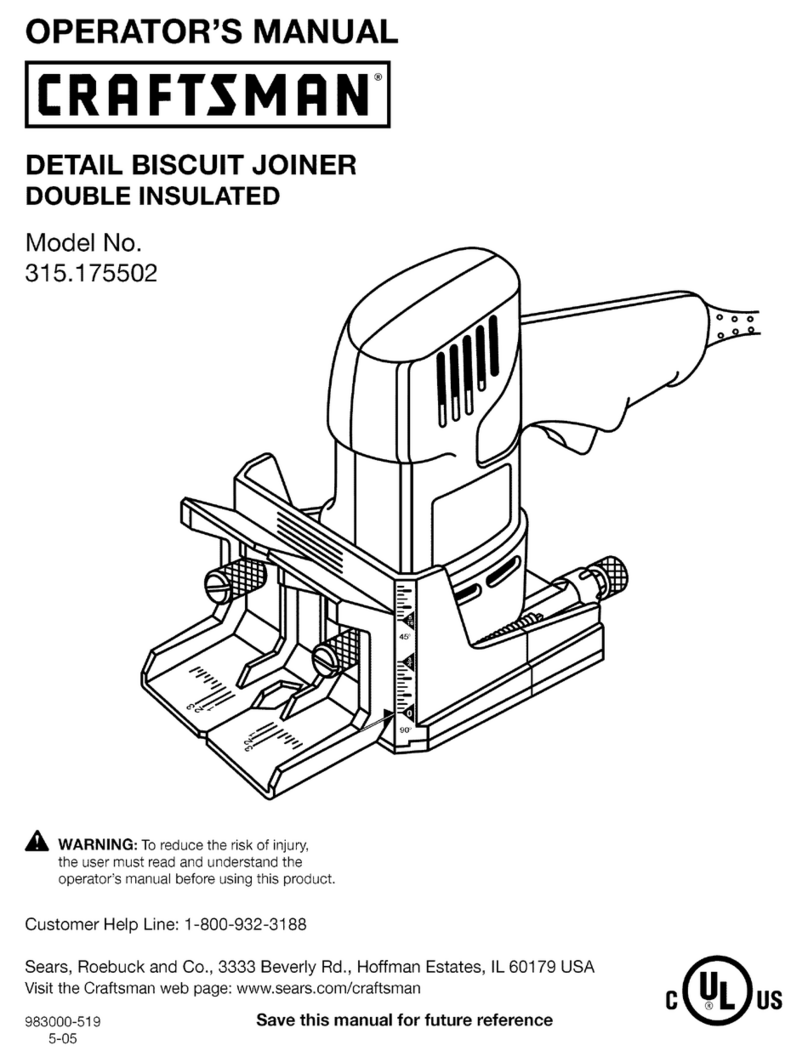

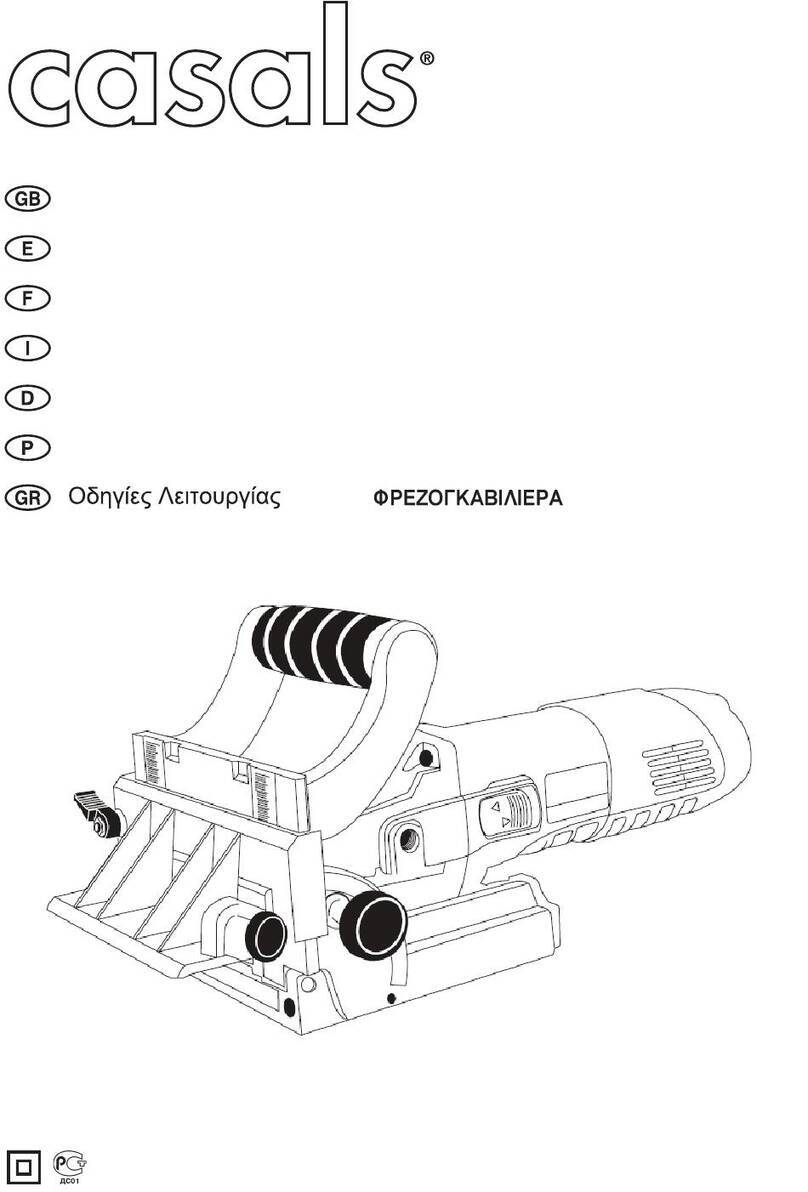

DESCRIPTIONS & SPECIFICATIONS .................................................................................................8

Functional description.......................................................................................................................8

Symbols............................................................................................................................................9

Specifications....................................................................................................................................9

ASSEMBLY & OPERATION ...............................................................................................................10

Prior to operation ............................................................................................................................10

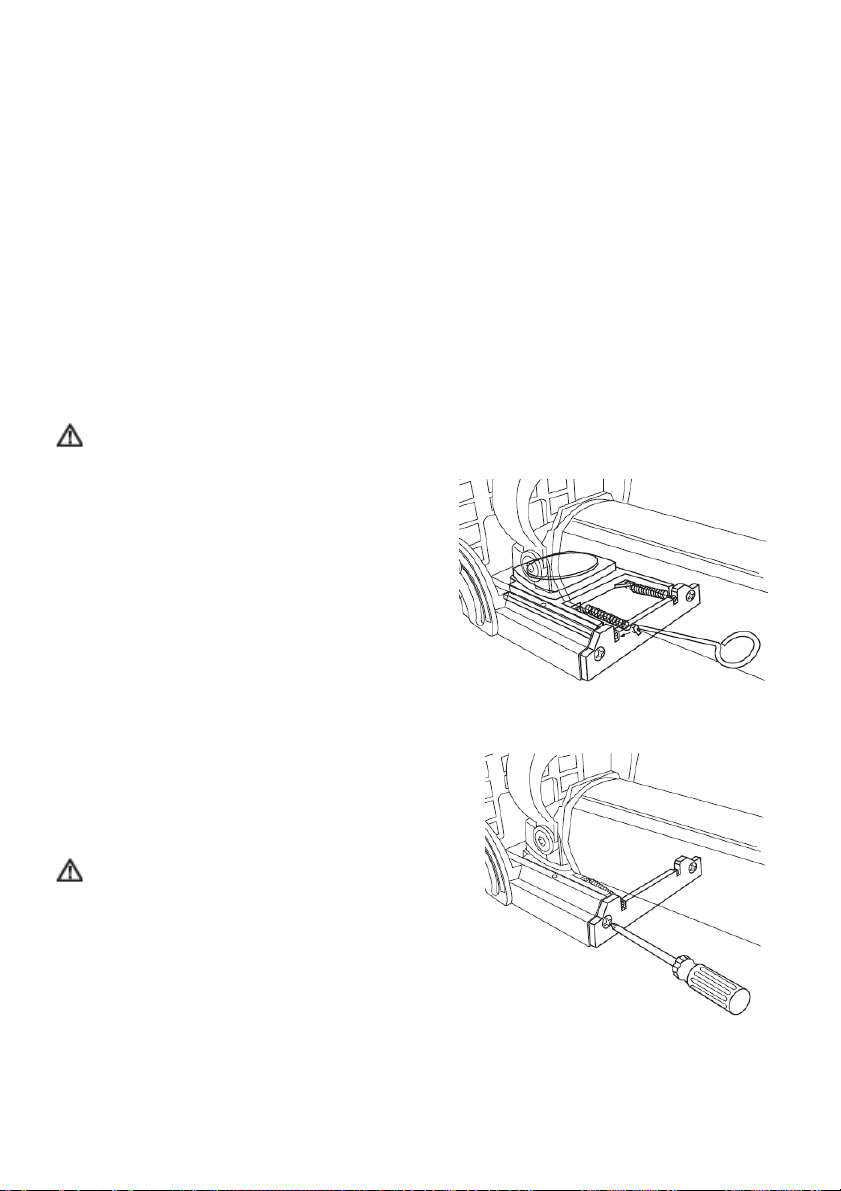

Changing the blade.........................................................................................................................10

Using the dust bag..........................................................................................................................11

Adjusting the depth of cut ...............................................................................................................11

Using the plunge depth stop...........................................................................................................12

Starting the tool...............................................................................................................................13

Making a cut....................................................................................................................................13

Machine maintenance.....................................................................................................................14

APPLICATIONS...................................................................................................................................14

Edge To Edge Joint ........................................................................................................................14

T-Joint.............................................................................................................................................15

Frame Joint.....................................................................................................................................16

Edge Miter Joint..............................................................................................................................16

Corner joint .....................................................................................................................................18

MAINTENANCE & INSPECTION........................................................................................................19

Service............................................................................................................................................19

Power Cord.....................................................................................................................................19

Tool Lubrication ..............................................................................................................................19

Ventilation Openings.......................................................................................................................19

Bearings..........................................................................................................................................19

Inspect Accessories........................................................................................................................19

Inspect Screws................................................................................................................................19

ACCESSORIES...................................................................................................................................20

Standard Accessories.....................................................................................................................20

SERVICE LOCATIONS .......................................................................................................................20